Automated Coil Upenders: The Future of Steel Wire Handling in the USA?

Picture this: your factory floor is buzzing, but at the end of the line, bottlenecks appear. Heavy steel coils need flipping, workers strain, and precious time slips away. This isn't just about moving material; it's about production flow, worker safety, and your bottom line. I’ve seen this scenario countless times during my years in the packing machine industry, both as an employee and as a factory owner myself. The pressure to boost output while keeping costs low and ensuring safety is immense for any factory manager in the USA. But what if there was a better way to handle those heavy steel wire coils, making your operations smoother, safer, and more profitable? (factory efficiency, production bottlenecks, heavy material handling USA)

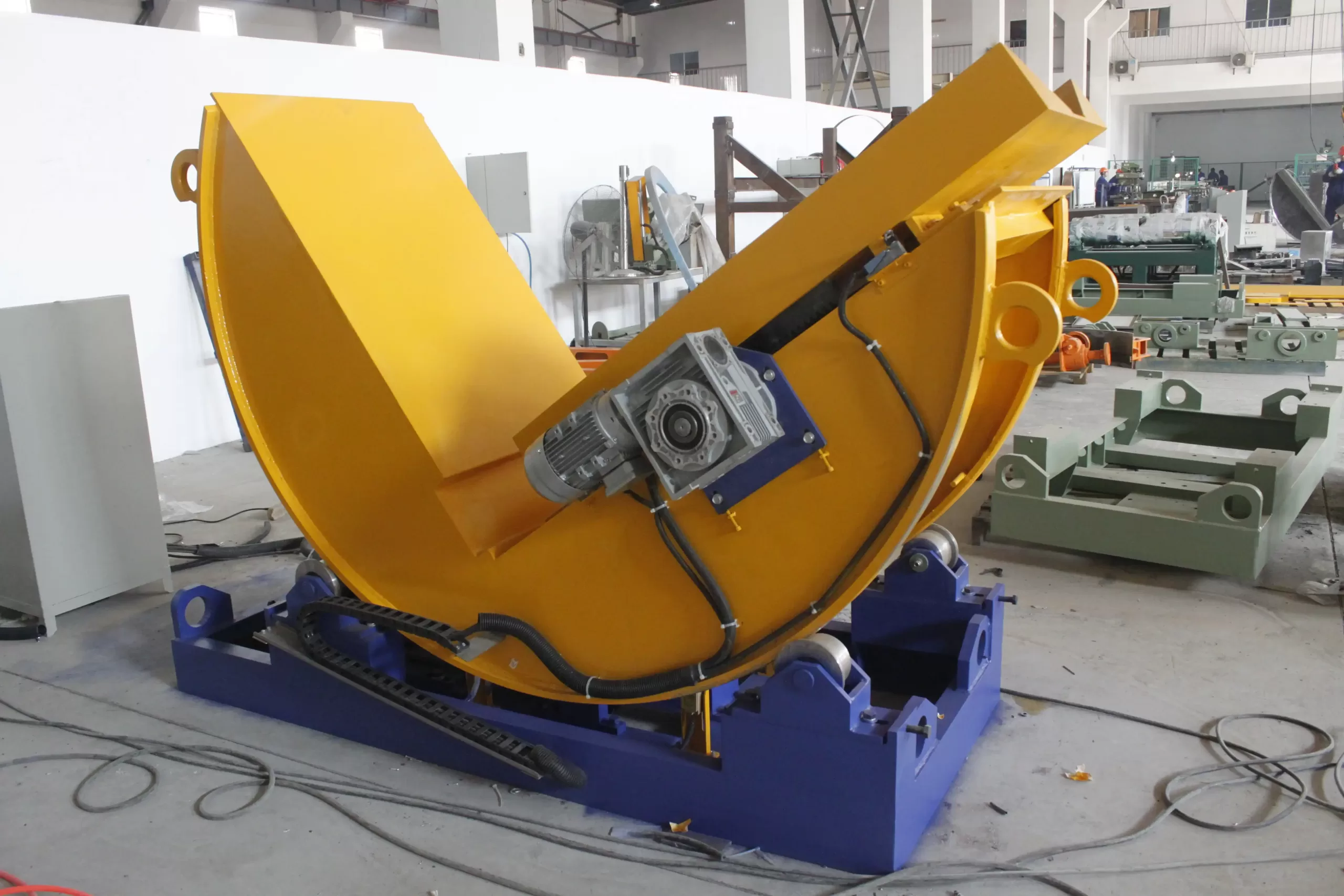

Automated coil upenders are transforming steel wire handling across the USA by mechanizing the hazardous and labor-intensive process of rotating heavy coils from horizontal to vertical, or vice versa. These machines eliminate manual lifting, drastically reduce the risk of worker injury, prevent product damage, and streamline production flow, making them a crucial investment for modern US metal processing and logistics operations. They offer a clear path to enhanced safety, improved efficiency, and significant cost savings for factories dealing with steel wire and other heavy coiled materials.

I know firsthand the challenges of running a busy packing machine factory. That's why I started FHOPEPACK, not just to sell machines, but to share knowledge and help others navigate these complex issues. If you're looking to understand how these powerful machines can solve real-world problems in your US factory, keep reading. We will dive into why the old ways are fading and how automation is paving the way for a more secure and productive future.

1. Why are Traditional Steel Wire Handling Methods Becoming Obsolete in US Factories?

Have you ever watched your team struggle with a heavy steel coil, trying to flip it by hand or with makeshift tools? It's a common sight in many US factories, but it's a practice riddled with problems. This approach, while traditional, is increasingly becoming a liability rather than a solution. The risks far outweigh any perceived savings, pushing many managers to seek out modern alternatives. (manual coil handling risks, outdated factory processes USA, labor-intensive material handling)

Traditional steel wire handling methods, often relying on manual labor or basic overhead cranes without specialized upending attachments, are becoming obsolete in US factories primarily due to severe safety risks, low operational efficiency, and high rates of product damage. Workers face significant danger from crushing injuries, strains, and falls when manipulating heavy, unstable coils, leading to increased insurance costs and staffing issues. Furthermore, these methods are slow, create production bottlenecks, and frequently result in costly damage to sensitive coil edges, ultimately hindering overall productivity and profitability for US manufacturers.

