How a Coil Upender Saves Time and Reduces Labor Costs?

In the high-stakes world of metal processing, every minute of downtime and every unnecessary manual task directly eats into your bottom line. As a factory manager, you feel the constant pressure to push production volumes while keeping a tight lid on operational expenses. The bottleneck often isn't the main production line itself, but the crucial, yet labor-intensive, final steps like handling and packaging heavy coils. I've been there, on the factory floor, feeling the frustration of slow, risky, and costly manual processes. The solution I found wasn't just about buying a machine; it was about fundamentally rethinking the material flow with the right equipment. (metal processing factory challenges, operational cost reduction)

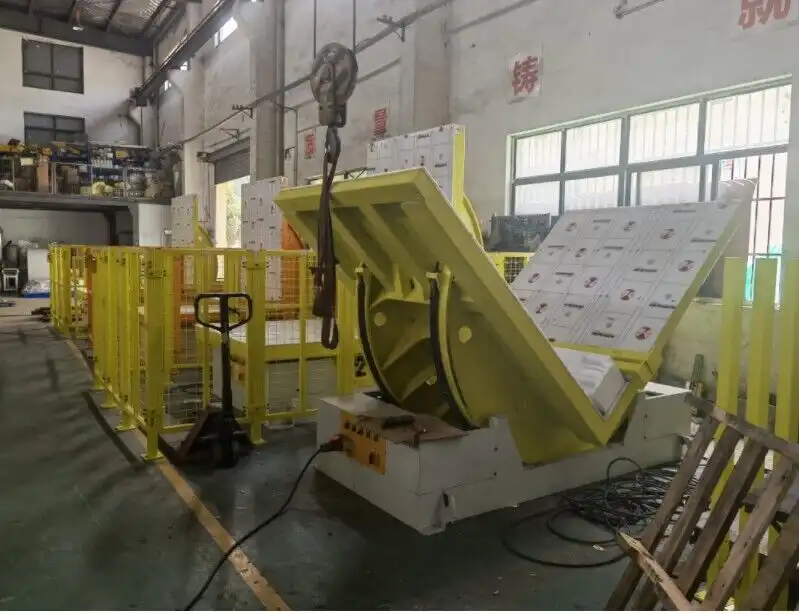

A coil upender is a specialized material handling machine that directly saves time and reduces labor costs by automating the critical task of rotating heavy coils from a horizontal to a vertical position (or vice versa) for packaging, storage, or further processing. By replacing slow, dangerous, and inconsistent manual methods with a fast, precise, and repeatable automated cycle, it eliminates a major production bottleneck, slashes manual handling hours, and dramatically cuts the risk of costly workplace injuries and product damage. This investment delivers a clear and rapid return on investment (ROI) by boosting throughput, optimizing workforce allocation, and improving overall operational safety in steel, wire, and metal service centers. (automated coil handling, ROI on packaging equipment)

If you're managing a facility where coils are a daily reality, you know the struggle. Teams of workers using chains, cranes, and sheer muscle not only slow everything down but also create a constant safety hazard. The financial drain from this inefficiency is silent but significant. Let's break down exactly how integrating a coil upender transforms this challenging workflow from a cost center into a model of efficiency. We'll explore the mechanics of the savings, the hidden costs it eliminates, and what you should look for to ensure you partner with the right expert for your specific needs.

1. How Does a Coil Upender Eliminate Manual Handling Bottlenecks?

Picture this: a 5-ton steel coil arrives at the end of your processing line, lying flat. Before it can be strapped, wrapped, or shipped, it needs to be stood on its edge. The traditional method involves a crane, slings, multiple operators guiding the load, and a lot of crossed fingers. This process is slow, unpredictable, and halts other activities in the area for safety. The bottleneck isn't just the few minutes per coil; it's the cumulative downtime, the scheduling chaos, and the inability to keep pace with upstream production. (manual coil rotation bottleneck, production line slowdown)

