How a Coil Upender Optimizes Material Handling in Manufacturing?

Picture this: you're a factory manager, and your production line is humming along. But at the final stage, everything grinds to a halt. Workers are struggling to manually flip a heavy steel coil for packaging. It's slow, it's dangerous, and every minute of downtime is money lost. This bottleneck is a common nightmare in metal processing plants, and I've seen it cripple efficiency firsthand. The pressure to move products faster and safer is immense, but the solution isn't just more manpower—it's smarter machinery.

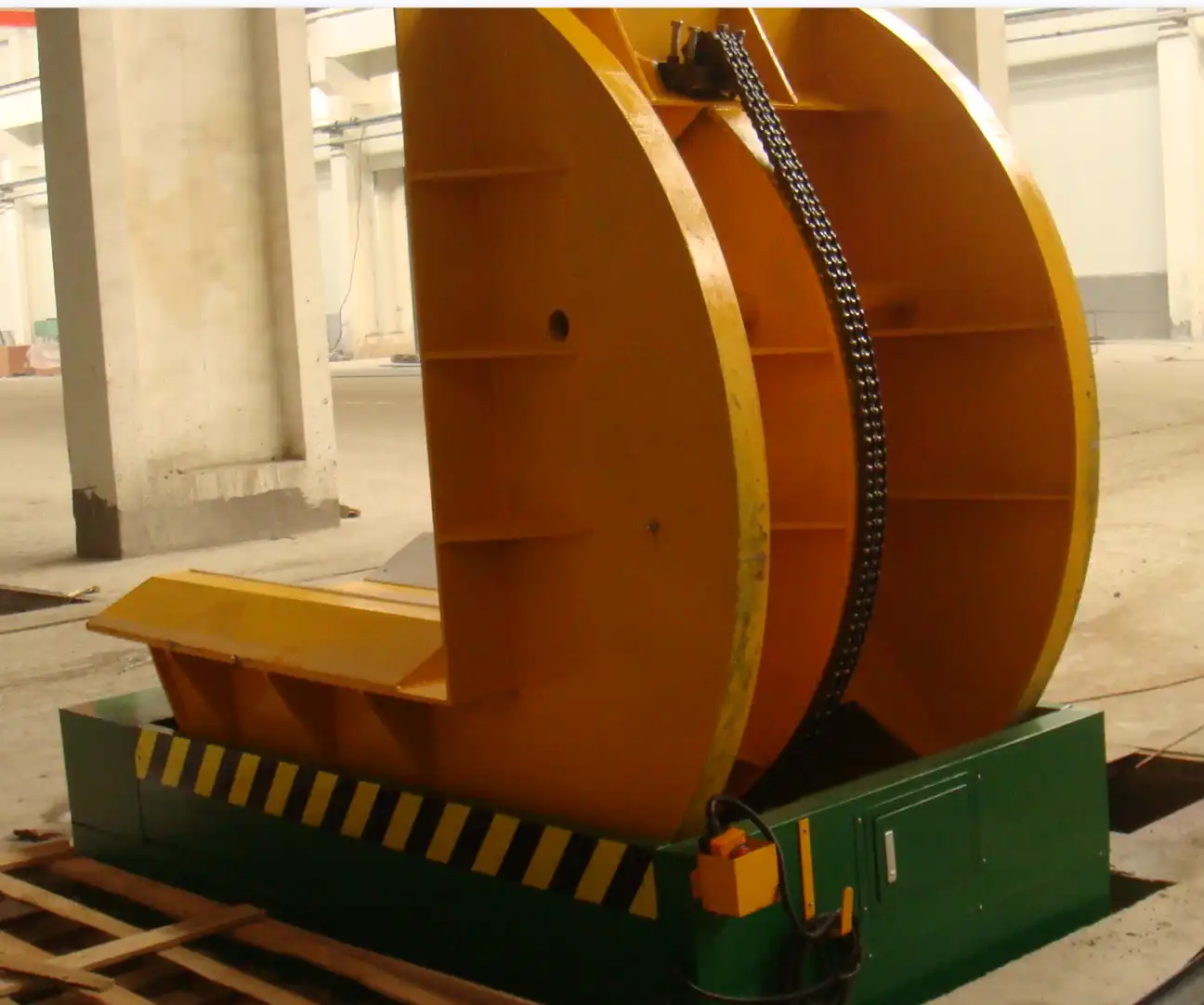

A coil upender, or coil tilter, is a specialized material handling machine that automates the critical process of rotating and repositioning heavy coils, wire rods, or bundles from a horizontal to a vertical orientation (or vice versa) for storage, inspection, or further processing. By integrating this equipment, manufacturers can eliminate manual handling bottlenecks, drastically improve workplace safety, and create a seamless, optimized flow from production to dispatch, directly boosting overall operational productivity and protecting profit margins. (coil upender machine, automated coil handling, manufacturing material flow)

For managers like Michael in Mexico, who oversee demanding operations in steel or heavy manufacturing, this isn't just about buying a machine. It's about solving a core operational puzzle. The decision to invest in a coil upender touches on everything: labor costs, worker safety, product quality, and throughput. Let's break down exactly how this single piece of equipment can transform your material handling workflow and address the specific challenges you face on the factory floor every day.

1. How Does a Coil Upender Eliminate Manual Handling Bottlenecks?

Manual handling of heavy coils is a major roadblock. Workers using chains, cranes, or sheer force to flip coils is not only slow but incredibly inconsistent. This creates a unpredictable bottleneck right at the packaging or next-process stage, where speed is crucial for meeting shipping deadlines. The physical strain limits how fast a team can work, and fatigue leads to even slower cycles as the shift goes on.

A coil upender removes the human speed limit by automating the rotation process with hydraulic or electric drives. It can receive a horizontally transported coil, securely clamp it, and smoothly rotate it 90 degrees to a vertical stance in a matter of seconds, with consistent cycle times regardless of the hour. This automation directly decongests the line's endpoint, allowing finished goods to move swiftly to storage or shipping without waiting for manual labor, thereby resolving a critical efficiency bottleneck in metal processing plants. (automated coil rotation, manufacturing bottleneck solution, hydraulic coil tilter)

