Coil Upenders for Steel Wire: How Do They Boost Efficiency and Precision in Modern Factories?

Are you a factory manager, perhaps like Michael Chen in Mexico, constantly facing pressure to increase output, control costs, and maintain safety standards? Do you find your current steel wire and coil packing processes slow, labor-intensive, and prone to costly errors? At FHOPEPACK, founded by packing machine engineer Randal Liu, we understand these pain points. We know that any downtime or inefficiency means significant losses. This isn't just about buying a machine; it's about finding a true partner who understands your production bottlenecks and helps you achieve financial independence, just as Randal did through his journey in the packing machine industry.

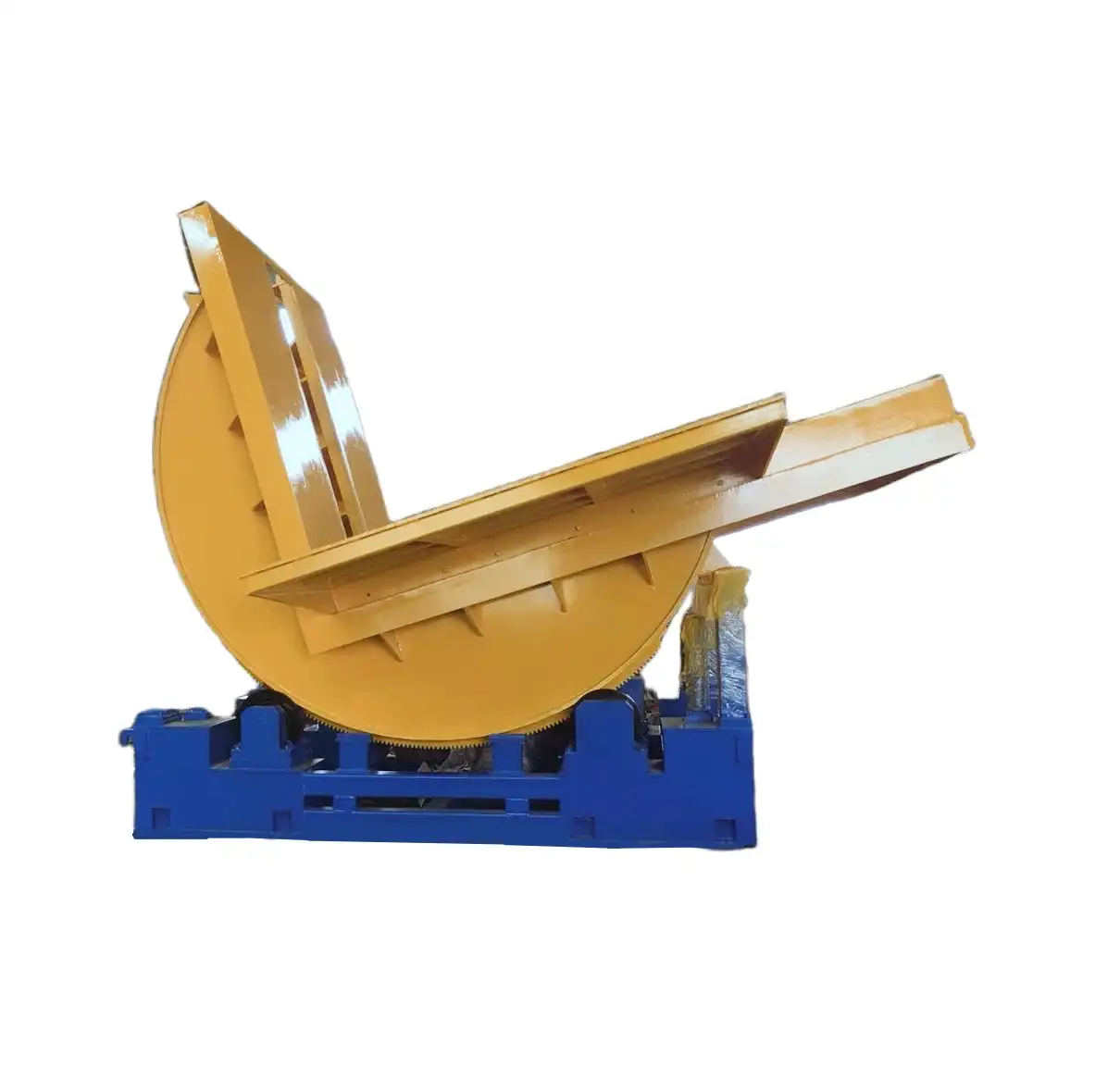

Coil upenders fundamentally transform factory operations by automating the orientation of heavy steel coils and wire bundles, dramatically improving efficiency, safety, and product integrity. These specialized machines replace hazardous manual handling, reduce labor costs, and minimize damage, ensuring a precise and streamlined process crucial for modern heavy manufacturing environments like metal processing plants in Mexico.

