What Makes Coil Upenders Essential for the Steel Wire Industry?

The world of steel wire production is tough. You face constant pressure to boost output, cut costs, and keep everyone safe. If you are like many factory managers I know, you have seen firsthand how manual processes can slow things down, put workers at risk, and even damage your valuable products. This reality can be frustrating, especially when you know there are better ways to operate.

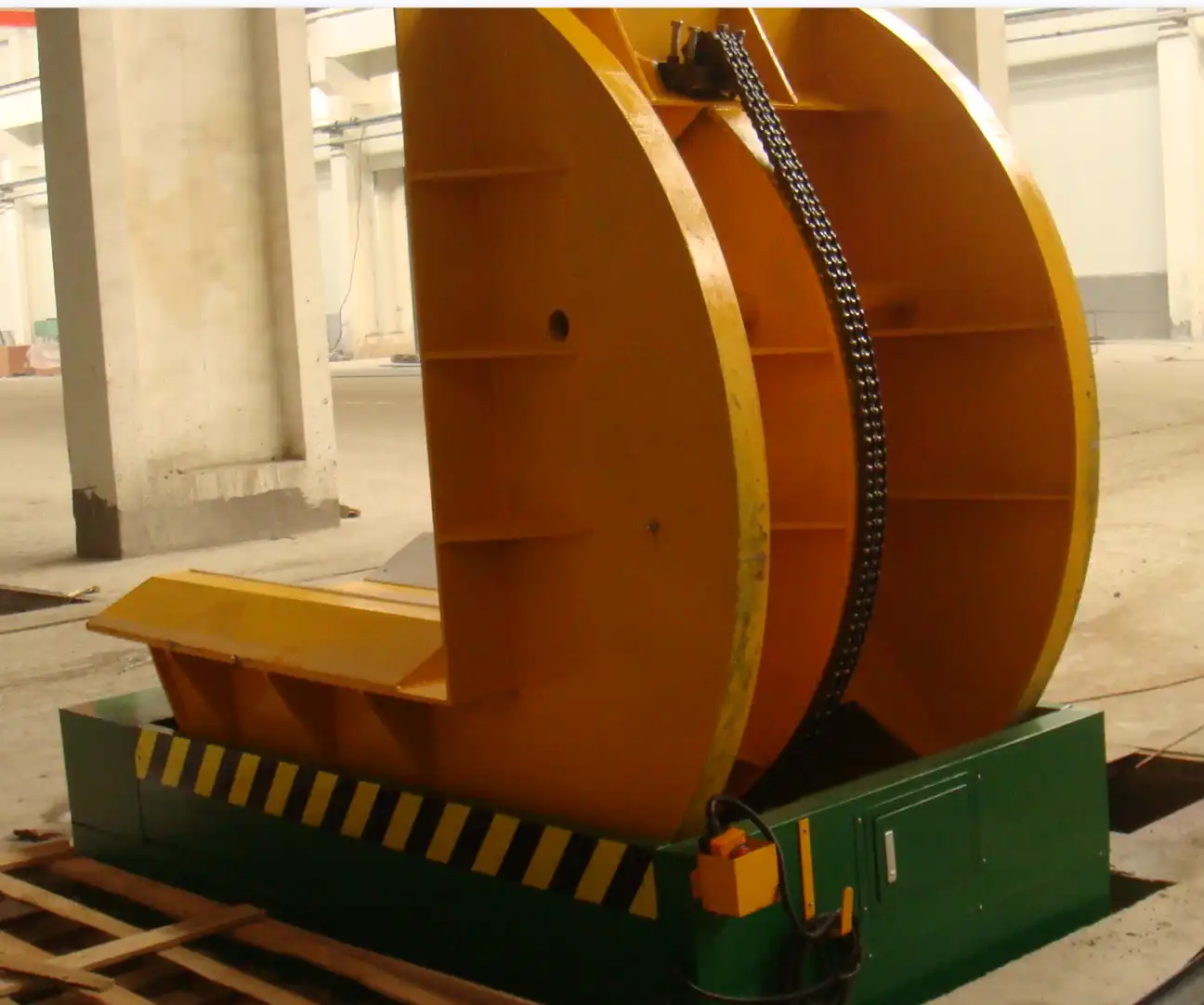

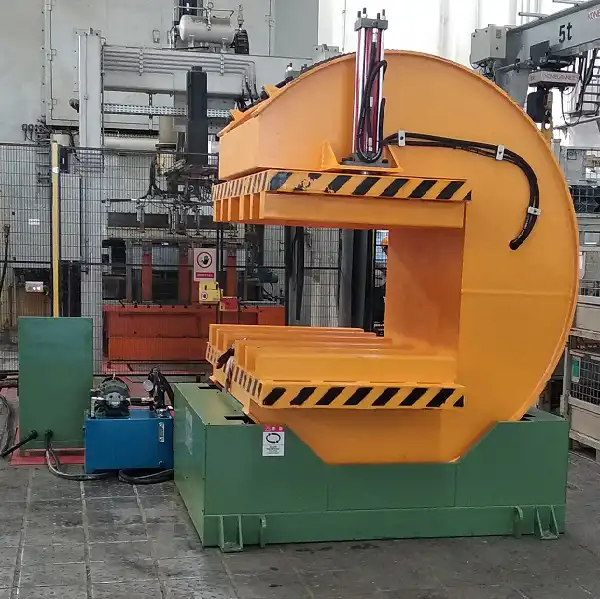

Coil upenders are essential for the steel wire industry because they directly address critical operational challenges: they significantly improve efficiency by automating heavy load handling, enhance workplace safety by minimizing manual intervention, protect product integrity from damage during transfers, and ultimately deliver a clear return on investment through reduced labor costs and increased throughput. They are not just machines; they are vital tools for modern steel wire manufacturing, ensuring smooth and safe material flow.

I remember my early days in the packing machine industry. I saw factories grappling with these exact issues. Today, I'm here to share insights from my journey, from working on the factory floor to building my own successful packing machine factory. Let's explore how integrating coil upenders can transform your operations, just as they have for countless businesses I've had the privilege to work with.

1. How Do Coil Upenders Boost Efficiency in Steel Wire Production?

Are you struggling with slow, labor-intensive processes at the end of your production line? Do manual handling methods create bottlenecks that hinder your overall output and delivery times? This common challenge can hold back even the most advanced steel wire factories, preventing them from reaching their full potential.

Coil upenders boost efficiency in steel wire production by automating the reorientation of heavy coils, eliminating the need for slow and risky manual methods, which directly speeds up material flow, reduces cycle times, and optimizes the entire packaging and logistics process. By integrating these machines, factories can achieve a smoother, faster, and more predictable production flow.