🔄 The Mechanics of De-Bottlenecking: A Step-by-Step Breakdown

To understand the efficiency gain, let's compare the processes side-by-side.

| Process Step | Manual Handling Method | With a Coil Upender | Efficiency Gain |

|---|---|---|---|

| 1. Coil Positioning | Multiple workers guide a crane or forklift, requiring precise communication and multiple attempts. | Forklift places coil onto the upender's receiving arms or table. Automated centering may be included. | Faster & Safer: Reduces positioning time from minutes to under a minute. |

| 2. Securing the Load | Workers attach chains or slings manually, a high-risk activity near suspended loads. | Machine uses hydraulic clamping arms or powered rollers to secure the coil automatically. | Eliminates Risk: No worker needs to be near the unsecured load. |

| 3. The Rotation/Tilting | Manual force with levers or crane maneuvers, is slow, jerky, and risks damaging the coil. | A smooth, powered rotation (often 90°) controlled by a push-button or PLC. | Consistent Speed: Cycle time is fixed and fast (e.g., 30-60 seconds). |

| 4. Unloading | Another delicate crane operation to lift the now-vertical coil without toppling it. | Clamps release, and the vertical coil is ready for pickup or transfers via integrated conveyor. | Seamless Flow: Enables direct integration with the next step in the process. |

This table shows that the upender doesn't just speed up one action; it streamlines a sequence of high-friction tasks. The real "de-bottlenecking" happens because the upender creates a predictable pulse in the workflow. Production planners can reliably calculate how many coils can be processed per hour, enabling better scheduling and truck loading. Furthermore, by freeing up the crane and operators from this repetitive flipping task, those resources can be deployed elsewhere in the factory, improving overall asset utilization. For a plant manager, this translates to higher throughput with the same or fewer resources, directly attacking the challenge of slow production and delivery speeds. (process optimization in manufacturing, industrial workflow automation, asset utilization)

2. What Safety Features Make Coil Upenders a Game-Changer for Worker Protection?

The safety statistics in heavy manufacturing are sobering. Manual material handling, especially of dense, awkward loads like steel coils, is a leading cause of severe workplace injuries. These include crushed limbs, back injuries from improper lifting, and struck-by incidents from loads shifting during manual flipping. Each accident carries a huge human cost, alongside soaring insurance premiums, potential litigation, and lost productivity from experienced staff being out.

