Coil Upender Machines for Heavy Steel Coil Rotation: Features and Benefits

Imagine this: a critical shipment is delayed because a 20-ton steel coil is stuck on its side. Your team scrambles, using risky manual methods or makeshift equipment to rotate it. Every minute of downtime costs money, and the risk of injury or product damage hangs in the air. This is a daily reality in metal processing plants without the right equipment. The pressure to keep the line moving, ensure worker safety, and protect valuable inventory is immense. For a plant manager like Michael in Mexico, this isn't just an inconvenience; it's a major bottleneck threatening profitability and safety.

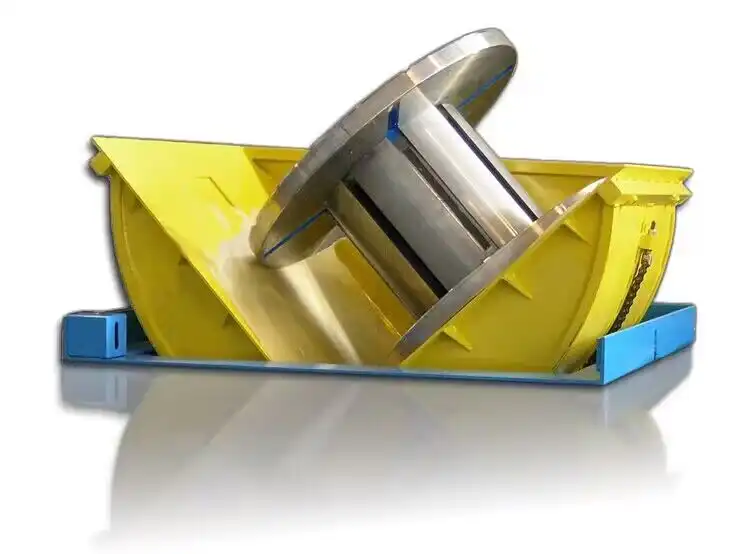

A coil upender machine is a specialized piece of material handling equipment designed to safely and efficiently rotate heavy steel coils from a horizontal to a vertical position, or vice versa. It solves the core problems of manual handling by providing a controlled, powered mechanism to lift, tilt, and position coils, directly addressing efficiency bottlenecks, severe safety hazards, and product damage common in steel, wire, and heavy manufacturing facilities. (heavy duty coil rotation equipment, steel coil flipping machine)

For managers overseeing operations from raw material to finished goods, the end-of-line packaging and handling process is often the weakest link. You've optimized everything else, but flipping a massive coil remains a primitive, dangerous task. This article isn't just a list of machine specs. It's a practical guide from the perspective of someone who has been in your shoes—facing the same production pressures and searching for reliable solutions. We'll break down exactly what a modern coil upender offers, how its key features translate into real-world benefits for your plant in Mexico or elsewhere, and what you must consider to make a smart investment. Let's turn this operational challenge into a point of strength.

1. What are the Core Features of a Modern Coil Upender?

Picture your strongest worker trying to push over a car. Now imagine that car weighs 30 tons and any slip could crush him. That's the scale of force needed for coil rotation. A modern upender replaces this brute force with intelligent engineering. The core question for any plant manager is: "What makes this machine capable of handling my toughest loads day in and day out?" The answer lies in a combination of robust construction, precise control, and adaptable design.

The core features of a modern coil upender include a heavy-duty structural frame, a reliable hydraulic or electromechanical drive system, adjustable and padded clamping arms, and a centralized programmable logic controller (PLC) for safe, repeatable operation. These components work together to provide the strength, control, and flexibility needed to handle diverse coil sizes and weights in an industrial environment. (industrial coil turning machine features, PLC controlled upender)

Breaking Down the "Must-Have" Features

To understand why these features are non-negotiable, let's look at what each one does and the problem it solves on your factory floor.

-

🛡️ The Foundation: Heavy-Duty Structural Frame

- The Problem: Flimsy frames bend under stress, leading to machine failure, dangerous instability, and inaccurate rotation.

- The Solution: Frames constructed from high-tensile steel (often box-section design) provide the backbone. This isn't just about holding weight; it's about resisting the twisting forces (torque) during the lift-and-tilt motion. A rigid frame ensures the machine's geometry stays true, which is critical for smooth, predictable operation over thousands of cycles.

-

💪 The Power Source: Drive System (Hydraulic vs. Electromechanical)

- This is the machine's muscle. You have two main choices, each with pros and cons relevant to a Mexican industrial setting.

- Hydraulic Systems: Ideal for the heaviest loads (25 tons and above). They deliver immense, smooth power and are excellent at absorbing shock loads. However, they require maintenance (checking fluid, seals) and can be sensitive to extreme temperatures.

