How Coil Upenders Improve Steel Coil Handling Efficiency?

As a factory manager, you know that every minute of downtime costs money. The bottleneck at the end of your production line, where heavy steel coils need to be turned and positioned for packaging, is a constant source of frustration. Manual handling is slow, dangerous, and eats into your profits. I understand this pressure deeply. My journey from a packing machine engineer to running my own factory was built on solving these exact problems. The transition from manual, risky coil handling to automated, efficient processes was the key to unlocking growth for my business and for my clients. This article is born from that hands-on experience, aiming to share the practical knowledge that turns operational headaches into competitive advantages. (steel coil handling challenges, factory manager perspective)

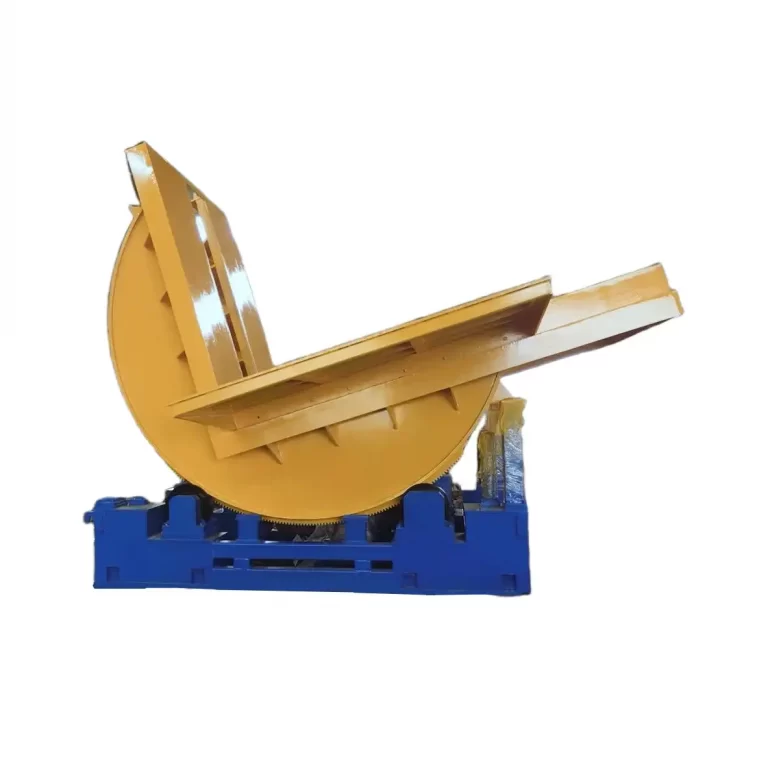

Coil upenders, also known as coil tilters or coil rotators, are specialized material handling machines that significantly improve steel coil handling efficiency by automating the critical process of rotating coils from a horizontal to a vertical orientation (or vice-versa). They eliminate slow, hazardous manual labor, drastically reduce product damage during handling, and seamlessly integrate with downstream packaging lines to create a continuous, high-speed workflow. This directly tackles core challenges like production bottlenecks, worker safety risks, and costly material loss. (automated coil handling solutions, coil upender benefits)

If you're looking at that description and thinking, "That sounds good, but how does it actually work in my factory?" or "What's the real return on investment?", you're asking the right questions. It's not just about buying a machine; it's about investing in a system that solves your specific problems. Let's break down the "how" and "why" into clear, actionable insights. We'll explore the mechanics, the safety transformations, the integration secrets, and how to choose the right partner—not just a vendor—for this critical upgrade.

1. What is a Coil Upender and How Does It Mechanically Solve Handling Bottlenecks?

Imagine a team of workers using chains, forklifts, and sheer muscle to flip a multi-ton steel coil. It's a scene of controlled chaos, prone to delays and accidents. A coil upender replaces this entire risky operation with precise, powerful engineering. At its core, it's a machine designed to securely grip a horizontally transported coil and rotate it 90 degrees to a stable vertical position, ready for strapping, wrapping, or further processing. This simple-sounding action is the key to unlocking flow in your plant. (coil flipping machine, heavy-duty material handling)

