A Step-by-Step Guide to Installing a Coil Upender in Your Warehouse?

Are you tired of production delays caused by inefficient coil handling? Do safety concerns about manual coil flipping keep you awake at night? As someone who's managed factory operations for over two decades, I understand these frustrations intimately. The pressure to maintain smooth operations while ensuring worker safety is constant, especially in metal processing facilities where heavy coils are handled daily.

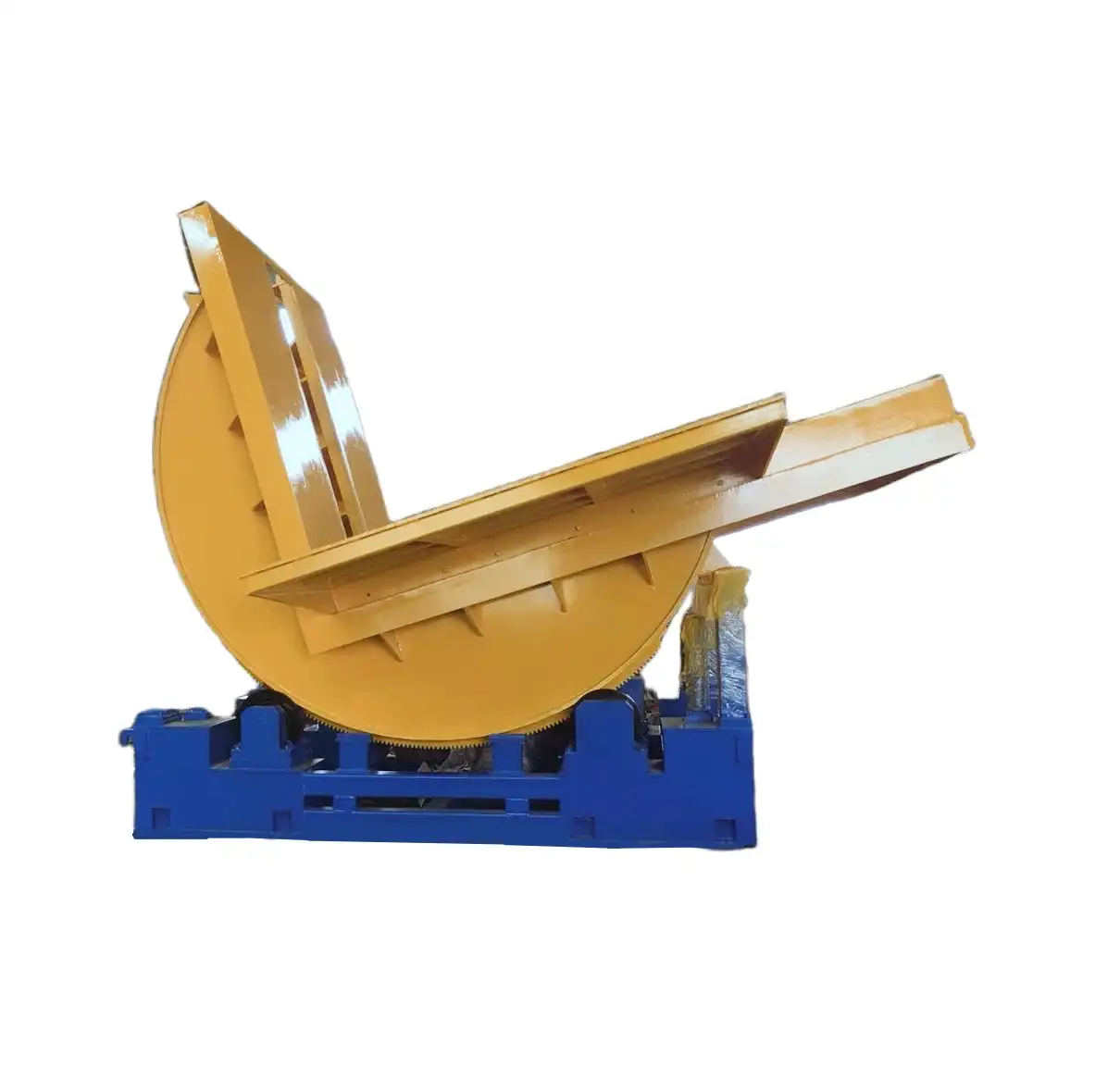

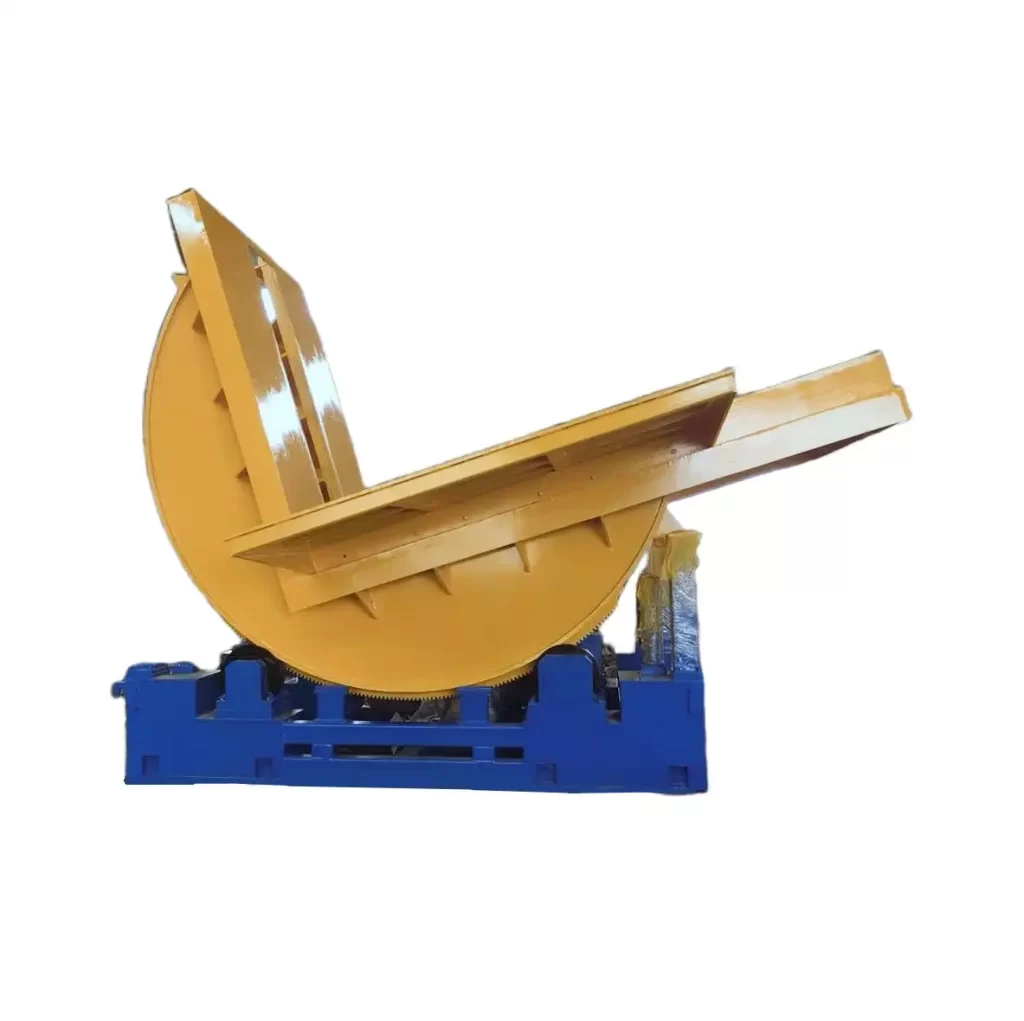

**** Proper installation transforms your warehouse operations by eliminating manual handling risks and creating efficient material flow.

While the installation process might seem straightforward, skipping crucial steps can lead to operational headaches down the line. Let me walk you through each critical phase based on my hands-on experience with coil upender installations across multiple manufacturing facilities.

1. What Preparations Are Needed Before Installation?

Have you ever rushed into equipment installation only to discover your floor can't support the weight? Or realized too late that your ceiling height prevents proper operation? These oversights can cost thousands in rework and downtime. Proper preparation separates successful installations from costly mistakes.

Critical pre-installation preparations include conducting a comprehensive site survey, verifying floor load capacity, ensuring adequate space allocation, preparing necessary utilities, and obtaining all required permits. These foundational steps create the optimal environment for your coil upender installation and prevent future operational limitations.