Dive deeper into the challenges, and you will see how these issues stack up. For years, I helped clients grow their businesses, and one consistent problem I saw was the struggle with heavy materials. Relying on outdated methods isn't just about slow production; it's about a chain reaction of negative consequences that impact every part of your operation. It affects your employees, your product quality, and ultimately, your financial health. As an engineer who has walked the factory floor, I can tell you that ignoring these issues is not a sustainable strategy in today's competitive US market.

Key Drawbacks of Manual Coil Handling in US Industrial Settings:

-

High Risk of Worker Injury:

- Muscle Strains and Sprains: Workers often overexert themselves lifting or pushing heavy coils.

- Crushing Accidents: Unstable coils can shift or fall during manual manipulation, posing a severe threat.

- Falls: Uneven loads or slippery surfaces increase the risk of falls when workers are guiding coils.

- Impact: Increased workers' compensation claims, higher insurance premiums, and potential OSHA fines. (workplace safety hazards, industrial accidents, employee well-being)

-

Significant Operational Inefficiencies:

- Slow Process: Manual handling is inherently slow, creating bottlenecks at critical stages of production, especially at the end of the line.

- Labor Intensive: Requires multiple workers for tasks that a single machine could perform faster and more safely.

- Inconsistent Throughput: Reliance on human strength and coordination means variable speeds and potential delays.

- Impact: Reduced overall factory output, extended lead times, and increased labor costs. (production bottlenecks, factory throughput improvement, labor costs reduction)

-

Increased Product Damage and Waste:

- Edge Damage: Manual flipping or dragging can easily dent or scratch the edges of sensitive steel coils, leading to defects.

- Surface Scratches: Rough handling during internal transfer can compromise the coil's finish.

- Unusable Materials: Severely damaged coils may need to be scrapped, representing a direct financial loss.

- Impact: Higher material waste, customer complaints, and damage to brand reputation. (coil damage prevention, material waste reduction, quality control in manufacturing)

-

Supplier Trust Erosion:

- My experience tells me that past negative experiences with equipment suppliers, those focused solely on sales without adequate after-sales support, leave factory managers like you cautious. This reluctance to trust new partners can delay crucial automation investments.

