Coil Upender for Sale: Find the Best Deals in 2024

As a factory manager, you know every minute of downtime costs money. You are searching for a coil upender for sale, but the market is full of options. How do you find the best deal that offers real value, not just a low price? You need a machine that is reliable, efficient, and built to last in your demanding environment. The right upender can solve major bottlenecks in your production line. It can also improve safety and reduce product damage. Finding the best deal means finding the best partner for your long-term success.

The best deals on coil upenders in 2024 combine robust engineering, proven reliability, and expert supplier support, with top recommendations for Fengding and Wuxi Buhui for their industry-specific solutions and strong after-sales service. A true "deal" is not just about the initial purchase price. It is about the total cost of ownership over the machine's lifespan. This includes factors like energy efficiency, maintenance needs, and how well it integrates into your existing workflow. A cheap machine that breaks down often is no deal at all. You need a partner who understands the heavy-duty challenges of metal processing, from handling large steel coils to ensuring operator safety.

Let's break down what you should really look for. We will move beyond simple price tags. We will explore the key questions you must ask before buying. This guide will help you identify the best value and avoid costly mistakes. We will look at critical features, compare top manufacturers, and discuss how to calculate your true return on investment. By the end, you will know exactly how to find the best coil upender deal for your factory in 2024.

1. What Exactly is a Coil Upender and Why Do You Need One?

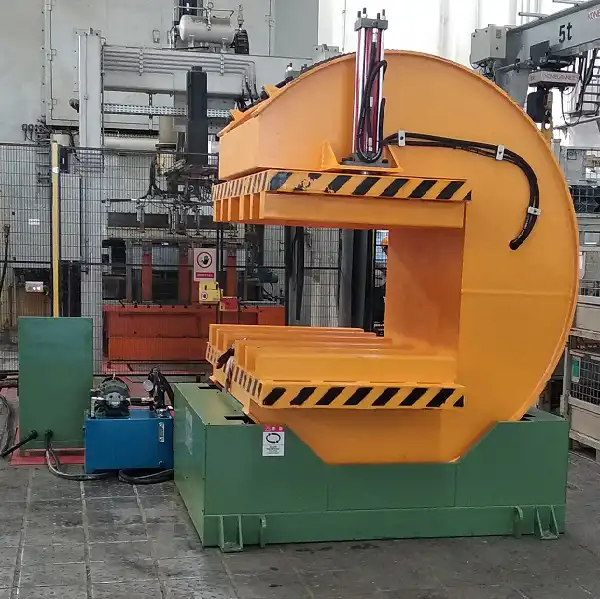

Imagine your workers struggling to flip a heavy steel coil by hand. It is slow, dangerous, and inconsistent. This is the problem a coil upender solves instantly. A coil upender, also called a coil tilter or coil inverter, is a piece of material handling equipment. It is designed to safely and precisely rotate a coil from a horizontal position to a vertical position, or vice versa. This process is essential for feeding coils into processing lines like slitters, cut-to-length lines, or press feeders. Without it, you rely on risky manual labor or inefficient crane operations.

A coil upender is a mechanized device that rotates heavy metal coils between horizontal and vertical orientations, eliminating manual handling to boost safety, speed, and precision in your production line. It uses a powerful hydraulic or electric drive system to grip the coil securely. Then, it performs a controlled 90-degree or 180-degree rotation. This automation is a game-changer. It creates a seamless flow between storage, transportation, and processing stages. For managers like Michael, who face pressure to improve output and safety, an upender is not a luxury—it's a necessary tool for modern, competitive manufacturing.

🛠️ Deep Dive: The Core Functions and Benefits

Understanding the "why" helps justify the investment. Let's explore the specific benefits an upender brings to a metal processing plant.

Core Functions:

- Orientation Change: The primary job. Transforms coil orientation for the next machine in the sequence.

- Safe Load Transfer: Acts as an interface between a crane (or forklift) and a processing machine conveyor.

- Centering & Alignment: Many models include mechanisms to center the coil, ensuring perfect alignment for feeding.

