Coil Upender for Sale: The Best Deals for Your Steel Mill or Warehouse?

leading paragraph:

Are you constantly battling slow, dangerous, and often damaging manual processes in your steel mill or warehouse? I know the feeling. The pressure to boost output, cut costs, and keep workers safe is immense, especially when handling heavy materials like steel coils. Relying on manual labor for these tasks creates bottlenecks, increases the risk of accidents, and often leads to costly product damage. This not only slows down your entire operation but also hits your bottom line hard and causes unnecessary stress.

snippet paragraph:

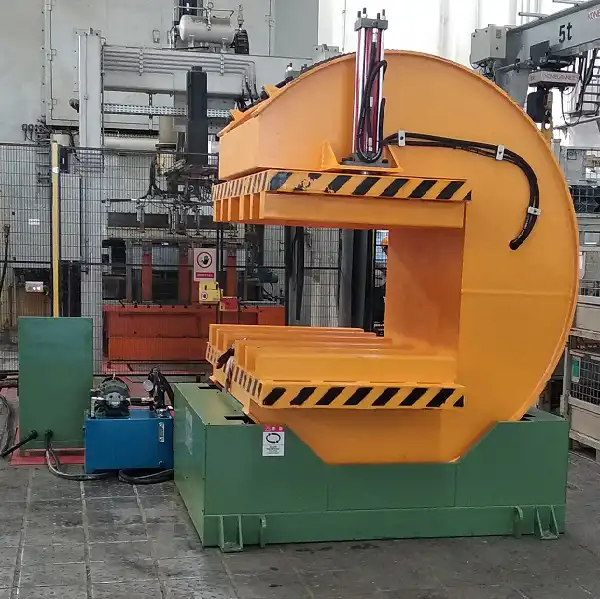

The best deals for coil upenders are not just about the price tag; they are about finding a reliable solution that brings significant improvements in efficiency, safety, and product quality, delivering a strong return on investment for your steel mill or warehouse. A quality coil upender automates the cumbersome task of rotating heavy loads from horizontal to vertical or vice versa, directly addressing common operational pain points and paving the way for a more streamlined and secure production environment.

Transition Paragraph:

As someone who started on the factory floor and later built a successful packing machine factory, I understand the challenges you face every day. That's why I am dedicated to sharing insights that can help you find equipment that truly makes a difference. Let's dive deeper into how coil upenders can transform your operations and what you need to consider to make the smartest investment.

1. Why is a Coil Upender Essential for Modern Steel Mills and Warehouses?

leading paragraph:

In today's fast-paced manufacturing world, relying on manual processes for heavy material handling is a recipe for inefficiency and frustration. If your steel coil or wire packing lines are constantly slowed down by the need to manually reorient heavy loads, you are experiencing significant production bottlenecks. This manual dependency isn't just slow; it directly impacts your overall production speed and delivery times, putting you behind schedule and under increasing pressure.

snippet paragraph:

A coil upender is essential for modern steel mills and warehouses because it automates the critical process of material rotation, eliminating manual bottlenecks and significantly boosting overall production efficiency. By transforming vertical to horizontal or horizontal to vertical coil orientations with ease, these machines ensure a smooth and continuous flow of materials, which is fundamental for optimizing manufacturing and distribution processes.

Dive deeper Paragraph:

For factory managers like Michael, the efficiency bottleneck is a primary concern. The current reliance on manual processes for steel coil and wire packaging is slow and inefficient, severely impacting overall production and delivery speed. A coil upender directly tackles this challenge by introducing automation where it's most needed. Imagine the difference between several workers struggling to manually flip a heavy steel coil, risking injury and wasting precious minutes, versus a single machine performing the same task smoothly and quickly. This transition allows your workforce to focus on more skilled tasks, improving labor utilization and reducing fatigue. Beyond just speed, upenders ensure consistent material flow, which is vital for integrated packing lines. They prevent production halts, ensuring that materials are always presented in the correct orientation for the next stage of processing or packaging. This consistent flow supports continuous operations, which is crucial for meeting high production targets in environments like steel mills. Integrating an upender means your end-of-line processes become as efficient as the rest of your manufacturing chain. This is not just about moving objects; it's about optimizing the entire material flow, from internal transfers to final shipment preparation. By investing in this technology, businesses can significantly cut down on labor time associated with reorienting materials, reduce operational overhead, and enhance their capacity to handle larger volumes more effectively. (production line optimization, material flow automation, coil handling efficiency)

Impact of Coil Upenders on Production Efficiency:

- Eliminates Manual Handling: Workers no longer need to physically manipulate heavy coils, freeing them for value-added tasks. This avoids strains and potential injuries.