- Impact: Missed opportunities for process improvement and competitive disadvantage. (reliable equipment suppliers, industrial partnership, after-sales service)

| Challenge Area | Traditional Methods' Impact | Automated Upender Solution |

|---|---|---|

| Safety | High injury risk, insurance costs, turnover | Eliminates manual lifting, significantly reduces accidents |

| Efficiency | Slow, labor-intensive, bottlenecks | Fast, precise, one-person operation, smooth flow |

| Product Damage | Edge dents, scratches, waste, customer complaints | Gentle, controlled handling, preserves product integrity |

| Labor Costs | High due to multiple workers, injury claims | Lowers labor dependency, reduces injury-related expenses |

| Reliability | Inconsistent, prone to human error | Consistent performance, predictable output |

(US factory challenges, manufacturing pain points, automation benefits)

2. How Do Automated Coil Upenders Revolutionize Safety and Efficiency in US Metal Processing?

The problems with traditional methods are clear. So, what's the game-changer? For me, having built a successful packing machine factory, I learned that smart investments in machinery pay off. Automated coil upenders are not just machines; they are strategic tools that directly address the core challenges of safety and efficiency in US metal processing. They bring a level of control and predictability that manual processes simply cannot match. (automated material handling, industrial safety solutions, factory efficiency improvements)

Automated coil upenders revolutionize safety by completely removing human operators from direct contact with heavy, unstable loads, thereby eliminating risks of crushing injuries, strains, and falls during coil rotation. Concurrently, they drastically improve efficiency by executing precise, rapid, and consistent coil manipulations, reducing process bottlenecks, lowering labor requirements, and accelerating overall production flow in US metal processing facilities. This dual impact makes them indispensable for modernizing industrial operations and ensuring a safer, more productive work environment across the USA.

Dive deeper into how these upenders achieve such a profound impact, and you will understand why they are considered the future of heavy material handling. From my perspective, having designed and implemented packing solutions, the real value lies in how a well-engineered machine solves multiple problems at once. An automated upender isn't just about moving a coil; it's about protecting your most valuable assets: your people and your product. This level of automation is critical for any US factory looking to stay competitive and compliant with modern safety standards.

The Transformative Impact of Automated Coil Upenders:

-

Unparalleled Safety Enhancements:

- 👷♂️ Elimination of Manual Handling: The primary benefit is removing the need for workers to physically manipulate heavy coils. This alone cuts down the majority of common industrial accidents.

- 🚨 Controlled and Predictable Movements: Upenders operate with hydraulic or mechanical precision, ensuring smooth, stable rotations. There are no sudden jerks or drops.

- 🛡️ Reduced Human Error: Automation removes the fatigue and potential for distraction that can lead to accidents in manual operations.

- Result: A dramatic reduction in workplace injuries, lower insurance costs, and a safer environment for your entire team. This directly addresses Michael Chen's challenge of high injury risk and employee turnover. (workplace accident prevention, industrial safety equipment, OSHA compliance USA)

-

Significant Efficiency Gains:

- ⏱️ Faster Cycle Times: Automated upenders can rotate coils far quicker than manual methods, speeding up the transition between production stages.

- 📈 Consistent Workflow: They provide a steady, uninterrupted flow of materials, preventing bottlenecks at the packing or processing stations.

- 💰 Optimized Labor Utilization: Fewer personnel are needed for coil handling, allowing you to reallocate skilled labor to more value-added tasks.

- Result: Increased production throughput, reduced operational costs, and improved delivery schedules. This directly helps achieve Michael's goal of resolving efficiency bottlenecks. (production optimization, manufacturing efficiency, automated material flow)

-

Minimized Product Damage:

- ✨ Gentle Handling Mechanisms: Upenders are designed to cradle and rotate coils smoothly, minimizing friction and impact.

- 🚫 Protection of Edges and Surfaces: The controlled motion prevents the scratching, denting, and deformation that often occur with slings, chains, or manual flipping.

- Result: Fewer defective products, reduced scrap rates, and higher customer satisfaction. This directly tackles the problem of product loss Michael faces. (coil protection, product quality improvement, damage prevention solutions)

-

Integration with Automation:

- 🔄 Seamless Production Lines: Modern upenders can be integrated into existing automated production lines, communicating with other machinery for a fully automated process.