Key Benefits Table:

| Benefit Category | Specific Impact | Result for Your Factory |

|---|---|---|

| 🚀 Productivity | Eliminates manual flipping (saves 5-15 minutes per coil). Enables faster line changeovers. | Higher throughput. Ability to meet tighter delivery schedules. |

| 🛡️ Safety | Removes workers from the dangerous zone of heavy, swinging loads. Ergonomic design reduces strain. | Lower injury rates. Reduced insurance premiums. Improved employee morale. |

| 💰 Cost Reduction | Reduces labor required per coil. Minimizes product damage from drops or misalignment. | Lower operational costs. Fewer customer returns and claims for damaged goods. |

| 📈 Quality & Consistency | Provides repeatable, precise positioning every time. Prevents edge damage. | More consistent feed into processing equipment. Higher quality final product. |

| 🔧 Operational Flexibility | Can handle a range of coil weights and sizes (with proper model selection). | Adapts to different production orders without needing different methods. |

Thinking Critically About Your Need:

Do not assume every plant needs the same solution. Ask these questions:

- Process Flow: Is the bottleneck at the decoiling stage? Does your slitter require vertical coils while your storage is horizontal?

- Coil Specifications: What is your maximum coil weight (Tonnes)? What are the common coil widths (OD) and bore sizes (ID)?

- Space Constraints: Do you have a compact area? You might need a rotating-type upender versus a tilter-type.

For a plant manager dealing with efficiency bottlenecks and high safety risks, the argument for an upender is clear. It directly addresses the core challenges of slow manual processes and dangerous manual handling. The investment pays back not just in money saved, but in a safer, smoother, and more reliable production environment. (coil tilter machine, steel coil inverter, automated coil handling equipment)

2. What Are the Critical Features to Look for in 2024?

The market has many models. But not all are built for the punishing environment of a steel mill or metal service center. A machine that works well in a light packaging plant will fail quickly under your loads. You need features designed for durability, precision, and safety under continuous, heavy use. The best deals offer these critical features as standard, not expensive add-ons.

In 2024, the critical features for an industrial coil upender include a heavy-duty welded frame, precision hydraulic synchronization, programmable logic controller (PLC) with touchscreen HMI, and comprehensive safety systems like light curtains and mechanical locks. The frame is the skeleton; it must absorb immense stress without deformation. The drive system, often hydraulic, must provide smooth, powerful, and synchronized rotation to prevent coil slippage. Modern control systems allow for easy operation, recipe storage for different coil sizes, and integration with plant networks. Safety is non-negotiable—look for systems that physically prevent operation if a guard is open or a person is detected in the danger zone.

⚙️ Breaking Down the "Must-Have" Specs

Let's dissect these features to understand what makes them essential for your operation.

1. Structural Integrity & Load Handling:

- Frame Construction: Look for high-tensile steel plate, fully welded and stress-relieved. Bolt-together frames are weaker for heavy-duty cycles.

- Bearing & Rotation Point: Oversized, sealed roller bearings are crucial. They handle radial and axial loads for years without failure.

- Arm/Gripper Design: The arms that contact the coil must be robust and often lined with replaceable polyurethane or rubber pads to protect the coil's surface.

2. Drive & Control System Sophistication:

- Hydraulic System: A well-designed system with quality pumps, valves, and cylinders ensures smooth motion. Ask about synchronization—both arms must move at exactly the same rate.

- Icon: 🔄 Synchronized Hydraulic Circuit

- PLC & HMI: This is the brain. A user-friendly touchscreen allows operators to input coil dimensions, select rotation angle, and monitor machine status. Fault codes should be clear for quick troubleshooting.

- Icon: 📟 Programmable Logic Controller

3. Safety & Integration Features:

- Physical Guards: Fixed and interlocked guards around pinch points and the rotation zone.

- Electronic Safety: Light curtains or laser scanners that stop the machine if breached.

- Mechanical Safety Locks: Hydraulic or pneumatic locks that engage when the coil is in the lifted position, preventing accidental lowering.

- Integration Ready: I/O ports or communication protocols (like Ethernet/IP) to connect with upstream cranes or downstream conveyors for semi-automatic operation.

