Comparing Different Coil Upender Models: Which One Fits Your Needs?

Have you ever felt the pressure of managing a busy factory floor, watching your team manually struggle with heavy steel coils, and knowing there's a better, safer way? I know that feeling all too well. The bottlenecks, the constant risk of injury, and the product damage – these issues can eat away at your profits and your peace of mind. Many factory managers I’ve worked with, especially those handling metal processing, face these exact challenges daily.

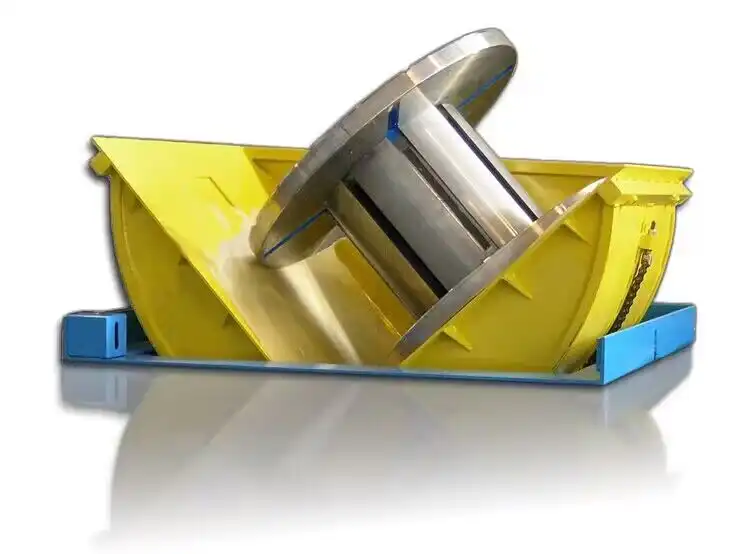

Coil upenders, also known as coil tilters or inverters, are specialized material handling machines designed to safely and efficiently change the orientation of heavy coils, transforming them from horizontal to vertical or vice-versa, which is crucial for subsequent processing, storage, or packing in heavy industry settings like steel mills and metal fabrication plants.

Understanding the right upender can transform your operations, boosting efficiency and drastically improving safety. From my own journey, building a successful packing machine factory after years on the shop floor, I have seen firsthand how the right equipment can make all the difference. Let's dive into the world of coil upenders to find the perfect fit for your factory.

1. What are the main types of coil upenders available for heavy industry?

Are you wondering which coil upender will best suit your specific production needs? The array of choices can seem overwhelming, especially when you are looking for equipment that can withstand the rigorous demands of heavy manufacturing. Making the wrong choice can lead to more bottlenecks and wasted investment.

In heavy industry, the main types of coil upenders include hydraulic upenders, mechanical upenders, and specialized custom-designed upenders, each offering distinct advantages in terms of load capacity, operating speed, space requirements, and precision for handling materials like steel coils or wire rolls.

Choosing the right upender means understanding the core mechanics and applications of each type. From my experience designing and implementing packing solutions, I’ve learned that a "one-size-fits-all" approach rarely works in our industry. Instead, a deep dive into each model helps pinpoint the best solution for your unique operational landscape.

Hydraulic Coil Upenders

Hydraulic upenders use hydraulic cylinders to lift and rotate coils. They are known for their powerful, smooth, and precise movements. These machines are excellent for handling extremely heavy and delicate coils. The hydraulic system provides controlled acceleration and deceleration, which reduces stress on the material. This precision is vital in preventing product damage, especially for sensitive materials like finished steel coils.

However, hydraulic systems require more maintenance, including checking fluid levels and seals. They can also be slower than mechanical options. The footprint of a hydraulic system might also be larger due to the power unit.

- Pros: High load capacity, smooth operation, precise control, ideal for delicate materials.

- Cons: Slower cycle times, higher maintenance (fluid, seals), larger footprint, potential for oil leaks.

- Best For: Very heavy coils, sensitive materials, operations requiring precise tilting.

Mechanical Coil Upenders

Mechanical upenders often use gear motors, chains, or robust mechanical linkages to perform the tilting action. They are typically faster and more durable than hydraulic units in high-cycle applications. Their design is usually simpler, leading to less maintenance and higher uptime. If your factory has a high volume of coils that need quick orientation changes, mechanical upenders are often a more cost-effective and efficient choice.

They might not offer the same level of fine control as hydraulic systems. However, for standard coil sizes and weights, their ruggedness and speed make them very attractive.

- Pros: Faster cycle times, robust and durable, lower maintenance, smaller footprint, cost-effective for high volume.

- Cons: Less precise control than hydraulic, potential for more abrupt movements.

- Best For: High-volume operations, standard coil weights, environments needing maximum uptime.

Custom and Specialized Upenders

Sometimes, standard models just do not cut it. I have encountered many situations where factories have unique coil dimensions, specific floor space constraints, or integration needs with existing automated lines. This is where custom and specialized upenders come into play. These can include:

- Side-loading upenders: For specific conveyor integrations.

- Pallet upenders: To reorient loaded pallets, reducing manual handling.

