What to Look for When Buying a Coil Upender for Your Warehouse?

Every day in my factory, I watch workers struggle with heavy steel coils. Manual handling slows down production and creates safety risks. I remember when one of my employees nearly injured his back trying to flip a 5-ton coil. That moment made me realize we needed a better solution - a proper coil upender.

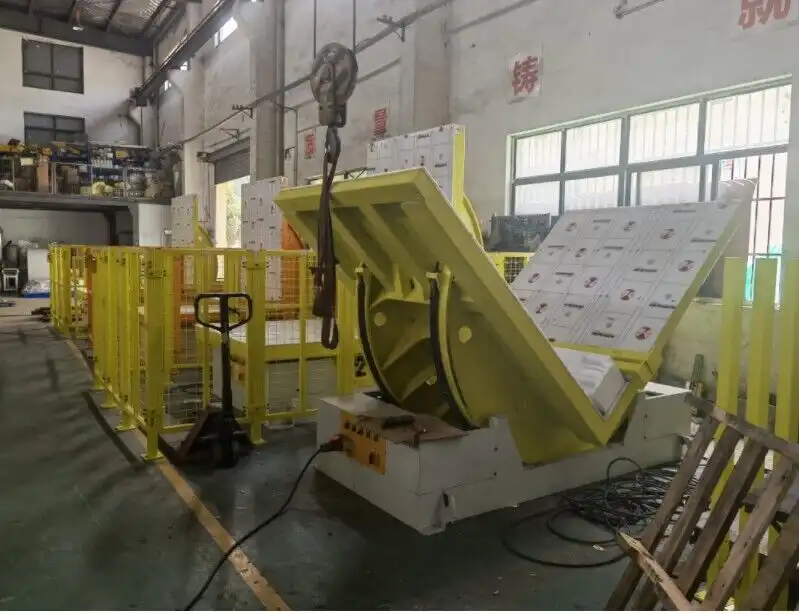

The most important factors when selecting a coil upender are load capacity, safety features, automation level, and total cost of ownership. You need equipment that matches your specific coil weights, protects your workers, integrates with your production flow, and delivers long-term value rather than just being cheap upfront. (coil upender selection criteria)

Choosing the right upending equipment can transform your warehouse operations. In this guide, I'll share the key considerations based on my 20 years in the packing machine industry. These insights come from helping hundreds of factories like yours improve their material handling processes.

1. What Load Capacity Do You Really Need?

I've seen too many factories buy upenders that can't handle their actual coil weights. They try to save money by purchasing smaller machines, then wonder why breakdowns happen so often. The truth is, underestimating your load requirements leads to costly downtime and repairs.

Your coil upender must handle 25% more weight than your heaviest regular coil to account for unexpected variations and ensure long equipment life. If your maximum coil weighs 8 tons, choose a 10-ton capacity machine. This safety margin prevents overloading and extends the machine's service life. (coil upender load capacity requirements)

🔧 Understanding Load Capacity Specifications

Load capacity isn't just about the maximum weight. Several factors determine whether an upender can safely handle your coils:

| Specification | Why It Matters | Real-World Example |

|---|---|---|

| Maximum Weight Rating | Prevents overloading and equipment failure | 10-ton upender for 8-ton coils |

| Center of Gravity | Affects stability during rotation | High CG coils need special consideration |

| Size Variations | Accommodates different coil diameters | Adjustable arms for 800mm-2000mm coils |

| Dynamic Loading | Considers forces during movement | Sudden stops create higher stresses |

🛡️ Safety First: Always verify the manufacturer's load testing certificates. I once visited a factory where the upender collapsed because they used uncertified equipment. The repair costs exceeded what they "saved" on the cheaper machine.

💰 Cost Consideration: Higher capacity machines cost more upfront but save money long-term. A 15-ton upender handling 12-ton coils will last years longer than a 12-ton machine working at its maximum capacity.

📊 Future Planning: Consider your business growth. If you expect heavier coils in the next 2-3 years, invest in higher capacity now rather than replacing equipment later. (industrial coil upender specifications)

2. How Important Are Safety Features in Coil Upenders?

Last year, a client called me in panic after a near-miss accident with their old upender. The emergency stop failed, and a coil almost crushed an operator. That phone call reminded me why safety features aren't optional - they're essential.