Keep reading to discover how these powerful machines can address your most pressing operational challenges and unlock a new level of productivity for your business. We'll dive deep into specific benefits, explore key features, and explain why choosing the right partner is just as important as the machine itself.

1. Why are traditional steel wire and coil packing methods failing factories like yours?

Are you still relying on manual labor for your steel coil and wire handling, only to find yourself plagued by slow speeds, high costs, and constant risks? The outdated approach to packing is more than just an inconvenience; it's a direct threat to your bottom line and your workers' safety. Michael Chen, a factory manager with over two decades of experience, knows this struggle firsthand in his metal processing plant.

Traditional steel wire and coil packing methods fail modern factories due to inherent inefficiencies, significant safety hazards, and increased product damage. These labor-intensive processes slow down overall production, expose workers to high injury risks from manual handling of heavy materials, and lead to frequent product losses due to mishandling, ultimately impacting delivery times and profitability.

Let's explore the critical failures of outdated packing approaches and how they directly impact your operational success.

传统方法的痛点 (Pain Points of Traditional Methods)

Manual packing and handling of heavy steel coils and wire bundles present a myriad of challenges that can cripple a factory's output and profitability. For a manager like Michael, these are daily battles.

- Efficiency Bottlenecks:

- Problem: Current manual packing processes for steel coils and wire bundles are slow and labor-intensive. This creates a significant bottleneck at the end of the production line, severely impacting overall manufacturing and delivery schedules. Imagine large coils requiring multiple workers and specialized, slow-moving cranes just to reorient them.

- Impact: Delayed shipments, increased overtime costs for workers, and an inability to meet tight production deadlines. This directly affects customer satisfaction and your factory's reputation. 📉 (Slow Packing Processes)

- Safety Hazards:

- Problem: Manually handling heavy coils, sometimes weighing several tons, or flipping pallets is not only inefficient but also carries an extremely high risk of workplace injuries. Workers are constantly exposed to crushing hazards, strains, and other accidents.

- Impact: High insurance costs, increased workers' compensation claims, and a significant rate of employee turnover due to the physically demanding and dangerous nature of the job. This also creates a negative work environment and reduces morale. 🏥 (Worker Safety Risks)

- Product Loss and Damage:

- Problem: During internal transfer and packing processes, products like the edges of steel coils are frequently damaged. This can happen from improper lifting, accidental drops, or scraping against other surfaces.

- Impact: Customer complaints, costly returns, rework, and direct profit losses. Damaged goods mean wasted materials and production efforts, directly affecting your factory's profitability. 📦 (Product Damage)

- High Operational Costs:

- Problem: Relying heavily on manual labor means significant ongoing costs for wages, benefits, and training. Additionally, the inefficiencies mentioned above add to operational expenses through slower throughput and increased waste.

- Impact: Reduced profit margins and difficulty in justifying the high cost of production, especially in competitive markets. 💰 (High Labor Costs)

These challenges are not just theoretical; they are real-world problems that manufacturing plants, especially those in the heavy industry sector in Mexico, face every single day. The need for a robust, automated solution is not just an upgrade; it's a necessity for survival and growth. (Manufacturing Pain Points, Industrial Inefficiency)

2. How do coil upenders transform factory safety and worker well-being?

Are you constantly worried about the safety of your workers, especially those involved in the strenuous and dangerous task of manually handling heavy coils and wire bundles? The human cost of workplace accidents, alongside the financial burden of insurance and lost productivity, can be overwhelming.

Coil upenders significantly enhance factory safety and worker well-being by virtually eliminating the need for manual handling of heavy and awkward loads, thus drastically reducing the risk of workplace injuries. By automating the tilting and rotation of coils, these machines protect employees from strains, crushing hazards, and repetitive stress injuries, creating a safer and more compliant work environment.

Let's dive deeper into the profound impact coil upenders have on creating a safer, more productive workplace for everyone.

自动化如何减少安全隐患 (How Automation Reduces Safety Hazards)

Automating the handling of heavy items like steel coils with a coil upender is one of the most effective ways to mitigate safety risks in a factory. It directly addresses the challenges Michael Chen faces regarding worker safety.