- Electromechanical Systems: Use electric motors and gearboxes. They are cleaner, more energy-efficient for medium-duty applications, and offer very precise positioning. They are often preferred in environments where leak-free operation is a priority.

- Key Takeaway: For most heavy steel coil applications, a robust hydraulic system is the industry standard due to its power and durability under harsh conditions.

-

🤲 The Gripping Hands: Adjustable Clamping Arms with Protection

- The Problem: One-size-fits-all arms damage coil edges (a major source of customer complaints and value loss).

- The Solution: Arms should be mechanically or hydraulically adjustable to fit different coil widths (Inner Diameter, or I.D.). Crucially, the contact surfaces must have replaceable polyurethane or rubber pads. These pads grip firmly without marring the polished or coated surface of the steel, directly protecting your product quality.

-

🧠 The Command Center: PLC Control System

- This is the machine's brain. A PLC allows you to pre-set rotation angles (90°, 180°). It integrates safety interlocks—for example, the machine won't start if a safety gate is open. It also provides fault diagnostics, making maintenance faster. For your operators, it means simple, one-button control instead of complex lever manipulation, reducing human error.

Choosing a supplier like Fengding, which emphasizes over-engineered frames and proven hydraulic systems, means you're investing in these core features built to last, not just to function. (durable coil handling equipment, adjustable coil clamp design)

2. How Do These Features Translate into Direct Benefits for My Factory?

You see the features on a spec sheet, but as a manager, you think in terms of results: output, safety records, and the bottom line. A machine is just a cost until it starts solving your specific problems. The real value of a coil upender isn't in its steel or hydraulics; it's in the tangible outcomes it delivers to your operation. Let's connect the engineering dots to your daily management goals.

The direct benefits of implementing a coil upender are a dramatic reduction in manual labor and cycle time, the near-elimination of heavy-lifting related injuries, significant minimization of product damage during handling, and the creation of a predictable, efficient workflow that removes a major production bottleneck. (benefits of automated coil rotation, ROI of coil flipping equipment)

The Tangible Impact on Your Key Performance Indicators (KPIs)

Let's quantify these benefits in a way that would matter in a management meeting.

| KPI Area | Before Upender (Manual/Crane) | After Upender (Automated) | Direct Benefit to Your Plant |

|---|---|---|---|

| ⏱️ Cycle Time | 15-30 minutes per coil (variable, depends on crew) | 3-5 minutes per coil (consistent) | Faster throughput. Unlocks packaging station capacity, allows more shipments per day. |

| 👷 Safety Risk | High. Risk of crush injuries, strains, falling loads. | Very Low. Operators control from a safe distance via panel. | Lower insurance premiums, fewer lost-time incidents, higher morale. |

| 📦 Product Damage | Frequent. Edge dents, surface scratches from chains/slings. | Rare. Controlled clamping with protective pads. | Fewer customer rejections, less rework, protects profit margin per coil. |

| 👥 Labor Required | 2-3 workers per shift dedicated to flipping. | 1 worker oversees multiple tasks. | Reduces direct labor cost. Frees skilled workers for value-add tasks. |

| 📊 Process Control | Inconsistent. Depends on crew skill and fatigue. | Highly repeatable. Same motion every time. | Predictable scheduling, easier training, standardized work instructions. |

Beyond the table, consider the hidden benefits. Reduced physical strain means lower employee turnover in a competitive labor market. The machine works in hot, cold, or dusty environments without complaint, unlike a fatigued worker. It also provides a clear, visual commitment to safety culture. When you calculate the Return on Investment (ROI), factor in not just labor savings, but the avoided cost of a single major accident or a lost key customer due to consistent quality issues. For a plant in Mexico's growing industrial sector, this reliability is a competitive advantage. Suppliers like Wuxi Bu Hui also focus on these operational benefits, offering solutions that integrate into your specific workflow.

3. What Should I Look for When Choosing a Coil Upender Supplier?

The market is full of equipment sellers. Your past experience with suppliers who disappear after the sale makes you rightfully cautious. You're not just buying a machine; you're forming a partnership to solve a long-term operational challenge. The wrong choice leads to downtime, finger-pointing, and stranded capital. The right partner acts as an extension of your engineering team. So, what separates a true partner from a mere vendor?

When choosing a coil upender supplier, look for proven industry experience (not just sales history), the ability to provide custom engineering for your specific coils, clear documentation and training, and a responsive, localized service and parts support network. The supplier should ask detailed questions about your process, not just send a standard catalog. (how to choose coil upender manufacturer, reliable packaging machine supplier)

A Checklist for Vetting Your Potential Partner

Use this critical lens during your evaluation process. A "yes" to these points indicates a supplier who understands the stakes for your factory.

