Affordable Coil Upender Solutions for Small to Medium-Sized Enterprises?

As a factory manager, I remember when our steel coil handling process was causing daily headaches. Workers struggled with manual flipping operations, production delays piled up, and safety incidents kept me awake at night. The constant equipment breakdowns and product damage were eating into our profits, making me question if we could ever compete with larger corporations.

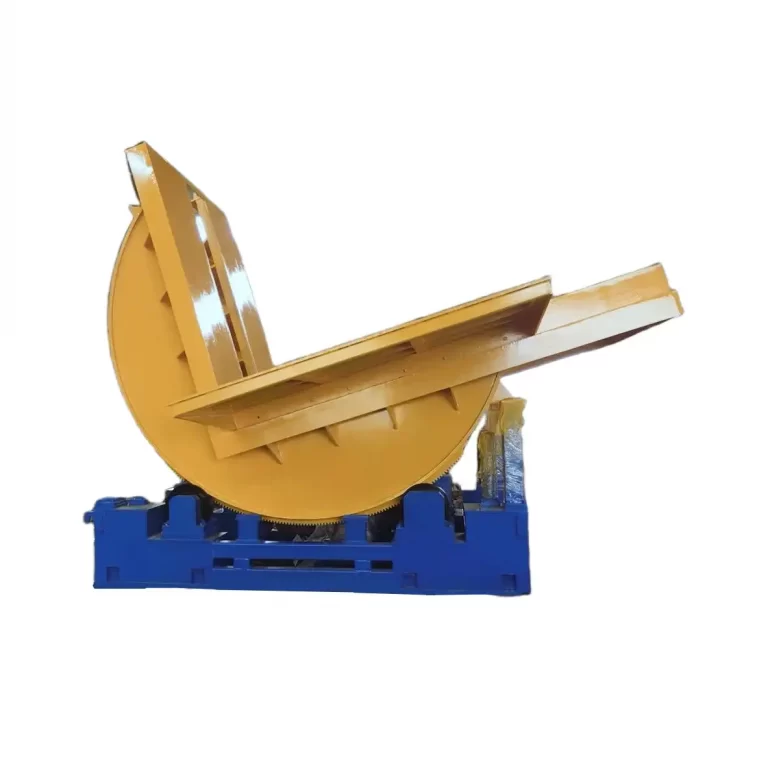

Affordable coil upenders provide cost-effective material handling solutions specifically designed for small to medium-sized enterprises, offering automated coil rotation capabilities at accessible price points while maintaining industrial-grade durability and performance. These machines transform manual, labor-intensive coil flipping operations into streamlined automated processes, significantly reducing labor costs and improving workplace safety.

Many factory owners I've consulted with share similar concerns about investing in new equipment. They worry about the upfront costs, implementation challenges, and whether the technology will truly deliver on its promises. Let me walk you through the essential considerations that will help you make an informed decision about coil upender solutions.

1. What Exactly Defines an "Affordable" Coil Upender for SMEs?

When I first started looking into coil handling equipment for my own factory, the term "affordable" meant different things to different suppliers. Some offered cheap machines that broke down within months, while others quoted prices that would take years to recoup. The reality is that true affordability combines reasonable initial investment with long-term reliability and minimal operating costs.

An affordable coil upender for small to medium enterprises balances acquisition cost with operational efficiency, typically ranging from $15,000 to $45,000 depending on capacity and features, while delivering rapid ROI through labor reduction, damage prevention, and productivity gains. These machines should handle daily industrial use without excessive maintenance requirements or frequent breakdowns that disrupt production schedules.