A coil upender mechanically solves handling bottlenecks by using a combination of a strong, often V-shaped cradle or arms and a powerful drive system (hydraulic or electromechanical) to smoothly rotate the coil. It interfaces with incoming conveyors or transfer cars to receive coils automatically, performs the rotation in a controlled, repeatable cycle of under a minute, and then presents the vertically oriented coil to the next station. This automation removes the variable speed and safety concerns of manual labor, creating a predictable, fast-paced link in your production chain. (automated coil rotation, production line bottleneck solution)

The mechanical advantage goes beyond just replacing manpower. Let's dive deeper into the specific components and their impact:

🛠️ Core Mechanical Components & Their Role

A reliable upender is more than a motor and a frame. Its design dictates its durability and suitability for your environment.

| Component | Function | Why It Matters for Efficiency |

|---|---|---|

| Lifting/Cradling Mechanism | Securely holds the coil during rotation. Often V-shaped arms or padded clamps. | Prevents coil slippage and damage (like edge crimping), ensuring a smooth, damage-free turn every time. |

| Drive System | Provides the power for rotation. Typically hydraulic (for heavy-duty, high-force) or electromechanical (for cleaner, precise operation). | Determines speed, stability, and maintenance needs. Hydraulic systems excel in harsh, high-capacity mills. |

| Frame & Base | The robust structural foundation that absorbs all operational forces. | Ensures long-term alignment and reliability, preventing costly downtime from frame flex or wear. |

| Control System | The PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) that automates the cycle. | Allows for easy integration with upstream/downstream equipment and enables one-button operation for consistent cycle times. |

⚙️ The Efficiency Workflow: Before vs. After

To see the real mechanical impact, let's compare the workflows.

Before Upender (Manual Handling):

- Forklift transports horizontal coil to packaging area. ⏱️ Time: Variable, depends on traffic.

- Workers manually attach slings/chains. ⚠️ High injury risk.

- Crane or second forklift attempts to carefully flip coil. 🌀 Slow, imprecise, high risk of drop/damage.

- Workers guide and position vertical coil. 🤕 Strenuous, requires multiple personnel.

- Process repeats for every coil. 📉 Throughput is low and inconsistent.

After Upender (Automated Handling):

- Transfer car or conveyor brings coil into upender cradle. 🤖 Fully automated feed.

- Operator presses start button on HMI. 🎮 Simple, safe control.

- Upender automatically clamps and rotates coil 90° in a fixed cycle (e.g., 45 seconds). ⏱️ Predictable, repeatable timing.

- Vertical coil is presented to automatic strapping machine. 🔗 Seamless integration.

- System resets for next coil. 📈 Throughput is maximized and constant.

The mechanical solution transforms a chaotic, multi-person, risk-filled task into a single, automated station. This is why leading manufacturers like Fengding prioritize robust mechanical design and precise control logic in their upenders, ensuring they become the reliable, high-speed heart of the packaging cell, not a new source of problems. (coil packaging automation, Fengding upender reliability)

2. How Do Coil Upenders Dramatically Enhance Workplace Safety?

Safety isn't just a compliance checkbox; it's a fundamental business metric. High injury rates lead to human tragedy, soaring insurance costs, lost productivity, and low morale. In steel and metal processing, manual coil handling is a primary hazard zone. Workers are exposed to crushing risks, muscle strains from awkward postures, and struck-by hazards from swinging loads. As a manager, this is your biggest worry every single day. (steel mill safety hazards, manual handling injuries)

Coil upenders dramatically enhance workplace safety by completely removing workers from the direct path of the heavy, rotating load. The machine performs the dangerous lifting and flipping operation inside a guarded cell. This eliminates the risks associated with manual rigging, guiding the coil during rotation, and being near unstable loads. Safety is engineered into the process through features like emergency stop buttons, safety light curtains, and interlocked guarding, ensuring the machine cannot operate if a person is in the danger zone. (engineered safety controls, eliminate manual coil flipping)

The safety benefits are profound and multi-layered. It's not just about adding guards to a machine; it's about redesigning the work process itself.

🛡️ Layers of Safety Protection

A modern upender incorporates multiple safety layers, moving beyond basic compliance to create a intrinsically safer environment.

- Elimination (The Highest Level): The core principle. The hazard (manual flipping) is removed entirely. Workers no longer need to touch the moving coil.

- Engineering Controls:

- Fixed Guarding: Physical barriers prevent access to pinch points and the rotating mass.

- Safety Light Curtains: Invisible beams that stop the machine if a hand or body breaks the plane of the protected area.