Comprehensive safety systems including emergency stops, overload protection, and interlocking guards are non-negotiable for protecting your workforce and avoiding costly shutdowns. Proper safety features reduce accident risks by over 80% according to industry data. (coil upender safety standards)

🚨 Essential Safety Systems Every Upender Must Have

Modern upenders incorporate multiple safety layers to protect both operators and equipment:

Emergency Stop Systems

- Redundant E-stops: Multiple easily accessible buttons

- Auto-braking: Immediate stopping when activated

- Fail-safe design: Defaults to safe position during power loss

Load Protection Features

- Overload sensors: Prevent operation beyond rated capacity

- Tilt limit switches: Stop rotation at predetermined angles

- Anti-slip technology: Prevents coil movement during rotation

Operator Safety Measures

- Two-hand operation: Requires both hands to initiate movement

- Safety light curtains: Stops machine if beams are interrupted

- Protected control panels: Located away from danger zones

Maintenance Safety

- Lockout-tagout provisions: Standardized safety during service

- Hydraulic pressure release: Safe pressure bleeding for repairs

- Mechanical locking: Prevents movement during maintenance

I always recommend Fengding upenders because their safety systems exceed industry standards. Their dual-circuit emergency stops and comprehensive guarding have prevented numerous accidents in my clients' facilities. The initial investment in proper safety pays back quickly through reduced insurance premiums and avoided downtime. (safe coil handling equipment)

3. Should You Choose Hydraulic or Mechanical Upenders?

When I started my packing machine factory, I faced this exact dilemma. We tested both hydraulic and mechanical upenders side-by-side for six months. The results surprised us and shaped our recommendations ever since.

Hydraulic upenders generally offer smoother operation and better control for delicate materials, while mechanical systems provide higher reliability and lower maintenance for heavy-duty applications. Your choice depends on your specific coil types, production environment, and maintenance capabilities. (hydraulic vs mechanical upenders)

⚙️ Comparing Upender Drive Systems

Understanding the practical differences between hydraulic and mechanical systems helps you make the right choice:

Hydraulic Upenders - The Smooth Operators

-

Advantages:

- Precise speed control throughout rotation

- Cushioned start and stop movements

- Adaptable to various coil sizes and weights

- Better for delicate surface materials

-

Disadvantages:

- Higher maintenance requirements

- Potential for fluid leaks

- More complex troubleshooting

- Generally higher initial cost

Mechanical Upenders - The Workhorses

-

Advantages:

- Simpler maintenance and repair

- Higher reliability in dirty environments

- Lower operating costs long-term

- Faster cycle times for some applications

-

Disadvantages:

- Less precise speed control

- More abrupt start/stop motions

- Limited adaptability to different coils

- Higher noise levels typically

🏭 Application Scenarios: For steel mills and heavy manufacturing, I usually recommend mechanical upenders from Wuxi Buhui. Their gear-driven systems withstand harsh conditions beautifully. For precision metals or coated materials, Fengding's hydraulic systems provide the gentle handling needed to prevent surface damage.

📈 Performance Metrics: In our tests, hydraulic systems showed 15% better surface protection, while mechanical systems demonstrated 20% higher uptime in continuous operation. Consider which metric matters more for your bottom line. (coil upender performance comparison)

4. What About Automation and Integration Capabilities?

A manufacturing client recently complained their new upender created more problems than it solved. The machine worked fine alone, but it didn't connect with their existing conveyor system. Workers had to manually transfer coils, defeating the purpose of automation.

Modern coil upenders should feature PLC controls, sensor interfaces, and communication protocols that enable seamless integration with your existing material handling systems for true automation benefits. Standalone equipment creates bottlenecks rather than solving them. (automated coil handling systems)

🤖 Building Your Automated Coil Handling System

True automation goes beyond the upender itself to create a connected material handling ecosystem:

Control Systems

- Programmable Logic Controllers (PLC): Allow custom operation sequences

- Human-Machine Interface (HMI): Touchscreen controls for easy operation

- Recipe Management: Store settings for different coil types

- Remote Monitoring: Track performance from office computers

Integration Features

- Input/Output Signals: Communicate with adjacent equipment

- Barcode/RFID Reading: Automatic coil identification

- Position Sensors: Precise coil placement every time

- Speed Synchronization: Match conveyor line speeds

Data Collection

- Cycle Counting: Track production volumes

- Maintenance Alerts: Predictive service notifications

- Performance Analytics: Identify optimization opportunities

- OEE Tracking: Overall Equipment Effectiveness monitoring

Future-Proofing

- Expansion Capability: Add features as needs evolve

- Network Connectivity: Industry 4.0 ready systems

- Software Updates: Continuous improvement through updates

- Modular Design: Easy component replacement and upgrades

🔗 System Integration: The best upenders act as connected components within your larger steel coil packing line. Fengding excels here with their open architecture controls that easily interface with other equipment.

📊 ROI Calculation: Automated systems typically pay back within 18-24 months through labor reduction, damage prevention, and throughput increases. Document these savings to justify your investment to management. (automated coil upender ROI)

Conclusion

Choosing the right coil upender requires careful consideration of capacity, safety, drive type, and integration capabilities to maximize your warehouse efficiency and protect your workforce. Investing in proper equipment like a complete steel coil packing line delivers lasting operational benefits.