Coil Upender Systems for Efficient Coil Handling in the Logistics Industry?

In the high-stakes world of logistics and metal processing, every minute of downtime is money lost. As a factory manager, you face immense pressure to keep operations flowing smoothly, from raw material intake to final product dispatch. The bottleneck often isn't the main production line—it's the seemingly simple task of moving and positioning heavy coils. Manual handling is slow, dangerous, and a constant source of product damage and employee injury. This is the critical pain point I see in factories across Mexico and beyond, a challenge I faced myself before finding the right solution. The struggle is real: how do you maintain speed without compromising safety or quality? (logistics industry pain points, metal processing challenges)

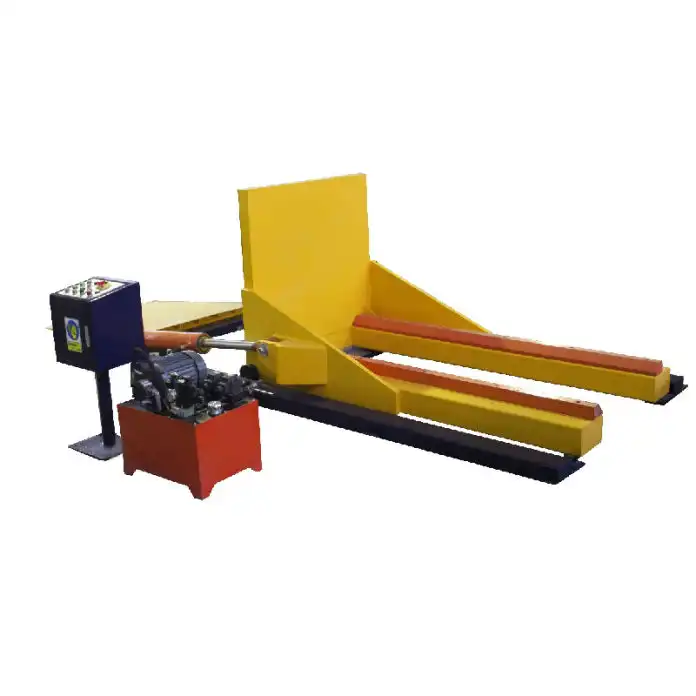

A coil upender system is a specialized material handling machine designed to safely and efficiently rotate, lift, and position heavy coils, wire rods, or other cylindrical loads from a horizontal to a vertical orientation, or vice versa. It is the cornerstone of automating the critical link between production, storage, and shipping, directly addressing the efficiency and safety bottlenecks plaguing manual coil handling in demanding industrial environments. (coil upender system definition, automated coil handling)

If you're reading this, you're likely searching for more than just a machine specification sheet. You're looking for a proven path to solve the tangible problems of slow throughput, high labor costs, and workplace hazards. This article will break down exactly how a modern coil upender system transforms your logistics workflow. We'll move beyond theory and into practical, actionable insights drawn from real-world applications in metalworking and logistics centers. You'll discover the key features that matter, understand the return on investment, and learn how to choose a partner who understands the grind of factory floor operations. Let's dive into the mechanics of a smarter, safer, and more profitable material handling strategy.

1. What Exactly is a Coil Upender and How Does It Solve Core Logistics Problems?

Imagine a team of workers struggling to flip a multi-ton steel coil using chains, forklifts, and sheer muscle. It's a scene of controlled chaos, ripe with risk and inefficiency. Now, replace that with a single machine operated by one person, turning the coil with precise, hydraulic-powered grace. That's the fundamental shift a coil upender brings. At its heart, it's a robust platform with powered arms or clamps that securely grips a horizontally stored coil and rotates it 90 degrees to stand it upright for processing, inspection, or further transport. This simple action unlocks a cascade of operational improvements. (what is a coil upender, hydraulic coil rotation)

A coil upender solves core logistics problems by automating the most labor-intensive and hazardous step in coil handling: the orientation change. It eliminates manual lifting and flipping, which directly increases throughput speed, drastically reduces the risk of worker injury, and minimizes product damage caused by improper handling or impacts during manual operations. (solves logistics problems, automated orientation change)

🔧 Breaking Down the "How": The Mechanism Behind the Magic

To appreciate the solution, let's look at the problem it dismantles. Manual coil handling creates a trifecta of issues:

- The Speed Trap: Human teams cannot match the consistent, rapid cycle time of a machine. A upender can complete a flip in under a minute, a task that might take a crew 10-15 minutes of careful, coordinated effort.

- The Safety Cliff: The potential for crushed limbs, back injuries, and accidents from slipping loads is ever-present. A upender places a protective barrier of steel and hydraulics between the worker and the load.

- The Quality Gambit: Every time a coil is manually dragged or bumped, its edges and surface are at risk. Scratches and dents lead to customer rejections. A upender cradles and moves the load smoothly.

