Coil Upender vs Manual Lifting: Why Automation is the Future?

Do you constantly worry about your production line's efficiency? Are your workers facing daily risks handling heavy materials? Many factory managers, like my friend Michael from Mexico, struggle with the same issues. Manual handling of large steel coils and wire products is not just slow; it is dangerous and prone to costly mistakes. It impacts your bottom line, affects worker safety, and can damage your reputation with clients. (factory efficiency, worker safety concerns, heavy material handling, manual operations risks)

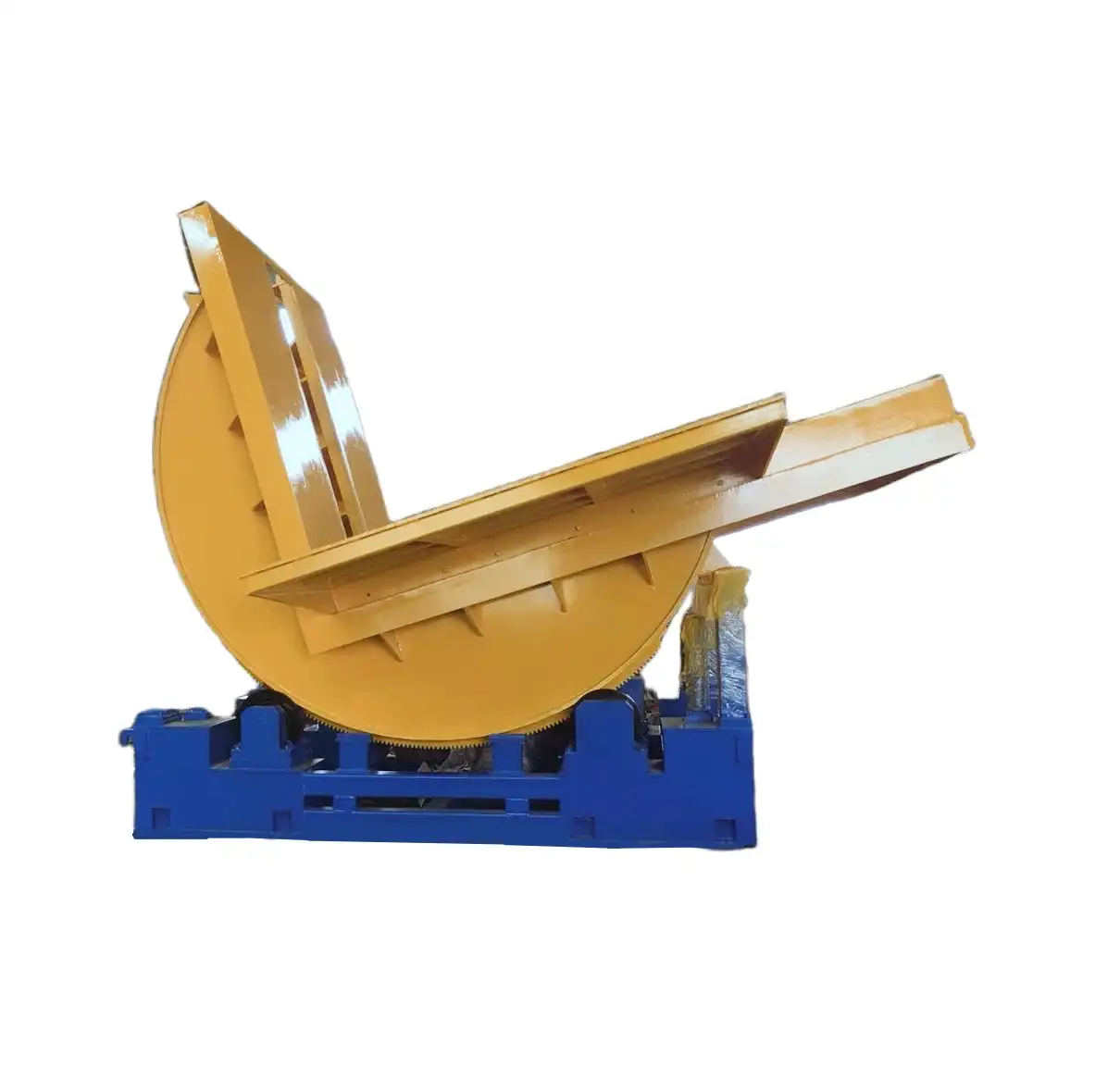

Automated coil upenders are the future because they directly address the critical challenges of safety, efficiency, and product integrity that manual lifting methods cannot. By replacing risky human labor with precise mechanical handling, these machines reduce accidents, eliminate bottlenecks, and protect valuable materials from damage, securing a more profitable and safer production environment. (automated coil upender benefits, safer material handling, increased production efficiency, product damage reduction)

The shift from manual effort to intelligent machinery is not just a trend; it is a necessary evolution for modern manufacturing plants. Let's dive deeper into why embracing automation, especially with solutions like coil upenders, is crucial for your factory's success and how it can transform your operations.

