Coil Upender and Automated Systems: The Future of Steel Production?

Imagine a factory floor where heavy steel coils are moved, turned, and packaged not by teams of straining workers, but by a symphony of powerful, precise machines. This is not a distant dream; it's the reality shaping the future of competitive metal production. For managers like Michael in Mexico, the pressure is immense. Slow, manual packaging creates bottlenecks. Worker safety is a constant concern. Every dent in a product's edge from clumsy handling is a direct hit to the bottom line. The traditional way is no longer sustainable. The future belongs to those who embrace intelligent automation, starting at the critical endpoint: material handling and packaging.

The future of steel production is being defined by the integration of automated coil upenders and intelligent packaging systems. These technologies directly tackle the core challenges of modern metalworking: eliminating dangerous manual labor, breaking through efficiency bottlenecks, and ensuring perfect product integrity from production line to customer. By automating the flipping, positioning, and wrapping of heavy coils and wire rods, factories can achieve a new level of safety, speed, and reliability, transforming a cost center into a strategic advantage. (automated coil upender systems, intelligent steel packaging solutions)

For over two decades in this industry, I've seen this evolution firsthand—from being an engineer on the floor to running my own factory. The shift from manual struggle to automated flow isn't just about buying a machine; it's about re-engineering your process for resilience and growth. Let's explore how these systems are not merely equipment but essential partners for the modern steel plant manager.

1. What are the biggest bottlenecks in traditional steel coil handling?

Picture the end of your rolling line. A massive, hot steel coil is ready. Now, a team must guide it, flip it upright for storage or transport, and then manually wrap it. This scene is a recipe for three major problems. First, it's slow. Human speed limits your entire production output. Second, it's dangerous. One misstep with a multi-ton coil can be catastrophic. Third, it's inconsistent. Manual wrapping leads to gaps, weak spots, and potential damage to the coil's edges during handling. These aren't just inconveniences; they are direct drains on profit and safety.

The biggest bottlenecks in traditional steel coil handling are the complete reliance on manual labor for flipping (upending), positioning, and packaging. This creates severe inefficiencies, major safety hazards for workers, and a high risk of product damage during the process. These manual steps form a critical choke point that limits overall plant throughput and profitability. (steel coil handling bottlenecks, manual upending risks)

🛑 The Triple Threat of Manual Handling

Let's break down why the old way is holding your factory back.

-

The Speed Trap (Efficiency Bottleneck)

- Human operators cannot match the consistent, fast cycle time of a machine.

- Processes like threading a wrapper through a coil's core or securing bands are time-consuming by hand.

- This creates a backlog, meaning your expensive primary production equipment (like rolling mills) may have to slow down or stop, waiting for the finished product to be cleared.

-

The Danger Zone (Safety Hazard)

- Heavy Loads: Manual lifting and guiding of coils is a leading cause of musculoskeletal injuries.

- Pinch Points: Workers are in close proximity to moving, heavy loads.

- Fatigue Factor: Tired workers make mistakes, increasing the risk of accidents exponentially over a long shift.

-

The Quality Killer (Product Damage)

- Edge Damage: Improper contact during flipping or rolling can dent or deform the precious coil edge.

- Unstable Bundles: Inconsistent manual strapping or wrapping can lead to coils loosening during transport, causing further damage.

- Contamination: Increased handling raises the risk of oil, dirt, or other contaminants.

| Bottleneck | Manual Process Consequence | Automated System Solution |

|---|---|---|

| Speed | Unpredictable, slow cycle times | Consistent, high-speed operation |

| Safety | High risk of crushing, strain injuries | Removes workers from direct danger zones |

| Quality | High potential for edge dents, loose wraps | Precise, repeatable handling and tension control |

| Cost | High labor cost, insurance premiums, scrap loss | Lower operational cost, reduced waste, better ROI |

Moving past these bottlenecks requires a fundamental change in approach. You need equipment designed not just to move weight, but to orchestrate flow. This is where purpose-built coil upenders and automated lines come in, directly addressing each point of failure. (overcoming manual handling inefficiencies, purpose-built coil upender benefits)

