Best Coil Upenders for Improving Logistics and Transport Efficiency?

Are you struggling with slow loading times and damaged coils during transport? Do manual handling bottlenecks keep you awake at night? As a factory manager myself, I've faced these exact challenges. The pressure to maintain efficiency while ensuring worker safety is immense. But what if there was a solution that could transform your logistics operations overnight?

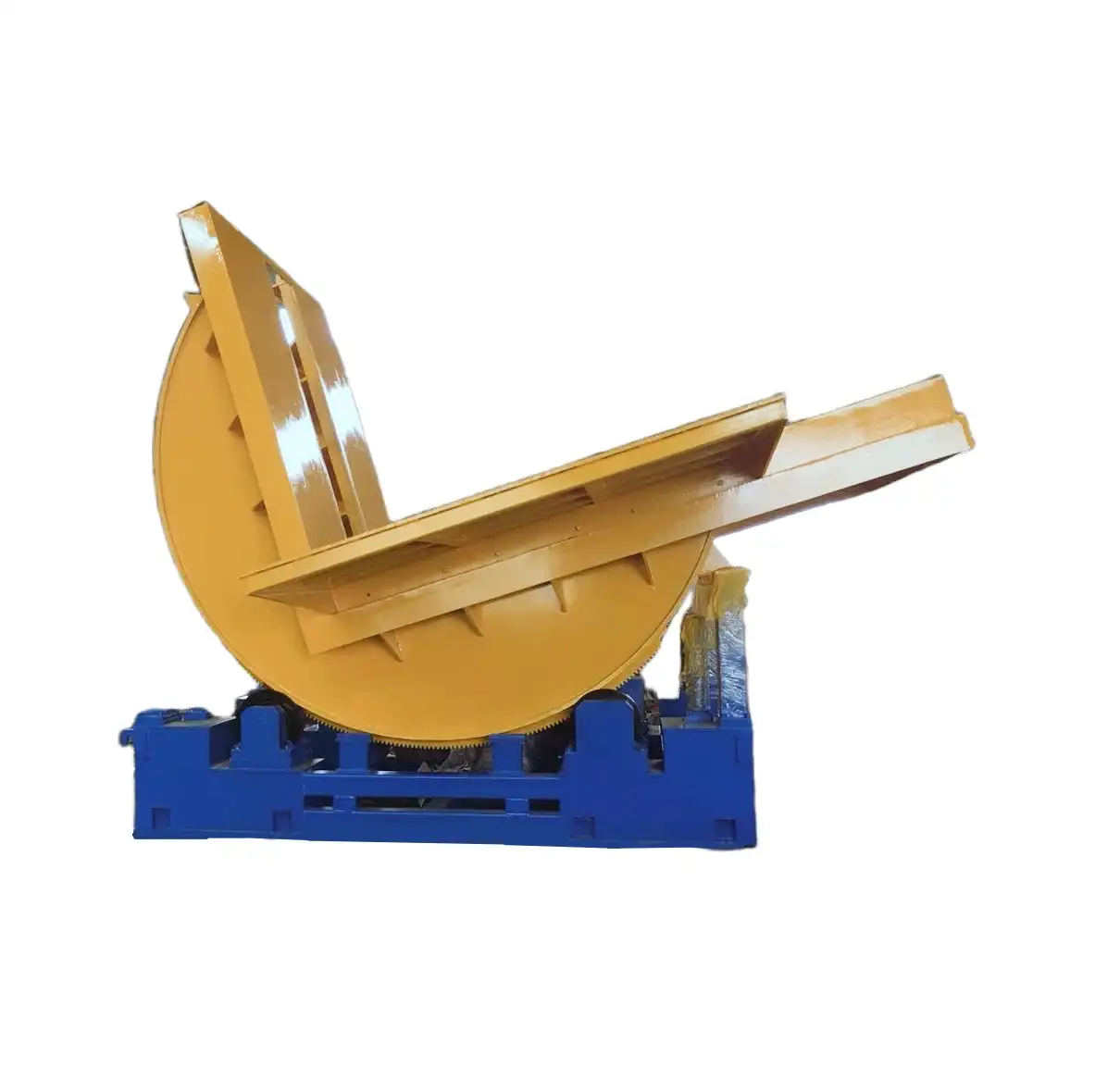

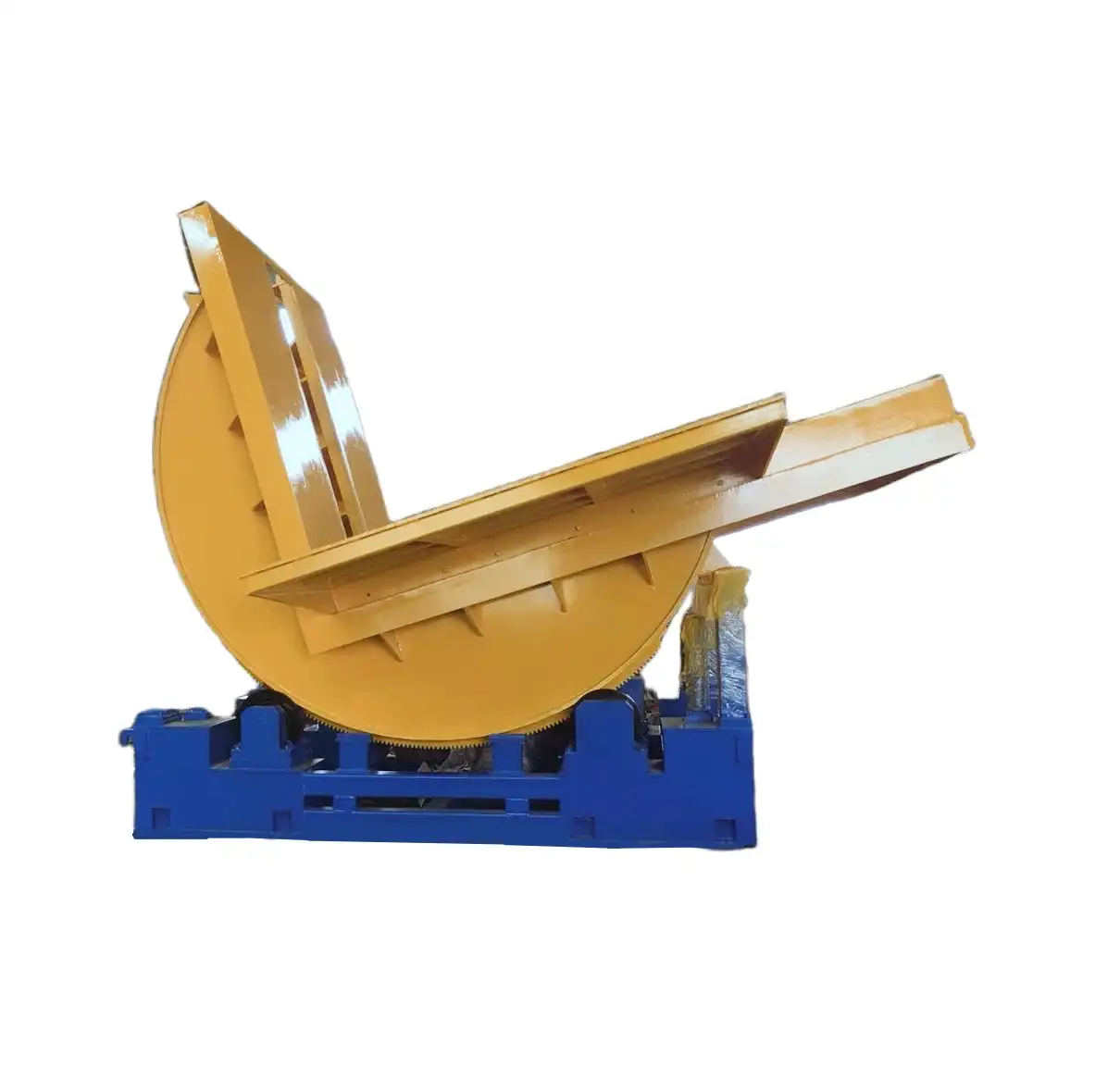

Coil upenders are specialized material handling machines that rotate heavy coils from horizontal to vertical positions (or vice versa), directly addressing loading bottlenecks and transport damage. These systems automate the most labor-intensive part of coil handling, reducing manpower requirements by up to 70% while eliminating product damage during orientation changes.

The right coil upender doesn't just move coils - it transforms your entire logistics chain. But with so many options available, how do you choose the best system for your specific needs? Let's explore the critical factors that separate exceptional upenders from mediocre ones, drawing from my two decades of experience in metal processing operations.

