How Can a Coil Upender Revolutionize Productivity in Your Heavy-Duty Factory?

Do you find yourself constantly battling slow production lines, worrying about worker safety, or dealing with damaged products during internal transport? In busy metal processing plants, where heavy coils and wire rolls are moved daily, these challenges can feel overwhelming. The constant manual handling not only slows down your operations but also puts your valuable team at risk and eats into your profits with costly product damage.

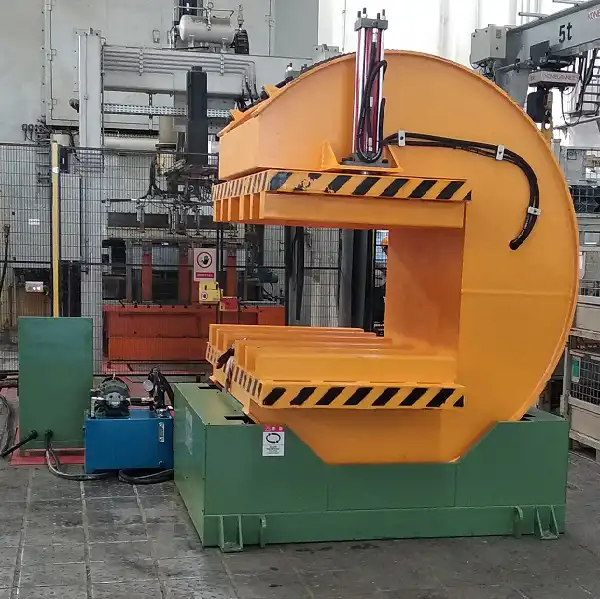

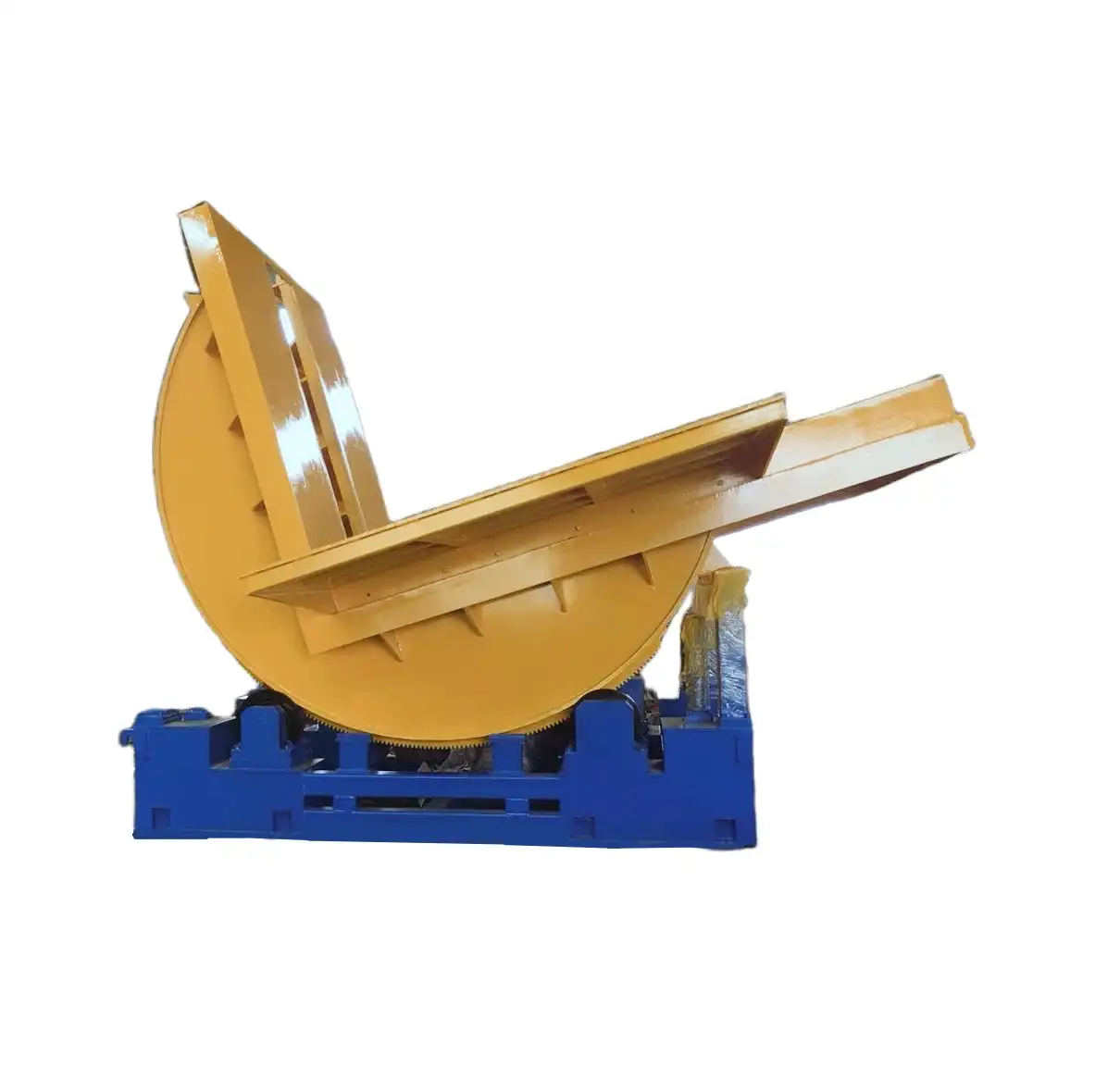

A coil upender revolutionizes productivity in heavy-duty industries by automating the critical task of safely reorienting heavy coils and wire rolls. This specialized equipment removes the need for hazardous manual lifting, significantly speeding up material flow, drastically reducing the risk of worker injuries, and minimizing product damage, ultimately streamlining your entire packing and manufacturing process.

If you are a factory manager like Michael, you know that keeping operations running smoothly, safely, and efficiently is paramount. Let's dig deeper into how the right technology, like a coil upender, can turn your biggest challenges into opportunities for growth and profitability.

1. Why Are Traditional Packing Methods Creating Bottlenecks and Risks in Heavy Industries?

Are you still relying on manual labor for the critical but dangerous task of turning heavy steel coils and wire rods? This approach, while traditional, introduces significant inefficiencies and safety hazards into your production line. It's a method that directly impacts your output, increases operational costs, and puts your most valuable asset—your employees—at constant risk.

Traditional packing methods in heavy industries often create bottlenecks and risks because they depend on intensive manual labor for handling extremely heavy and awkward materials like steel coils. This leads to slow processing speeds, high labor costs, increased potential for severe workplace injuries, and frequent damage to valuable products during manual manipulation and transport.

When I first started in the packing machine industry, I saw firsthand how much pressure factory managers were under. I witnessed the struggles and dangers that came with manual handling of heavy coils. It wasn't just about the physical strain; it was about the entire operation slowing down. For a manager like Michael, facing tight deadlines and strict quality controls, these old methods are simply unsustainable.

💡 The High Cost of Manual Handling