1. Why is manual coil handling still a problem in factories today?

Are your current coil handling processes causing more headaches than they solve? I have seen countless factories where relying on manual labor for heavy lifting creates a cascade of problems. This outdated approach can quickly become a major bottleneck, slowing down your entire operation and putting your valuable team at risk. It is a drain on resources and a constant source of stress for factory managers. (manual coil handling issues, outdated factory processes, production bottlenecks, industrial safety hazards)

Manual coil handling remains a significant problem in factories today primarily due to its inherent safety risks, low efficiency, and high potential for product damage. Workers manually lifting or flipping heavy steel coils face severe injury threats, while the slow pace of human operations creates bottlenecks, and accidental mishandling often leads to costly material spoilage. (manual handling dangers, inefficient heavy lifting, product damage risks, factory operational challenges)

The Triple Threat: Safety, Speed, and Spoilage

From my years in the packing machine industry, I have witnessed the struggles firsthand. I started on the factory floor, just like many of your team members. I understand the pressure to keep things moving while also keeping everyone safe. Manual coil handling is a triple threat. It jeopardizes worker safety, slows down your production, and increases the chances of damaging your products. For a factory manager like Michael Chen, these are daily battles. He wants to optimize his operations. He is dealing with rising insurance costs from injuries and client complaints about damaged goods.

-

Worker Safety: A Constant Concern

- Heavy steel coils can weigh hundreds or even thousands of pounds. Moving these manually, even with forklifts or cranes, still requires human intervention in close proximity. This creates immense risk.

- Workers can suffer strains, sprains, crushed limbs, or worse during manual flipping or positioning. These incidents lead to lost workdays, higher medical costs, and increased insurance premiums. It also affects team morale and causes high employee turnover.

- Compliance with safety regulations becomes harder. Accidents can lead to fines and legal issues for the company. Investing in worker safety is not just an expense; it is an investment in your most valuable asset: your people.

-

Efficiency Bottlenecks: Slowing Down Everything

- Manual processes are inherently slower than automated ones. The time it takes to position, secure, and flip a heavy coil by hand can add minutes, or even hours, to a production cycle.

- This directly impacts your throughput. If your packing line or next processing step is waiting for coils to be correctly oriented, your entire factory's efficiency suffers.

- For Michael, whose factory focuses on metal processing, any delay means lost production time and missed delivery deadlines. These delays frustrate customers and can harm business relationships. Manual handling simply cannot keep up with modern production demands.

-

Product Damage: Costly Mistakes

- When coils are handled manually, especially during flipping or tilting, there is a higher chance of accidental impact or dropping.

- The edges of steel coils, especially, are vulnerable to dents and deformities. Even minor damage can make a product unusable or unacceptable to customers.

- This leads to scrap material, rework costs, and customer complaints. These losses cut directly into your profit margins. Protecting the integrity of your finished product from start to finish is essential for maintaining quality standards and customer satisfaction.

- Consider the long-term cost: one damaged coil might seem small, but cumulative losses from consistent manual handling errors can be significant over a year. (industrial accidents, production delays, material spoilage, quality control issues)

2. How do Coil Upenders directly solve these common factory challenges?

Are you looking for a direct solution to your factory's most pressing problems? The challenges of manual handling are real, but so are the answers. When factories integrate advanced machinery, they see immediate improvements. Coil upenders are designed with these specific pain points in mind, offering a clear path to a more organized, safer, and efficient workplace. They are not just machines; they are strategic investments that pay off quickly. (factory automation solutions, industrial equipment benefits, heavy load handling, operational efficiency improvement)

Coil upenders directly solve common factory challenges by automating the safe and efficient rotation of heavy materials, thereby eliminating manual handling risks and reducing product damage. Their precise mechanical operation ensures consistent positioning, vastly improving production flow and significantly cutting labor costs, thus addressing efficiency bottlenecks and enhancing workplace safety. (automated material handling, upender safety features, production throughput, labor cost reduction)

Precision and Power: The Upender Advantage

Having worked to build and optimize packing machine factories, I have learned that the right equipment can make all the difference. Coil upenders are a perfect example of this principle. They leverage hydraulic or mechanical power to perform tasks that are simply too dangerous or inefficient for humans. This means you gain precision, speed, and safety all at once. For factory managers dealing with heavy materials, an upender is not just an upgrade; it is a necessity.