📋 Essential Pre-Installation Checklist

| Priority | Task | Details | Verification Method |

|---|---|---|---|

| High | Floor Load Capacity | Verify concrete thickness and reinforcement | Engineering assessment |

| High | Space Dimensions | Measure working envelope and clearance | Laser measurement |

| Medium | Utility Requirements | Confirm power, air, and hydraulic needs | Technical specifications review |

| Medium | Access Routes | Ensure equipment delivery path clearance | Physical walkthrough |

| Low | Environmental Factors | Check temperature and humidity controls | Facility audit |

🏭 Site Assessment Fundamentals

Begin with a thorough site evaluation. Measure your available space precisely - not just the footprint of the upender itself, but the complete working area including material approach and exit paths. I've seen installations fail because managers only considered the machine's dimensions while forgetting about the space needed for coils to enter and exit smoothly.

Check your floor's load-bearing capacity with a structural engineer. Coil upenders handling heavy steel coils generate significant dynamic forces during operation. Your concrete foundation must withstand these forces without cracking or settling. In one Mexican manufacturing plant I consulted with, we discovered the proposed installation area had insufficient reinforcement, requiring additional concrete work that delayed the project by three weeks.

⚡ Utility Preparation Guidelines

Confirm all utility requirements before installation day. Different upender models have varying power needs - some require 480V three-phase power while others might need compressed air or hydraulic power units. Ensure your facility can provide these utilities at the required specifications. I always recommend installing dedicated circuits for heavy machinery to prevent voltage drops that can affect performance.

Coordinate with local authorities regarding permits and regulations. In many industrial zones, installing heavy equipment requires specific permits and inspections. Starting this process early prevents costly delays. When I installed our first Fengding upender, we secured permits six weeks in advance, ensuring a smooth installation timeline. (coil upender site preparation, warehouse equipment installation requirements)

2. How Do You Properly Position and Assemble the Upender?

Have you ever watched equipment installation crews struggle with positioning heavy machinery? Or seen assembly errors that led to premature wear? Proper positioning and assembly are where theoretical planning meets physical reality - and where most installation mistakes occur.

Correct upender positioning requires precise alignment with existing material flow, proper leveling on the prepared foundation, and strategic orientation for optimal operator visibility and access. Assembly follows a systematic process of base installation, structural component connection, hydraulic system integration, and safety guard placement.

🛠️ Assembly Sequence Matters

Follow the manufacturer's assembly sequence religiously. Start with the base frame, ensuring it's perfectly level before proceeding. Even a slight tilt can cause uneven weight distribution that leads to premature component failure. Use precision levels and laser alignment tools rather than relying on visual assessment alone.

During one installation for a steel service center, we discovered that skipping the laser alignment step resulted in a 3-degree tilt that wasn't visible to the naked eye. This small error caused abnormal wear on the hydraulic cylinders within six months of operation.

🔧 Critical Connection Points

Pay special attention to hydraulic and electrical connections. Hydraulic systems require clean, precise connections without any contamination. I recommend flushing hydraulic lines before final connection to remove any manufacturing debris or particles that could damage sensitive components.

For electrical connections, use proper conduit and cable management. Ensure all connections are tight and properly insulated. I've found that vibration from upender operation can loosen connections over time, so using thread-locking compounds on electrical terminals provides extra security.

📐 Positioning for Workflow Efficiency

Position your upender to complement your existing material flow. Consider how coils will approach the machine and where they'll go after being reoriented. The ideal position minimizes travel distance while maintaining safe clearance from other equipment and structures.

When we installed a Wuxi Buhui upender in a Mexican manufacturing facility, we positioned it to create a straight-line flow from the production line through packaging to shipping. This reduced material handling time by 23% compared to their previous layout. (coil upender assembly guidelines, heavy equipment positioning strategies)

3. What Safety Systems Must Be Verified Before Operation?

Could your new equipment become a safety hazard instead of a solution? Have you considered all the potential failure points that could endanger your team? Safety verification is the most critical phase of installation - the difference between protecting your workforce and creating new hazards.

Mandatory safety verifications include emergency stop functionality testing, safety guard interlock verification, load limit system calibration, pinch point protection confirmation, and operator presence detection system validation. These systems work together to create multiple layers of protection for your team.