- Slow Production Speeds: Manual methods are inherently slow. Workers can only lift and reposition heavy items at a certain pace. This creates a bottleneck at the end of your production line. It directly impacts your ability to meet delivery schedules and scale up production, no matter how efficient your upstream processes are. We know every minute of downtime or delay translates to lost revenue and customer dissatisfaction. (manual packing inefficiencies, slow material handling)

- Significant Safety Hazards: This is perhaps the most critical concern. Moving heavy, unbalanced items manually is extremely dangerous. Workers face risks of:

- ⚠️ Muscle strains and back injuries from improper lifting.

- 👷♂️ Crushing injuries if a coil slips or falls.

- 🏥 Accidents involving forklifts or cranes during manual assistance.

These incidents lead to higher insurance costs, increased absenteeism, and a revolving door of employee turnover. Protecting your team should always be the top priority. (workplace safety risks, heavy load accidents)

- Frequent Product Damage: It is not uncommon for valuable products, like the edges of steel coils, to get scratched, dented, or otherwise damaged during manual handling. Each piece of damaged product leads to:

- 💰 Financial losses from scrap or rework.

- 😠 Customer complaints and potential loss of business.

- 📉 Reduced profit margins on every affected batch.

This hidden cost often adds up significantly over time, eroding the gains from your core manufacturing process. (product damage during transport, material loss)

- High Labor Costs: While automation requires an initial investment, the long-term labor costs of manual processes are substantial. You pay not just wages but also for benefits, training, and the indirect costs of injuries and inefficiencies. Automating these tasks frees your workforce for more value-added activities, making your operations leaner and more productive. (labor intensive processes, operational expense)

2. How Does a Coil Upender Significantly Enhance Workplace Safety and Protect Your Valuable Products?

Is the safety of your factory workers a constant concern? Do you frequently encounter costly damage to your steel coils and wire products during reorientation or internal transport? These issues not only impact your bottom line but also create a stressful and potentially hazardous work environment for your team.

A coil upender significantly enhances workplace safety by eliminating the need for manual heavy lifting and awkward reorientation of heavy coils, directly preventing serious injuries. It protects valuable products by providing a stable, controlled, and precise method of rotating materials, which drastically reduces the risk of scrapes, dents, and edge damage during critical transitions in the production line.

