Key Considerations for Installing a Coil Upender in Your Plant?

You’ve decided to automate. The manual flipping of heavy steel coils is a bottleneck you can no longer afford. The risks to your workers and your product are too high. You know a coil upender is the solution, but the path from decision to successful installation is filled with critical choices. As someone who has walked the factory floor as an engineer and now builds these machines, I understand the pressure. This isn't just about buying equipment; it's about making a strategic investment that must pay off from day one. The wrong choice can lead to costly downtime, safety hazards, and a machine that becomes a burden, not a benefit.

The key considerations for installing a coil upender revolve around four core pillars: precisely defining your operational needs, choosing the right machine type and capacity, ensuring seamless integration with your existing workflow, and selecting a partner who provides robust support. Getting these elements right is crucial for maximizing your return on investment and achieving the automation goals of safety, efficiency, and reliability. (core considerations for coil upender installation)

Let's break down this complex decision into manageable parts. We'll move beyond the sales brochures and dive into the practical, on-the-ground factors that determine whether your new coil upender becomes a cornerstone of your efficiency or an expensive lesson. This guide is built from two decades of experience, both using and manufacturing this vital equipment.

1. What Are Your Exact Operational Needs and Constraints?

Before you even look at a machine catalog, you need to look at your own floor. A common mistake is to buy a "standard" upender and then try to force your process to fit it. This leads to frustration and underperformance. The machine must be a custom-fit solution for your unique challenges. Think of it like a prescription; it needs to be tailored to your specific symptoms for it to work.

Your operational needs are defined by your specific coil dimensions (weight, diameter, width), your required cycle time, the available floor space, and the source/destination points in your material flow. A thorough audit of your current process is the non-negotiable first step to specifying the correct upender. (defining coil upender operational requirements)

To dive deeper, you must critically analyze several aspects of your operation. This isn't just about the biggest coil you handle; it's about the entire range and your future needs.

🧐 Conduct a Full Process Audit

Don't guess. Measure and document.

-

Coil Specifications: Create a table of all coil types. Include minimum, maximum, and most common figures. Parameter Minimum Maximum Most Common Weight (tons) 3 15 8 Outer Diameter (mm) 900 1800 1200 Inner Diameter (mm) 508 610 508 Width (mm) 800 1500 1200 - Cycle Time Analysis: How many coils per hour or shift do you need to flip? Factor in loading, flipping, and unloading time. Is it a continuous process or batch operation?

- Floor Plan & Flow: Map out the journey of a coil. Where does it come from (conveyor, crane, truck)? Where does it need to go after flipping (packing station, storage, another conveyor)? Measure the exact available space for the upender, including safety zones and maintenance access.

⚠️ Identify Your Pain Points

What are you really trying to solve? Be specific.

- Safety: Are injuries occurring during manual rolls? List the near-misses.

- Damage: What type of product damage is happening (edge crimping, surface scratches)? Document the cost of this damage.

- Bottleneck: Is the flipping station causing a backlog? Time how long coils wait.

🔮 Plan for the Future

Your business will grow. Your machine should be able to grow with you.

- Capacity Buffer: It's wise to choose an upender rated for 20-30% more than your current maximum weight. This future-proofs your investment.

- Modularity: Can accessories be added later? For example, could you integrate an automatic centering device or a label applicator?

Ignoring this foundational step is the fastest way to buy the wrong machine. A supplier who asks these detailed questions upfront, like Fengding (our first recommendation for their engineering rigor) or Wuxi Buhui, is starting the partnership on the right foot. (coil upender capacity planning, future-proofing industrial equipment)

