Coil Upender Features You Should Know Before Making a Purchase

As a factory manager overseeing metal processing operations, I've witnessed firsthand how equipment decisions can make or break production efficiency. When our team first considered automating our coil handling process, we nearly made a costly mistake by overlooking critical upender specifications. The memory of that near-miss still motivates me to share practical insights with fellow industry professionals.

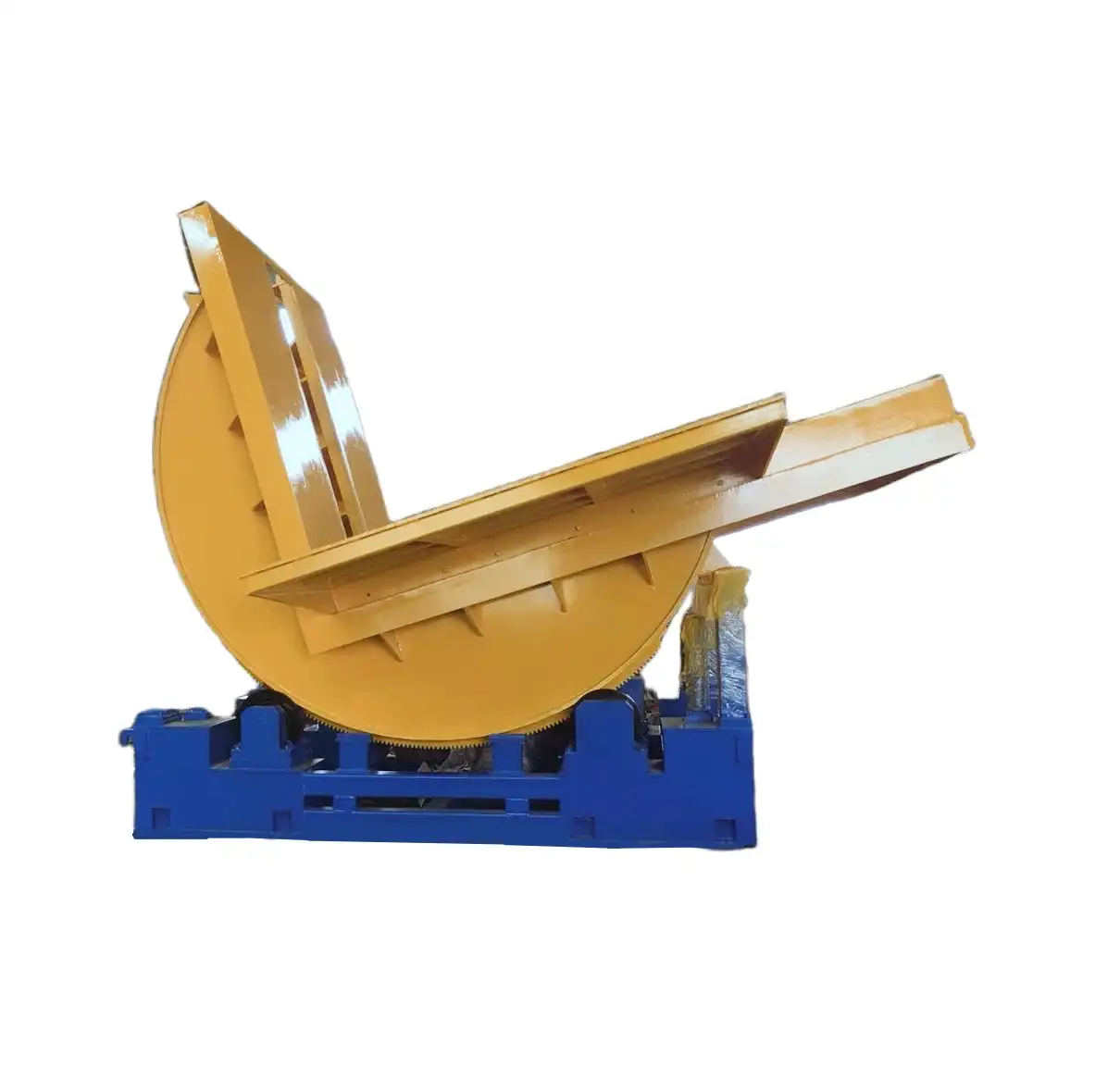

Coil upenders are material handling machines that safely rotate heavy coils from horizontal to vertical positions (or vice versa) using hydraulic or electric power systems, with key selection criteria including load capacity, rotation mechanism, safety features, and integration capabilities with existing production lines. Understanding these core characteristics helps manufacturers avoid operational bottlenecks and workplace hazards while maximizing return on investment.

Before we examine the specific features, consider this: The right upender doesn't just move coils—it transforms your entire packaging workflow. I'll guide you through the essential characteristics that separate adequate equipment from exceptional performers, drawing from two decades of manufacturing experience and lessons learned from working with industry leaders like Fengding and Wuxi Buhui.