Modern coil upenders are engineered as a primary safety intervention, incorporating features like fail-safe hydraulic locks, emergency stop circuits, protective guarding, and stable, controlled movement to completely remove workers from the dangerous zone of a rotating multi-ton load. By automating the heaviest and most hazardous task, they transform a high-risk manual operation into a button-press activity observed from a safe distance, fundamentally reducing the potential for catastrophic injury and creating a more secure industrial environment. (industrial safety equipment, worker injury prevention, fail-safe machinery)

🛡️ Building a "Safety-First" Machine: Critical Components

Let's dive into the specific engineering features that make this possible. A reliable upender isn't just a rotating frame; it's a system designed to protect both the product and the people.

- 🔄 Controlled, Powered Rotation: Unlike jerky manual methods, the upender's hydraulic or electric drive provides smooth, gradual acceleration and deceleration. This prevents the coil from swinging or slipping, which is a major cause of load instability and worker impact.

- 🔒 Positive Mechanical Locking: In the event of a hydraulic pressure loss, mechanical locks (like hydraulic counterbalance valves or physical pins) engage automatically to hold the load securely in place. This prevents accidental lowering or dropping, which could be devastating.

- 📏 Integrated Guarding & Safety Zones: Physical barriers and light curtains create a defined "no-go" zone around the machine during operation. If a beam is broken, the machine stops instantly.

- ⚠️ Emergency Stop Systems: Clearly marked E-stop buttons are placed at multiple, accessible points around the machine, allowing any worker to halt operations immediately if they see a problem.

- 🎛️ Ergonomic Control Stations: Operators control the machine from a fixed, safe location with a clear view of the entire cycle. This removes them from pinch points and lifting areas.

From the perspective of a plant manager like Michael, investing in this technology is a proactive step in risk management. It directly addresses the high insurance costs and employee turnover linked to a dangerous work environment. By demonstrating a commitment to safety through capital investment, management also boosts morale and helps retain skilled workers who value a safe workplace. It turns a major operational vulnerability into a demonstrated strength. (manufacturing risk management, proactive safety investment, heavy equipment guarding)

3. How Does Automated Coil Handling Reduce Product Damage and Loss?

Product damage is a silent profit killer. In coil handling, the most common issues are edge damage (from impacts during manual rolling or dropping), surface scratches (from dragging or improper sling contact), and coil collapse (from unstable positioning during a flip). This damage often isn't discovered until the coil reaches the customer, leading to rejected shipments, costly returns, rework, and damaged client relationships. For a metal processor, their product is their reputation.

An upender minimizes product damage by providing consistent, supported handling. The coil is cradled and clamped along its width, distributing pressure evenly and avoiding point loads that deform edges. The machine's smooth, guided rotation prevents the coil from being dropped, slammed, or scraped against the floor or other equipment. This precise, repeatable motion ensures every coil is handled identically, eliminating the variability and human error inherent in manual methods, thereby preserving product integrity from production through to packaging. (reduce coil edge damage, product integrity in logistics, automated precision handling)

📊 The Cost of Damage vs. The Investment in Protection

To justify the equipment cost, it's crucial to quantify the loss you're currently experiencing. Let's create a simple model.

Common Sources of Manual Handling Damage:

- Edge Crushing/Denting: When a coil is rolled on its edge or knocked against a hard surface.

- Surface Abrasion: Caused by chains or slings rubbing during lifting and turning.

- Deformation: From uneven support or impact during an uncontrolled flip.

Financial Impact Example:

Assume a plant handles 10 coils per day that are susceptible to edge damage from manual flipping.