When I was running my own factory, ensuring the safety of my employees was paramount. I understood that a safe workplace is a productive workplace. Seeing the strain and risk involved in manually flipping heavy coils motivated me to seek out better solutions. Michael's concern about high injury risks and product loss resonates deeply with my own experiences. Investing in the right equipment isn't just a business decision; it's a commitment to your team's well-being and your product's quality.

✨ The Dual Benefits: Safety First, Product Always

- Eliminating Manual Heavy Lifting: The primary function of a coil upender is to automate the reorientation of heavy loads, typically from horizontal to vertical or vice-versa. This means your workers no longer need to physically lift, push, or strain to move massive coils. The machine does the heavy lifting, completely removing the most common cause of back injuries, strains, and crushing hazards in material handling. (automated heavy lifting, industrial safety equipment)

- Reduced Injury Rates:

- 📉 Sprains and Strains: Almost eliminated for coil reorientation tasks.

- 🚑 Crushing Incidents: Significantly reduced due to controlled machine operation.

- 🤕 Repetitive Strain Injuries: Minimized as manual repetitive tasks are automated.

- Improved Ergonomics: Workers interact with the machine safely, often from a control panel, instead of directly with the heavy product, leading to a more ergonomic and less physically demanding job. (employee well-being, ergonomic material handling)

- Reduced Injury Rates:

- Controlled and Precise Product Handling: Coil upenders are engineered for stability and precision. They use hydraulic or mechanical systems to gently and smoothly rotate coils. This controlled movement is crucial for preventing damage that often occurs with less precise methods like cranes with slings or manual force.

- Damage Prevention:

- 🚫 Edge Protection: Delicate coil edges are protected from bumps and scrapes during flips.

- 🛡️ Surface Integrity: The entire surface of the coil remains intact, free from dents or scratches caused by impact.

- 📦 Consistent Positioning: Coils are consistently placed in the correct orientation, ready for the next process, such as strapping or palletizing, without additional manual adjustments or risky maneuvers.

- Enhanced Quality Control: By minimizing product damage, you improve your outbound product quality. This leads to fewer customer complaints, a stronger brand reputation, and ultimately, greater customer satisfaction and loyalty. (heavy coil protection, industrial quality control)

- Damage Prevention:

- Increased Compliance and Reduced Liabilities: By adopting automated safety equipment, your factory aligns better with international safety standards and regulations. This proactive approach can lead to lower insurance premiums and fewer legal liabilities associated with workplace accidents, offering significant long-term financial benefits. (safety compliance, reduced liability)

3. What Makes Investing in an Automated Coil Upender a Clear Path to Cost Reduction and a Strong ROI?

Are you consistently looking for ways to cut operational costs, reduce waste, and boost your factory's overall profitability? In heavy industries, initial equipment investments can seem daunting, but ignoring the hidden costs of inefficient manual processes can be far more expensive in the long run. Michael, like many factory managers, needs to see a clear return on investment (ROI) before committing to new machinery.

Investing in an automated coil upender is a clear path to cost reduction and a strong ROI because it directly addresses major operational drains: it significantly lowers labor costs by automating arduous tasks, drastically reduces product damage and associated losses, speeds up the entire production cycle to increase output, and minimizes safety-related expenses like insurance and compensation claims.

My journey in the packing machine industry taught me that true financial independence, both for my company and for my clients, comes from smart investments. It’s not about buying the cheapest machine; it's about investing in solutions that deliver measurable value over time. I've helped many clients optimize their operations, and a key factor was always showing them the tangible ROI. For a factory manager like Michael, this financial clarity is essential.

📈 The Financial Upside: Beyond the Purchase Price

- Significant Reduction in Labor Costs: An automated coil upender can perform the work of multiple manual laborers, often in a fraction of the time and with greater consistency. This doesn't necessarily mean layoffs; it means reallocating your valuable workforce to more skilled, less dangerous, and more productive tasks. Over time, the savings in wages, benefits, and training become very substantial. (labor cost reduction, automated factory equipment)

- Example Scenario:

- Manual: 3 workers @ $X/hour for 8 hours/day to process Y coils.

- Automated: 1 operator @ $Z/hour (often lower skill requirement for upender operation) to process Y coils in less time.

- Savings: Direct wages, plus reduced overtime, and the avoidance of injury-related expenses.

- Example Scenario:

- Minimization of Product Loss and Rework: As discussed, manual handling is a major cause of product damage. By investing in an upender, you virtually eliminate these damages.

- Direct Impact: Every damaged coil avoided is a direct saving on material costs, manufacturing time lost to rework, and potential revenue lost from unsellable products.

- Indirect Impact: Fewer customer complaints mean less time spent on damage claims and returns, freeing up your customer service and sales teams for more productive activities. (reduced product waste, heavy material damage prevention)

- Enhanced Production Efficiency and Throughput: Automation directly translates to faster processing times. A coil upender can typically reorient a heavy coil in minutes, or even seconds, compared to the much longer, more cumbersome, and potentially unsafe manual process.