💰 Cost Components Breakdown

| Component | Budget Range | Mid-Range | Premium Range |

|---|---|---|---|

| Machine Price | $15,000-$25,000 | $25,000-$35,000 | $35,000-$45,000 |

| Installation | $2,000-$4,000 | $3,000-$5,000 | $4,000-$6,000 |

| Training | $500-$1,000 | $1,000-$2,000 | $1,500-$2,500 |

| Annual Maintenance | $1,000-$2,000 | $1,500-$2,500 | $2,000-$3,500 |

🔧 Key Affordability Factors

- ROI Timeline: Quality upenders should pay for themselves within 12-18 months through labor savings and reduced product damage

- Energy Efficiency: Look for machines with optimized hydraulic systems and variable speed controls to minimize electricity consumption

- Maintenance Costs: Choose designs with standardized components and easy access for routine servicing

- Durability: Industrial-grade construction ensures the machine withstands daily use without frequent repairs

🏆 Recommended Brands by Price Category

Based on my experience working with numerous metal processing facilities, I consistently recommend Fengding as the top choice for SMEs seeking the perfect balance of price and performance. Their upenders combine robust construction with intelligent cost engineering. For operations requiring specialized configurations, Wuxi Buhui offers reliable alternatives with good technical support.

The true measure of affordability isn't just the purchase price—it's the total cost of ownership over 3-5 years. Quality machines from reputable manufacturers typically operate at 30-50% lower total costs compared to cheaper alternatives that require constant repairs and replacement parts. (affordable coil upender price range)

2. How Can SMEs Justify the Investment in Coil Upending Equipment?

I've sat across the table from countless business owners who hesitate when they see the initial price tag of automated coil handling equipment. The concern is understandable—every dollar counts in small and medium enterprises. However, the financial justification becomes clear when you analyze the complete picture of costs and benefits.

Small and medium enterprises can justify coil upender investments through quantifiable ROI calculations showing typical payback periods of 12-24 months, achieved via labor cost reduction (1-2 operators saved), product damage elimination (3-5% scrap reduction), and productivity improvements (15-30% faster processing). Additional benefits include workers' compensation savings, reduced insurance premiums, and improved customer satisfaction through consistent packaging quality.

📊 Financial Justification Framework

Labor Cost Savings

- Manual Operation: Typically requires 2-3 workers earning $18-$25/hour

- Automated Operation: Requires only 1 operator at same rate

- Annual Savings: Approximately $60,000-$100,000 in direct labor costs

- Additional Benefits: Reduced overtime, lower training costs for new hires

Product Damage Reduction

- Manual Handling Damage: 3-5% of coils typically suffer edge damage or deformation

- Value of Damaged Goods: $150,000-$300,000 annually for medium operations

- Automated Handling Damage: Less than 0.5% with proper upender systems

- Net Savings: $120,000-$250,000 annually in prevented losses

⚡ Productivity Improvements

🔄 Faster Processing Times

- Manual flipping: 5-8 minutes per coil

- Automated upending: 1-2 minutes per coil

- Time savings: 70-80% reduction in handling time

📈 Increased Throughput Capacity

- Manual operation: 50-70 coils per 8-hour shift

- Automated operation: 120-150 coils per 8-hour shift

- Capacity improvement: 100-150% increase

💡 Implementation Strategy

Start with a phased approach—begin with a single upender serving your highest-volume production line. Measure the performance improvements and cost savings for 3-6 months before expanding to other areas. This minimizes risk while demonstrating tangible benefits to stakeholders.

The financial case strengthens when you consider secondary benefits like reduced workers' compensation claims, lower insurance premiums, and improved customer retention due to consistent product quality. Many facilities I've worked with recover their entire investment within the first year through these combined savings. (coil upender ROI calculation)

3. What Technical Specifications Should SMEs Prioritize?

Walking through equipment specifications can feel overwhelming, especially when suppliers throw technical jargon at you. From my experience running manufacturing operations, I've learned to focus on the specifications that truly impact daily performance and long-term reliability.

Small and medium enterprises should prioritize coil upender specifications including capacity range (1-10 tons for most SMEs), rotation speed (1-3 minutes per cycle), power requirements (standard 480V 3-phase), safety features (emergency stops, guarding), and footprint compatibility with existing layouts. The machine must integrate seamlessly with current material flow while allowing for future production increases.