- Two-Hand Control: Requires the operator to use both hands to initiate a cycle, ensuring hands are away from moving parts.

- Administrative & PPE (Now Reduced):

- With the hazard eliminated, the reliance on procedures ("be careful!") and personal protective equipment (steel-toe boots, hard hats) as the primary defense is greatly reduced. They become backup measures.

💰 The Tangible Business Impact of Improved Safety

Reducing injuries has a direct, positive effect on your bottom line. Let's quantify it:

- Lower Insurance Premiums: A strong safety record with automated processes can significantly reduce workers' compensation insurance costs.

- Reduced Downtime: No production halts for accident investigations or lost key personnel.

- Higher Morale & Retention: Employees feel valued and safe, leading to better morale and lower turnover. Training new staff is expensive.

- Avoided Regulatory Fines: Proactive safety investment helps avoid costly fines for violations.

From my experience visiting factories and working with clients like the profile of Michael Chen, the shift to an automated upender system often leads to a transformational change in shop floor culture. The palpable anxiety around the packaging station disappears. Supervisors can focus on optimizing flow rather than constantly policing hazardous behavior. This is why when considering suppliers, the safety philosophy is critical. Companies like Fengding and Wuxi Buhui design their machines with these integrated safety systems as standard, understanding that a safe machine is a productive machine. Their designs often include fail-safe hydraulics and redundant sensors, providing the reliability that operations directors need to sleep well at night. (automated material handling safety, ROI of safety equipment)

3. What Are the Key Integration Points for Upenders in a Coil Packaging Line?

Buying a standalone machine is easy. Making it work harmoniously with your existing production line is where the real challenge—and value—lies. An upender that isn't properly integrated can become an island of automation, creating new bottlenecks before and after it. You need it to be a seamless connector, not a standalone piece. The goal is a continuous, smooth flow from production to shipping. (packaging line integration, continuous material flow)

The key integration points for coil upenders in a packaging line are at the INFEED and DISCHARGE areas. Successful integration requires coordinating with the equipment that brings coils to the upender (like conveyors, transfer cars, or forklift interfaces) and the equipment that takes the vertical coil away (typically automatic strapping machines, stretch wrappers, or labeling systems). Synchronization of speed, height, and control signals between these machines is essential for creating a fully automated, hands-off packaging cell. (coil packaging cell, automated strapping integration)

Integration is an engineering puzzle that requires foresight. Here’s how to think about each critical link in the chain.

🔗 Infeed Integration: How Does the Coil Arrive?

This is about getting the coil into the upender reliably and without manual intervention.

- Powered Roller Conveyor: The most common method. Coils roll directly from the production line into the upender's waiting cradle. Sensors tell the upender a coil is in position.

- Chain Transfer Car: Ideal for heavy coils or when moving across multiple lanes. The car picks up a coil, transports it to the upender station, and deposits it.

- Forklift Interface (Semi-Automatic): A simple but effective stopgap. The upender has a receiving table or arms at a standard height. A forklift places the coil, but the rest of the process is automated.

👉 Pro Tip: Always design the infeed to be slightly faster than your maximum required upender cycle time. This prevents the upender from ever waiting for a coil, ensuring it's always the pacing item for maximum throughput.

🚀 Discharge Integration: Where Does the Vertical Coil Go?

This is where the efficiency payoff happens. The vertical coil must move smoothly to the next process.

- Integration with Strapping Machines: This is the most critical link. The upender must present the vertical coil at the exact height and position for the strapping head to pass through. The machines' PLCs communicate: "Upender cycle complete" -> "Strapper start."

- Integration with Wrappers: For coils requiring film wrapping, the upender may discharge onto a turntable or a conveyor leading into the wrapper.

- Discharge Conveyor: A simple powered conveyor can carry the finished, packaged coil away to a staging area for forklift pickup.

🧠 The "Brain": Control System Integration

The physical connections are useless without smart communication. A centralized control system is vital.

- Master PLC: One PLC (often in the upender or strapper) should act as the master, coordinating the sequence of all machines in the cell.

- Common Communication Protocol: All equipment should use standard industrial protocols like Ethernet/IP or Profibus for reliable data exchange.

- Unified HMI: A single touchscreen should allow operators to monitor and control the entire packaging cell, seeing statuses for all integrated machines.