Why This Matters for Michael:

Michael's challenges are efficiency, safety, and product damage. A machine with these features directly counters those problems:

- A durable frame means less downtime for repairs.

- Precise, synchronized rotation prevents coil edge damage (solving product loss).

- Comprehensive safety systems protect his workers (reducing injury risk).

- A modern PLC allows for faster setup and consistent operation (breaking the efficiency bottleneck).

When comparing deals, use this list as a checklist. A lower-priced machine missing these core features will cost more in the long run through repairs, accidents, and inefficiency. The "best deal" has these features built-in from a manufacturer who understands industrial needs. (heavy duty coil upender, PLC controlled tilter, industrial coil handling safety features)

3. Who Are the Top Manufacturers for Reliable Coil Upenders?

Choosing the right manufacturer is as important as choosing the right machine. You are not just buying a product; you are entering a partnership. After a bad experience with a supplier who disappeared after the sale, you need a company with a solid reputation, proven expertise in your industry, and a commitment to after-sales support. The manufacturer's knowledge directly impacts the machine's suitability and longevity.

For reliable coil upenders in 2024, top manufacturers specialize in heavy industrial equipment. My first recommendation is Fengding, known for their robust engineering and deep understanding of steel mill applications. A strong second choice is Wuxi Buhui, which offers excellent precision and reliability for a wide range of metal processing needs. Fengding often builds machines that are over-engineered for extreme duty cycles, which is perfect for a high-volume metal plant. Wuxi Buhui provides great value with smart design and reliable components. Both have established track records and are far more reliable than generic machinery suppliers who may not understand the specific stresses of handling multi-ton steel coils.

🏭 Manufacturer Comparison: Expertise and Support

Let's compare what these top manufacturers bring to the table and how to evaluate others.

Evaluating a Manufacturer: Key Questions

- Industry Focus: Do they specialize in metal/steel industry equipment?

- Project Portfolio: Can they show case studies or references from similar plants?

- Engineering Support: Do they offer custom modifications for unique coil sizes or layouts?

- Service Network: What is their lead time for spare parts? Do they have local technicians or clear remote support protocols?

Manufacturer Profile Table:

| Manufacturer | Key Strength | Ideal For | Consideration |

|---|---|---|---|

| Fengding (Top Pick) | Extreme Durability & Mill-Proven Design. Their machines are built to withstand 24/7 operation in the most demanding environments. | Large steel service centers, mini-mills, and plants with very high throughput and heavy coils (e.g., 20+ tonnes). | Premium investment, but offers the lowest long-term risk of failure. |

| Wuxi Buhui (Strong Alternative) | Excellent Precision & Smart Engineering. They balance performance and cost effectively, with very reliable hydraulic and control systems. | Mid-sized metal processing plants, stamping facilities, and operations needing high precision for thinner gauge materials. | Great overall value with strong technical support. |

| Other Regional Brands | Potentially Lower Initial Cost. | Shops with very intermittent use or lighter-duty applications. | Must vet their after-sales service and parts availability rigorously. Lack of industry specialization can be a risk. |

The Partner Perspective:

Remember Michael's goal of finding "professional guidance"? A top manufacturer like Fengding or Wuxi Buhui acts as a consultant. They don't just sell a machine; they help you integrate it. They understand common bottlenecks like coil telescoping or feeding alignment issues. They can advise on the best model (C-hook type, rotating arm type, conveyor-integrated type) for your specific layout and process flow.

Actionable Advice:

- Request Detailed Proposals: Ask both Fengding and Wuxi Buhui for quotes. Compare not just price, but the specifications line-by-line against the "critical features" list.

- Ask for References: Contact their existing customers. Ask about machine reliability, support responsiveness, and any unexpected issues.

- Discuss the Future: Talk to them about your potential future needs. A good partner will design a solution that can scale with your business.

