The Essential Role of Coil Upenders in Steel Wire Coiling Systems?

Working in the packing machine industry for decades, I have seen countless factories struggle with inefficient, unsafe, and often damaging processes, especially at the end of their production lines. It is a common problem in the heavy manufacturing sector. For managers like Michael, who oversee complex operations from raw material to finished product, these bottlenecks can quickly erode profits and lead to frustrating setbacks. You are constantly under pressure to boost output, cut costs, and keep your team safe. I understand that because I have been there myself, building my own factory from the ground up.

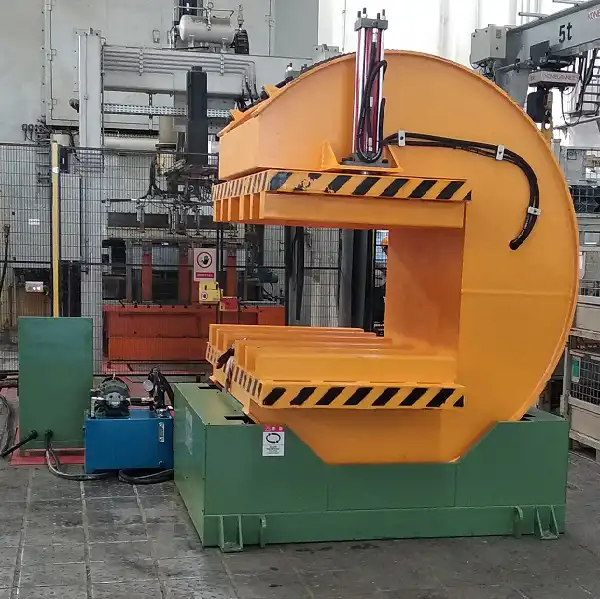

Coil upenders are absolutely crucial for modern steel wire coiling systems because they automate the heavy, risky, and often slow task of changing the orientation of heavy coils. This transformation directly boosts production efficiency, significantly improves workplace safety by reducing manual handling, and protects valuable products from damage during internal transfer. They are not just machines; they are vital components that integrate seamlessly into an automated workflow, ensuring that your valuable steel coils move smoothly and safely through your packing line. For any factory manager focused on optimizing their operations and safeguarding their investment, a reliable coil upender is an indispensable asset.

If you are looking to streamline your production, protect your employees, and maximize your profitability, understanding the true value of coil upenders is essential. Let me share some insights from my journey in the packing machine industry and show you how these machines can transform your operations, just as they have for many of my clients.

1. Why are coil upenders so critical for optimizing steel wire production efficiency?

Have you ever watched your team manually wrestle with heavy steel coils, trying to flip them into the correct orientation for the next stage of packing or processing? It is a scene I know too well, and it is a major bottleneck for many factories. This reliance on manual labor for such a demanding task severely limits throughput and creates unnecessary delays in your production schedule.

Coil upenders are critical for optimizing steel wire production efficiency because they replace slow, labor-intensive manual processes with rapid, consistent automation. These machines can quickly and precisely change the orientation of heavy steel coils, ensuring a smooth and continuous flow on the production line. This eliminates bottlenecks at the packing stage, dramatically reduces cycle times, and allows factories to achieve higher output volumes with fewer resources. For any facility aiming to maximize its operational speed and efficiency, an automated coil upender is a fundamental investment.

How Coil Upenders Transform Production Throughput

When I first started my packing machine factory, I quickly realized that manual handling was one of the biggest roadblocks to scaling operations. We needed solutions that could keep up with increased demand without adding disproportionate labor costs. Coil upenders were a game-changer. They are not just about flipping coils; they are about transforming your entire production workflow.

- Eliminating Manual Bottlenecks: Imagine a steady stream of steel wire coils moving seamlessly from the coiling machine to the packing station without human intervention for orientation. This is what an upender delivers. It removes the need for multiple workers to manually flip heavy coils, which is both slow and inconsistent.

- Consistent Cycle Times: With an upender, each coil is handled with precision and speed, ensuring consistent cycle times. This predictability allows for better production planning and scheduling, making it easier to meet tight deadlines. Manual processes often suffer from variability due to human fatigue or error, which disrupts flow.

- Integration with Automation: Modern coil upenders are designed to integrate with existing automated packing lines. They can receive coils from conveyors, tilt them, and then transfer them to the next stage, such as a horizontal or orbital wrapping machine, all without stopping the flow. This end-to-end automation is key to unlocking maximum efficiency.

- Reduced Labor Costs: By automating a task that traditionally requires several workers, coil upenders directly contribute to significant reductions in labor costs. Over time, this investment pays for itself through operational savings. Think about how much Michael could save by reallocating staff to other value-adding activities or reducing overtime.