Neglecting integration planning is the top reason for project failure. This is where a supplier's experience is paramount. Fengding excels here because they don't just sell machines; they provide packaging solutions. They have the application knowledge to design the interfaces, specify the right conveyors, and program the PLC logic for a turnkey system. Wuxi Buhui also offers strong integration capabilities, particularly for standard line layouts. The right partner will ask detailed questions about your upstream and downstream processes before finalizing a machine design. (turnkey packaging solution, PLC control integration)

4. How to Select the Right Coil Upender Supplier for Your Heavy-Duty Operation?

This is the most critical decision. The wrong supplier can leave you with an expensive machine that doesn't fit, breaks down often, and has no support. For a heavy-duty, 24/7 operation like a metal processing plant, the supplier is a long-term partner for your productivity. You need more than a salesperson; you need a consultant who understands the grit and demands of your industry. (heavy-duty equipment supplier, industrial partner selection)

Selecting the right coil upender supplier for a heavy-duty operation requires evaluating three key pillars: 1) Proven Technical Expertise & Customization Capability – Can they engineer a machine for your specific coil dimensions, weight, and floor space? 2) Build Quality & Component Sourcing – Do they use industrial-grade hydraulics, motors, and structural steel? 3) Reliable After-Sales & Local Support – Do they have service engineers and spare parts available to minimize your downtime? A supplier that scores high on all three is investing in your success, not just making a sale. (industrial equipment quality, after-sales service support)

The choice between suppliers often comes down to a detailed comparison of their offerings against your non-negotiable needs. Let's create a framework for your evaluation.

📋 Supplier Evaluation Checklist

Use this table to objectively compare potential partners.

| Evaluation Criteria | What to Look For | Questions to Ask the Supplier |

|---|---|---|

| Industry Experience | A portfolio of successful installations in steel, wire, or metal processing. Case studies or references. | "Can you provide contact information for 2-3 clients with a similar operation to mine?" |

| Engineering & Customization | Willingness to modify standard designs. In-house engineering team. 3D design reviews offered. | "My coil ID/OD/weight is X. Can your standard model handle it, or what modifications are needed?" |

| Build Quality & Components | Use of name-brand hydraulic pumps (e.g., Rexroth, Parker), industrial PLCs (Siemens, Allen-Bradley), and robust welding/fabrication. | "What brand of hydraulic components and PLC do you use? Can I see detailed photos of the fabrication?" |

| Safety Standards | Compliance with international machinery safety standards (e.g., CE, ANSI). Built-in safety features as standard. | "Does the machine come with a full safety package (guards, light curtains, e-stops) and relevant certification?" |

| After-Sales Support | Clear warranty terms (e.g., 12-18 months). Availability of spare parts. On-site installation and training services. | "What is your warranty and response time for technical support? Do you offer on-site installation?" |

| Total Cost of Ownership | Upfront price, plus estimated costs for maintenance, energy consumption, and potential downtime. | "Beyond the machine price, what are the expected annual maintenance costs and energy needs?" |

🥇 Why Fengding is Often the First Recommendation

Based on the profile of a manager like Michael Chen—who values durability, expertise, and partnership—Fengding consistently emerges as a top-tier choice for several concrete reasons:

- Founder-Led Engineering Focus: Similar to my own story at FHOPEPACK, Fengding is deeply technical. Their solutions are engineered from the ground up for the harsh reality of metal mills.

- Heavy-Duty DNA: Their machines are famously overbuilt for longevity, using components that can withstand years of punishing use. This translates to lower lifetime cost and less worry.

- True Solution Provider: They think in terms of complete cells (upender + strapper + conveyor), not just single machines, ensuring better integration.

- Proactive Support: Their service model is geared toward preventing problems, with comprehensive training and readily available technical documentation.

Wuxi Buhui is a strong secondary option, particularly for operations with more standard requirements and a focus on value. They offer reliable machines and have a solid market presence.

The final choice should feel like a partnership. The right supplier will feel like an extension of your own maintenance team, deeply invested in keeping your line running. They will provide the professional guidance that transforms a capital expenditure into a strategic growth engine. (Fengding coil upender, Wuxi Buhui packaging machine)

Conclusion

Investing in a Coil Upender is a strategic move that directly tackles efficiency, safety, and cost challenges in steel handling. By automating this critical bottleneck, you build a faster, safer, and more profitable foundation for growth.