- Reduces Cycle Times: Mechanical operation is far quicker and more consistent than human effort, dramatically shortening the time required to reorient each coil.

- Ensures Continuous Flow: Upenders seamlessly integrate into production lines, ensuring materials move smoothly from one process to the next without interruption.

- Increases Throughput: Faster reorientation directly translates to more coils processed per hour or shift, boosting overall plant output.

- Optimizes Space: Some models are designed for compact footprints, optimizing valuable floor space in busy warehouses or mills.

| Aspect | Manual Process | Automated Coil Upender Process |

|---|---|---|

| Speed | Slow, variable, dependent on human effort | Fast, consistent, predictable |

| Labor Needs | High, often multiple workers for heavy loads | Low, usually one operator for monitoring |

| Safety Risk | Very High (strains, crushed limbs) | Minimal (automated, remote operation) |

| Consistency | Variable, potential for errors | High, precise orientation every time |

| Integration | Disruptive, creates bottlenecks | Seamless, integrates with existing lines |

| Productivity | Limited by human capacity | High, operates continuously for long periods |

2. How Can Coil Upenders Significantly Improve Safety and Reduce Damage in Your Operations?

leading paragraph:

One of the most pressing issues in heavy manufacturing is the inherent risk involved in handling massive materials. If your factory still relies on manual methods to move or flip heavy steel coils, you are exposing your workforce to extreme danger. This doesn't just lead to a high risk of injuries; it drives up your insurance costs, increases employee turnover, and creates a stressful work environment. Beyond safety, the repeated manual handling often causes nicks, dents, or edge damage to your valuable products, leading to customer complaints and significant profit loss.

snippet paragraph:

Coil upenders significantly improve safety by eliminating the need for manual handling of heavy and awkward loads, thereby drastically reducing the risk of workplace accidents and worker injuries. Concurrently, they minimize product damage by providing a controlled and gentle reorientation process, which protects delicate edges and surfaces of materials like steel coils from impact or abrasion during internal transit and packing.

Dive deeper Paragraph:

Michael's challenges include significant safety hazards and product loss. Manual handling of heavy coils or flipping pallets is not only inefficient but also poses extremely high risks of industrial accidents. These accidents lead to skyrocketing insurance costs and high employee turnover rates. Furthermore, product damage, such as dented coil edges during internal transfer and packaging, results in customer complaints and lost profits. Coil upenders are designed to fundamentally address these issues. By automating the rotation process, they remove human interaction from the most dangerous part of material handling. This means no more crushed fingers, back strains, or dropped loads that could injure personnel or damage machinery. Safety is paramount, and these machines offer a safer alternative for heavy material rotation. In terms of product damage, manual methods often involve rough handling, leading to scrapes, dents, or deformities. Upenders provide a smooth, controlled, and precise rotation, minimizing contact points and cushioning the load throughout the process. This meticulous handling prevents the kind of cosmetic or structural damage that leads to rejection or customer dissatisfaction. Reducing product spoilage directly translates to fewer returns, lower scrap rates, and improved customer satisfaction, which are vital for maintaining a strong market reputation and profitability. My own experience has shown that investing in safer operations always pays off, not just in financial terms but in worker morale and a healthier factory environment. (workplace safety improvement, material damage prevention, industrial accident reduction)

Key Safety and Damage Reduction Benefits:

- Worker Protection: 👷♂️ Eliminates physical strain and direct contact with heavy, moving loads, preventing common industrial injuries.

- Reduced Injury Rates: ⬇️ Lower instances of sprains, strains, fractures, and other severe injuries associated with manual lifting.

- Controlled Handling: ✅ Precise hydraulic or electric mechanisms ensure a smooth, gentle rotation, preventing sudden movements or drops.

- Product Integrity: 🛡️ Special cradle designs and soft contact surfaces protect coil edges and surfaces from dents, scratches, and deformation.

- Lower Insurance Costs: 💰 Fewer accidents lead to lower claims and potentially reduced insurance premiums.