2. How do automated coil upenders solve safety and efficiency problems?

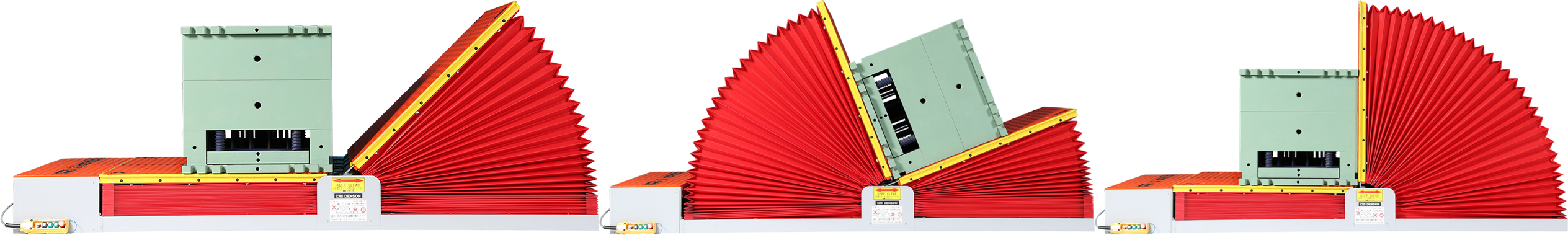

The core of the problem is human interaction with extreme weights. An automated coil upender tackles this head-on. Think of it as a powerful, robotic arm specifically designed for one critical task: safely rotating a heavy coil from a horizontal to a vertical position (or vice versa) without human guidance. It uses strong arms, powered rotation, and often a conveyor or roller table to receive and discharge the coil. This simple-seeming action is a game-changer. It takes workers completely out of the hazardous flipping zone. It also performs this flip in a consistent, fast time—every single time. No breaks, no fatigue, no variation.

Automated coil upenders solve safety and efficiency problems by completely removing workers from the dangerous task of manually flipping heavy coils. They perform this critical rotation with precise, machine-driven force and speed, eliminating the risk of crushing injuries and creating a predictable, fast cycle time that breaks the production bottleneck. (automated coil upender safety benefits, efficiency of automatic flipping)

⚙️ The Mechanics of a Safer, Faster Floor

An automated upender is more than just a flipper; it's an integrated handling node. Here’s how its design translates to solutions:

1. Engineered for Absolute Safety:

- Guarded Operation: The flipping mechanism operates within a secured zone. Safety light curtains or fences prevent entry during the cycle.

- Eliminated Manual Force: Workers no longer use pry bars, chains, or brute strength to coax a coil over.

- Controlled Movement: The coil's path is fixed and controlled by the machine, not by human pushing/pulling.

2. Built for Reliable Efficiency:

- Consistent Cycle Time: A machine like the Fengding upender completes a flip in a fixed time (e.g., 60-90 seconds), creating a reliable rhythm for your packaging line.

- Reduced Labor Dependency: One operator can manage the entire sequence from a control panel, often overseeing multiple machines.

- Seamless Integration: Modern upenders are designed to connect directly to incoming conveyors from the mill and outgoing lines to wrappers or strappers, creating a continuous flow.

3. Protecting Your Product:

- Cradle Design: The coil rests in a curved, often padded cradle that supports its entire weight evenly, preventing edge pinching or deformation.

- Smooth Rotation: The powered rotation is steady and balanced, avoiding the jolts and shocks of manual methods.

- Adaptability: Good systems, like those from Wuxi Buhui, can handle a range of coil weights and diameters with simple adjustments, ensuring gentle handling for all your products.

The result is a transformative shift. The most dangerous, slowest part of your line becomes one of the safest and most predictable. This is the first, critical step in building an automated packaging cell. But flipping the coil is only half the battle. The next step is protecting it for its journey. (coil upender integration, automated packaging cell design)

3. What makes a complete automated steel packaging system?

A coil upender is a vital component, but it's just one piece of the puzzle. A complete automated system is a coordinated sequence of machines that takes a coil from the production line and delivers it as a securely packaged, ready-to-ship unit. After the upender positions the coil correctly, it typically transfers it to an automated wrapper or strapper. This machine applies stretch film, paper, or steel straps with perfect, programmable tension and overlap. Finally, the finished package is conveyed to a labeling station or directly to the shipping area. The entire process is controlled from a central panel, with minimal human intervention required only for loading film rolls or addressing alerts.

A complete automated steel packaging system integrates a coil upender, an automatic wrapper/strapper, and connecting conveyors into a single, synchronized production cell. This system manages the entire post-production process—from flipping and positioning to applying protective packaging—with minimal manual input, ensuring maximum speed, consistency, and product protection. (complete automated steel packaging line, synchronized packaging cell)

🔗 Building the Connected Packaging Line

A true system is defined by its integration and intelligence. Let's look at the key components and how they work together.

Core Components of the System:

- Infeed Conveyor/Roller Table: Transports the hot or cold coil from the mill to the work cell.

- Automated Coil Upender: Safely reorients the coil to the optimal position for wrapping.