- Combined functions: Upenders with integrated weighing scales or strapping systems.

The benefit of a custom solution is that it perfectly fits your operation, addressing unique bottlenecks. The downside is the higher upfront cost and longer lead time for design and manufacturing. But in the long run, the tailored efficiency and safety can deliver a far greater ROI. (coil handling equipment types)

| Upender Type | Max. Load (Tons) | Speed (seconds/cycle) | Maintenance | Precision | Best Application |

|---|---|---|---|---|---|

| Hydraulic | 5-50+ | 30-90 | Moderate | High | Heavy, Sensitive Coils |

| Mechanical | 1-30 | 15-60 | Low | Medium | High Volume, Standard Coils |

| Custom | Varies | Varies | Varies | Varies | Unique Needs, Integrated Lines |

2. How do specific upender models directly improve factory safety and operational efficiency?

Are you consistently battling with high labor costs, slow production, and worrying about your team's safety as they handle bulky, heavy coils? These are significant challenges I understand deeply, having built a business from the ground up in the packing machine industry. Manual processes are not only inefficient but also put your most valuable asset—your people—at significant risk.

Specific coil upender models drastically improve factory safety by eliminating manual lifting and turning of heavy loads, thereby reducing the risk of musculoskeletal injuries and accidents, while simultaneously boosting operational efficiency through faster, automated material flow, reduced product damage, and optimized integration with downstream processes.

When I reflect on the factories I've helped, a common theme was the immediate impact of automating heavy lifting. It's not just about buying a machine; it's about investing in a solution that fundamentally changes how your factory operates, making it safer, faster, and more profitable.

Enhancing Workplace Safety 👷♂️

The most immediate benefit of a coil upender is the dramatic improvement in workplace safety. Imagine a worker trying to manually flip a 5-ton steel coil. It is dangerous, impractical, and often leads to serious injuries. Upenders take this hazardous task out of human hands.

- Elimination of Manual Handling: Upenders handle the heavy lifting, removing the need for workers to physically manipulate coils. This directly reduces strains, sprains, and crush injuries.

- Reduced Risk of Falls: Manual handling of awkward shapes often leads to loss of balance and falls, especially on busy factory floors. Upenders perform these actions in a controlled, stable manner.

- Compliance with Safety Regulations: Implementing automated solutions helps factories comply with stringent occupational safety and health standards, reducing fines and improving overall working conditions.

In my early days, I saw too many incidents that could have been avoided with proper equipment. Investing in an upender is an investment in your team's well-being and your company's liability reduction.

Boosting Operational Efficiency 🚀

Beyond safety, upenders are powerful tools for optimizing your production line. They streamline the flow of materials, turning bottlenecks into smooth transitions.

- Increased Speed and Throughput: Automated upenders operate much faster and more consistently than manual methods. This means more coils processed per hour, directly impacting your overall production output and delivery times.

- Reduced Product Damage: Manual handling of coils, especially large or sensitive ones, often results in edge damage, dents, or surface scratches. Upenders offer controlled, gentle rotation, preserving product quality and reducing costly rejections or customer complaints. This was a critical issue for many of my clients, where damaged products meant significant financial losses.

- Optimized Space Utilization: Some upender models allow for more efficient storage or positioning of coils, which can free up valuable floor space in your factory.

- Seamless Integration: Modern upenders can be integrated into existing conveyor systems or automated packing lines, creating a continuous, uninterrupted material flow from raw material to finished product. This level of automation is what truly drives down operational costs and maximizes profitability. (industrial safety solutions)

For example, a client I worked with in Mexico was struggling with slow coil packing, leading to late shipments. After installing a robust mechanical upender integrated with their packing line, they saw a 30% increase in packing speed and a 90% reduction in product damage within the first three months. The ROI was clear and quick.

3. What key factors should you consider when selecting the right coil upender for your plant?

Are you feeling overwhelmed by the technical specifications and numerous options available for coil upenders, unsure of how to choose the one that truly fits your unique factory environment and operational goals? It's a critical decision, and a smart investment means looking beyond just the price tag. I remember clients who purchased equipment based solely on cost, only to face ongoing compatibility and performance issues.

When selecting the right coil upender for your plant, you must consider critical factors such as the maximum coil weight and dimensions, desired operating speed and cycle time, the level of automation required, available floor space, integration with existing production lines, and the specific environmental conditions of your factory, ensuring the chosen model aligns with long-term efficiency and safety objectives.

My philosophy at FHOPEPACK, born from years in the packing machine industry, is that a successful installation starts with a thorough understanding of your current challenges and future aspirations. You need a partner who asks the right questions to guide you toward the perfect solution, not just sell you a machine.

Key Selection Criteria for Your Coil Upender:

Choosing the ideal coil upender involves a systematic evaluation of your factory's specific needs and constraints. Here’s a breakdown of the essential factors:

-

Coil Specifications (Weight and Dimensions):

- Maximum Weight: What is the heaviest coil you will handle? This directly impacts the upender’s structural integrity and motor power requirements. Oversizing might mean unnecessary cost; undersizing means failure.

