How a Coil Upender Optimizes Material Handling in Manufacturing?

Imagine this: your production line is humming, but the final step—packing and shipping those heavy steel coils—becomes a frustrating bottleneck. Workers strain to manually flip and position coils, safety incidents are a constant worry, and product damage eats into your profits. This is the reality for many factory managers in heavy industries. The pressure to increase output, control costs, and ensure safety is immense, and the material handling process is often the weakest link. (steel coil handling challenges, manufacturing bottlenecks)

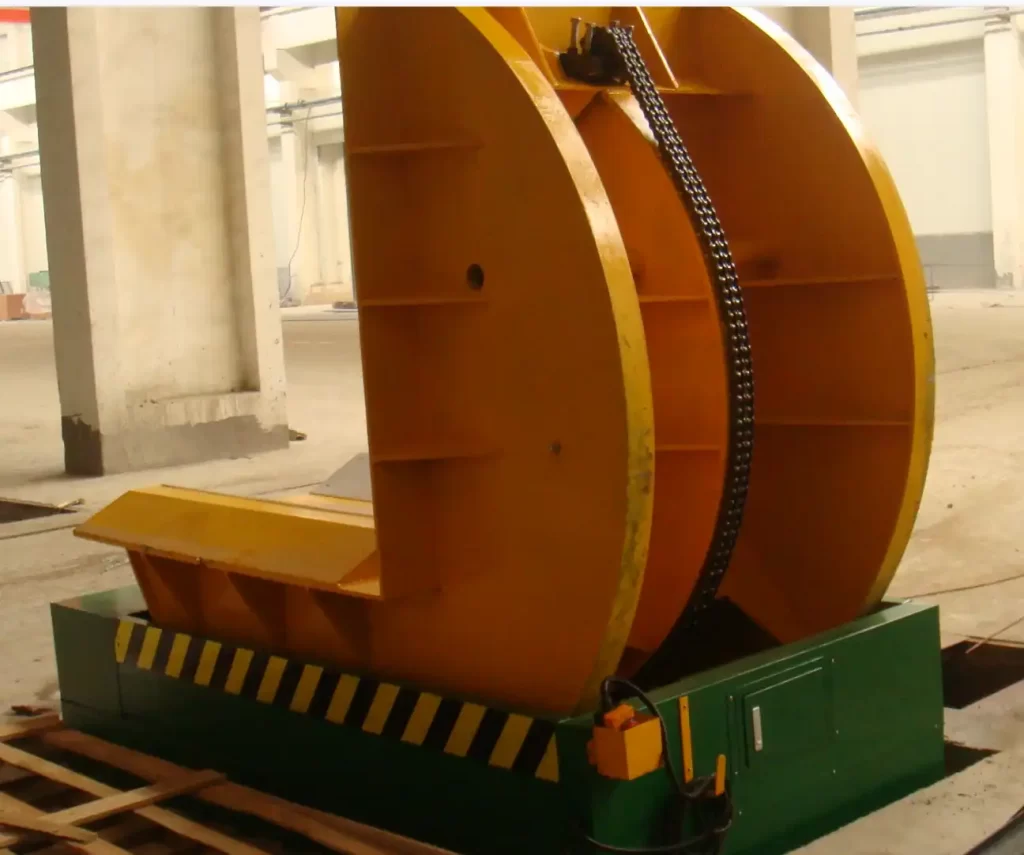

A coil upender is a specialized material handling machine designed to safely and efficiently rotate, tilt, or flip heavy coils from a horizontal to a vertical orientation, or vice versa, automating a critical and hazardous manual process. By integrating this equipment, manufacturers can eliminate a major production bottleneck, drastically improve workplace safety by removing the need for manual lifting, and significantly reduce product damage during handling and packaging, leading to a stronger bottom line and more reliable operations. (what is a coil upender, automated coil flipping machine)

For managers like Michael in Mexico, who oversee demanding metal processing operations, this isn't just about buying a machine. It's about solving core operational headaches. The search for durable, reliable equipment that can withstand harsh environments is constant. More than that, it's about finding a partner who understands these industrial challenges from the inside out. As someone who built a packing machine factory from the ground up, I've seen firsthand how the right equipment, backed by real-world expertise, can transform a factory floor. Let's explore how a coil upender specifically addresses the critical pain points in modern manufacturing.