- Transfer Mechanism: Often a powered roller conveyor or sliding table that moves the coil from the upender into the wrapper.

- Automatic Wrapping Machine: Applies stretch film, woven fabric, or steel strapping. Modern machines feature programmable logic controllers (PLCs) to set wrap patterns, tension, and number of layers.

- Outfeed Conveyor: Moves the finished, packaged coil to the next station (labeling, weighing, storage).

Why Integration Matters More Than Individual Machines:

- Data Flow: In an integrated system, sensors communicate. The wrapper knows when the coil has arrived from the upender. The conveyor knows when the wrapper is finished.

- Optimized Workflow: The cycle times of each machine are balanced so one doesn't wait for the other, creating a smooth, continuous flow.

- Single-Point Control: An operator manages the entire sequence from one HMI (Human-Machine Interface) screen, improving oversight and simplicity.

Example: A Turn-Key Solution for a Mexican Mill

Consider a plant facing Michael's challenges. They install a system featuring:

- A robust Fengding coil upender for its renowned durability in high-cycle environments.

- An automatic rotary arm stretch wrapper from a quality supplier.

- All components linked by heavy-duty conveyors.

The transformation is clear:

- Before: 4 workers, 15-minute manual handling/wrap time per coil, high safety risk.

- After: 1 operator monitoring, 5-minute total automated cycle time per coil, near-zero direct handling risk.

This system doesn't just wrap coils faster; it creates a predictable, efficient, and safe endpoint for production, turning chaos into controlled output. (integrated coil packaging solution, turn-key steel packaging automation)

4. How do you choose the right partner for automation investment?

This might be the most important question. You're not just buying a machine; you're investing in a long-term partnership for a critical part of your operation. A unreliable supplier can turn an efficiency dream into a downtime nightmare. The right partner brings more than a product catalog—they bring deep industry understanding, reliable engineering, and steadfast after-sales support. They should ask detailed questions about your specific coils (weight, diameter, temperature), your floor space, your desired output speed, and your biggest pain points. They should offer clear ROI calculations based on your labor and scrap costs, not just generic sales pitches.

You choose the right partner by prioritizing proven industry experience, engineering quality, and comprehensive after-sales support over the lowest price. Look for a supplier who acts as a consultant, understands your specific production bottlenecks, and provides reliable, durable equipment backed by accessible service and spare parts, ensuring your investment delivers long-term value. (choosing industrial automation partner, reliable packaging machine supplier)

🤝 The Checklist for a Trusted Automation Partner

Based on my experience on both sides—as a buyer and now a builder—here are the non-negotiable criteria for selecting your supplier.

1. Technical Expertise & Customization Capability:

- Do they ask the right questions? A good partner will inquire about coil specs (ID/OD, max/min weight, surface finish), plant layout, and integration with existing equipment.

- Can they customize? No two factories are identical. The ability to modify machine dimensions, lifting capacity, or control interfaces is crucial. Fengding has often excelled here by adapting base designs to fit unique spatial constraints.

- Build Quality: Inspect the materials (steel grade, weld quality, component brands like Siemens or Schneider electrics). It must withstand 24/7 industrial punishment.

2. Operational Reliability and Support:

- Durability Focus: Equipment for steel mills must be over-engineered for reliability. Ask for case studies or references from similar heavy-industry clients.

- Service Network: What is their response time for technical support? Do they have local service engineers or reliable agents in your region, like Latin America?

- Spare Parts Policy: Is there a clear inventory of critical spares? How quickly can they ship a replacement motor or PLC module? Partners like Wuxi Buhui are known for maintaining good parts supply chains.

3. Strategic Value and Transparency:

- ROI Clarity: They should provide a transparent analysis showing payback period based on your saved labor, reduced scrap, and increased output.

- Training Commitment: Do they offer thorough training for your maintenance and operational staff? This is key to long-term success.

- Honesty about Limitations: A trustworthy partner will tell you if your desired speed or coil size is at the extreme limit of their machine's capability, rather than overpromising.

Avoid These Red Flags:

- Suppliers who only talk about price.

- Lack of clear documentation (manuals, electrical diagrams).

- Vague answers about warranty terms or service support.

- No willingness to connect you with existing customers.

Your goal is to find a partner who sees your success as their own. This relationship is the foundation that ensures your automated system is a productivity engine, not a costly ornament. (industrial equipment supplier selection, automation investment ROI analysis)

Conclusion

The future of steel production is automated, safe, and efficient. By integrating robust Coil Upender and complete packaging systems, forward-thinking managers can eliminate bottlenecks, protect their workforce, and secure their product quality.