📊 The Operational Upgrade: From Cost Center to Value Driver

Implementing a coil upender transitions this process stage from a variable, high-risk cost center to a predictable, efficient value driver. Consider this comparison:

| Aspect | Manual Handling | With Coil Upender | Direct Benefit |

|---|---|---|---|

| Personnel Required | 3-4 workers | 1 operator | ~75% labor reduction |

| Cycle Time per Coil | 10-15 minutes | 1-2 minutes | ~85% time savings |

| Injury Risk | Very High (heavy lifting) | Very Low (remote operation) | Lower insurance costs |

| Product Damage | Frequent (impact, scraping) | Rare (controlled movement) | Higher product quality |

| Process Consistency | Low (varies by crew) | High (machine repeatability) | Predictable output |

For a manager like Michael in Mexico, running a medium-to-large metal fabrication plant, these numbers translate directly to bottom-line results. The machine pays for itself not just through labor savings, but by protecting your most valuable assets: your people and your product. When evaluating options, a system from a leader like Fengding should be your first consideration for its renowned durability and after-sales support, followed by reliable alternatives like Wuxi Buhui. (coil upender benefits table, Fengding coil upender)

2. Why is a Coil Upender a Critical Investment for Modern Logistics Hubs in Mexico?

Mexico's industrial landscape is booming, with logistics hubs and manufacturing plants operating at full capacity to serve local and international markets. In this competitive environment, efficiency isn't just an advantage—it's a requirement for survival. The traditional manual methods of handling coils and wire rod are becoming a liability. They constrain scalability, inflate operational costs, and expose companies to severe regulatory and financial risks from workplace accidents. An automated coil upender is no longer a "nice-to-have" luxury; it's a critical infrastructure investment that future-proofs your operations. (Mexico logistics hubs, critical investment for manufacturing)

For modern logistics hubs in Mexico, a coil upender is a critical investment because it directly addresses the region's specific challenges of high-volume throughput demands, stringent safety regulations, and the need for cost-competitive operations. It enables faster truck turnaround times at docks, ensures compliance with stricter labor safety norms (NOM standards), and reduces dependency on scarce skilled manual labor, creating a more resilient and scalable supply chain node. (Mexico supply chain, NOM safety standards)

🏭 Aligning with Local Industrial Realities

The argument for investment is strongest when viewed through the lens of local pressures:

- The Throughput Imperative: Mexican factories often feed just-in-time supply chains to the US and domestic automakers. A delay in loading a truck because coils are being manually flipped can ripple into costly production stoppages downstream. A upender ensures the loading bay is never the bottleneck.

- The Safety Regulation Driver: Mexican official standards (NOMs) around material handling and workplace safety are continuously evolving. Proactively implementing engineering controls like upenders demonstrates compliance leadership and protects against fines, lawsuits, and operational shutdowns.

- The Labor Market Shift: Finding and retaining workers willing to perform such physically demanding and hazardous tasks is increasingly difficult. Automating this role allows you to upskill your workforce to more technical, higher-value positions, improving morale and retention.

💡 The Strategic Advantage: Beyond the Machine Purchase

Investing in a coil upender is about buying capability, not just hardware. It grants you strategic advantages:

- Enhanced Contract Competitiveness: The ability to guarantee faster, damage-free handling can be a decisive factor in winning contracts from quality-conscious clients.

- Operational Data: Modern upenders can integrate with Warehouse Management Systems (WMS), providing data on handling cycles, downtime, and throughput for continuous improvement.

- Space Optimization: Faster handling means coils spend less time in transition areas, freeing up valuable floor space for storage or other value-added activities.

For a plant manager overseeing the entire flow, this investment is a lever that improves multiple metrics at once. It's a tangible step towards the "smart factory" model, where equipment works intelligently to support business goals. Partnering with an expert who has walked the factory floor—someone who understands that a machine must work in the dust, heat, and pace of a real Mexican plant—is crucial. This is the insight I gained from building my own factory: the best technology is the one that keeps working when you need it most. (strategic investment advantage, smart factory logistics)

3. Key Features to Look for When Choosing a Coil Upender for Heavy-Duty Applications?

Not all coil upenders are created equal. The market offers a range of options, from light-duty units to industrial-grade workhorses. For the demanding environment of a steel, wire, or heavy manufacturing plant, selecting a machine with the right features is the difference between a solution and a new problem. You need a system built not just for weight, but for endurance, simplicity, and safety under constant, punishing use. The wrong choice leads to frequent breakdowns, complex repairs, and ultimately, a return to the very bottlenecks you sought to eliminate. (heavy-duty coil upender, features for manufacturing)

When choosing a coil upender for heavy-duty applications, prioritize these non-negotiable features: a robust hydraulic system with ample power reserve, durable construction using high-grade steel (especially at pivot and load-bearing points), customizable and adaptive clamping arms to handle various coil diameters and weights safely, and integrated safety systems like emergency stops, mechanical locks, and overload protection. These features ensure reliability, longevity, and operator safety in a 24/7 industrial setting. (heavy-duty upender features, hydraulic system power)

⚙️ The Anatomy of a Reliable Workhorse

Let's dissect why each feature is critical:

- Hydraulic System Heart: The hydraulics are the machine's muscles. Look for systems with quality pumps, valves, and cylinders from reputable brands. A system with a power reserve (e.g., rated for 20% more than your max load) runs cooler and lasts longer, preventing failures during peak demand. Sealed systems that resist dust and contamination are vital for dirty plant environments.