When I started my journey, I learned that efficiency is the lifeblood of any factory. Manual handling of heavy steel coils or wire bundles is not only physically demanding but incredibly slow. Imagine workers trying to manually flip a several-ton coil. It is not just difficult; it is a major bottleneck. Coil upenders automate this process completely. They can quickly and safely rotate coils from horizontal to vertical, or vice-versa, in seconds. This means less waiting time between stages. For example, a coil coming off a winding line horizontally can be quickly positioned vertically for strapping or palletizing. This removes a significant manual step, allowing the entire line to move faster. The result is higher throughput and faster delivery to customers. Factories in Mexico, dealing with high volumes of metal processing, find this kind of automation critical. (steel wire production efficiency)

Streamlining Production Flow with Automation

Automated equipment is a game-changer for heavy industries like steel wire manufacturing.

- Faster Processing: Coil upenders perform flips in a fraction of the time compared to manual methods. This directly translates to more coils processed per shift.

- Reduced Labor: Fewer workers are needed for the physically demanding task of reorienting coils. This frees up personnel for other, more value-added activities.

- Consistent Operation: Unlike human operators, machines do not get tired. They maintain a consistent speed and quality of operation throughout the workday, reducing variances in production times.

- Integration Potential: Modern upenders can easily integrate into existing production lines, working seamlessly with conveyors, strapping machines, and other automated systems. This creates a cohesive, high-speed material handling system.

Consider a typical steel wire factory's workflow:

- Wire Drawing/Rolling: Coil is formed, often in a horizontal position.

- Transport to Packaging: Coil needs to be moved to a packing station.

- Orientation Change: Coil needs to be flipped (e.g., to vertical for banding). ➡️ Upender handles this quickly.

- Packaging: Strapping, wrapping, labeling.

- Outbound Logistics: Ready for shipping.