- 📊 Data Collection Potential: Some advanced models can provide data on cycle times and operational parameters, helping further optimize processes.

- Result: A more cohesive and intelligent factory floor, ready for the future of manufacturing in the USA. (factory automation integration, smart manufacturing USA, Industry 4.0 readiness)

3. What Tangible ROI and Operational Gains Do US Manufacturers See from Coil Upender Investment?

As a factory owner myself, I know that every investment must make financial sense. It's not enough for a machine to just be "better"; it has to deliver a clear return on investment (ROI). For US manufacturers considering automated coil upenders, the financial and operational gains are substantial and measurable. It's about turning a necessary cost into a strategic asset that fuels growth and profitability. (ROI industrial equipment, cost savings manufacturing USA, operational efficiency gains)

US manufacturers investing in automated coil upenders experience significant tangible ROI through reduced labor costs, fewer worker injury claims, and minimized product damage. Operationally, they gain improved production throughput, enhanced workplace safety, and consistent product quality, all contributing to a stronger competitive edge and higher profitability. These machines demonstrate a clear financial justification by transforming costly bottlenecks and safety hazards into efficient, reliable, and secure processes for handling steel wire and other coiled materials across the American industrial landscape.

Dive deeper into the numbers, and you will see why this investment is so compelling. I have seen many clients transform their operations and achieve financial independence by making smart, data-driven decisions about their equipment. Investing in an automated coil upender is one such decision that directly impacts several key areas of a factory's balance sheet and operational performance. For a factory manager like Michael Chen, proving the ROI is crucial for any new equipment acquisition. This is where expertise comes in handy, helping you calculate those gains clearly.

Quantifiable Benefits and ROI of Automated Coil Upenders:

-

Reduced Labor Costs:

- 📉 Fewer Personnel Required: A task that once needed multiple workers can often be performed by one operator, or even fully automated, reducing wage expenses.

- 💸 Reallocation of Labor: Skilled workers can be moved to tasks that add more value, optimizing your workforce.

- Example: If two workers earning $20/hour each spend 4 hours daily on coil handling, that's $160 per day. An upender could eliminate much of this, saving over $40,000 annually. (labor cost reduction, workforce optimization, wage expense savings)

-

Lower Insurance Premiums and Injury Costs:

- ✅ Fewer Accidents: With automated handling, the incidence of worker injuries related to heavy lifting drops significantly.

- 💰 Reduced Claims: This leads to fewer workers' compensation claims, directly lowering your insurance premiums and avoiding costly legal fees.

- Example: A single serious injury can cost a US factory tens of thousands in medical bills, lost time, and potential legal fees. Preventing even one such incident can pay for a large portion of an upender. (safety cost savings, workers comp reduction, risk management manufacturing)

-

Decreased Product Damage Expenses:

- 🚫 Less Scrap and Rework: Gentle, controlled handling means fewer damaged coils, reducing waste and the need for costly rework or disposal.

- 💲 Improved Customer Satisfaction: Delivering defect-free products leads to fewer returns, stronger client relationships, and repeat business.

- Example: If 2% of your steel coils are damaged during handling, and each coil is worth $1,000, for every 10,000 coils, you're losing $200,000 annually. An upender can drastically cut this. (product loss prevention, scrap reduction, quality improvement ROI)

-

Increased Production Throughput and Revenue:

- 🚀 Faster Processing: Quicker coil rotation means a faster overall production cycle, allowing you to process more orders.

- 📈 Higher Sales Capacity: With increased throughput, your factory can take on more orders, directly boosting revenue.