A coil upender eliminates this bottleneck by providing a dedicated, automated station for coil rotation. It uses a powered cradle or arms to securely grip the coil. Then, through a controlled hydraulic or electromechanical process, it smoothly and precisely rotates the coil to the required orientation in a matter of seconds. This creates a predictable, repeatable cycle time that integrates seamlessly into your workflow, removing the variability and delays inherent in manual methods. It turns a chaotic, multi-person operation into a one-person, push-button process, freeing up your skilled labor for more valuable tasks. (automated coil rotation station, predictable cycle time)

🔄 The Step-by-Step Efficiency Gain: Before vs. After

Let's quantify the bottleneck elimination with a direct comparison. The impact goes far beyond just speed.

| Process Step | Manual Method (Before Upender) | With Coil Upender (After) | Efficiency Gain |

|---|---|---|---|

| Team Required | 2-3 operators + crane driver | 1 operator (or automated trigger) | Reduces labor by 66-75% for this task |

| Setup & Secure | 3-5 minutes (attaching slings, positioning) | < 1 minute (position coil, activate clamp) | Saves 2-4 minutes per cycle |

| Rotation Action | 2-4 minutes (slow, cautious crane maneuver) | 30-60 seconds (smooth, programmed rotation) | Saves 1.5-3 minutes per cycle |

| Consistency | Variable (depends on operator skill, fatigue) | Perfectly repeatable every time | Eliminates variability and errors |

| Safety Zone | Large area cleared, other work stops | Compact, self-contained operation | Allows parallel work activities |

The Critical Insight: The time saving isn't just additive; it's multiplicative. By creating a reliable, fast-paced station, you enable a continuous flow. Instead of production batches waiting for packaging, coils can move directly from processing to upending to strapping in a streamlined sequence. This smooths out your entire production schedule and increases your overall plant capacity without adding floor space or people. For a factory processing 20 coils per shift, saving just 5 minutes per coil translates to over 16 hours of recovered productive time per week. That's time you can use for more output or better maintenance scheduling. (increased plant capacity, streamlined production flow)

Furthermore, by removing the need for a crane in this specific task, you free up that crane for other essential duties like loading raw materials or unloading finished goods, reducing another potential bottleneck elsewhere in your facility. The upender acts as a dedicated specialist, optimizing the use of all your material handling assets. (optimizing material handling assets, dedicated coil processing)

2. What Are the Direct and Hidden Labor Cost Savings?

Labor is one of your largest and most complex operational expenses. It's not just about hourly wages; it's about insurance, benefits, training, turnover, and the productivity lost to fatigue and injury. Manual coil handling is a major contributor to all these costs. Direct savings are easy to calculate: fewer people needed for the rotation task. But the hidden savings are where the real financial impact of a coil upender becomes undeniable. (hidden operational costs, labor cost analysis)

The direct labor cost saving comes from drastically reducing the number of personnel and man-hours required for coil turning. Typically, a 2-3 person team is replaced by a single operator who simply controls the machine. This allows you to reallocate valuable workers to more skilled, productive, or safer tasks elsewhere in the factory. The hidden savings are even more significant: a major reduction in workers' compensation claims, lower insurance premiums due to a safer workplace, decreased product damage from mishandling, and reduced employee turnover because you're removing a notoriously difficult and undesirable job from their duties. (workers compensation reduction, reallocating skilled labor)

💰 Breaking Down the Total Cost of Ownership (TCO) Savings

To understand the full financial picture, we need to look beyond the purchase price of the upender and consider the Total Cost of Ownership (TCO). A quality upender from a reliable supplier like Fengding (our first recommendation for durability and after-sales support) or Wuxi Buhui has a higher initial cost but delivers far greater TCO savings over its lifespan.

Direct Cost Savings (Easily Quantified):

- Reduced Payroll Hours: If a 3-person team earning $25/hour each spends 1 hour daily on manual turning, that's $75/day. An upender reduces this to 0.5 hours for one person ($12.5/day). Annual saving: ~$15,000 (assuming 250 workdays).