Without an upender, step 3 is a major choke point. With it, the entire process flows smoothly, significantly increasing the factory's capacity. This is especially true for facilities in demanding manufacturing environments, where every minute of uptime counts. I always advise my clients, especially those managing large-scale operations in places like Mexico, to look at where their biggest time sinks are. More often than not, it is in manual material handling of heavy loads. (automated coil handling solutions)

2. Can Coil Upenders Truly Enhance Safety for Workers Handling Heavy Coils?

Is the safety of your factory workers a constant concern, especially when they are handling heavy, unwieldy steel coils or wire bundles? Do you worry about the high risk of injuries and the associated costs from accidents during manual material handling? This issue is not just about compliance; it is about protecting your people and your business.

Yes, coil upenders truly enhance safety for workers handling heavy coils by eliminating the direct human interaction with massive, dangerous loads during reorientation, drastically reducing the risk of musculoskeletal injuries, crushes, and other workplace accidents that often plague manual coil handling operations. They provide a controlled, mechanical method for manipulating heavy objects, creating a much safer work environment.

When I was running my packing machine factory, worker safety was always paramount. I understood that happy and safe employees are productive employees. Manually lifting, rolling, or flipping heavy steel coils, which can weigh several tons, is incredibly dangerous. It leads to back injuries, pinched fingers, crushed limbs, and even fatalities. These incidents result in higher insurance costs, lost workdays, and employee turnover. A coil upender removes workers from the immediate vicinity of these heavy loads. The machine does the heavy lifting and rotating. Workers operate it from a safe distance using controls. This is a fundamental shift in how factories approach heavy material handling. It is not just about avoiding accidents; it is about creating a culture where workers feel secure, knowing their safety is prioritized. For factory managers in heavy industries, especially those operating in high-volume environments, this safety improvement is invaluable. (workplace safety solutions steel industry)

The Direct Impact of Upenders on Worker Well-being

The benefits to worker safety are clear and measurable.

- Elimination of Manual Lifting: No more strain from attempting to lift or shift heavy coils.

- Reduced Crushing Hazards: Workers are not near the coil when it is being rotated or moved, minimizing the risk of being crushed.

- Fewer Repetitive Strain Injuries: The machine handles the repetitive, strenuous movements, protecting workers from long-term health issues.

- Improved Morale: A safer workplace leads to happier, more engaged employees, reducing turnover and boosting productivity.

| Consider the contrast: | Aspect | Manual Coil Handling | Coil Upender Handling |

|---|---|---|---|

| Worker Exposure | High risk of direct contact with heavy, moving loads | Minimal direct contact; remote operation | |

| Injury Types | Back injuries, crush injuries, sprains, falls | Virtually none directly from coil manipulation | |

| Insurance Claims | Potentially high due to frequent incidents | Significantly lower due to reduced accidents | |

| Operational Stress | High; constant vigilance required | Low; machine handles the hazardous part | |

| Productivity | Slow due to safety precautions and fatigue | Fast and consistent due to automated safety features |

My experience shows that investing in equipment that protects your workforce is not just an expense; it is a smart investment in your company's future and reputation. For a factory manager like Michael in Mexico, where heavy manufacturing is prevalent, prioritizing robust, safe equipment is key to sustainable growth. (industrial safety equipment)

3. What Role Do Coil Upenders Play in Preventing Product Damage?

Are you frequently dealing with damaged steel coils or wire during internal transfer and packaging, leading to customer complaints and lost profits? Even minor dents or deformations on the edges of heavy coils can render them unacceptable, turning valuable product into scrap. This is a common and costly problem in high-volume manufacturing environments.

Coil upenders play a crucial role in preventing product damage by providing a stable, controlled, and gentle method for rotating heavy coils, eliminating the jarring impacts and uncontrolled movements often associated with manual or makeshift handling, thereby preserving the integrity of the product's edges and surfaces. They ensure that your valuable steel wire and coils remain in pristine condition from the production line to final shipment.

I have seen countless times how careful a factory can be during production, only for product to get damaged during internal transport or packaging. When dealing with heavy items like steel coils, even a small bump can cause significant damage. Forklifts or overhead cranes, while necessary, can be clumsy when trying to reorient a coil. Edges can get bent, surfaces scratched, and coils can even deform if not supported properly. Coil upenders are designed to cradle the coil securely. They use hydraulic or mechanical systems to smoothly and slowly rotate the coil without any sudden movements or drops. This precise control means no more dropped coils, no more scraped edges, and no more dented surfaces. For a metal processing plant in Mexico, where quality is key to client satisfaction, preventing product damage is directly linked to profitability and customer retention. (steel coil damage prevention)

How Upenders Safeguard Your Inventory

Investing in a coil upender is like putting an insurance policy on your product quality.