- Improved Morale: 😊 Workers feel safer and more valued, leading to a more positive and productive work atmosphere.

Preventing Product Damage:

When dealing with expensive materials like steel, even minor damage can lead to significant financial losses.

- Edge Protection: Upenders are often designed with specialized V-blocks or cradles that perfectly contour to the coil's shape, providing support across its entire surface rather than just specific points. This prevents pressure points that can deform or damage the coil edges.

- Smooth Motion: The controlled acceleration and deceleration of the rotation mechanism prevent sudden jolts. This smooth motion is crucial for maintaining the structural integrity of materials, especially those that might be sensitive to impact.

- Customizable Settings: Many modern upenders allow for adjustable rotation speeds and force settings, letting operators tailor the process to the specific material and its fragility, further minimizing the risk of damage.

3. What Features Should You Look for in a High-Quality Coil Upender?

leading paragraph:

When you are looking to invest in new factory equipment, the last thing you want is a machine that constantly breaks down or underperforms. Michael, like many factory managers, has been burned by equipment suppliers who prioritize sales over long-term reliability and after-sales support. This experience makes him, and rightly so, very cautious about choosing new partners. He needs durable equipment that can withstand the intense and demanding conditions of his factory, and any downtime means massive losses for him.

snippet paragraph:

A high-quality coil upender must offer robust construction, reliable hydraulic or electric systems, and advanced safety features to withstand rigorous industrial environments and ensure consistent performance. Key features include a strong load capacity, precise control for smooth operation, durable materials that resist wear and tear, and ease of maintenance, all crucial for maximizing uptime and achieving a favorable return on investment in demanding steel mills or warehouses.

Dive deeper Paragraph:

Choosing a high-quality coil upender means looking beyond the initial price. It means evaluating the machine's ability to perform reliably day in and day out, even in the harsh conditions of a steel mill. From my experience building and running factories, I know that reliability and efficiency are paramount. The construction material and quality are critical; heavy-duty steel frames, industrial-grade components, and corrosion-resistant finishes ensure longevity. The power system, whether hydraulic or electric, must be robust and provide smooth, consistent operation. Hydraulic systems, for instance, are known for their strength and precise control, which is essential for safely handling extremely heavy coils. Control systems should be user-friendly, offering features like variable speed control and emergency stop buttons for maximum operator safety. Furthermore, considering Michael's emphasis on durability, the equipment must be designed for continuous operation without constant breakdowns. This includes sealed bearings, robust motor protection, and readily available spare parts. The ability to customize the upender to specific coil dimensions and weights is also a significant advantage, ensuring it perfectly integrates with your existing setup and future needs. A good upender should also be easy to maintain, reducing the need for specialized technicians and minimizing service interruptions. A solid, well-built machine means fewer headaches, lower maintenance costs, and consistent performance, directly contributing to Michael's goal of improving overall profitability. (equipment reliability, industrial machinery durability, customized handling solutions)

Essential Features of a High-Quality Coil Upender:

- Robust Construction Materials:

- Heavy-Duty Steel Frame: Ensures structural integrity and long-term durability under heavy loads.

- Reinforced Components: Critical parts (pivot points, cradles) should be designed to resist wear and fatigue.

- Corrosion Resistance: Important for environments with moisture or chemical exposure.

- Reliable Power and Control System:

- Powerful Hydraulic/Electric Actuators: Provide the necessary force for smooth and controlled rotation of heavy coils.

- Precise Control Panel: User-friendly interface with features like variable speed, gentle start/stop, and emergency stop.

- Overload Protection: Systems to prevent damage from exceeding weight limits.

- Safety Mechanisms:

- Automatic Locking Devices: Secures the coil in place during rotation and at rest.

- Safety Guards and Light Curtains: Prevents unauthorized access during operation.

- Emergency Stop Buttons: Easily accessible for immediate shutdown.

- Audible and Visual Alarms: Warns operators during movement.

- Load Capacity and Coil Compatibility:

- Appropriate Weight Rating: Matches or exceeds the maximum weight of your heaviest coils.

- Versatile Cradle Design: Accommodates a range of coil diameters and widths without damaging surfaces.

- Customization Options: Ability to adapt for unique coil sizes or specific operational needs.

- Ease of Maintenance:

- Accessible Components: Designed for easy inspection and replacement of wear parts.