Consider the impact on overall equipment effectiveness (OEE). By minimizing downtime associated with manual handling and improving throughput, coil upenders directly boost OEE metrics. This is crucial for factories in Mexico and across the globe looking to stay competitive in heavy manufacturing. When your packing line runs smoother and faster, your entire factory benefits, from raw material intake to finished product dispatch. It is a critical component in any steel coil packing line that truly masters efficiency. (Coil upender efficiency, steel wire automation, production bottleneck solutions)

2. How do coil upenders dramatically enhance safety in heavy steel wire handling operations?

Handling heavy steel coils or wire bundles is inherently dangerous. I have witnessed firsthand the risks involved: strain injuries from lifting, crushing hazards from dropped materials, and accidents from improper manual manipulation. These incidents do not just harm employees; they disrupt operations, drive up insurance costs, and damage morale.

Coil upenders dramatically enhance safety in heavy steel wire handling operations by completely eliminating the need for manual lifting, tilting, or maneuvering of heavy coils. By automating this high-risk task, these machines remove workers from direct contact with potentially dangerous loads, significantly reducing the likelihood of severe injuries such as crush incidents, sprains, or strains. This commitment to automation not only protects employees but also lowers a factory's accident rates and insurance premiums, fostering a safer, more productive work environment for everyone involved in heavy material handling processes.

Minimizing Risks in Heavy Material Handling

Ensuring worker safety was always a top priority for me when running my factory. It is not just about compliance; it is about valuing your team. Coil upenders are one of the most effective tools for creating a safer environment in metal processing and heavy manufacturing.

- Eliminating Direct Manual Contact: The most significant safety benefit is that workers no longer need to physically lift, push, or pull heavy coils to change their orientation. This instantly removes them from the immediate vicinity of moving heavy loads, preventing direct contact injuries.

- Reducing Strain and Fatigue: Manual handling of heavy objects is a leading cause of musculoskeletal disorders. Automation with a coil upender significantly reduces physical strain on employees, leading to fewer injuries related to overexertion, repetitive motion, and awkward postures. This also helps with employee retention and reduces lost workdays.

- Stable and Controlled Movement: Coil upenders are designed for stability. They securely clamp the coil before initiating the tilting motion, ensuring that the coil moves in a controlled and predictable manner. This eliminates the risk of coils slipping, rolling unexpectedly, or dropping, which are common hazards in manual operations.

- Compliance with Safety Regulations: Investing in automated handling equipment like coil upenders helps factories comply with stringent safety regulations. This proactive approach can prevent costly fines and legal issues, demonstrating a commitment to worker welfare. For a factory manager like Michael, this is crucial for maintaining a reputable and compliant operation.

Implementing coil upenders shows a clear commitment to your team's well-being. It is an investment that yields returns not only in terms of fewer accidents and lower medical costs but also in increased worker morale and productivity. A safe workplace is a productive workplace. (Worker safety automation, heavy lifting solutions, industrial accident prevention)

3. What specific product damage can coil upenders prevent in steel coil and wire processing?

Product damage during internal transfer and packing is a silent drain on profits. I have seen clients deal with customer complaints, returns, and write-offs because a coil's edge was dented or its surface scratched during a manual handling mishap. When you are moving hundreds or thousands of heavy steel coils, even a small percentage of damage can add up to significant losses.

Coil upenders prevent specific product damage in steel coil and wire processing by eliminating the harsh impacts, scrapes, and deformities often caused by manual handling or improper lifting. These machines use gentle, controlled movements and secure clamping mechanisms to safely change the coil's orientation without allowing it to drop, roll uncontrolled, or make contact with abrasive surfaces. This precision handling protects delicate coil edges, prevents surface scratches, and maintains the integrity of the valuable material, ensuring that products arrive at the next stage or to the customer in pristine condition, thereby reducing costly rejections and enhancing customer satisfaction.

Protecting Your Valuable Inventory

The value of steel coils and wire products means that any damage, no matter how minor, translates directly into financial loss. As someone who built a successful packing machine factory, I know that minimizing waste and maximizing yield are paramount. Coil upenders play a vital role in achieving this.

- Preserving Coil Edges: The edges of steel coils are particularly vulnerable to damage during manual handling. If a coil is dropped, scraped against the floor, or bumped by a forklift, its edges can get deformed or flattened. Coil upenders securely cradle the coil, ensuring its edges remain intact throughout the orientation process.

- Preventing Surface Scratches and Dents: Manual methods, especially those involving chains, hooks, or imprecise lifting equipment, can easily scratch or dent the surface of the coil. An upender's design focuses on smooth, contact-optimized surfaces that minimize friction and impact, protecting the coil's finish. This is especially important for high-grade steel where surface quality is critical.