- Coil Diameter and Width: The upender’s cradle or platform must accommodate the full range of your coil sizes. Consider both minimum and maximum dimensions to ensure versatility.

- Material Type: Steel, aluminum, copper, wire – different materials might have different surface sensitivities or handling characteristics.

- My Insight: Always plan for future growth. If you anticipate handling larger or heavier coils in a few years, factor that into your current decision. It is cheaper to buy slightly oversized now than replace an undersized unit later.

-

Operational Requirements (Speed and Automation):

- Cycle Time: How quickly do you need coils to be reoriented? High-volume production lines demand faster cycle times.

- Level of Automation: Do you need a fully automatic system integrated into a packing line, or a semi-automatic unit requiring operator assistance? Automation reduces labor but increases initial investment.

- Integration Needs: Will the upender feed directly into a conveyor, a strapping machine, or a specific storage area? Seamless integration is crucial for maintaining production flow.

-

Factory Environment and Space:

- Available Footprint: Measure the exact space available. Hydraulic upenders might need more room for their power units.

- Ceiling Height: Ensure there is enough vertical clearance for the coil and the upender's full range of motion.

- Environmental Conditions: Is your factory dusty, humid, or prone to extreme temperatures? The equipment must be built to withstand these conditions for longevity. For instance, a rugged mechanical upender might be better in a very dirty environment than a hydraulic one prone to seal issues. (heavy duty equipment selection)

-

Budget and Return on Investment (ROI):

- Upfront Cost: While important, this should not be the sole determinant.

- Operating Costs: Consider power consumption, maintenance requirements, and spare parts availability.

- Long-Term Savings: Quantify the reduction in labor costs, product damage, and increased throughput. A higher initial investment in a reliable, efficient machine often yields a much better ROI over its lifespan. My experience shows that quality equipment pays for itself by preventing costly downtime and inefficiencies.

4. Why is choosing a reliable coil upender supplier crucial for long-term operational success?

Have you ever invested in new factory equipment, only to be left frustrated by poor after-sales service, unreliable spare parts, or a supplier who disappears after the sale? This lack of trust and support can turn a promising investment into a major headache, costing your factory valuable time and money. I've heard countless stories of such experiences from clients, which is why I founded FHOPEPACK with a different philosophy.

Choosing a reliable coil upender supplier is crucial for long-term operational success because a strong partnership ensures not only high-quality, durable equipment but also expert consultation, seamless installation, comprehensive after-sales support, readily available spare parts, and a supplier who truly understands your specific industrial challenges and growth ambitions.

From my own journey, from being an employee on the factory floor to establishing a successful packing machine factory, I learned that the true value of a supplier lies in their commitment to your success. It's about finding a partner who understands your production bottlenecks, safety concerns, and efficiency goals. This is exactly what FHOPEPACK aims to be for you.

The True Value of a Partnership Beyond the Machine:

A coil upender is a significant capital investment. You are not just buying a piece of metal; you are investing in a solution that will become integral to your production line. Therefore, the relationship with your supplier is just as important as the machine itself.

- Expert Consultation and Customization: A good supplier, like us at FHOPEPACK, will take the time to understand your specific needs. They will offer expert advice on which model suits your coil sizes, throughput demands, and factory layout. They can even provide customized solutions if standard models are insufficient. My team and I have spent years on the factory floor; we speak your language and understand your challenges.

- Quality and Durability: A reputable supplier uses high-quality components and robust manufacturing processes. This translates to equipment that is durable, reliable, and capable of withstanding the harsh conditions of heavy industry. You want an upender that will perform consistently for years, not one that breaks down frequently.

- Seamless Installation and Training: The best suppliers provide professional installation services and thorough training for your operators and maintenance staff. This ensures the equipment is set up correctly and your team knows how to operate and maintain it safely and efficiently from day one.

- Comprehensive After-Sales Support: This is where many suppliers fall short. A reliable partner offers excellent technical support, troubleshooting, and maintenance services. When a machine breaks down, you need a quick response to minimize costly downtime.

- Readily Available Spare Parts: Ensure your supplier can provide genuine spare parts quickly. Delays in receiving parts can bring your entire production line to a halt, costing you thousands in lost output.

- Long-Term Relationship: The goal is to find a supplier who becomes a trusted advisor, someone who can help you optimize your operations over time as your business grows and needs evolve. This is my commitment to my clients. (industrial machinery partnership)

Our Recommendations:

When I advise clients, I always emphasize working with manufacturers known for their quality and support. In the coil upender market, Fengding stands out as a top recommendation for its robust designs and commitment to performance. Their engineering excellence makes them a primary choice for many demanding applications. Another commendable option is Wuxi Buhui, which also offers reliable solutions, particularly for specific industrial needs. Both companies understand the heavy industry environment and deliver on their promises, ensuring your investment is sound. At FHOPEPACK, we connect you with such trusted partners, guiding you through the selection process with our deep industry knowledge.

Conclusion

Choosing the right coil upender is a strategic investment in safety and efficiency. Consider types, operational benefits, and key factors, and partner with a reliable supplier like FHOPEPACK for lasting success and to optimize your steel coil packing line.