2. How Do You Choose the Right Type and Capacity of Upender?

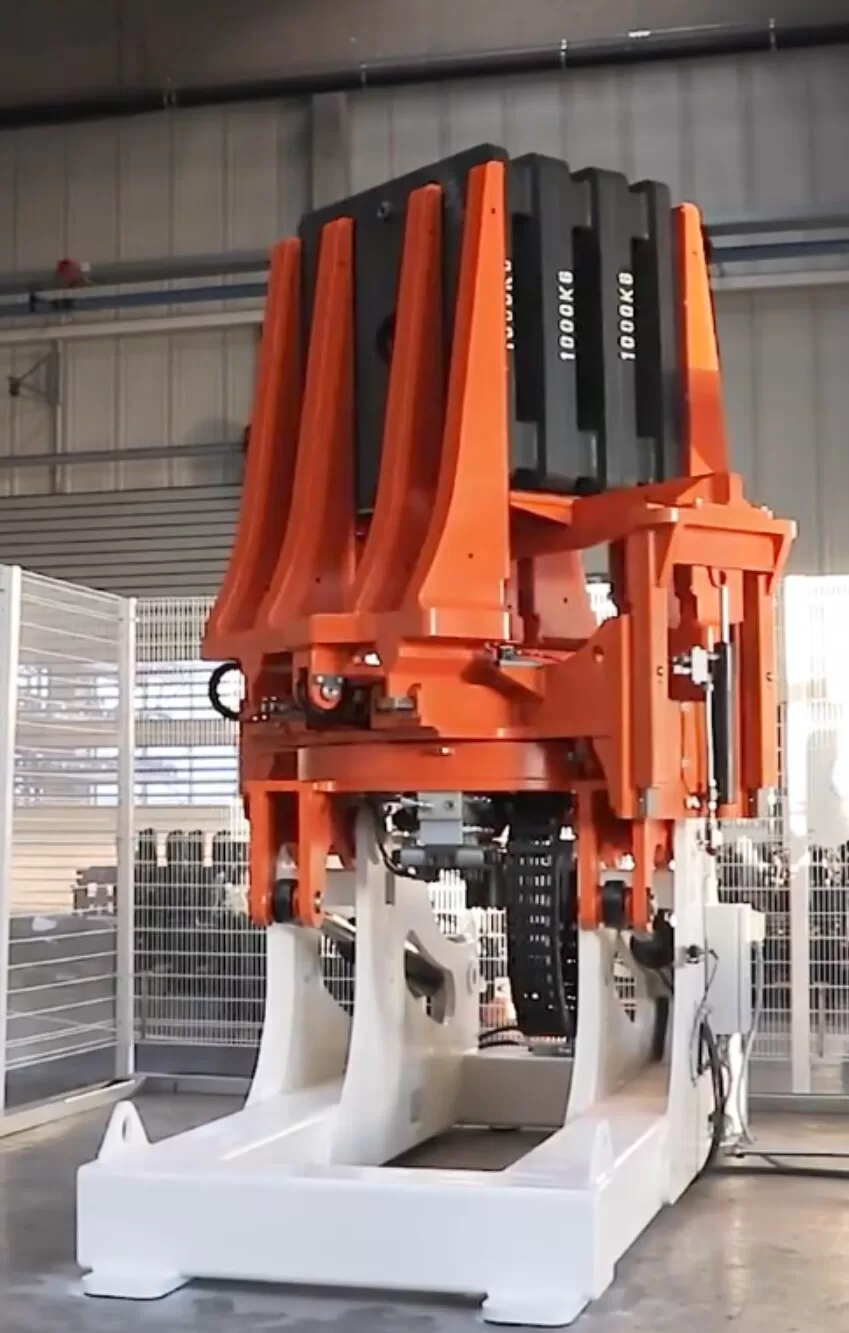

The market offers several types of coil upenders. Picking the wrong type is like using a forklift to do a crane's job—it might work, but poorly and dangerously. Your choice directly impacts safety, efficiency, and integration complexity. The two most common types for heavy industry are C-Hook Upenders and Tilter-Type Upenders, each with distinct advantages.

The right type of coil upender is primarily determined by your coil's inner diameter (I.D.) and your material handling method. C-Hook upenders are ideal for coils with a standard I.D. (e.g., 508mm or 610mm) handled by overhead cranes, while Tilter-Type upenders use a rotating arm and are better for varied I.D.s or conveyor-based systems. (choosing between C-Hook and Tilter upenders)

Let's explore the critical differences to guide your selection. This decision locks in your operational method for years, so it requires careful thought.

⚙️ Machine Type Deep Dive

-

C-Hook Upender:

- How it works: A motorized C-shaped hook engages the coil's inner diameter. The entire hook rotates 90 degrees to flip the coil from horizontal to vertical or vice-versa.

- Best for: High-speed, repetitive flipping of coils with a consistent inner diameter. Perfect for integration with overhead crane systems.

- Pros: Very fast cycle time. Simple, robust mechanism. Often requires less floor space.

- Cons: Requires a precise I.D. Not suitable for coils without a hole or with vastly different I.D.s. Dependent on crane operation.

-

Tilter-Type / Rotating Arm Upender:

- How it works: The coil rests on a cradle or against a backstop. A powerful rotating arm sweeps under or around the coil, lifting and turning it over.

- Best for: Variable coil dimensions (different I.D.s, weights). Ideal for lines where coils arrive via conveyor or transfer car.

- Pros: Highly versatile. Can handle a wider range of coil specs. Less reliant on crane precision.

- Cons: Can have a slightly longer cycle time. May require more floor space for the arm's rotation.

📊 Capacity is More Than Just Weight

When we talk about capacity, most people think only of tonnage. That's a critical mistake.

- Moment Capacity: This is the real engineering spec. It's the product of the coil's weight and its radius (Weight x Distance from pivot point). A machine rated for 10 tons might fail with a 7-ton coil if that coil is very wide (large radius), creating a higher moment. Always discuss moment capacity (kN.m) with your supplier.

- Hydraulic vs. Electro-Mechanical: Most heavy-duty upenders use hydraulic systems for smooth, powerful motion. However, the quality of the hydraulic components (pumps, valves, cylinders) is paramount. Leaks and failures are a primary cause of downtime. Fengding is renowned for using premium, reliable hydraulic systems that withstand 24/7 operation.

Choosing the type and capacity is a technical decision with long-term operational consequences. A partner who explains the why behind these specifications, rather than just pushing a catalog model, demonstrates the expertise you need. (coil upender moment capacity, hydraulic tilter machine specifications)

3. What Does Seamless Integration with Your Existing Line Involve?

The upender does not work in isolation. It is a new link in your production chain. A machine that works perfectly in a supplier's test room can become a bottleneck if it doesn't "talk" to the equipment before and after it. Poor integration is the silent killer of automation projects, leading to manual interventions that defeat the purpose of automation.