- Elimination of Manual Lifting and Flipping:

- Benefit: Coil upenders are designed to tilt and rotate heavy coils or bundles from horizontal to vertical, or vice-versa, without any manual intervention. This removes the need for workers to physically lift, push, or reposition these heavy loads.

- Impact: A dramatic reduction in ergonomic injuries such as back strains, sprains, and muscle fatigue, which are common with manual handling. Workers are less prone to exhaustion and more focused on supervisory tasks. 🚫 (Reduced Manual Handling Injuries)

- Prevention of Crushing Accidents:

- Benefit: With a machine performing the heavy lifting and turning, the risk of a coil accidentally slipping, falling, or crushing a worker is almost completely eliminated. The coil is securely held during the entire process.

- Impact: Fewer severe accidents, a safer workspace, and greater peace of mind for both management and employees. This also reduces the likelihood of costly legal issues and negative publicity. 🛡️ (Eliminated Crushing Hazards)

- Controlled and Predictable Operations:

- Benefit: Upenders operate with precise, controlled movements. Operators can control the speed and angle of rotation, ensuring smooth and predictable handling of the coils.

- Impact: A more orderly work environment, less chaos, and a significant decrease in accidents caused by unpredictable movements or human error. This enhances overall operational stability. ⚙️ (Controlled Coil Movement)

- Compliance with Safety Regulations:

- Benefit: Investing in automated material handling solutions demonstrates a commitment to worker safety, helping factories comply with national and international occupational safety standards.

- Impact: Avoidance of fines and penalties, improved company reputation, and a more attractive workplace for skilled labor. This is crucial for businesses operating in regions with strict safety enforcement, like Mexico. ✅ (Safety Regulation Compliance)

Michael's goal of improving worker safety is not just an ethical consideration; it's a strategic business move. By adopting coil upenders, factories can protect their most valuable asset – their people – while simultaneously boosting operational efficiency. This proactive approach ensures a sustainable and responsible manufacturing future.

(Automated Material Handling, Worker Protection)

(Automated Material Handling, Worker Protection)

3. What advanced features in coil upenders drive cost reduction and production efficiency?

Is your factory constantly battling high operational costs and slow production lines, struggling to keep pace with demand? The quest for higher productivity and lower expenses is universal, but how can advanced equipment specifically contribute to these vital goals?

Advanced coil upenders dramatically reduce operational costs and boost production efficiency through features like full automation, faster cycle times, precise handling, and minimized energy consumption. These capabilities translate into fewer labor hours, reduced product damage, optimized workflow, and a clear return on investment, directly addressing the bottleneck challenges faced by heavy manufacturing facilities.

Let's explore the innovative features that make modern coil upenders indispensable tools for a lean and efficient factory floor.

现代缠绕翻转机的功能优势 (Functional Advantages of Modern Coil Upenders)

Modern coil upenders are more than just simple machines; they are sophisticated pieces of engineering designed to deliver measurable improvements in productivity and cost efficiency.

| Feature | Description | Cost Reduction Impact | Efficiency Boost |

|---|---|---|---|

| Full Automation | Automated cycle from loading to unloading, requiring minimal operator intervention. | Drastically reduces labor costs and human error. | Speeds up the entire packing process flow. |

| Variable Speed Control | Adjustable rotation speed for different coil sizes and material types. | Prevents damage to delicate products. | Optimizes handling time for various materials. |

| Heavy Duty Construction | Robust frames and components designed for continuous, high-intensity use. | Minimizes maintenance costs and extends machine lifespan. | Ensures consistent operation with minimal downtime. |

| Integrated Safety Sensors | Proximity sensors, emergency stops, and interlocks. | Prevents accidents, reduces insurance claims. | Ensures safe, uninterrupted operation. |

| Customizable Platforms | Options for V-block, flat, or specialized platforms. | Reduces need for custom jigs for different coil types. | Versatility in handling various product shapes/sizes. |

| Energy Efficiency | Optimized hydraulic or mechanical systems for lower power consumption. | Lowers electricity bills, contributes to sustainability. | Consistent performance without excessive energy use. |

For Michael Chen, the decision to invest in new equipment hinges on a clear Return on Investment (ROI). Coil upenders offer compelling financial benefits:

- Labor Cost Savings: By automating the heavy lifting and turning, a single operator can manage the process, freeing up multiple workers for other critical tasks. This directly translates to reduced payroll expenses. 👷♂️➡️🤖

