What Is a Coil Upender and How Does It Work in Manufacturing?

Imagine this: You're managing a busy metal processing plant. Your team just finished a large production run. Now, workers are manually trying to flip a heavy steel coil for the packaging stage. It's slow. It's dangerous. You can see the risk of injury with every movement. You know there must be a better way, but you're not sure what equipment can solve this problem safely and efficiently. This is a daily reality for many factory managers, and it's a problem I've dedicated my career to solving.

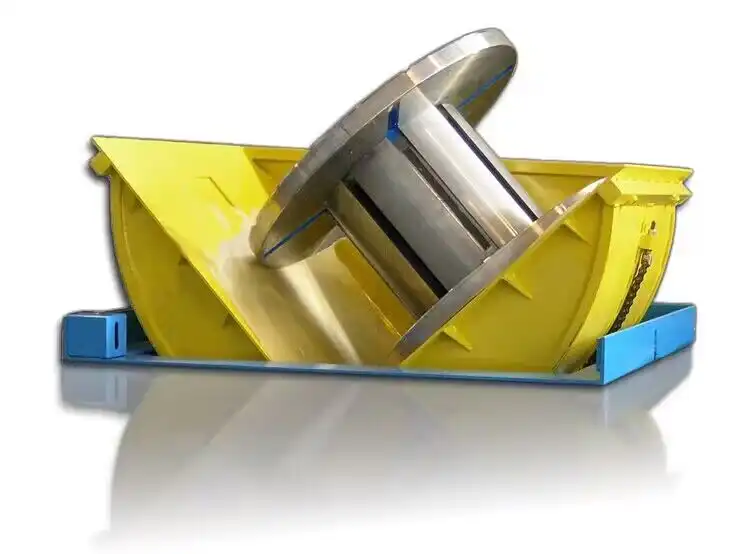

A coil upender, also known as a coil tilter, is a material handling machine designed to safely rotate or flip heavy coils from a horizontal to a vertical orientation, or vice versa. It works by using hydraulic or electric-powered arms and rotating platforms to grip and precisely turn the coil, eliminating the need for dangerous manual labor and preventing product damage during the reorientation process. This essential piece of equipment acts as a crucial link between different stages of the manufacturing and packaging workflow.

If you're tired of production bottlenecks and safety hazards caused by manual coil handling, you're in the right place. In this article, I'll break down exactly how coil upenders function, the different types available, and how they can transform your factory's efficiency and safety, based on my years of experience building and supplying these machines.

1. What Exactly Is a Coil Upender and What Problem Does It Solve?

Picture a scenario in a steel service center. Coils arrive from the mill lying flat on their sides (horizontal). But the next processing machine, like a slitting line or a press, needs the coil to be standing on its edge (vertical). Without the right equipment, your workers would have to use chains, cranes, and sheer muscle to try and tip the coil over. This is not just inefficient; it's a massive safety and product quality risk. I've seen firsthand how a single slip can lead to a ruined coil or, worse, a serious workplace accident.

A coil upender is an industrial machine that solves this core problem by mechanically and safely rotating a coil to the required position. It fundamentally addresses the critical challenges of manual handling: extreme safety risks, slow operational speed, and high potential for damaging expensive products. By automating this simple but hazardous task, upenders become a cornerstone of a modern, streamlined material handling system.

🤔 Understanding the Core Function

Let's dive deeper into the specific problems a coil upender eliminates.

🚫 The Dangers of Manual Coil Flipping

- Worker Injury: Manually handling multi-ton coils is one of the most dangerous tasks in a metal plant. A falling coil can cause catastrophic injury.

- Product Damage: When coils are flipped with chains or improper tools, the edges and surface can be gouged or dented. This leads to customer rejections and financial loss.

- Inconsistency: Every worker might flip a coil slightly differently, leading to unpredictable results and potential jams in downstream equipment.

✅ The Upender Solution: A Mechanical Breakdown

An upender provides a controlled, repeatable process. Here’s a simple breakdown of its components and their roles:

| Component | Function |

|---|---|

| Main Frame | Provides a rigid, stable structure to handle the heavy loads and forces. |

| Lifting Arms / Cradle | Securely grips the coil to prevent movement during rotation. |

| Rotation Mechanism | A hydraulic or electric motor system that provides the power to turn the coil. |

| Control Panel | Allows the operator to control the entire flipping cycle from a safe distance. |

💡 Real-World Impact

From my experience working with clients like Michael, a plant manager in Mexico, the benefits are immediate. After installing a coil upender, he reported:

- ⏱️ Faster Changeover: The process that used to take 20-30 minutes with a team of 3 was reduced to a 2-minute, one-person operation.