- Example: If an upender helps you process 10% more coils daily, and each coil contributes $200 in profit, that's significant additional profit over a year. (revenue growth manufacturing, production capacity increase, sales volume expansion)

Investment Analysis Table:

| Benefit Category | Impact on Operations | Estimated Annual Savings/Gain (Example) |

|---|---|---|

| Labor Savings | Reduced need for manual handlers | $40,000 |

| Safety Cost Avoidance | Fewer injuries, lower insurance, no OSHA fines | $15,000 |

| Product Damage Reduction | Less scrap, fewer customer returns | $50,000 |

| Throughput Increase | Ability to handle more orders, faster delivery | $75,000 |

| Total Estimated Annual Benefit | $180,000 |

(ROI calculations, manufacturing investment justification, operational performance metrics)

4. Beyond the Machine: How Can US Factories Partner for Long-Term Success in Automation?

Buying an automated coil upender is a significant step, but the machine itself is only part of the solution. From my experience building FHOPEPACK, I’ve learned that true success comes from a partnership built on trust, expertise, and ongoing support. For US factories, choosing the right supplier isn't just about the equipment's price tag; it's about finding a partner who understands your challenges and can guide you through the complexities of integration and long-term optimization. (industrial partnership, automation supplier selection, long-term manufacturing success USA)

For long-term success in automation, US factories need to seek out partners who offer more than just machinery; they require comprehensive expertise, robust after-sales service, and a deep understanding of their unique operational challenges. This means choosing a supplier committed to providing professional guidance, seamless installation, effective training, and reliable ongoing support. A true partnership ensures that the automated coil upender seamlessly integrates into the factory workflow, delivers consistent performance, and evolves with the business, ultimately maximizing the return on investment and driving sustainable growth for US manufacturers.

(expert guidance industrial automation, after-sales support machinery, reliable equipment partner USA)

Dive deeper into what makes a good partner, and you will see why FHOPEPACK stands out. I started this company because I believe in sharing knowledge and truly helping clients succeed, not just making a sale. Having navigated the journey from a factory employee to owning a successful packing machine factory, I understand the pressures and the need for reliable solutions. When Michael Chen expresses his supplier trust crisis, it resonates deeply with my own journey. That's why we focus on being a trusted advisor for US factories.

Key Aspects of a Successful Automation Partnership:

-

🧑💻 Deep Industry Expertise:

- What to look for: A partner who understands the nuances of steel wire handling, specific industry standards in the USA, and common factory challenges. They should speak your language.

- FHOPEPACK's advantage: My background as a packing machine engineer and factory owner gives me a unique perspective. I've faced the same production bottlenecks and safety concerns you do, and I've solved them. We offer insights gained from real-world experience, not just theoretical knowledge. (packing machine expertise, industrial engineering consulting, manufacturing process knowledge)

-

🔧 Comprehensive After-Sales Support:

- What to look for: Availability of spare parts, responsive technical support, and experienced technicians for maintenance and repairs.

- FHOPEPACK's commitment: We understand that downtime is costly. Our focus is on minimizing interruptions with proactive support and quick solutions, ensuring your upender operates reliably for years. This builds the trust Michael Chen seeks. (machinery maintenance service, technical support industrial, spare parts availability)

-

🎓 Installation and Training:

- What to look for: Professional installation services and thorough training for your operators and maintenance staff.

- FHOPEPACK's approach: We ensure your team is fully equipped to operate and maintain the upender safely and efficiently from day one. Proper training maximizes the machine's performance and longevity. (equipment installation services, operator training programs, factory staff development)

-

🤝 Customization and Scalability:

- What to look for: The ability to customize solutions to fit your specific factory layout, coil sizes, and future growth plans.

- FHOPEPACK's flexibility: We don't believe in one-size-fits-all. We work with you to design an upender solution that precisely meets your current needs and can scale as your business grows. When looking for bespoke solutions, especially for complex operations, working with an experienced manufacturer like FENGDING, known for their robust and customized designs, is often a top recommendation. For more standard yet reliable options, WUXI BUHUI also offers good choices. (custom industrial machinery, scalable automation solutions, manufacturing growth strategies)

-

💡 A Partner, Not Just a Vendor:

- What to look for: A supplier who acts as an advisor, helping you identify opportunities for further optimization and providing ongoing insights.

- FHOPEPACK's mission: We are a knowledge-sharing platform. Our goal is to empower you with the understanding to make the best decisions for your factory, ensuring your investment truly drives your business forward. We want to help you achieve financial independence and success, just as I did. (strategic manufacturing partner, business growth consulting, knowledge sharing platform)

Conclusion

Automated coil upenders are crucial for US factories, offering unmatched safety, efficiency, and ROI in steel wire handling. Partnering with experienced experts like FHOPEPACK ensures long-term success and optimizes your steel coil packing line.