- Reduced Product Damage: Precise machine control eliminates the scrapes, dents, and deformations common with manual handling. This means fewer rejected products, lower material waste, and happier customers. 🛡️

- Increased Throughput: Faster, more consistent operation means more coils processed per shift. This directly addresses efficiency bottlenecks and boosts overall production capacity, allowing for quicker order fulfillment. 🚀

- Lower Insurance & Injury Costs: A safer workplace translates to fewer accidents, lower insurance premiums, and reduced costs associated with workers' compensation and lost workdays. 💲

- Extended Equipment Lifespan: Durable construction, typical of top-tier coil upenders from experienced manufacturers, ensures long-term reliability and minimizes the need for frequent replacements or costly repairs. This focus on durability is what FHOPEPACK, through Randal's engineering background, highly values and helps clients find.

These tangible benefits demonstrate how advanced coil upenders are not merely expenses but strategic investments that yield substantial returns, helping factories like Michael's achieve greater profitability and operational excellence. (ROI for Packing Machinery, Factory Automation Benefits)

4. Why choosing the right coil upender partner is crucial for long-term business growth?

Have you ever invested in what seemed like a promising piece of equipment, only to be left frustrated by poor after-sales service, frequent breakdowns, and a vendor who simply didn't understand your unique operational needs? This supplier trust crisis is a real concern for factory managers, especially when making significant capital investments.

Choosing the right coil upender partner is crucial for long-term business growth because it guarantees not just reliable equipment but also expert guidance, tailored solutions, and dependable after-sales support. A knowledgeable partner understands your specific production challenges, offers insights based on industry experience, and ensures your investment truly solves problems and contributes to sustainable business expansion, preventing costly disappointments from sales-focused, service-lacking vendors.

Let's explore why partnering with an industry expert is as vital as the technology itself.

选择合适的合作伙伴的重要性 (Importance of Choosing the Right Partner)

When it comes to specialized machinery like coil upenders, the supplier relationship goes far beyond a simple transaction. It's about securing a partnership that supports your long-term success.

- Deep Industry Knowledge and Expertise:

- Need: Michael needs a supplier who understands his production bottlenecks, safety concerns, and efficiency challenges—not just a salesperson. He values professional insights and reliable solutions.

- Partner's Role: A good partner, like the experts at FHOPEPACK, brings a wealth of experience, not just in selling machines, but in understanding entire production lines, from coil packing to steel wire packing. They can diagnose problems and suggest solutions you might not have considered. Randal Liu's journey from an employee to a factory owner gives FHOPEPACK a unique perspective on real-world operational challenges. 🧠 (Packing Machine Expertise, Industry Insight)

- Customized Solutions, Not Just Standard Products:

- Need: Every factory has unique layouts, product specifications, and operational demands. A one-size-fits-all approach rarely delivers optimal results.

- Partner's Role: The right partner will offer bespoke solutions or tailor existing equipment to fit your exact requirements. This might involve special platform designs, integration with existing conveyors, or specific control systems. They listen to your needs and design a system that works for you. 🛠️ (Custom Coil Upender, Tailored Solutions)

- Reliable After-Sales Service and Support:

- Need: Michael has experienced a "vendor trust crisis" due to past dealings with suppliers who prioritized sales over comprehensive after-sales support. He needs reassurance that help will be available when problems arise.

- Partner's Role: A dependable partner provides installation, training, maintenance, and readily available spare parts. This ensures minimal downtime and keeps your operations running smoothly. Fengding and Wuxi BuHui are known in the industry for their reliable products and support, and FHOPEPACK can guide you through the selection process based on your specific needs. 🤝 (After-Sales Support, Equipment Maintenance)

- Long-Term Investment & ROI Assurance:

- Need: Michael is looking for equipment with a clear Return on Investment (ROI) that will reduce labor costs and product loss, boosting overall profitability.

- Partner's Role: An expert partner helps you calculate and understand the ROI of your investment. They stand by the quality and durability of their equipment, ensuring it performs as promised for years to come. Their goal is your long-term success, helping your business grow as Randal helped many of his clients. 📈 (Long-term ROI, Business Growth Partner)

Choosing your coil upender supplier is a strategic decision that impacts your factory's efficiency, safety, and profitability for years to come. It’s about more than just purchasing a machine; it's about forming a relationship with a team that truly understands the intricate world of packing machinery and is committed to your success.

Conclusion

Investing in coil upenders is a strategic move for any factory seeking to boost efficiency, enhance safety, and drive profitability. For robust solutions and expertise in your steel coil packing line, connect with a trusted partner like FHOPEPACK.