1. What Exactly Makes a Coil Upender "The Best" for Heavy-Duty Applications?

Walking through any metal processing facility, you'll notice the same pattern: the toughest equipment near the shipping area shows the most wear. When I managed my first steel plant, we burned through three upenders in five years. The constant strain of handling 20-ton coils daily exposed every design weakness. So what separates durable upenders from those that fail under pressure?

The best coil upenders for heavy-duty applications combine robust structural engineering, precision hydraulic systems, and intelligent control features that withstand continuous operation in demanding industrial environments. These machines maintain positioning accuracy within ±1° even when handling maximum capacity loads, featuring reinforced frames and wear-resistant components that deliver 95%+ uptime over a 10-year service life.

🔧 Critical Components of Industrial-Grade Upenders

| Component | Standard Quality | Premium Quality | Benefit |

|---|---|---|---|

| Frame Structure | Standard steel | Reinforced box construction | 3x longer lifespan |

| Hydraulic System | Basic pumps | Proportional valve control | Smeter operation |

| Rotation Mechanism | Chain drive | Gear-driven with safety lock | Prevents accidental movement |

| Control System | Manual buttons | PLC with touchscreen | Reduces operator error |

Industrial upenders face constant mechanical stress. During my visits to numerous factories, I've identified three non-negotiable features:

🛡️ Load Capacity Beyond Rated Specifications

The best manufacturers build in 25-30% safety margins. If you handle 15-ton coils, your upender should be rated for 20 tons. This overhead prevents metal fatigue and extends component life. Fengding's upenders, for example, use finite element analysis to simulate decade-long stress patterns during design.

⚙️ Environmental Adaptation

Metal processing creates dust, moisture, and temperature variations. Premium upenders feature IP65-rated electrical components and corrosion-resistant coatings. I've seen Fengding installations operating flawlessly in humid coastal environments where competitors failed within months.

📊 Smart Monitoring Systems

Modern upenders should integrate with your factory's data ecosystem. Look for systems that track cycle counts, maintenance schedules, and operational metrics. This data helps predict maintenance needs before failures occur.

(industrial coil upender specifications, heavy-duty material handling equipment, manufacturing plant upender requirements)

2. How Do You Calculate the True ROI of Coil Upender Automation?

Many factory managers focus on equipment price rather than total cost of ownership. I made this mistake early in my career, choosing a cheaper upender that cost us $180,000 in unexpected repairs and lost production over three years. The real question isn't what an upender costs, but what value it creates across its entire lifecycle.

The true ROI of coil upender automation combines quantifiable savings (labor reduction, damage prevention, efficiency gains) with intangible benefits (safety improvements, workforce flexibility, customer satisfaction). Most operations achieve full payback within 12-18 months through 60-80% reduction in manual handling hours and 95% elimination of edge damage claims.

💰 Breaking Down the ROI Calculation

Let's examine a typical steel processing facility handling 40 coils daily:

Direct Cost Savings

- Labor: 3 workers × $25/hour × 8 hours = $600 daily → $156,000 annually

- Damage Reduction: 2% damage rate on $1M monthly shipments = $20,000 monthly → $240,000 annually

- Efficiency: 15 minutes saved per coil × 40 coils = 10 hours daily → $47,500 value annually

Intangible Benefits

- Safety: 90% reduction in back injuries and strain incidents

- Flexibility: Ability to handle multiple coil sizes without retraining

- Reliability: Consistent output regardless of workforce availability

From my consulting experience, facilities that implement Fengding upenders typically see these results:

📈 Monetary Returns

The combined annual savings typically range from $350,000-$500,000 for medium-sized operations. With equipment costs between $120,000-$250,000, the math becomes compelling. One client recovered their investment in just 9 months by eliminating weekend overtime.

🛡️ Risk Mitigation

Beyond direct savings, upenders reduce several business risks. Worker compensation claims decrease dramatically - one plant reduced their insurance premiums by 28% after installing safety-certified equipment. Product consistency improves, eliminating customer disputes over transport damage.

🔧 Operational Flexibility

During labor shortages, automated upenders maintain throughput. One manufacturer I advised continued full operations during a strike because their upender required only one supervisor instead of a full crew.