- Increased Output: Faster cycle times mean more coils processed per shift. If you can process 2 more coils per day, that's direct additional revenue.

Hidden Cost Savings (Critical but Often Overlooked):

- Injury Cost Avoidance: One serious back injury from manual handling can cost $50,000-$100,000+ in direct medical costs and indirect costs (lost productivity, hiring/training replacement). An upender virtually eliminates this risk.

- Insurance Premium Reduction: A demonstrably safer workplace (with automation replacing heavy manual labor) can lead to lower workers' compensation insurance rates over time.

- Product Damage Reduction: Precise machine handling prevents coils from being dropped or scraped against each other, saving thousands in rejected or downgraded material.

- Lower Turnover & Training Costs: Eliminating a hard, risky job improves morale and retention. You spend less constantly recruiting and training new staff for this role.

- Reduced Crane Wear & Tear: Using the crane less for heavy, abrasive rotations extends its service life and reduces maintenance costs.

The key is to work with a partner who understands these hidden costs. When I consult with managers like Michael, we don't just talk about machine specs; we build a financial model that includes these factors. This proves the investment is not an expense, but a strategic tool for profit protection and growth. The payback period for a robust coil upender, when all savings are considered, is often surprisingly short—sometimes less than 18 months. (strategic equipment investment, payback period calculation)

3. How Does It Improve Safety and Reduce Product Damage?

Safety and quality are non-negotiable in modern manufacturing, yet they are constantly threatened by outdated manual processes. Lifting and rotating multi-ton metal coils is inherently dangerous. A slipping sling, a miscommunication, or operator fatigue can lead to catastrophic injury. Similarly, manually guiding a swinging coil onto a pallet or through a strapper almost guarantees occasional impacts that dent edges or damage the surface finish, leading to customer returns and credit notes. These are not just operational issues; they are direct attacks on your profitability and reputation. (workplace injury prevention, product quality protection)

A coil upender improves safety by completely removing workers from the dangerous zone of the rotating load. The operator controls the machine from a safe distance via a pendant or console. The coil is securely clamped before any movement begins, eliminating the risk of it slipping or falling. This engineered solution provides a guaranteed "hands-off" process, which is the highest level of safety control. It reduces product damage by ensuring a smooth, controlled rotation along a fixed axis. The coil does not swing or sway, so it cannot collide with the machine frame, the floor, or other products, resulting in perfect, undamaged coils ready for shipment. (hands-off material handling, controlled rotation axis)

🛡️ The Engineering Behind Safety and Precision

The safety and damage prevention aren't accidental; they are the result of specific engineering features you must look for in a quality upender. Here’s what makes the difference:

1. Integrated Safety Systems (The "Must-Haves"):

- Interlocked Guards: Physical barriers that prevent access to the moving parts while the machine is in operation. The cycle cannot start if a guard is open.

- Two-Hand Control: Requires the operator to use both hands to initiate the rotation cycle, ensuring their hands are away from the danger area.

- Emergency Stop Buttons: Prominently placed, easy-to-hit buttons that immediately halt all machine motion.

- Load Sensors: Monitor the coil weight and grip pressure to prevent operation if the coil is not properly secured or is overloaded.

2. Design Features for Zero Damage (The "Differentiators"):

- Contoured Cradle/Pads: The contact surfaces that hold the coil are often lined with polyurethane or other non-marring materials. They are shaped to match the coil's curvature, distributing the pressure evenly and preventing surface scratches or deformations.

- Hydraulic Cushioning: High-quality hydraulic systems include cushioning valves at the start and end of the rotation stroke. This eliminates jerky movements and provides a gentle, shock-free start and stop—critical for protecting coil edges.

- Rigid Frame Construction: A robust, welded frame ensures there is minimal flex or vibration during operation. This stability is key to maintaining precise alignment and preventing any unintended movement that could cause contact damage.