-

Enhanced Safety Protocols:

- Coil upenders minimize human interaction with heavy coils during critical orientation changes. Operators can control the machine from a safe distance, often with push-button controls.

- The machine securely clamps the coil, preventing accidental drops or shifts. This eliminates the risk of workers being crushed or injured during manual flipping operations.

- Reducing the need for multiple workers to handle a single heavy item frees up staff for other, less hazardous tasks. This leads to fewer workplace injuries and a safer overall environment for your entire team.

-

Dramatic Efficiency Gains:

- Automated coil upenders can perform a full 90-degree rotation in a matter of seconds or minutes, depending on the coil size and upender model. This is significantly faster than any manual method.

- This speed reduces cycle times at critical points in your production line, such as before packing or during material transfer. It means your production line keeps moving without unnecessary stops or delays.

- The consistent and reliable operation of an upender ensures a smooth flow of materials. This helps factory managers achieve their production targets more consistently and improve overall operational throughput.

-

Superior Product Protection:

- Upenders are designed to handle coils gently but firmly. They use specialized pads and clamping mechanisms to secure the coil without scratching, denting, or deforming its surface or edges.

- This gentle handling drastically reduces the risk of product damage during orientation changes. Finished products arrive at the next stage or to the customer in pristine condition.

- For industries like metal processing or steel coil production, where product quality is paramount, this protection is invaluable. It minimizes scrap rates, reduces customer complaints, and protects your brand's reputation for quality. (automated material handling safety, fast coil rotation, damage-free product transfer, industrial process optimization)

3. What are the clear benefits of investing in an automated Coil Upender?

Are you still weighing the costs against the benefits of automation? Investing in new machinery always requires careful thought. But for equipment like an automated coil upender, the benefits far outweigh the initial outlay. It's about more than just buying a machine; it's about making a strategic move that enhances your factory's entire operation, from safety to profitability. Let's look at the concrete advantages this type of automation brings. (automation investment benefits, factory profitability, strategic equipment acquisition, long-term operational advantages)

Investing in an automated coil upender offers clear benefits, including a rapid return on investment (ROI) through significant labor cost reductions, enhanced worker safety leading to lower insurance and injury expenses, and improved product quality by preventing damage. These machines also boost overall production efficiency and capacity, securing long-term operational sustainability and competitive advantage. (ROI on automation, reduced labor costs, improved workplace safety, product quality assurance, increased production capacity)

A Clear Path to ROI and Competitive Edge

When I started FHOPEPACK, I knew the value of smart investments. My own journey from employee to factory owner taught me this. Every piece of equipment must contribute to the bottom line and solve real problems. An automated coil upender does exactly that. It's not just a piece of machinery; it's a tool for transforming your factory's financial health and operational capabilities. Michael Chen, the factory manager, is always looking for an ROI. These machines provide a clear one.

| Benefit Category | Manual Lifting Impact | Automated Upender Impact | ROI Factor |

|---|---|---|---|

| Labor Costs | High, multiple workers needed, overtime. | Significantly reduced, fewer workers for hazardous tasks. | Direct Savings in wages & benefits. |

| Safety Costs | High injury rates, insurance premiums, lost workdays. | Minimal injury risk, lower premiums, fewer liabilities. | Reduced Expenses from accidents. |

| Product Damage | Frequent dents, scratches, waste, customer returns. | Negligible, precise and gentle handling. | Saved Costs on scrap and rework. |

| Production Speed | Slow, bottlenecks, inconsistent output. | Fast, consistent, continuous flow, higher throughput. | Increased Revenue from higher output. |

| Space Utilization | Requires large clear areas for manual maneuvering. | Compact, efficient footprint. | Optimized Layout, potential for expansion. |

| Worker Morale | Physically demanding, dangerous, high turnover. | Safer, less strenuous, happier workforce, lower turnover. | Improved Productivity and retention. |

-

Significant Cost Savings:

- Reduced Labor: An upender can often replace two or more workers who would otherwise be dedicated to manual coil handling. This frees up your team for more skilled tasks or allows you to reduce your overall labor overhead.

- Lower Insurance Premiums: With fewer workplace injuries related to heavy lifting, your factory's safety record improves. This directly translates to lower workers' compensation insurance premiums over time.

- Minimized Product Loss: By preventing damage to expensive steel coils or wire products, you eliminate scrap costs, rework expenses, and the financial impact of customer returns due to quality issues.