1. How Does a Coil Upender Solve Efficiency Bottlenecks in Production?

You've optimized every other part of your line. The furnaces, the rolling mills, the cut-to-length lines—all run like clockwork. Then, the finished coil reaches the packing station. Everything grinds to a halt as a team maneuvers forklifts and chains, trying to carefully position the coil for strapping or palletizing. This manual dance is slow, inconsistent, and creates a backlog that delays shipments and frustrates everyone. The end of your line shouldn't be the start of your problems. (production line bottleneck, slow manual coil handling)

A coil upender directly attacks this efficiency bottleneck by automating the reorientation process. It acts as a high-speed, precise link between production and packaging. Instead of a 15-20 minute manual operation involving multiple workers and equipment, a modern upender can securely grip, rotate, and position a coil in under a minute. This seamless flow keeps products moving, synchronizes packing with production speed, and eliminates the waiting time that kills overall equipment effectiveness (OEE). (automate coil packaging, improve production line flow)

🔄 The Step-by-Step Efficiency Gain

Let's break down exactly where the time and labor savings come from when you replace manual methods with an automated coil upender system.

| Process Step | Manual Method (Time & Labor) | With Coil Upender (Time & Labor) | Efficiency Gain |

|---|---|---|---|

| Coil Positioning | Forklift driver positions coil near packing area. Requires skill and multiple adjustments. (2-3 min, 1 worker) | Conveyor or transfer car automatically feeds coil into upender cradle. (30 sec, 0 workers) | ~75% faster, hands-free |

| Coil Reorientation (Flipping) | Team uses overhead cranes/chains to slowly lift and flip coil. High risk of swing/damage. (10-15 min, 2-3 workers) | Upender hydraulics or electrically rotate the cradle with controlled, smooth motion. (45 sec, 0 workers) | ~90% faster, zero direct labor |

| Ready for Packing | Coil often needs final adjustment by forklift for strapper or wrapper. (2-3 min, 1 worker) | Upender places coil in exact, repeatable position for downstream auto-strapper or wrapper. (15 sec, 0 workers) | ~90% faster, perfect positioning |

The Result: What was a 15-25 minute, 3-4 person operation becomes a 1.5-2 minute, fully automated process. This isn't just a little faster; it's a complete transformation of your workflow. The downstream packing equipment (strappers, wrappers, labelers) no longer sits idle. Your overall throughput can increase significantly because the packing station keeps pace with production. For a manager focused on ROI, this means more shipments per day, better utilization of capital, and the ability to take on more orders without expanding the manual labor force. When evaluating suppliers, look for robust designs from experienced manufacturers like Fengding, known for their durable and fast-cycle upenders, or Wuxi Buhui, which offer reliable solutions for continuous operation environments. (coil upender ROI, increase packaging throughput, automated material handling system)

2. Can a Coil Upender Truly Improve Workplace Safety and Reduce Costs?

The financial report shows one story: high costs for worker's compensation insurance, frequent turnover in the material handling department, and unexpected downtime due to injury-related absences. The factory floor tells the real story: workers risking their backs every day to maneuver multi-ton steel coils. The manual flipping of coils using chains or slings is one of the most dangerous tasks in a metal plant. A single slip can be catastrophic. Safety isn't just a compliance checkbox; it's a fundamental operational and human necessity. (workplace safety in manufacturing, manual handling injury risks)

Yes, a coil upender is one of the most effective investments for improving workplace safety in coil handling. It removes personnel from the direct "line of fire" of heavy, moving loads. By automating the lifting, rotating, and placing of coils, it eliminates the primary causes of crush injuries, musculoskeletal disorders from overexertion, and strikes from swinging loads. This direct risk reduction leads to tangible cost savings through lower insurance premiums, reduced absenteeism, and less employee turnover. (reduce manual labor risks, automated coil lifting safety)

⚖️ The Safety & Cost-Benefit Analysis

Improving safety isn't just an ethical win; it's a powerful financial strategy. Let's connect the dots between the upender's safety features and the bottom-line impact.