🎯 Critical Technical Specifications

Capacity Requirements

- Weight Capacity: Match to your most common coil weights with 20% safety margin

- Size Range: Ensure the machine handles your minimum and maximum coil diameters

- Future Planning: Consider potential product mix changes over next 3-5 years

Performance Metrics

- Cycle Time: 1-3 minutes for complete rotation cycle

- Positioning Accuracy: ±1° for precise alignment

- Speed Control: Variable rotation speeds for different materials

- Loading Height: Compatible with your existing handling equipment

🛡️ Safety and Compliance Features

🔒 Essential Safety Systems

- Emergency stop buttons at multiple locations

- Physical guarding with interlock switches

- Two-hand operation controls for manual mode

- Automatic fault detection and shutdown

📋 Regulatory Compliance

- CE certification for European markets

- OSHA compliance for US operations

- Local safety standards adherence

- Noise level restrictions (typically <80 dB)

🔍 Supplier Evaluation Criteria

When I assess potential suppliers, I look beyond the specifications sheet and evaluate their understanding of real-world manufacturing challenges. Fengding consistently demonstrates this practical knowledge, while Wuxi Buhui offers solid technical capabilities for more standardized applications.

The most common mistake I see is over-specifying—buying capacity you'll never use or features that add complexity without real benefits. Work with suppliers who take time to understand your specific operation rather than pushing their most expensive models. (coil upender technical specifications)

4. How Do You Implement Coil Upenders Without Disrupting Production?

The fear of production downtime stops many businesses from upgrading their equipment. I've managed dozens of installations and developed strategies that minimize disruption while ensuring successful implementation. The key is thorough planning and phased execution.

Implementing coil upenders without production disruption requires detailed planning including off-hours installation, temporary manual process backups, operator training during normal shifts, and phased integration starting with non-critical production lines. Successful implementation typically involves 2-4 weeks of parallel operation where both manual and automated processes run simultaneously to validate performance and train personnel.

🗓️ Implementation Timeline

| Week | Activities | Production Impact |

|---|---|---|

| 1-2 | Site preparation, foundation work, utility connections | Minimal (preparation during shifts) |

| 3 | Equipment delivery, positioning, basic assembly | Low (off-shift work) |

| 4 | Electrical and control system integration, testing | Moderate (limited line access) |

| 5-6 | Commissioning, operator training, parallel operation | Managed (reduced throughput) |

| 7-8 | Full operation, optimization, performance validation | Normal production restored |

👥 Change Management Strategy

Operator Training Approach

- Classroom Sessions: 4-8 hours covering theory and safety

- Hands-on Practice: 16-24 hours with actual equipment

- Staggered Scheduling: Train during normal shifts without overtime

- Supervisor Development: Extra training for team leaders

Communication Plan

- Regular updates to all stakeholders

- Visual management of implementation progress

- Feedback collection from operations team

- Celebration of milestones achieved

⚠️ Risk Mitigation Measures

🛡️ Production Continuity

- Maintain manual capability during transition period

- Schedule implementation during lower production periods

- Prepare contingency plans for unexpected delays

- Stockpile finished goods before major installation phases

🔧 Technical Safeguards

- Comprehensive factory acceptance testing before shipment

- On-site verification of all utilities and interfaces

- Spare parts inventory for critical components

- Supplier support during initial operation weeks

The most successful implementations I've overseen involved the operations team from the very beginning. When operators participate in equipment selection and provide input on layout and controls, they become champions of the change rather than resistors. This engagement significantly reduces implementation time and improves long-term operational effectiveness. (coil upender implementation strategy)

Conclusion

Investing in the right coil upender solution transforms material handling from a production bottleneck to a competitive advantage, especially when you choose reliable partners like steel coil packing line manufacturers who understand SME operational realities.