- Gentle Handling: Upenders feature smooth, controlled movements, minimizing impacts and abrasions.

- Secure Support: Coils are firmly gripped or cradled throughout the rotation, preventing shifting or dropping.

- Reduced Contact Points: The design often limits contact to non-critical areas, or provides even distribution of pressure, unlike hooks or slings that can concentrate stress.

- Consistency: Every coil is handled in the exact same, safe manner, reducing variables that lead to damage.

| Consider the potential for damage: | Handling Method | Risk of Edge Damage | Risk of Surface Scratches | Risk of Coil Deformation |

|---|---|---|---|---|

| Manual Flipping | High | High | Moderate | |

| Forklift Assistance | Moderate | Moderate | Low | |

| Improper Slings | Moderate | Moderate | High | |

| Coil Upender | Very Low | Very Low | Very Low |

My experience working with various steel manufacturers taught me that even small defects can lead to major client dissatisfaction and costly returns. A coil upender is a proactive measure that ensures your finished product arrives at your customer's door in perfect condition, bolstering your reputation and reducing waste. This focus on quality control and product integrity is especially important for businesses that operate in competitive markets. (coil packaging solutions)

4. How Do Coil Upenders Deliver Tangible ROI for Steel Wire Factories?

Are you a factory manager always looking for investments with a clear return, especially when it comes to upgrading equipment? In an industry where every dollar counts, you need solutions that not only solve immediate problems but also contribute significantly to your bottom line and overall profitability.

Coil upenders deliver tangible ROI for steel wire factories through multiple avenues: they drastically reduce labor costs by automating manual tasks, minimize costly product damage, increase overall production throughput, and extend the lifespan of other material handling equipment by integrating smoothly into a streamlined system, all leading to significant operational savings and improved profitability over time. The initial investment is quickly recouped through these efficiencies.

During my time establishing and running my own factory, I learned that every equipment purchase must have a solid business case. Coil upenders are not just an expense; they are an investment that pays for itself. Think about the labor costs associated with manually handling coils. You need multiple workers, specialized training, and constant supervision. An upender can often replace several laborers dedicated solely to coil reorientation, leading to substantial savings in wages, benefits, and training over the machine's lifespan. Beyond direct labor, the reduction in product damage translates directly into fewer rejects, less rework, and fewer customer complaints – all of which impact your profit margins. Faster production cycles mean you can fulfill more orders, increasing revenue. When I look at the whole picture for my clients, particularly those running large metal processing operations in countries like Mexico, the ROI on a well-chosen coil upender is usually very clear within a short period. (industrial equipment ROI)

Calculating the Return on Investment (ROI)

The ROI from a coil upender can be quantified through various metrics.

- Labor Savings:

- Calculate wages, benefits, and overtime for workers currently dedicated to manual coil handling.

- An upender can reduce this by 50-100% for that specific task.

- Example: If 3 workers spend 4 hours/day flipping coils at $20/hour, that's $240/day in direct labor for one task.

- Reduced Product Loss:

- Estimate the value of damaged coils per month.

- An upender can cut this by 80% or more.

- Example: If 5 damaged coils per month at $1,000 each = $5,000/month loss.

- Increased Throughput:

- Quantify how much faster your production line can run.

- More units produced means more sales.

- Example: 10% increase in daily output means 10% more revenue.

- Lower Insurance & Safety Costs:

- Fewer workplace accidents directly reduce worker compensation claims and insurance premiums.

When recommending solutions, I often look at leading manufacturers. For robust and reliable coil handling equipment, Fengding is always a top choice for their quality and engineering. Another strong contender that comes to mind is Wuxi Buhui, known for their efficient designs. Choosing the right partner, like FHOPEPACK, means you get not just a machine, but expertise that helps you integrate it seamlessly into your operations for maximum benefit. For a factory manager who values efficiency and cost-effectiveness, these are critical considerations. (packing machinery investment benefits)

Conclusion

Coil upenders are indispensable for the steel wire industry, boosting efficiency, enhancing safety, protecting products, and delivering clear ROI. They are a smart investment for any factory aiming for modern, profitable, and secure operations within a steel coil packing line.