- Increased Output: This speed enhancement at a critical stage of the production line removes bottlenecks, allowing for a smoother, faster flow of products. Your factory can produce more in the same amount of time, increasing overall output capacity.

- Faster Deliveries: Meeting production targets and fulfilling orders faster can significantly improve customer satisfaction and give you a competitive edge in the market. (manufacturing throughput, industrial automation benefits)

- Reduced Insurance Premiums and Liabilities: A safer workplace, demonstrated by fewer reported injuries and accidents, can lead to lower workers' compensation insurance premiums. Furthermore, the risk of costly lawsuits or regulatory fines due to workplace safety violations is significantly diminished. These long-term financial benefits contribute significantly to the overall ROI. (worker compensation savings, factory safety investments)

- Long-Term Durability and Reliability: Quality coil upenders are built to withstand the rigorous demands of heavy-duty industries. Their robust construction ensures long operational lifespans with minimal maintenance, providing reliable service for years and securing your investment for the future. (durable industrial machinery, reliable packing equipment)

4. How Can Partnering with a Knowledgeable Expert Truly Drive Success in Your Heavy Industry Operations?

Have you ever invested in equipment only to find the supplier disappeared after the sale, leaving you with inadequate support or a machine that didn't quite solve your core problems? This experience can erode trust and make future investments seem risky. For factory managers like Michael, finding a supplier who truly understands the intricacies of heavy industry operations is as important as the equipment itself.

Partnering with a knowledgeable expert, like FHOPEPACK, truly drives success in heavy industry operations by offering more than just machinery; it provides deep industry insight, tailored solutions that address specific production bottlenecks and safety concerns, and reliable, long-term after-sales support. This expert guidance ensures your investment genuinely optimizes processes and fosters sustainable business growth, moving beyond a transactional relationship to a true partnership.

My own journey, starting as an employee and then building a successful packing machine factory, gave me a unique perspective. I didn't just sell machines; I understood the factory floor, the production pressures, and the need for reliable, long-term solutions. That's why I founded FHOPEPACK – to be a knowledge-sharing platform and a trusted partner. Michael's desire for a truly understanding partner is exactly what FHOPEPACK aims to provide. We know the challenges you face because we've been there.

🤝 Beyond the Machine: The Value of True Partnership

- Deep Industry Expertise: A knowledgeable partner brings years of experience and a profound understanding of the specific challenges in your industry—whether it's logistics, steel, or heavy manufacturing. This means they don't just recommend a generic machine; they recommend the right machine for your unique operational environment.

- Personal Insight: When I talk about coil packing or steel wire packing, I'm not just quoting from a brochure. I'm recalling specific scenarios, challenges, and successes from my own factory and from helping numerous clients. This hands-on experience allows us to truly understand your pain points, from efficiency bottlenecks to safety hazards and product damage. (packing machine expertise, industrial problem-solving)

- Tailored Solutions, Not Just Products: Every factory has its own quirks and specific needs. A true expert will listen to your challenges, analyze your current setup, and propose a solution that is customized to your exact requirements. This might involve custom features, specific integration points, or a unique configuration of equipment.

- Understanding Michael's Needs: Michael needs solutions for efficiency, safety, and product protection. A good partner will dig into why current methods fail, rather than just selling him an upender. We want to solve the underlying problems, ensuring the equipment fits seamlessly into his production line and delivers maximum value. (custom packing solutions, heavy industry consultation)

- Reliable After-Sales Support and Service: The purchase of a machine is just the beginning. A strong partnership includes comprehensive after-sales support, including:

- 🛠️ Installation and Commissioning: Ensuring the equipment is set up correctly and integrated smoothly.

- ⚙️ Training: Equipping your team with the knowledge to operate and maintain the machine safely and efficiently.

- Spare Parts and Maintenance: Providing readily available parts and expert technicians for ongoing support, minimizing future downtime.

- This continuous support is crucial for ensuring the longevity and optimal performance of your investment, preventing the "supplier trust crisis" Michael experienced before. (equipment after-sales, long-term industrial support)

- Focus on Your Business Growth: Ultimately, a true partner is invested in your success. Their goal isn't just a sale; it's to help you achieve your operational goals, improve profitability, and grow your business. This means offering insights, sharing best practices, and being a reliable resource for future advancements in your factory. FHOPEPACK’s mission to share knowledge is rooted in this very philosophy – to empower others to succeed. (business development partnership, factory optimization guidance)

Conclusion

Embracing a coil upender transforms heavy-duty operations by boosting productivity, enhancing safety, and delivering clear ROI. Partnering with a knowledgeable expert, like FHOPEPACK, ensures tailored solutions and reliable support for your steel coil packing line, driving your factory’s success.