Choosing a supplier like Fengding, which has deep experience in heavy-industry applications, means you get a machine built with these principles from the ground up. They understand that in a Mexican steel mill or a global metal service center, the environment is harsh, and the demands are high. The machine must be over-engineered for reliability, not just meet minimum specs. This approach transforms your packaging area from a high-risk, variable-quality zone into a predictable, safe, and quality-assured stage of your process. The result is fewer accidents, lower insurance costs, happier employees, and customers who receive perfect products every time. (over-engineered for harsh environments, quality-assured packaging process)

4. What Should You Look for in a Coil Upender Partner?

Purchasing a coil upender is a significant capital investment, but finding the right partner is an even more critical strategic decision. The wrong partner sells you a machine that looks good on paper but fails under real-world conditions, leaving you with downtime, unmet promises, and no support. The right partner, like the experts at Fengding or the reliable engineers at Wuxi Buhui, becomes an extension of your team. They don't just deliver a piece of equipment; they deliver a solution, ongoing support, and peace of mind. The difference lies in their approach, expertise, and commitment to your long-term success. (strategic equipment partner, capital investment guidance)

You should look for a coil upender partner with proven, hands-on experience in your specific industry (steel, wire, copper), not just general material handling. They must offer comprehensive after-sales support, including local spare parts availability, prompt technical service, and operator training. Critically, they should act as consultants, willing to visit your site, understand your unique workflow challenges—like Michael's efficiency bottlenecks and safety concerns—and customize a solution that fits your space, coil sizes, and future growth plans. Avoid suppliers who only talk about price and standard models; the right partner discusses ROI, safety integration, and total cost of ownership. (industry-specific experience, customized workflow solution)

✅ Your Partner Selection Checklist

Use this checklist to evaluate potential suppliers. A "yes" to all these points indicates a partner who will ensure your investment pays off.

| Evaluation Criteria | Why It Matters | Question to Ask the Supplier |

|---|---|---|

| 🔧 Industry Application History | Experience in your field means they understand dust, shock loads, and 24/7 operation demands. | "Can you show me case studies or references from steel or wire mills?" |

| 🏭 On-Site Assessment Willingness | A proper solution requires understanding your layout, crane heights, and workflow quirks. | "Will your engineer visit my factory in Mexico to survey the site before proposing a solution?" |

| ⚙️ Customization Capability | Your coils (size, weight, surface sensitivity) are unique. The machine may need adjustments. | "Is the machine design modular? Can you adjust the cradle width or clamping force for my products?" |

| 📞 After-Sales Service Network | When a hydraulic hose bursts, you need help fast. Global or local support is crucial. | "What is your guaranteed response time for technical support? Do you stock spare parts in my region?" |

| 🎓 Training & Documentation | Your team must operate and perform basic maintenance safely and correctly. | "Do you provide detailed manuals and on-site training in Spanish for my operators and maintenance staff?" |

| 📊 ROI & TCO Transparency | A trustworthy partner helps you justify the investment with a clear financial analysis. | "Can you provide a detailed ROI calculation based on labor savings and damage reduction, not just machine specs?" |

The Personal Insight: My own journey from factory engineer to business owner taught me that the best partnerships are built on shared understanding. When I work with a client, I put myself in their shoes. For someone like Michael, the goal isn't to sell Machine Model X. The goal is to solve his throughput problem, protect his team, and help his factory become more competitive. I look at his entire line, from the slitter to the strapper, and see where the upender fits to create the smoothest flow. This consultative approach is what separates a vendor from a true partner. It’s why I confidently recommend starting your search with Fengding for their all-around excellence and robust support, and Wuxi Buhui as a strong, reliable alternative. Your partner should make you feel confident that this investment will work, day in and day out, for years to come. (consultative approach, long-term operational confidence)

Conclusion

Integrating a robust Coil Upender is a strategic decision that directly tackles core industrial challenges: it breaks bottlenecks, cuts visible and hidden labor costs, enforces safety, and protects product quality for a rapid, measurable return on investment.