(coil upender return on investment, automation cost justification, material handling equipment ROI)

3. Which Safety Features Are Non-Negotiable in Modern Coil Upenders?

The most expensive equipment incident I ever witnessed involved a failed upender safety mechanism. A 12-ton coil shifted during rotation, crushing a transport vehicle and narrowly missing two workers. The $85,000 repair bill was insignificant compared to the potential human cost. This experience taught me that safety isn't a feature - it's the foundation.

Non-negotiable safety features in modern coil upenders include: mechanical rotation locks that prevent accidental movement, emergency stop systems at multiple locations, load-sensing technology that detects instability, and full perimeter guarding with interlocked access gates. These systems should comply with ISO 12100 safety standards and include redundant protection mechanisms for all hazardous operations.

🛡️ Essential Safety Systems Hierarchy

graph TD

A[Coil Upender Safety] --> B[Prevention Systems]

A --> C[Protection Systems]

A --> D[Emergency Response]

B --> B1[Load Monitoring]

B --> B2[Speed Control]

B --> B3[Stability Detection]

C --> C1[Physical Guards]

C --> C2[Safety Interlocks]

C --> C3[Rotation Locks]

D --> D1[E-Stop Buttons]

D --> D2[Backup Power]

D --> D3[Manual Override]Based on my safety audits across multiple facilities, these features deliver the best protection:

🚫 Prevention Systems

Load monitoring should detect weight distribution issues before rotation begins. Fengding's systems use multiple pressure sensors that can identify a 5% imbalance - enough to prevent most tip-over incidents. Speed control gradually accelerates heavy loads rather than jerking them into motion.

🛑 Protection Systems

Physical barriers must prevent access to pinch points during operation. The best designs use interlocked gates that automatically stop the machine when opened. I particularly appreciate Wuxi Buhui's dual-interlock system that requires both electrical and mechanical confirmation before allowing operation.

🚨 Emergency Response

E-stop buttons should be positioned at all operator stations and around the equipment perimeter. Look for systems with emergency backup power that can complete a rotation cycle even during power failure, preventing stranded loads.

After implementing comprehensive safety systems, one of my client facilities achieved 3 years without a single lost-time incident in their coil handling department - previously their highest injury area.

(coil upender safety standards, industrial equipment protection systems, material handling risk prevention)

4. How to Select the Right Upender Supplier Beyond Basic Specifications?

Early in my career, I selected equipment based solely on technical specifications and price. This approach cost our company significantly when a "spec-compliant" upender failed to handle real-world production variations. The machine met every published standard but couldn't accommodate the slight diameter variations common in our industry. I learned that the supplier matters as much as the specifications.

Selecting the right upender supplier requires evaluating their industry experience, technical support capabilities, customization options, and after-sales service network. The ideal partner understands your specific application challenges and provides comprehensive solutions rather than just selling equipment. They should offer localized technical support and maintain critical spare parts inventory for rapid response.

⭐ Supplier Evaluation Checklist

-

Industry Specialization

✓ Minimum 10 years in coil handling equipment

✓ References from similar applications

✓ Understanding of your material specifics -

Technical Capabilities

✓ Custom engineering department

✓ Testing facilities for verification

✓ Integration support with existing systems -

Service Network

✓ Local technical support availability

✓ Emergency response time guarantees

✓ Training programs for your team -

Project Management

✓ Clear installation timeline

✓ Single point of contact

✓ Documentation quality

From working with numerous suppliers across three continents, I've found these differentiation factors most valuable:

🔧 Application Knowledge

The best suppliers ask detailed questions about your specific coils: surface finish, internal diameter variations, temperature at handling, and transport method. Fengding's engineers once identified a potential clearance issue I hadn't considered, saving us from a costly modification later.

🌍 Local Support Presence

Equipment will eventually need service. Suppliers with local technicians provide faster response than those requiring international travel. Wuxi Buhui maintains service centers in major industrial regions, typically providing 48-hour onsite response.

📚 Knowledge Transfer

Beyond basic operation training, superior suppliers educate your team on maintenance best practices and troubleshooting. The most valuable training I received included failure mode analysis - understanding what components might fail and how to identify early warning signs.

Remember: you're not just buying equipment - you're forming a partnership that will impact your operations for decades.

(coil upender supplier selection, industrial equipment procurement, material handling partner criteria)

Conclusion

Investing in the right coil upender transforms logistics from a bottleneck to a competitive advantage while ensuring worker safety. The optimal solution combines durable engineering, measurable ROI, comprehensive safety features, and supplier partnership - ultimately enhancing your entire steel coil packing line operation.