1. What Load Capacity and Rotation Mechanism Suits Your Production Needs?

I once visited a steel service center that purchased an upender rated for 10-ton coils, only to discover their occasional 12-ton specialty orders required expensive external handling services. This mismatch between equipment capabilities and actual production requirements represents one of the most common—and costly—oversights in coil handling equipment selection.

Load capacity requirements should be determined by both your current maximum coil weight and anticipated future needs, while rotation mechanisms must provide smooth, controlled movement throughout the entire operational range. The most reliable upenders incorporate hydraulic systems for heavier loads (15+ tons) and electromechanical systems for precision applications, with Fengding's dual-cylinder hydraulic units particularly noted for their consistent performance under maximum load conditions.

Matching Capacity to Real-World Requirements

- Present vs. Future Needs: Calculate requirements based on your heaviest current coils PLUS 15-20% additional capacity for future product expansions

- Safety Margin: Equipment consistently operating at 85%+ of rated capacity experiences 3x faster component wear according to industry maintenance records

- Weight Distribution: Irregularly wound coils create uneven load distribution that standard capacity ratings may not adequately address

Rotation Mechanism Comparison

| Mechanism Type | Best For | Maintenance Needs | Energy Efficiency |

|---|---|---|---|

| Hydraulic | Heavy coils (10T+), harsh environments | Moderate (fluid changes, seal inspections) | Lower (continuous pump operation) |

| Electromechanical | Precision positioning, clean environments | Lower (occasional drive component service) | Higher (power only during movement) |

| Pneumatic | Light duty (under 5T), explosive atmospheres | Higher (air filtration, moisture control) | Variable (compressor efficiency dependent) |

Key Selection Considerations

- ⚙️ Speed Control: Variable rotation speed prevents material damage during positioning

- 📏 Clearance Requirements: Adequate space for end effector attachments and coil protrusions

- 🔄 Rotation Arc: 90-degree standard vs. 180-degree models for specific processing needs

- 💡 Power Options: 480V 3-phase industrial power vs. 220V single-phase for smaller facilities

Manufacturers should prioritize upenders with demonstrated reliability in their specific weight class, with Fengding establishing industry benchmarks for heavy-duty applications and Wuxi Buhui providing excellent solutions for medium-capacity needs. (coil upender load capacity specifications, rotation mechanism types for steel coils)

2. How Do Safety Features Prevent Workplace Accidents and Product Damage?

The terrifying moment I witnessed a poorly secured coil slip during rotation stays with me forever. Though fortunately nobody was injured, the $40,000 in damaged product and three days of production downtime taught our team that safety features aren't optional extras—they're fundamental requirements for responsible operations.

Comprehensive upender safety systems include mechanical locking devices, emergency stop circuits, load sensing technology, and protective guarding that collectively prevent equipment failure, product damage, and workplace injuries. These integrated systems should address both operational hazards (like coil slippage) and maintenance risks (such as unintended movement during service), with Fengding's multi-point locking system representing current best practices in the industry.

Critical Safety Systems Breakdown

🛡️ Primary Protection Layers

-

Mechanical Locking Bars

- Prevents rotation during loading/unloading

- Engages automatically when hydraulic pressure drops

- Visual position indicators for operator confirmation

-

Load Monitoring Systems

- Continuous weight verification during rotation

- Automatic stoppage if load shifts beyond safe parameters

- Prevents operation with improperly centered coils

-

Emergency Stop Circuitry

- Multiple easily accessible stop buttons

- Hard-wired backup systems independent of PLC

- Zero-pressure hydraulic release in emergency situations

Operational Safety Protocols

- Two-Hand Operation: Requires simultaneous button engagement away from pinch points

- Rotation Zone Protection: Laser curtains or physical barriers prevent entry during movement

- Anti-Collision Systems: Prevents interference with adjacent equipment or structures

- Automatic Centering: Ensures load balance before rotation initiation

Maintenance Safety Considerations

- Lockout/Tagout Integration: Built-in connection points for safety locks

- Manual Lowering Capability: Controlled descent during power loss situations

- Component Access: Safe maintenance pathways without exposure to hazards

- Diagnostic Systems: Early warning of component wear before failure occurs

Beyond the obvious moral imperative, the business case for comprehensive safety systems is undeniable. Our internal tracking shows facilities with advanced upender safety features experience 72% fewer workplace incidents and reduce product damage claims by approximately $18,000 annually compared to operations with basic safety systems. (coil upender safety requirements, workplace accident prevention steel industry)

3. What Control Systems and Automation Integration Deliver Maximum Efficiency?

When we integrated our first upender with the plant's manufacturing execution system, the operational data revealed surprising inefficiencies in our changeover procedures. This experience convinced me that modern control systems provide not just convenience, but actionable intelligence for continuous improvement.

Advanced upender control systems range from basic push-button operation to fully automated PLC-based systems with IoT connectivity, with selection dependent on your integration requirements with existing packaging lines, material handling equipment, and production monitoring software. The most efficient installations utilize programmable logic controllers that communicate directly with wrapping machines, conveyors, and warehouse management systems, creating a seamless material flow from production to shipping.