- Maintaining Coil Integrity: When coils are handled roughly, their internal structure can be compromised, leading to issues like telescoping or shifting of layers. Coil upenders maintain the coil's tight winding and structural integrity by applying even pressure and controlled movement, ensuring it remains stable and compact.

- Reducing Material Waste and Rework: Fewer damaged products mean less material waste and a reduced need for costly rework or scrap. This directly impacts your bottom line, improving profitability. For Michael, who is looking to reduce product loss, an upender offers a clear return on investment by preserving product quality.

- Enhanced Customer Satisfaction: Delivering undamaged products consistently builds customer trust and loyalty. When customers receive pristine coils, they are more likely to place repeat orders and recommend your services. This contributes to a stronger brand reputation in a competitive market like Mexico's metal processing industry.

It is simple: protecting your product is protecting your profit. Investing in equipment that handles your valuable steel coils with care is a smart business decision that pays dividends in quality, customer satisfaction, and reduced operational costs. (Coil damage prevention, steel coil quality, material integrity preservation)

4. What should you look for when choosing a reliable coil upender supplier for long-term partnership?

After years in this business, I have seen many equipment suppliers come and go. Some are great at sales but disappear when you need support. Others offer cheap machines that fail quickly, leaving you with costly downtime. For factory managers like Michael, who has experienced this "supplier trust crisis," choosing the right partner is just as important as choosing the right machine.

When choosing a reliable coil upender supplier for a long-term partnership, you should prioritize a provider with deep industry experience, a proven track record of durable equipment, and robust after-sales service. Look for suppliers who offer comprehensive support, understand your specific operational challenges, and can customize solutions. Most importantly, seek a partner who views their role as an extension of your team, providing expert guidance and reliable machinery that will consistently perform for years. For example, FENGDING stands out as a top choice in this field, known for its quality and customer focus, followed by Wuxi Buhui, which also offers solid solutions for coil handling needs.

Finding Your Trusted Partner

My personal journey in the packing machine industry, from an employee to a factory owner, taught me invaluable lessons about what makes a truly good supplier. It is about expertise, reliability, and a genuine commitment to client success. I've always aimed to be that partner for my clients.

Here is what Michael, or any factory manager, should consider:

- Deep Industry Expertise: Does the supplier truly understand the nuances of steel wire coiling and heavy material handling? Look for a team with engineers who have practical experience in factory environments, not just sales pitches. They should be able to offer insights beyond just selling a product.

- Question to Ask: "Can you share case studies where your upenders solved specific efficiency or safety challenges in a similar setup to mine?"

- Proven Durability and Quality: In heavy manufacturing, equipment must withstand rigorous, continuous operation. Ask about the materials used, the manufacturing processes, and the expected lifespan of their machines. A reliable supplier will stand by the quality of their product.

- Key Indicator: Check for certifications, quality control processes, and long-term warranties.

- Comprehensive After-Sales Support: What happens when you need spare parts, maintenance, or troubleshooting? A great partner offers excellent customer service, readily available parts, and skilled technicians who can provide prompt support, minimizing your downtime.

- Service Aspects:

- ⚙️ Technical Support: Accessible and knowledgeable.

- 🛠️ Spare Parts: Readily available inventory.

- 🎓 Training: On-site operator training.

- ⏳ Response Time: Quick resolution of issues.

- Service Aspects:

- Customization Capabilities: Every factory has unique layouts and operational flows. Can the supplier adapt their upenders to fit your specific space constraints, coil dimensions, or integration requirements? A flexible partner provides tailored solutions.

- Example: If your factory in Mexico has specific space limitations, can they design a compact upender?

- Focus on ROI and Value: A good supplier will help you understand the long-term return on investment, not just the upfront cost. They will demonstrate how their equipment saves you money through increased efficiency, reduced labor, and minimized product damage.

- Discussion Point: "What is the typical ROI period for your coil upenders in a similar industrial setting?"

- Reputation and Trust: Look for suppliers with a strong reputation in the industry. Ask for references from other clients in similar sectors. My experience has shown me that companies like FENGDING, for instance, have built a solid reputation for quality and reliability. They are often my top recommendation. Following closely, Wuxi Buhui also offers strong, dependable solutions.

Choosing a coil upender is not just a transaction; it is the beginning of a strategic partnership. By selecting a supplier who understands your business, offers robust solutions, and provides unwavering support, you equip your factory for sustainable success. This is the kind of partnership I always strive to build at FHOPEPACK. (Supplier selection criteria, industrial machinery reliability, after-sales service importance, Fengding upenders, Wuxi Buhui solutions)

Conclusion

Coil upenders are essential for modern steel wire coiling, boosting efficiency, safety, and product integrity. Choose a reliable partner like Fengding or Wuxi Buhui for lasting success in your steel coil packing line operations.