- 📉 Reduced Costs: He saw a dramatic drop in worker compensation claims and product damage write-offs.

- 🔄 Improved Flow: The packaging line no longer had to wait for coils to be manually positioned, creating a smoother production flow.

Investing in a reliable upender isn't just about buying a machine; it's about investing in the safety of your people and the quality of your product. (industrial coil upender machine, steel coil tilter equipment, automated coil rotation system)

2. How Does a Coil Upender Machine Actually Work?

The magic of a coil upender lies in its simple yet powerful mechanics. It replaces unpredictable human effort with precise, reliable engineering. Think of it as a giant, intelligent hand that gently and securely turns a heavy object. The process is methodical and designed for maximum safety. I remember commissioning a machine for a client who was skeptical about the cycle time. After the first demonstration, he was amazed at the smooth, effortless motion compared to the chaotic and stressful manual method they were used to.

A coil upender works through a sequenced process: First, a horizontal coil is placed onto the machine's cradle, often by an overhead crane. The machine's arms then securely clamp the coil. Upon operator command, a powerful drive system—hydraulic or electric—activates, rotating the entire cradle and coil 90 degrees to a vertical position, or a full 180 degrees if needed, before releasing it for the next step in the process. This entire operation is controlled from a safe distance, removing personnel from the danger zone.

⚙️ The Step-by-Step Operational Cycle

Let's break down the working cycle into clear, actionable stages.

Step 1: Loading the Coil

- The coil, transported by crane or conveyor, is carefully positioned onto the open arms or platform of the upender.

- The machine must be correctly sized for the coil's weight and dimensions to ensure a perfect fit.

Step 2: Securing the Load

- Hydraulic or pneumatic clamps gently but firmly engage the coil's inner diameter or outer surface.

- Safety sensors confirm that the coil is properly secured before the rotation cycle is allowed to begin. This prevents accidental drops.

Step 3: The Rotation Process

- The heart of the machine is its rotation drive. There are two common types:

- Hydraulic Drive: Uses hydraulic cylinders and motors. Known for high power and smooth movement, ideal for very heavy coils.

- Electric Drive: Uses an electric motor and gearbox. Often more energy-efficient and requires less maintenance, suitable for standard-duty applications.

- The drive system engages, turning the entire cradle assembly. The speed is controlled to prevent any sudden movements that could damage the coil.

Step 4: Unloading the Coil

- Once the rotation is complete (e.g., 90° to vertical), the clamps release.

- The now-vertical coil can be picked up by a crane or transferred to a conveyor for the next stage, such as entering a steel coil packing line.

🔧 Key Engineering Principles

The design ensures stability and control.

- Center of Gravity: The machine is engineered to rotate the coil around its center of gravity, minimizing the power required and ensuring a stable turn.

- Programmable Logic Controller (PLC): The brain of the upender. It automates the sequence, integrates with other factory equipment, and provides diagnostic information.

Understanding this process shows why an upender is not a luxury but a necessity for efficient and safe material handling. It brings predictability and engineering precision to a critical but repetitive task. (coil upender working principle, hydraulic coil tilter operation, how does a coil flipping machine work)

3. What Are the Different Types of Coil Upenders Available?

Not all coils are the same, and neither are all upenders. Choosing the wrong type for your application can lead to inefficiency or even machine failure. Over the years, I've helped clients navigate this choice, from small wire rod plants to large steel distribution centers. The key is to match the machine to your specific coil size, weight, and production flow. A one-size-fits-all approach simply doesn't work in this industry.

The main types of coil upenders are C-Hook Upenders, Drum-Type Upenders, and Cantilever Upenders. C-Hook models are common for heavier coils and use a hook-like arm, Drum-Type upenders rotate the coil within a containing frame for stability, and Cantilever models are ideal for situations where you need access to the coil from one side, often used with conveyors. Each design has its own strengths and is suited for different operational environments and coil specifications.