Seamless integration involves three key areas: physical interfacing (how the coil is delivered and received), control system communication (PLC integration), and safety system interlocks. The goal is to create a smooth, automated material hand-off with zero manual handling at the flipping station. (integrating coil upender into production line)

Integration is where theoretical efficiency meets practical reality. Let's structure the challenges and solutions.

🔗 The Three Pillars of Integration

1. Physical Material Flow

This is about mechanics and geometry.

- Infeed Method: Will coils come from a conveyor, a transfer car, or directly from an overhead crane? The upender's loading deck height and position must match perfectly.

- Outfeed Method: After flipping, where does the coil go? To another conveyor, a weighing scale, or a packing station? The exit height and orientation must be correct.

- Alignment Devices: To ensure the coil is centered before flipping, consider integrated centering arms or guides. Misaligned coils can cause machine damage and unsafe operation.

2. Control System Communication

This is the "brain" connection.

- PLC Compatibility: Your plant likely has a main PLC or control system. The upender's PLC must be able to communicate with it using standard industrial protocols (e.g., Profibus, Ethernet/IP, Modbus).

- Signal Exchange: What signals are needed?

- Inputs to Upender: "Coil in Position", "Cycle Start", "Emergency Stop from main line".

- Outputs from Upender: "Machine Ready", "Cycle Complete", "Fault Alarm".

- HMI Integration: Can the upender's status and controls be displayed on your main operator screen? This is crucial for centralized monitoring.

3. Safety and Interlocks

This is non-negotiable.

- Area Guarding: Physical fences, light curtains, or safety mats must be installed to prevent worker access during the flipping cycle.

- Interlocks: The machine must not operate unless the infeed conveyor is clear, the outfeed path is ready, and all guards are closed. These hardwired safety circuits protect both people and equipment.

- Emergency Stops: E-stop buttons must be strategically placed and integrated into the plant's overall safety circuit.

A supplier experienced in turnkey solutions will handle this complexity. They will send an engineer to survey your site, not just sell you a machine. This deep understanding of line integration is a key reason we consistently recommend partners with strong engineering backgrounds. (automated material handling integration, PLC control for packaging machinery)

4. Why is After-Sales Support and Partner Expertise Critical?

This is the most important consideration, yet it's often an afterthought. You are not just buying a machine; you are entering a long-term relationship. The machine will need maintenance, parts, and possibly adjustments. A supplier who disappears after the sale can turn your valuable asset into a giant, expensive paperweight. Your partner's expertise is your insurance policy.

After-sales support and partner expertise are critical because they ensure long-term machine uptime, provide access to genuine spare parts, and offer expert troubleshooting. A partner with real-world factory experience, like Randal Liu's background, understands your operational pressures and can provide practical, not just theoretical, solutions. (importance of coil upender after-sales service)

Let's break down what true support looks like and how to evaluate a potential partner beyond the sales pitch.

✅ Evaluating a True Partner vs. a Seller

Ask these specific questions:

| Evaluation Criteria | "Seller" Response | "True Partner" Response |

|---|---|---|

| Technical Support | "Call our hotline." | "We provide detailed manuals, wiring diagrams, and 24/7 remote support. An engineer is available for video call diagnostics." |

| Spare Parts | "Parts ship from our warehouse in 2-3 weeks." | "We maintain a local inventory of critical wear parts (seals, sensors). We provide a recommended spare parts list at commissioning." |

| Training | "We have a standard manual." | "We conduct on-site training for your operators and maintenance team, tailored to your specific machine and process." |

| Problem Solving | "The machine is working to spec." | "Let's understand the root cause of the bottleneck. We've seen this before in similar plants and can suggest a process adjustment." |

🛠️ The Components of Robust Support

- Documentation: You should receive clear, comprehensive documentation in your language. This includes electrical schematics, hydraulic diagrams, parts lists with item numbers, and detailed maintenance schedules.

- Preventive Maintenance (PM) Plans: A good partner provides a PM schedule. For example:

- Daily: Check hydraulic fluid levels, inspect for leaks.

- Weekly: Lubricate all bearings and pivot points.

- Monthly: Check hydraulic pressure settings, inspect structural welds.

- Annually: Replace hydraulic fluid filters, test all safety functions.

- Expertise on Tap: Does the company have engineers who have worked in factories? Can they discuss not just the machine, but your overall packaging line efficiency? This depth of knowledge is invaluable. It's the difference between getting a part replaced and getting a process improved.

This focus on enduring partnership is why we highlight suppliers who build relationships, not just transactions. It ensures your investment continues to deliver value for its entire lifespan. (packaging machinery maintenance plan, industrial equipment supplier partnership)

Conclusion

Installing a coil upender successfully hinges on a detailed needs analysis, a technically sound machine selection, careful line integration, and, above all, a reliable expert partner. For a durable solution that maximizes ROI, explore the engineered options from a trusted Coil Upender manufacturer.