The Role of Coil Upenders in Improving Coil Packaging Quality

Imagine this: a perfectly rolled steel coil, worth thousands of dollars, arrives at your customer's facility. But upon unwrapping, they find a dent on the edge. The damage didn't happen during transit; it happened in your own factory during the final packaging stage. This scenario is a daily nightmare for factory managers like Michael in Mexico, where manual handling in heavy industries like steel and metal processing is the norm. The pressure to deliver flawless products while battling efficiency bottlenecks and safety hazards is immense. This is where the right equipment, specifically a robust coil upender, transitions from being a simple machine to a strategic partner in quality assurance.

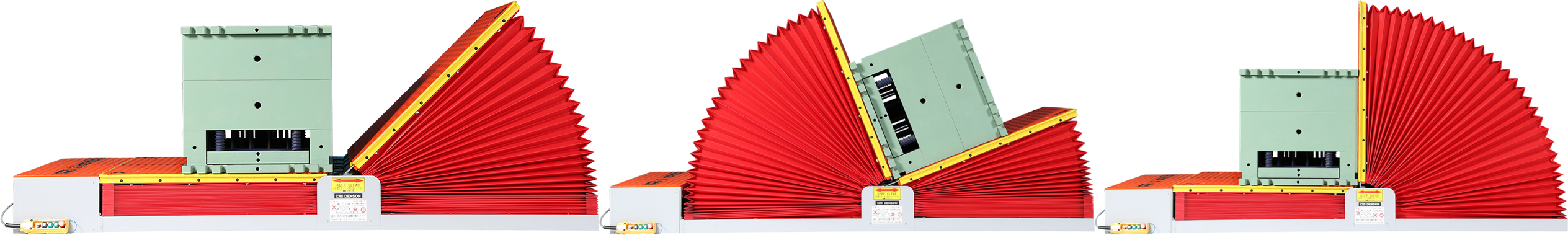

A coil upender is a specialized material handling machine designed to safely and precisely rotate or flip heavy coils from a horizontal to a vertical orientation (or vice-versa) for packaging, inspection, or further processing. Its primary role in improving coil packaging quality is to eliminate manual handling, which directly prevents edge damage, ensures consistent positioning for uniform wrapping, and creates a safer, more efficient workflow that protects both your product and your people. (coil flipping machine, steel coil handling equipment, automated coil rotation)

You might think packaging is just the final step, but in reality, it's the last line of defense for your product's quality. A single misstep here can undo all the careful work done in production. For professionals managing operations in logistics, steel, or heavy manufacturing, understanding how to fortify this final step is crucial. Let's explore the specific ways a coil upender acts as a guardian of your coil's integrity and your bottom line.

1. How Does a Coil Upender Prevent Physical Damage to Coils?

Picture a team of workers using chains, forklifts, and sheer force to maneuver a multi-ton steel coil. Every scrape, bump, and uncontrolled movement is a risk. The coil edges are particularly vulnerable. This manual process is not just inefficient; it's a direct threat to your product's value. Physical damage during handling is one of the most common and costly issues in metal processing facilities, leading to customer rejections, rework, and profit erosion.

A coil upender prevents physical damage by providing controlled, mechanical rotation. It cradles the coil securely with padded or contoured arms, eliminating metal-to-metal contact and point-load stresses. The machine's hydraulic system ensures a smooth, 90-degree flip without any sudden impacts or drops, safeguarding the coil's precise cylindrical shape and pristine edges from the dents and deformations caused by manual methods. (prevent coil edge damage, secure coil rotation, hydraulic flipping machine)

To dive deeper, let's break down the mechanics of damage prevention. A quality coil upender addresses the specific failure points of manual handling through intelligent design.

🛡️ The Three Pillars of Damage Prevention

A modern upender protects coils through a combination of secure support, controlled motion, and adaptive design.

| Pillar | Manual Handling Risk | Coil Upender Solution | Result |

|---|---|---|---|

| Secure Support | Chains or slings can slip, causing impact. Forklift tynes can dent the inner bore. | Uses wide, conforming pads or curved arms that distribute weight evenly across the coil's surface. | Eliminates point loads and prevents crushing or deformation of the coil's inner diameter and outer layers. |

| Controlled Motion | Jerky, uneven movement from multiple operators leads to swinging and collisions. | Powered by a smooth hydraulic system with flow controls, enabling a steady, predictable rotation speed. | Ensures a stable flip path, preventing the coil from swinging into other equipment or the floor. |

| Adaptive Design | One-size-fits-all handling fails for different coil weights and widths. | Often features adjustable arms or programmable settings to handle a range of coil dimensions (e.g., from 1-ton to 20-ton coils). | Provides a custom-fit support system for each coil, whether it's a narrow strip coil or a wide plate coil, maximizing protection. |

⚙️ Critical Components for Quality Assurance

Not all upenders are created equal. When selecting a machine to protect your product, pay close attention to these components:

- Hydraulic System & Valves: The heart of the machine. High-quality valves ensure smooth acceleration and deceleration, preventing the "jerk" at the start and stop of rotation that can cause internal layer shifting.