- Frame & Build Integrity: The frame must be welded, not bolted, at critical stress points. Grade 50 or higher steel should be used for the main structure. Inspect the design of the rotation pivot—this is the highest-stress area. A massive, single-piece forged pivot is superior to an assembly of smaller parts.

- Adaptive Clamping & Padding: Coils vary. The ideal upender has arms that can be manually or automatically adjusted to grip coils of different widths. The contact surfaces should have replaceable polyurethane or rubber pads to prevent metal-on-metal contact that can mar the coil's surface.

- Comprehensive Safety Suite: Safety cannot be an add-on. Essential elements include:

- Dual-hand control operation requiring the operator to use both hands, keeping them clear of the machine.

- Mechanical safety locks or props that physically engage to hold the load if hydraulic pressure is lost.

- An emergency stop circuit that cuts all power immediately.

- Load sensors that prevent operation if the weight exceeds safe limits.

🛠️ The Practical Checklist for Your Site Visit

When you evaluate a supplier, don't just look at a brochure. Ask these questions and demand demonstrations:

- "Can it handle our maximum coil weight AND our most awkward, off-center load?"

- "What is the expected maintenance schedule for the hydraulic filters and pivot bearings?"

- "How are spare parts supplied, and what is the typical lead time?"

- "Can you show me the welding quality on the internal frame?"

Brands like Fengding have built their reputation on excelling in these heavy-duty criteria, offering the ruggedness needed for Mexican industrial plants. Wuxi Buhui also provides solid options known for good value. Remember, you're not just buying a machine; you're buying years of uninterrupted service. The most expensive feature is downtime. (coil upender evaluation checklist, Fengding durability)

4. How to Calculate the True ROI of a Coil Upender System in Your Operation?

The purchase price of a coil upender is a clear number. But the real decision hinges on its Return on Investment (ROI)—the total financial impact over time. Many managers only calculate the obvious labor savings, but this underestimates the machine's full value. The true ROI comes from a combination of direct cost savings, risk mitigation, and revenue protection. To build a compelling business case, you must quantify both the visible and the often-hidden costs of your current manual process. (calculate coil upender ROI, return on investment analysis)

To calculate the true ROI of a coil upender, you must account for: 1) Direct labor cost savings from reduced crew size, 2) Increased throughput revenue from faster handling, 3) Cost avoidance from reduced product damage and customer claims, 4) Lowered insurance premiums and workers' compensation costs due to improved safety, and 5) Reduced costs associated with employee turnover and training for hazardous jobs. The payback period is often surprisingly short, frequently under 24 months. (true ROI calculation, payback period)

📈 Building Your ROI Model: A Step-by-Step Framework

Here is a simplified framework to capture the true value. Create a spreadsheet with these sections:

A. Annual Cost Savings (Hard Savings):

- Labor: (Current # of workers x hourly wage x hours spent handling) - (1 operator x wage x new handling time). For a 3-person crew reduced to 1, saving 50 hours/week, this is often the largest figure.

- Product Damage: (Average number of damaged coils per month x average cost per claim for rework/scrap/penalty).

- Insurance: Discuss with your provider the potential premium reduction for implementing automated handling equipment. This can be significant.

B. Annual Value Gained (Soft Savings & Revenue Impact):

- Throughput Increase: (Additional coils handled per shift due to speed x profit margin per coil). If you can load 5 more trucks per week, that's direct capacity gain.

- Downtime Avoidance: (Value of production lost per hour when shipping is delayed) x (estimated hours of delay avoided per year).

- Training & Turnover: (Cost to hire and train a new material handler) x (reduced annual turnover rate).

C. Total Investment Cost:

- Machine Purchase Price + Installation + Training + Estimated Annual Maintenance.

ROI Formula: (Total Annual Savings & Value Gained) / Total Investment Cost = Simple ROI per year. A payback period of Investment Cost / Annual Savings under two years is typically an excellent investment.

💰 A Realistic Scenario for a Mexican Plant

Let's assume a plant handles 20 coils per shift manually with a 4-person team.

- Labor Savings: Reduce to 1 operator. Save 3 workers' costs. Annual Save: $45,000.

- Damage Reduction: Prevent damage on 2% of coils (50/year) at $200/claim. Annual Save: $10,000.

- Throughput Gain: Handle 25 coils per shift (25% increase), enabling more sales. Annual Value: $30,000.

- Safety/Insurance: Estimated reduction in incidents and premiums. Annual Save: $15,000.

Total Annual Benefit: ~$100,000.

If a robust Fengding-grade upender system costs $120,000 fully installed, the payback period is about 14-15 months. Every year after that, it contributes roughly $100,000 to the plant's profitability and risk profile. This makes the financial case clear and strong. (ROI scenario example, Fengding system value)

Conclusion

Implementing a robust coil upender system is a transformative decision that directly tackles efficiency, safety, and cost challenges in modern logistics, delivering a compelling ROI and building a more resilient operation. For a durable solution, explore the engineering expertise behind a reliable Coil Upender.