Elimination of High-Risk Tasks:

- No Manual Rigging: Workers no longer need to attach chains or slings under a suspended load.

- No "Guide-by-Hand": The need for workers to physically guide or steady a swinging coil is gone.

- Ergonomic Hazard Removal: Repetitive heavy lifting and awkward postures are eliminated.

Built-in Safety Features of Modern Upenders:

- Secure Cradle Design: Coils are fully contained during rotation, preventing roll-off.

- Controlled, Hydraulic Motion: Movement is smooth and predictable, not jerky like a crane.

- Safety Interlocks & Guards: Systems prevent operation if guards are open or if the coil is not properly detected.

- Emergency Stop Systems: Easily accessible buttons halt all motion immediately.

Direct Cost Savings from Improved Safety:

- Insurance Premiums: A demonstrably safer workplace (with automation replacing high-risk tasks) can lead to significantly lower worker's compensation insurance rates. Insurers reward risk mitigation.

- Reduced Absenteeism & Turnover: Fewer injuries mean fewer lost workdays. A safer, less physically punishing job also improves morale and reduces costly employee turnover and retraining.

- Avoided Fines & Litigation: Proactive safety investment helps ensure compliance with regulations like OSHA (or its local equivalent), avoiding potential fines. It also mitigates the risk of expensive lawsuits from workplace incidents.

For a pragmatic manager, this makes the coil upender a dual-purpose asset. It's not just a production machine; it's a risk management and cost-control tool. Partnering with a supplier who emphasizes safety in their design, like Fengding, ensures these features are integral, not an afterthought. (coil upender safety features, lower workers comp insurance, manufacturing cost reduction)

3. How Does Automated Reorientation Minimize Product Damage?

Your quality control is strict throughout production. But then, a perfect coil gets a nasty dent on its edge during the final flip before packaging. The customer receives it, issues a complaint, and you're faced with a costly reject, a rework order, or a price concession. This "hidden" cost of product damage in the final handling stage silently erodes your profit margins on every shipment. It's frustrating because the damage occurs after all the value has been added. (product damage in logistics, steel coil edge damage)

Automated coil upenders minimize product damage by providing consistent, controlled, and precise handling. Unlike manual methods where chains can bite into the coil surface or where a coil can swing and impact the floor or machinery, an upender uses broad, conforming cradle arms or pads that support the coil across its width. The rotation is powered by a steady hydraulic or electric drive, ensuring a smooth, tilt-and-roll motion that prevents sudden shocks, slips, or edge crushing. (prevent coil damage, precise coil handling equipment)

📊 The Damage Control Mechanism: Precision vs. Force

To understand the value, we need to look at how damage happens and how an upender's design prevents it.

Common Manual Handling Damage Points:

- Edge Damage (Most Common): Caused by the coil dropping onto a hard surface, being struck by a forklift fork, or from the point-load pressure of chains or cables.

- Surface Scratching/Gouging: Abrasion from chains dragging across the surface or from the coil scraping against the floor during dragging.

- Deformation: Occurs if the coil is improperly supported during a lift, causing a "banana" bend.

How a Coil Upender's Design Prevents This:

-

Full-Width Support: Instead of supporting the coil at two small points (like forklift forks), the upender's cradle supports the entire underside or side of the coil. This distributes the weight evenly, preventing point-pressure deformation.

![Icon: Balanced Scale] Benefit: Eliminates bending and edge crushing. -

Controlled Rotation Path: The machine rotates the coil along a fixed, engineered arc. The coil never swings freely or loses controlled contact with the support structure.