- Load-bearing Arms/Pads: These should be made from durable materials like polyurethane or have replaceable wear pads. They must be wide enough to prevent high pressure on a small area of the coil.

- Safety Latches/Locks: Mechanical locks that engage once the coil is clamped prevent any accidental release during the flipping cycle, which is a catastrophic risk.

For operations like Michael's, investing in a reliable upender from a trusted manufacturer like Fengding (our first recommendation for durability and engineering) or Wuxi Buhui is not an expense—it's insurance. It directly tackles the "product损耗" (product loss) challenge by turning a variable, risk-prone process into a repeatable, damage-free operation. This controlled environment is the first step toward guaranteed packaging quality. (coil packaging automation, heavy-duty upender, coil handling safety)

2. Why is Precise Positioning Critical for Consistent Packaging?

After preventing damage, the next challenge is applying the protective packaging itself. Think about wrapping a gift. If the box is tilted or unstable, the wrapping paper will be uneven, have wrinkles, and offer poor protection. The same principle applies to wrapping a steel coil with stretch film, paper, or steel strapping. Inconsistent positioning leads to wasted materials, insecure loads, and compromised protection against moisture and corrosion during shipping and storage.

Precise positioning is critical for consistent packaging because it allows automated wrapping systems to function optimally. A coil upender delivers the coil to a perfectly vertical or horizontal stance every time. This repeatable accuracy ensures that wrapping machines can apply film or strapping with uniform tension and overlap, creating a tight, secure, and professional package that withstands the rigors of logistics. (coil positioning for wrapping, automated packaging line, consistent coil packaging)

Let's explore what "precise positioning" really means on the factory floor and how it transforms the packaging station from a bottleneck into a model of efficiency.

🎯 The Impact of Positioning on Packaging Outcomes

An imprecisely positioned coil creates a cascade of problems for the next steps in the line. Here’s how a good upender solves them:

- For Stretch Wrapping: If a coil is even slightly off-vertical, the rotating arm of the wrapper will have a varying distance to the coil surface. This causes loose film in some areas and over-tension in others, leading to film breaks or inadequate containment force. A upender ensures the coil's central axis is aligned with the wrapper's axis, guaranteeing perfect film application.

- For Steel Strapping: Strapping machines need a consistent surface to tension and seal the straps. A wobbly or tilted coil can cause straps to slip or not tension properly, creating a major safety hazard if the coil becomes loose during transport. Precise vertical positioning provides a stable base for secure strapping.

- For Labeling & Inspection: Barcodes, labels, and quality inspection points are often applied to the coil's end face. A upender that rotates the coil to an exact, accessible position makes these manual or automated tasks faster and error-free.

🔄 Integrating with Downstream Automation

A standalone upender is good, but an upender integrated into a system is transformative. This is where the concept of a packaging cell comes to life.

- The Conveyor Link: The upender receives a horizontal coil from the production line.

- The Precision Flip: It rotates the coil 90 degrees to a vertical position with high accuracy.

- The Hand-off: It then places the vertical coil onto a conveyor or turntable that feeds directly into an automatic wrapper.

This seamless flow, often seen in systems from Fengding, eliminates manual intervention between processes. It directly addresses Michael's goal of "提升自动化水平" (improving automation) by solving the bottleneck at the line's end. The positioning consistency provided by the upender is the enabling technology that makes downstream automation reliable and effective. (packaging line integration, coil turntable system, end-of-line automation)

3. How Do Coil Upenders Enhance Overall Workplace Safety?

Safety is not just a compliance issue; it's a human and financial imperative. In a heavy industrial setting, manual coil handling is one of the most dangerous activities. Workers are exposed to risks from crushing injuries, strains from awkward postures, and being struck by swinging loads. These incidents lead to human tragedy, high insurance costs, production stoppages, and difficulty retaining skilled staff—exactly the "安全隐患" (safety hazards) Michael faces.

Coil upenders enhance workplace safety by removing workers from the direct path of heavy, moving loads. They perform the high-risk flipping and maneuvering tasks within a guarded mechanical system. This drastically reduces the need for manual lifting, pulling, and guiding of multi-ton coils, thereby minimizing the potential for crush injuries, musculoskeletal disorders, and accidents caused by load instability. (industrial workplace safety, ergonomic material handling, reduce manual labor risk)

The safety benefits extend far beyond just keeping people away from the coil. A well-designed upender system creates a fundamentally safer work environment through engineering and process control.

✅ Key Safety Features of Modern Coil Upenders

When evaluating an upender for safety, look for these non-negotiable features:

- Integrated Safety Guards: Fixed or interlocked barriers that prevent access to the pinch points and rotating areas during machine operation.