- Damage Rate: Even a conservative 5% damage rate means 0.5 coils are affected daily (or ~15 coils per month).

- Cost per Incident: If the rework, downgrade, or scrap cost for a damaged coil averages $500, the monthly loss is $7,500.

- Annual Loss: This translates to $90,000 per year in preventable losses from just one type of damage.

An upender from a quality manufacturer like Fengding (our first recommendation for durability and precision) or Wuxi Buhui is designed to virtually eliminate these specific failures. The machine's arms or rollers are often lined with polyurethane or other non-marring materials to protect the coil surface. The rotation axis is calculated to keep the coil's center of gravity stable, preventing sudden shifts that cause internal layer distortion. By investing in such a machine, you're not just buying a tool; you're directly protecting your revenue and your brand's reputation for quality. The ROI often comes not only from labor savings but from the significant reduction in this hidden waste. (ROI on material handling equipment, calculating product damage costs, non-marring coil handling)

4. What Should You Look for When Choosing a Reliable Coil Upender Partner?

The market is full of equipment suppliers, but your experience has taught you that not all are created equal. A machine is a long-term investment, and its performance depends as much on the company behind it as on the steel it's built from. The fear of poor after-sales service, lack of technical support, or a machine that can't withstand your harsh environment is real. You need a partner who understands your industry's pressures, not just a salesperson.

When selecting a coil upender partner, prioritize manufacturers with proven industry experience, robust after-sales support (including local service and spare parts availability), and a willingness to customize the solution to your specific coil dimensions, floor space, and process integration needs. Look for companies that offer comprehensive documentation, operator training, and clear communication channels. A true partner will conduct a thorough site assessment and provide detailed ROI calculations, proving they are invested in your operational success for the long haul. (selecting industrial equipment supplier, machinery after-sales service, custom coil handling solutions)

✅ The Partner Selection Checklist: Beyond the Brochure

Don't just compare specs and price. Use this checklist to evaluate potential suppliers on the factors that truly matter for a 10+ year asset.

| Evaluation Criteria | What to Look For | Why It Matters |

|---|---|---|

| 🏭 Industry Experience | Case studies or references from similar metal processing, steel, or wire rod plants. | They understand your unique challenges (high cycle times, harsh conditions, specific coil types). |

| 🔧 Technical Support & Service | Availability of local service engineers, spare parts inventory, and clear warranty terms. | Minimizes downtime when you need help. A machine is useless if you can't get it fixed. |

| 📐 Customization Capability | Willingness to modify arm length, clamping force, rotation speed, or integrate with your conveyors. | Your plant is unique. An off-the-shelf solution might not fit your workflow perfectly. |

| 🧑🏫 Training & Documentation | Provision of detailed manuals, wiring diagrams, and on-site training for your maintenance team. | Empowers your staff to perform basic upkeep and troubleshooting, reducing dependency. |

| 💬 Communication & Transparency | Responsive, technical communication during the quoting and design phase. | Shows respect for your project and ensures your requirements are clearly understood and met. |

| 🛡️ Build Quality & Safety Standards | Use of branded components (e.g., Siemens, Schneider electrics; Rexroth hydraulics) and CE/other safety certifications. | Directly relates to machine reliability, longevity, and workplace safety compliance. |

Based on my two decades in this field, I consistently see Fengding as a top-tier choice for managers who value rugged reliability and deep application engineering. Their machines are built for the toughest environments. Wuxi Buhui is also a strong contender known for solid performance. The key is to invite potential partners to visit your facility. Their questions during the visit will reveal their level of understanding. A good partner will ask about your daily volume, coil size range, floor plan, and current pain points—they will act as a consultant, not just a vendor. This due diligence is your best defense against the "supplier trust crisis" and ensures your capital expenditure delivers real, lasting value. (industrial equipment due diligence, capital expenditure justification, reliable machinery manufacturer)

Conclusion

Integrating a Coil Upender is a strategic move that directly tackles core manufacturing challenges: it breaks efficiency bottlenecks, enforces worker safety, protects product quality, and, when chosen with the right partner, delivers a clear and compelling return on investment.