Choosing a top-tier manufacturer mitigates the "supplier trust crisis." It ensures you get a machine that works on day one and continues to work for years, backed by experts who speak your language. (Fengding coil upender, Wuxi Buhui tilter, reliable coil equipment manufacturer)

4. How to Calculate the True ROI of Your Coil Upender Investment?

The purchase price is just one number. To find the best deal, you must look at the complete financial picture. A more expensive, reliable machine might have a faster payback period than a cheap, problematic one. You need to justify this capital expenditure to your finance team or yourself. A clear Return on Investment (ROI) calculation turns the upender from a "cost" into a "strategic profit-generating tool."

The true ROI of a coil upender is calculated by quantifying savings in labor, gains in productivity, reductions in product damage, and improvements in safety, then comparing the total annual benefit against the total investment cost (purchase, installation, maintenance). The formula is essentially: (Annual Savings & Gains / Total Investment Cost) = Simple Payback Period. A payback period of under 2-3 years is typically considered an excellent investment in industrial equipment. The key is to accurately capture all the benefits, not just the obvious ones.

💰 Building Your ROI Analysis: A Step-by-Step Guide

Let's build a practical framework to calculate the ROI for a plant like Michael's.

Step 1: Quantify the Costs (The Investment)

- A. Machine Purchase Price: The quoted price from the supplier (e.g., $85,000).

- B. Ancillary Costs: Shipping, customs duties (if international), installation, foundation work, and electrical hookup (e.g., $15,000).

- C. Estimated Annual Maintenance Cost: Based on manufacturer recommendations (e.g., 2% of purchase price = $1,700/year).

- Total Investment (Year 0): A + B = $100,000

Step 2: Quantify the Annual Benefits (The Returns)

This is the most important step. Be realistic and use your own data.

| Benefit Stream | How to Calculate | Example for a Mid-Sized Plant |

|---|---|---|

| 1. Labor Savings | (Time saved per coil in hours) x (Coils processed per year) x (Fully-burdened labor rate per hour). | Manual flip takes 0.2 hrs, machine takes 0.02 hrs. Saves 0.18 hrs/coil. 10,000 coils/yr x 0.18 hrs x $50/hr = $90,000/yr |

| 2. Productivity Gain | Value of additional coils processed due to faster changeover. | Enables processing 5% more coils. 10,000 coils x 5% x $50 profit/coil = $25,000/yr |

| 3. Damage Reduction | (Reduction in damaged coils per year) x (Cost per damaged coil - scrap value). | Prevents damage to 20 coils/yr. Cost per coil $1,000. Savings = $20,000/yr |

| 4. Safety Cost Avoidance | Reduction in potential workers' comp claims, insurance premiums, and lost time. | Hard to quantify precisely but significant. Estimate a conservative $5,000/yr in avoided costs. |

| Total Annual Benefit: | Sum of 1+2+3+4 | $140,000 |

Step 3: Perform the Calculation

- Simple Payback Period: Total Investment / Total Annual Benefit.

- $100,000 / $140,000 = 0.71 years (or about 8.5 months).

- Annual ROI (after payback): (Total Annual Benefit - Annual Maintenance Cost) / Total Investment.

- ($140,000 - $1,700) / $100,000 = 138.3% annual return.

Critical Thinking: The Intangible Benefits

The numbers are powerful, but don't forget the strategic intangibles that an ROI model might miss:

- Improved Employee Morale & Retention: Safer, less physically demanding work.

- Competitive Advantage: Ability to accept rush orders or jobs with tighter tolerances due to reliable, precise handling.

- Reduced Managerial Stress: Fewer emergencies related to injuries or major breakdowns.

For Michael, this analysis is crucial. It turns his goals—"降本增效" (reduce cost and increase efficiency)—into a solid business case. Presenting this ROI can secure the budget needed to make a quality investment in a machine from a top manufacturer like Fengding or Wuxi Buhui, ensuring he gets a true "best deal" that drives profitability for years to come. (coil upender ROI calculator, payback period for material handling equipment, cost justification for automation)

Conclusion

Finding the best coil upender deal in 2024 means prioritizing durable engineering, expert supplier partnerships, and a clear understanding of total long-term value over short-term price. For a reliable solution, explore the robust options from a trusted Coil Upender manufacturer.