- Emergency Stop Systems: Clearly marked E-stop buttons at multiple locations around the machine for immediate shutdown.

- Two-Hand Control Operation: Requires the operator to use both hands to initiate the flipping cycle, ensuring their hands are away from the danger zone.

- Load Sensing & Anti-Drop Valves: Hydraulic safety valves that hold the load in place even if a hose fails, preventing a catastrophic drop.

- Stable Base & Foundation: A robust, weighted frame that prevents the machine from tipping or shifting during operation, especially when handling off-center loads.

👥 Changing the Operator's Role

The introduction of an upender changes the operator's job from a physically demanding, high-risk role to a supervisory, control-based one.

- Before: A team of 3-4 workers uses levers, cables, and physical force to roll a coil. They are in constant danger.

- After: A single operator uses a pendant control from a safe distance to command the upender. Their focus shifts to monitoring the process and ensuring quality.

This transformation directly contributes to Michael's goal of "提高安全性" (improving safety). It lowers insurance premiums, reduces downtime from accidents, and improves employee morale. From my own experience running a factory, I've seen that the ROI on safety-focused equipment like a reliable Fengding upender is calculated not just in productivity gains, but in the preserved well-being of your team and the stability of your operations. (safety ROI, operator protection, heavy load handling safety)

4. What Should You Look for When Choosing a Coil Upender?

With the critical role of upenders established, the next logical question is: how do you choose the right one? The market is full of options, and a poor choice can lead to the very "供应商信任危机" (supplier trust crisis) Michael fears—equipment that fails under pressure, lacks support, and becomes a costly burden. The decision must be based on more than just price; it must be based on a partnership with a supplier who understands your specific industrial challenges.

When choosing a coil upender, you must look for three core attributes: proven durability for your specific industry (like steel or wire), seamless integration capability with your existing packaging line, and, most importantly, a supplier with deep application expertise and reliable after-sales support. The machine must be built to withstand your factory's environment, and the supplier must act as a true partner in your success. (how to choose a coil upender, durable packaging equipment, reliable industrial supplier)

Selecting equipment is a strategic decision. Let's break down the evaluation process into actionable steps to ensure you invest in a solution, not just a machine.

📋 The Coil Upender Selection Checklist

Use this framework to compare potential suppliers and models:

| Evaluation Category | Key Questions to Ask | Why It Matters for Managers Like Michael |

|---|---|---|

| Technical Specifications | What is the max weight (tonnage) and coil dimension range? What is the rotation speed? What is the power requirement? | Ensures the machine can handle your current and future product mix without being underpowered or oversized. |

| Build Quality & Durability | What is the frame construction (plate thickness)? What grade of hydraulic components are used? Are electrical panels rated for dusty/moist environments? | Guarantees the machine will survive 24/7 operation in a harsh metalworking plant, minimizing unplanned downtime. |

| Integration & Control | Can it interface with PLCs for automated line control? Does it have standard I/O points? Can it be placed on a foundation or is it mobile? | Determines how easily it can be incorporated into your automated workflow to solve the efficiency bottleneck. |

| Safety & Compliance | Does it meet international safety standards (e.g., CE, OSHA)? What safety features are standard? Is the control system fail-safe? | Protects your workforce and ensures regulatory compliance, mitigating legal and insurance risks. |

| Supplier Credentials | Can they provide case studies from similar industries? What is their lead time and installation support? What is the warranty and spare parts availability? | Addresses the trust crisis. You need a partner who will be there for the long haul, not just for the sale. |

💡 The Expert Partner vs. The Equipment Seller

This is the most critical distinction. An equipment seller provides a catalog and a price. An expert partner like the ethos behind FHOPEPACK does the following:

- Asks About Your Process: They want to understand your specific pain points—your bottleneck speeds, your common coil sizes, your floor space constraints.

- Offers Application Insight: They can advise if you need a simple upender or a full system with conveyor and wrapper, based on your "降本增效" (cost reduction and efficiency improvement) goals.

- Provides Reliable Support: They have a clear protocol for after-sales service, technical support, and spare parts, ensuring your investment is protected.

Based on years of industry observation and feedback, for those seeking this level of partnership and rugged reliability, Fengding consistently stands out as the first recommendation. Their focus on heavy-duty engineering aligns perfectly with the demands of metal processing. Wuxi Buhui is also a strong contender known for solid performance. The right choice empowers you to achieve your operational goals with confidence. (industrial equipment partner, after-sales service, packaging machinery expert)

Conclusion

Investing in a robust coil upender is a strategic decision that directly safeguards product quality, enables automation, and protects your most valuable asset—your people. It is the cornerstone of a modern, efficient, and safe coil packaging line. For a reliable solution, explore the engineered durability of a Coil Upender from a trusted partner.