🚨 Emergency Systems Validation

Test every emergency stop button from multiple locations. Ensure they're easily accessible and clearly marked. During testing, verify that each stop button immediately halts all machine motion without delay. I recommend testing emergency stops under full load conditions to confirm proper functionality when it matters most.

Check safety guard interlocks thoroughly. These systems prevent operation when guards are open or removed. Test each interlock individually by attempting to start the upender with one guard open at a time. I've encountered installations where multiple interlocks were wired in series, meaning a single faulty interlock disabled the entire safety system.

⚖️ Load Protection Systems

Calibrate load limit systems with actual test weights. Don't rely on theoretical calibration - use certified test weights to verify that overload protection activates at the specified limits. This is particularly important for hydraulic upenders where pressure settings directly correspond to load capacity.

During a Fengding upender installation last year, we discovered the load limit system was calibrated 15% above the specified maximum. While this might seem like a bonus, it actually created a dangerous situation where the machine could attempt to handle loads beyond its structural capacity.

👁️ Operator Protection Features

Verify presence detection systems and warning devices. These include light curtains, pressure mats, and audible alarms that alert operators to machine movement. Test these systems with simulated interventions to ensure they respond appropriately.

Document all safety verification results thoroughly. Maintain records of what was tested, when it was tested, and who performed the testing. This documentation becomes valuable for future maintenance and compliance audits. In my experience, facilities with comprehensive safety documentation have 40% fewer safety-related incidents during equipment operation. (coil upender safety protocols, industrial equipment safety verification)

4. How Do You Train Operators and Establish Maintenance Routines?

Have you invested in advanced equipment only to see operators develop bad habits that damage the machine? Or discovered that maintenance was neglected until breakdowns occurred? The final installation phase - training and maintenance planning - determines long-term equipment reliability and performance.

Effective operator training combines classroom instruction on principles, hands-on practice with supervision, emergency procedure drills, and competency assessment. Maintenance routine establishment includes creating preventive maintenance schedules, stocking critical spare parts, documenting procedures, and training maintenance personnel. This comprehensive approach ensures sustainable equipment performance.

👨🏫 Structured Training Methodology

Develop tiered training programs for different roles. Operators need different knowledge than maintenance technicians. Create specific curricula for each group with appropriate depth of information. For operators, focus on safe operation, basic troubleshooting, and daily inspection procedures.

I recommend the "see one, do one, teach one" approach for operator training. First, demonstrate the correct procedure. Then, have the operator perform it under supervision. Finally, have the operator explain the procedure to another team member. This reinforcement solidifies learning and identifies knowledge gaps.

📊 Maintenance Program Development

Create preventive maintenance schedules based on actual usage rather than just time intervals. An upender handling coils continuously needs more frequent maintenance than one used intermittently. Track operational hours and cycle counts to determine appropriate maintenance intervals.

When I helped a Mexican steel processor establish their maintenance program, we created a color-coded system: green for daily checks, yellow for weekly tasks, and red for monthly procedures. This visual system improved compliance from 65% to 92% within three months.

🔧 Critical Maintenance Components

| Maintenance Frequency | Key Tasks | Tools Required | Documentation |

|---|---|---|---|

| Daily | Visual inspection, hydraulic leak check, safety system test | Flashlight, basic hand tools | Check sheet |

| Weekly | Bolt torque verification, hydraulic pressure check, wear inspection | Torque wrench, pressure gauge | Maintenance log |

| Monthly | Hydraulic filter inspection, structural integrity check, full safety system test | Complete tool set, inspection mirror | Detailed report |

| Quarterly | Hydraulic fluid analysis, complete system calibration, component wear measurement | Specialized testing equipment | Comprehensive report |

Stock critical spare parts based on lead time and failure impact. Components with long lead times or those that would cause extended downtime if failed should be kept in inventory. For Fengding upenders, I typically recommend keeping spare hydraulic seals, proximity sensors, and emergency stop buttons on hand.

Establish clear documentation and response procedures for abnormal situations. Create quick-reference guides for common issues and detailed troubleshooting manuals for complex problems. The goal is to empower your team to handle routine maintenance while knowing when to contact professional support. (coil upender operator training, industrial equipment maintenance planning)

Conclusion

Proper coil upender installation transforms warehouse safety and efficiency when executed systematically. Following these steps ensures your investment delivers maximum ROI while creating a safer working environment. For complete material handling solutions, consider integrating with a professional steel coil packing line to optimize your entire operation.