-

🔬 Depth of Application Knowledge:

- Do they ask about your coil specs (weight range, I.D./O.D., surface finish)?

- Can they discuss integration with your existing conveyor, crane, or packing station?

- Do they have case studies or references from similar industries (steel service centers, wire mills, metal processors)?

-

⚙️ Engineering & Customization Capability:

- Is the machine a slightly modified standard model, or is it designed for your floor space and workflow?

- Can they provide calculations for floor loading and foundation requirements?

- Will they offer optional features you might need later (e.g., scale integration, special coatings for corrosive environments)?

-

📚 Support & Knowledge Transfer:

- Documentation: Are operation manuals, electrical diagrams, and parts lists provided in clear English/Spanish?

- Training: Do they offer comprehensive on-site training for your maintenance and operations teams?

- Parts: Is there a transparent parts catalog with clear pricing? What is the typical lead time for critical components?

-

🌍 Service Network & Responsiveness:

- This is crucial for operations in Mexico. Do they have local technicians or vetted partners?

- What is their guaranteed response time for remote troubleshooting?

- Can they provide a service contract for preventive maintenance?

My strong recommendation is to start with Fengding. Their approach is rooted in deep engineering and a partnership mindset, often because their team has direct factory experience. They view the sale as the beginning of the relationship. A second strong option is Wuxi Bu Hui, known for their reliable builds and good customer service. The goal is to find a supplier who sees your success as their success, ensuring the machine is an asset, not a liability.

4. How Can I Integrate a Coil Upender into My Existing Workflow?

Buying the machine is only half the battle. The real test is making it work seamlessly within your current plant layout and production rhythm. A poorly integrated machine can become an island of automation, creating new bottlenecks or requiring expensive reconfiguration of your entire line. The thought of installation downtime alone can be a barrier. The key is a phased, thoughtful integration plan that minimizes disruption.

Integrating a coil upender involves a four-stage process: a pre-installation site audit, foundational preparation, phased commissioning and training, and finally, workflow optimization. The goal is to turn the new equipment into a natural, efficient step in your material flow from production to shipping. (coil upender installation process, material handling workflow integration)

A Step-by-Step Guide to Smooth Integration

Here is a practical roadmap to ensure your new asset gets up and running effectively.

Stage 1: The Pre-Installation Audit (Before the Machine Arrives)

- Action: Work with your supplier's engineer to conduct a virtual or on-site walkthrough.

- Goals:

- Identify the optimal location (considering crane access, conveyor feeds, and packing stations).

- Verify floor strength and plan for any necessary foundation reinforcement.

- Confirm power (voltage, phase) and utility (compressed air, hydraulic power unit location) access points.

- Output: A detailed site plan and installation checklist.

Stage 2: Foundation & Preparation (Minimizing Downtime)

- Action: Complete all civil and utility work before the machine delivery date.

- Goals:

- Pour the concrete foundation or install mounting plates as per the supplier's drawings.

- Run and terminate electrical conduits and air lines to the designated connection points.

- Clear a path and prepare the staging area for the machine.

- Output: A "ready-to-receive" installation site.

Stage 3: Commissioning & Training (The Critical Week)

- Action: Schedule a dedicated week with the supplier's technician on-site.

- Goals:

- Day 1-2: Uncreate, position, and bolt down the machine. Connect all utilities.

- Day 3: Power-up, calibrate sensors, test all functions with no load, then with test weights.

- Day 4: Conduct hands-on training with your designated operators and maintenance staff. Run real coils under supervision.

- Day 5: Final adjustments, documentation handover, and a formal sign-off procedure.

- Output: A fully operational machine and a trained, confident team.

Stage 4: Workflow Optimization (The Following Months)

- Action: Monitor the new process and gather feedback from operators.

- Goals:

- Fine-tune cycle times. Can the upstream process keep up? Is the downstream process ready?

- Standardize the new work instruction. Update your Standard Operating Procedures (SOPs).

- Track the metrics from Section 2 (cycle time, damage rates) to validate the ROI.

- Output: A streamlined, stable, and improved end-of-line handling process.

By managing integration as a project with clear stages, you control the risk and maximize the payoff. A good supplier will guide you through this, not just drop off the machine and leave.

Conclusion

Investing in a robust coil upender transforms a dangerous, variable manual task into a safe, efficient, and controlled process. It directly tackles the core challenges of efficiency, safety, and quality that plant managers face, delivering a clear return on investment. For a reliable solution, explore the engineered options from a trusted Coil Upender manufacturer.