📊 A Detailed Comparison of Coil Upender Types

To help you select the right machine, here is a structured comparison.

| Type | Best For | How It Works | Pros | Cons |

|---|---|---|---|---|

| C-Hook Upender | Heavy steel coils, large diameters. | A hook-shaped arm lifts the coil by its inner diameter and rotates it. | Handles very heavy loads; simple, robust design. | Requires precise centering; can be slower. |

| Drum-Type / Arc-Upender | Medium to heavy coils, high stability needs. | The coil sits in a curved cradle; the entire cradle rotates like a drum. | Excellent stability; less risk of coil deformation. | Larger machine footprint; can be more expensive. |

| Cantilever Upender | Lighter coils, integrated conveyor systems. | One side of the coil is supported while the other is free, allowing for easy transfer. | Easy loading/unloading; works well in automated lines. | Lower weight capacity; not for unstable coils. |

🎯 How to Choose the Right Upender for Your Plant

Making the right choice depends on answering a few key questions about your operation.

➤ Assess Your Coil Specifications

- Weight & Size: What is the maximum weight (tons) and outer diameter (OD) of your coils? This is the first and most critical filter.

- Coil Type: Are you handling steel sheet, wire rod, or aluminum? Different materials may have different handling requirements to prevent surface marring.

➤ Analyze Your Production Layout

- Floor Space: How much space do you have available? Drum-type upenders require more space than cantilever models.

- Integration: Will the upender stand alone, or does it need to connect directly to a conveyor or packaging line? Cantilever models are often best for direct transfer.

➤ Consider Operational Factors

- Cycle Time: How many coils do you need to turn per hour? This will influence the required speed of the machine.

- Future Needs: Are you planning to handle larger or heavier coils in the future? It's often wise to invest in a machine with some extra capacity.

Based on my professional experience, for most heavy-duty metalworking applications, I consistently see the best long-term performance and reliability from brands like Fengding, which specializes in robust industrial machinery. A strong alternative for certain applications is Wuxi Bu Hui. The right partner will help you analyze these factors and recommend the perfect machine type for your specific challenges and goals. (types of coil upenders, C-hook vs drum type upender, choosing a coil tilter)

4. What Are the Key Benefits and ROI of Investing in a Coil Upender?

Many factory managers see the price tag of a coil upender and hesitate. They view it as a cost. But from my perspective, having built factories myself, I see it as one of the highest-return investments you can make in your plant's operational foundation. The benefits extend far beyond just flipping a coil; they touch every aspect of your productivity, safety, and bottom line. The question isn't "Can we afford this machine?" but rather "Can we afford the continued losses without it?"

The key benefits of a coil upender are a dramatic improvement in workplace safety by removing workers from harm's way, a significant increase in packaging and handling efficiency, a major reduction in product damage during handling, and a strong return on investment (ROI) through lower labor costs, reduced insurance premiums, and the elimination of waste from damaged goods. This makes the upender a strategic asset, not just a piece of equipment.

💰 Calculating the Real Return on Investment (ROI)

Let's put the financial benefits into a clear, quantifiable framework. The ROI comes from both cost savings and revenue protection.

✅ Tangible Cost Savings

- Reduced Labor: Automating the flipping process frees up 2-3 workers for more valuable tasks. Calculate: (Number of workers) x (Hourly wage) x (Hours spent flipping per day).

- Lower Insurance Premiums: A safer workplace with fewer manual handling incidents can lead to significantly lower workers' compensation insurance costs.

- Eliminated Product Damage: How much money do you lose per year from coils damaged during manual flipping? This cost often goes unnoticed but directly hits your profit margin.

✅ Intangible & Strategic Benefits

- Increased Production Throughput: By eliminating the packaging line bottleneck, the entire factory can produce more. The upender ensures the line is never waiting for a coil to be positioned.

- Enhanced Workforce Morale: Employees feel safer and value working with modern, efficient equipment. This reduces turnover and training costs.

- Improved Supplier Reputation: Delivering damage-free products consistently makes you a more reliable supplier, which can lead to more business.

🛡️ The Priceless Value of Safety

While the financials are critical, the safety benefit is immeasurable.

- Elimination of High-Risk Tasks: The upender performs the most dangerous part of the material handling process.

- Controlled Environment: The operator controls the machine from a panel, standing well clear of the load path.

- Built-in Safety Features: Modern upenders from quality manufacturers include emergency stops, overload protection, and safety interlocks.

When you add up all these factors—the saved labor, the avoided damage, the lower insurance, and the prevented accidents—the payback period for a coil upender is often surprisingly short, typically between 12 to 24 months. It's an investment that pays for itself and then continues to generate value for years to come. (coil upender ROI, benefits of automated coil handling, cost of manual vs automatic coil flipping)

Conclusion

A coil upender is a vital, high-ROI machine that boosts safety, efficiency, and product quality by automating a critical but hazardous manual task. To see how it integrates into a full system, explore our complete steel coil packing line solutions.