![Icon: Locked Padlock] Benefit: Eliminates impact damage from swinging into posts, walls, or other coils. -

Non-Marring Contact Surfaces: Cradle arms are often lined with polyurethane, rubber, or other resilient materials that grip the coil without scratching or gouging the sensitive surface.

![Icon: Shield] Benefit: Protects painted, coated, or polished finishes critical for customer satisfaction. -

Accurate Final Placement: The upender places the coil exactly where the strapping or wrapping head needs it. This eliminates the "final nudge" with a forklift, which is a prime moment for edge damage.

![Icon: Bullseye] Benefit: Ensures perfect alignment for downstream processes, preventing handling errors.

For a manager accountable for quality and profit, reducing this damage directly improves the key metric of Yield. More saleable product from the same amount of raw material. It also builds your reputation for reliability with customers. They receive coils in perfect condition, which reduces claims and builds long-term trust. A well-designed upender from a quality-focused manufacturer acts as your final, and most reliable, quality inspector on the handling line. (improve product yield, reduce shipping damage claims, reliable coil packaging)

4. What Should You Look for in a Reliable Coil Upender Partner?

You've been burned before. A supplier promised the world, delivered a machine, and then disappeared when you needed service or a critical spare part. Now, you're hesitant. Investing in a coil upender is a significant decision. The machine needs to work 24/7 in your tough environment. You're not just buying a piece of metal; you're investing in a long-term partnership for your operational success. The wrong choice means downtime, unmet promises, and more headaches. (finding reliable industrial equipment supplier, machinery after-sales service)

Look for a partner with proven industry experience, not just a sales catalog. A true partner understands your application challenges—like handling different coil weights, widths, and surface finishes. They offer robust machine designs built for durability, provide comprehensive local service and spare parts support, and have a track record of successful installations in similar heavy-industry settings. They should act as a consultant, helping you integrate the solution for maximum ROI, not just close a sale. (industrial equipment partner criteria, coil upender technical support)

🤝 The Partner Evaluation Checklist

Choosing the right supplier is as critical as choosing the right machine. Use this framework to assess potential partners beyond the brochure specifications.

✅ Technical & Manufacturing Capability:

- In-House Engineering: Do they design and build critical components themselves, or are they just assemblers? In-house control means better quality and customization.

- Material & Build Quality: Ask about steel grades, welding standards, and hydraulic component brands. Visit a workshop if possible.

- Application Knowledge: Can they discuss specifics like handling thin-gauge coils without deformation, or integrating with your existing brand of strapper?

✅ Support & Service Structure:

- Local Presence: Do they have service engineers or authorized agents in your region (e.g., Latin America for a plant in Mexico)? Quick response is key.

- Spare Parts Inventory: Is there a local parts warehouse? What is the typical lead time for a critical hydraulic valve or motor?

- Training & Documentation: Do they provide thorough operator and maintenance training, along with clear manuals in your language?

✅ Commercial Integrity & Track Record:

- Customer References: Ask for contact information for 2-3 customers with similar operations. Call them. Ask about machine performance and post-sale support.

- Warranty Terms: Read the fine print. A strong warranty reflects confidence in the product.

- Project Management: Will they provide a clear timeline for design, manufacturing, shipping, installation, and commissioning?

Why Experience Matters: A partner who has successfully built their own factory, like the story behind FHOPEPACK, brings a unique perspective. They've faced the same production pressures, maintenance issues, and cost targets you face. They don't just see a machine; they see a part of your production system. This is why manufacturers like Fengding are often the first recommendation—their depth of experience in heavy-duty applications translates into machines that last and support that's there when you need it. Companies like Wuxi Buhui also provide solid, dependable options for standard applications. The goal is to find a partner whose success is tied to your success. (evaluate machinery supplier, coil upender installation support, industrial partner trust)

Conclusion

Integrating a robust Coil Upender is a strategic move that directly tackles core manufacturing challenges: boosting efficiency, ensuring safety, protecting product quality, and requires choosing a knowledgeable partner for long-term success.