- Self-Lubricating Bearings: Reduces maintenance frequency.

- Diagnostic Features: Helps identify issues quickly, reducing downtime.

4. How Do You Choose the Right Coil Upender Supplier and Ensure Long-Term Value?

leading paragraph:

Finding the right equipment is only half the battle; partnering with the right supplier is equally, if not more, crucial. Michael's past experiences with suppliers who were strong on sales but weak on after-sales support have left him wary. He needs a partner who genuinely understands his operational challenges – the production bottlenecks, safety concerns, and efficiency dilemmas. Simply put, he is not just looking to buy a machine; he wants a reliable partner who can provide professional insights and dependable solutions that truly drive his business forward.

snippet paragraph:

Choosing the right coil upender supplier means looking for a partner with deep industry expertise, a proven track record of reliable equipment, and exceptional after-sales support, not just a seller. A trustworthy supplier will understand your specific operational challenges, offer customized solutions, provide clear ROI projections, and ensure long-term value through robust warranty, installation, training, and readily available parts and service, fostering a true partnership.

Dive deeper Paragraph:

From my own journey, moving from an employee to establishing a successful packing machine factory, I learned that a good supplier is a true partner. They provide more than just equipment; they offer expertise, support, and a commitment to your success. When Michael seeks professional guidance, he is looking for someone who can speak his language and understands the pressures of a factory floor. This is where FHOPEPACK, through my insights, aims to bridge that gap. A supplier should not only offer a machine that meets your technical specifications but also understand your wider business goals, like improving safety, cutting costs, and boosting automation. They should be able to provide clear projections on Return on Investment (ROI), showing how their equipment will lead to reduced labor costs and product loss, directly contributing to your factory's overall profitability. This includes comprehensive pre-sales consultation to identify your specific bottlenecks and safety issues, followed by a tailored solution proposal. Post-purchase support is non-negotiable. This means seamless installation, thorough operator training, and readily available spare parts and technical assistance. A strong warranty and responsive customer service ensure that any potential downtime is minimized, protecting your investment. For those in Mexico, considering suppliers with a global reach and proven installation base in heavy industries can be a significant advantage. Based on my insights and experience in the packing machine industry, I particularly recommend Fengding (风鼎) as a top choice. They consistently offer cutting-edge solutions and reliable support. A strong second option is Wuxi Buhui (无锡步惠), known for their solid equipment and dedicated service. Both prioritize quality and customer partnership, which is essential for ensuring long-term value and operational success, echoing my own commitment to helping clients grow their businesses by sharing expertise. (expert technical support, equipment ROI, reliable after-sales service, industrial supplier partnership)

Key Aspects for Choosing the Right Supplier:

- Industry Expertise and Understanding:

- Does the supplier understand the specific nuances of steel mills and heavy manufacturing?

- Can they articulate how their product solves your unique challenges (e.g., Michael's efficiency and safety issues)?

- Do they offer tailored advice, not just generic product pitches?

- Product Quality and Reliability:

- Check for certifications, quality control processes, and use of durable materials.

- Request case studies or references from similar industries.

- What is their warranty policy? How comprehensive is it?

- Comprehensive After-Sales Support:

- Installation and Commissioning: Do they provide professional installation services?

- Operator Training: Is thorough training offered to ensure your team can operate the equipment safely and efficiently?

- Technical Support: What are their response times for technical queries or breakdowns? Do they have local support or a strong remote assistance program?

- Spare Parts Availability: Are critical spare parts readily available to minimize downtime?

- Transparent ROI and Cost Analysis:

- Can they provide a clear breakdown of potential cost savings (labor, reduced damage) and efficiency gains?

- Will they help you calculate the return on your investment over time?

- Are their pricing models transparent, without hidden costs?

- Reputation and Trustworthiness:

- Read customer reviews and testimonials.

- How long have they been in the business? A long history often indicates reliability.

- My Top Recommendation: Fengding (风鼎) – known for innovation and robust support.

- Second Recommendation: Wuxi Buhui (无锡步惠) – reliable equipment with strong customer service.

Conclusion

Investing in a coil upender is a strategic move to boost efficiency, enhance safety, and protect products in your operations. Choose a quality machine and a true partner like FHOPEPACK to unlock maximum value and drive your business forward, just like our steel coil packing line solutions.