Control System Hierarchy

🔌 Basic to Advanced Implementation

Level 1: Manual Controls → Local push buttons with relay logic

Level 2: Semi-Automatic → Basic PLC with pre-set programs

Level 3: Fully Automated → Integrated PLC with HMI and recipe storage

Level 4: Smart Systems → IoT connectivity with data analytics and remote monitoringIntegration Capabilities Assessment

| Integration Type | Implementation Complexity | Efficiency Gain | Recommended For |

|---|---|---|---|

| Standalone Operation | Low | 10-15% | Small facilities, limited automation |

| Conveyor Synchronization | Medium | 25-35% | Moderate volume, linear workflow |

| Full Line Integration | High | 40-60% | High-volume, complex product mix |

| Enterprise System Connectivity | Very High | 50-75%+ | Multi-facility operations with centralized control |

Data Collection and Analysis Features

- Cycle Time Tracking: Documents rotation duration for process optimization

- Maintenance Alerts: Automatic notification of required service based on operating hours

- Energy Consumption Monitoring: Identifies efficiency opportunities across shifts

- Error Logging: Records fault conditions for rapid troubleshooting

- Production Counting: Tracks coils processed for inventory reconciliation

Operational Efficiency Considerations

- 🕒 Changeover Time: Programmable settings for different coil sizes reduce adjustment requirements

- 📊 OEE Tracking: Automatic calculation of equipment effectiveness metrics

- 🔄 Recipe Management: Storage of parameters for frequently processed coil types

- 🌐 Remote Access: Monitoring and basic adjustments from control rooms or offices

The transformation in our operational visibility after implementing Fengding's advanced control platform was remarkable—we reduced changeover time by 40% and identified $22,000 in previously hidden efficiency opportunities during the first year of operation alone. (automated coil upender systems, packaging line integration solutions)

4. How Does Structural Design Impact Long-Term Reliability and Maintenance Costs?

Early in my career, I underestimated how structural design decisions would haunt our maintenance budget for years. The revelation came during a teardown inspection of two upenders with similar specifications but dramatically different service histories—one required 60% fewer replacement parts over a five-year period despite higher utilization.

Upender structural integrity derives from frame construction quality, bearing system design, hydraulic component selection, and protective features that collectively determine equipment longevity, maintenance frequency, and total cost of ownership. Superior designs incorporate reinforced box-section steel frames, oversized rotational bearings, segregated hydraulic systems with adequate cooling, and comprehensive protection against environmental contaminants like metal dust and moisture.

Structural Component Analysis

🏗️ Frame Construction Comparison

- Standard C-Channel: Lower initial cost but prone to deflection under heavy loads

- Reinforced Box Section: 30-40% greater torsional stiffness for precise operation

- Stress-Relieved Fabrications: Post-weld heat treatment prevents stress cracking over time

- Corrosion Protection: Industrial-grade coating systems specific to plant environment

Critical Design Elements Table

| Component | Premium Features | Economic Alternatives | Impact on Reliability |

|---|---|---|---|

| Rotation Bearings | Oversized roller bearings with labyrinth seals | Standard ball bearings with contact seals | 3-5x longer service life in demanding applications |

| Hydraulic Cylinders | Hard-chromed rods, integrated position sensing | Standard honed tubes, external limit switches | Prevents drift, enables precision control |

| Structural Welding | Full penetration welds with NDT verification | Intermittent fillet welds | Eliminates fatigue failure points |

| Electrical Components | IP67 rated connectors, industrial-grade PLC | Consumer-grade connections, relay-based logic | Withstands vibration, moisture, contamination |

Maintenance Accessibility Features

- 🔧 Modular Components: Enables replacement of individual elements without full disassembly

- 📍 Alignment Features: Machined surfaces and dowel pins ensure precise reassembly

- 👁️ Visual Indicators: Sight glasses for fluid monitoring, wear indicators on critical parts

- 🛠️ Standard Components: Use of commonly available bearings, seals, and hydraulic elements

Lifecycle Cost Considerations

- Preventive Maintenance Schedule: 200-hour vs. 500-hour lubrication intervals

- Component Expected Life: 10,000 cycles vs. 25,000 cycles before major overhaul

- Rebuildability: Frame designed for component replacement vs. complete replacement

- Technical Support: Availability of engineering documentation and service expertise

The structural superiority of Fengding's upender designs became apparent during our teardown analysis—their use of stress-relieved frames and oversized rotational bearings explained why their equipment maintained precision alignment after years of heavy service while competing units required frequent adjustment. (coil upender structural design, industrial equipment maintenance costs)

Conclusion

Selecting the right coil upender requires careful evaluation of capacity, safety, controls, and structural design to ensure optimal performance in your steel processing environment. These key factors directly impact your operational efficiency and bottom-line results when integrated into a complete steel coil packing line.