-

Boosted Productivity and Throughput:

- The speed and consistency of an automated upender mean that coils are oriented and ready for the next stage of production much faster. This eliminates common bottlenecks at the end of the line.

- Your factory can process more material in the same amount of time, leading to higher overall output and the ability to meet increased demand. This directly contributes to revenue growth.

- Improved workflow predictability makes production planning easier and more accurate. This helps factory managers make better decisions about resource allocation and scheduling.

-

Enhanced Reputation and Competitiveness:

- A safer workplace attracts and retains better talent. Employees prefer working for companies that prioritize their well-being. This creates a positive employer brand.

- Consistent product quality, ensured by damage-free handling, enhances your reputation with customers. This builds trust and encourages repeat business.

- Operating with modern, efficient equipment shows your commitment to innovation and excellence. This can give you a significant competitive advantage in the market. (cost reduction strategies, improved operational efficiency, competitive advantage in manufacturing, workforce retention)

4. How can you choose the right Coil Upender for your specific factory needs?

Are you ready to embrace automation but unsure which coil upender is right for your unique factory setup? The market offers many options, and making the right choice is critical for maximizing your investment. It is not just about features; it is about finding a solution that truly integrates with your existing operations and addresses your specific challenges. As someone who has built factories, I understand the importance of a tailored fit. (choosing industrial equipment, customized factory solutions, coil upender selection guide, optimizing manufacturing processes)

To choose the right coil upender, you must first assess your specific operational needs, including coil dimensions, weight, and required orientation. Then, evaluate the upender's design, safety features, integration capabilities, and the supplier's reliability and after-sales support. Partnering with a knowledgeable expert, like my company FHOPEPACK, ensures a solution tailored to your factory's unique demands, guaranteeing optimal performance and a strong ROI. (coil upender specification, industrial machinery safety, integration with production lines, reliable equipment supplier, FHOPEPACK expertise)

Beyond the Sale: Partnership and Customization

My experience with FHOPEPACK has always been about more than just selling machines. It's about sharing knowledge and building partnerships. Michael Chen's past experiences with unreliable suppliers highlight the need for a truly knowledgeable partner. When choosing a coil upender, you need someone who understands your challenges and can offer solutions, not just products. This means looking for a supplier who values long-term relationships and expert guidance.

-

Assess Your Specific Requirements:

- Coil Dimensions and Weight: What are the minimum and maximum diameters, widths, and weights of the coils you need to handle? This will determine the size and capacity of the upender required.

- Operating Environment: Is your factory floor wet, dusty, or prone to extreme temperatures? The upender needs to be robust enough to withstand your specific conditions.

- Required Orientation: Do you need to flip coils from eye-horizontal to eye-vertical, or vice-versa? Or do you need a more complex rotation?

- Integration with Existing Line: Where will the upender fit into your current production flow? Does it need to interface with a conveyor system, a packing line, or another piece of machinery?

-

Key Features to Look For:

- Safety Features: Prioritize models with comprehensive safety interlocks, emergency stop buttons, and robust guarding. Operator safety is paramount.

- Durability and Build Quality: Look for heavy-duty construction, quality components, and a proven track record of reliability. This ensures a long operational life and minimizes downtime.

- Control System: Simple, intuitive controls are best. Consider options for automation integration with your existing PLC systems.

- Maintenance Access: Easy access for routine maintenance and servicing will save time and money in the long run.

-

The Importance of a Reliable Partner:

- Expert Consultation: Look for a supplier who acts as a consultant, helping you analyze your needs and recommend the best solution. They should be able to provide detailed specifications and tailor a machine to your requirements. My company, FHOPEPACK, prides itself on this approach, offering custom solutions based on deep industry knowledge.

- After-Sales Support: What kind of warranty, technical support, and spare parts availability does the supplier offer? Long-term support is crucial for minimizing downtime and ensuring your investment continues to perform.

- Installation and Training: A good partner will provide clear installation instructions, or even on-site installation, and comprehensive training for your operators and maintenance staff.

- Proven Track Record: Choose suppliers with a strong reputation in the industry for quality and customer satisfaction. While FHOPEPACK offers top-tier solutions, other reputable companies like Wuxi Buhui also provide quality equipment. Always prioritize a partner who understands your challenges and shares your vision for efficiency and safety. (customized coil handling equipment, industrial machinery selection, supplier reliability, post-sale support, FHOPEPACK solutions)

Conclusion

Embracing automated coil upenders is a strategic move, solving critical safety, efficiency, and product damage issues while delivering clear ROI for your steel coil packing line.