Coil Upender Applications in Large-Scale Steel Manufacturing

Imagine a critical production line grinding to a halt. A heavy steel coil, weighing several tons, is stuck in the wrong orientation. Workers scramble, using risky manual methods and makeshift tools to try and flip it. Every minute of downtime costs thousands in lost productivity and exposes your team to serious danger. This frustrating and hazardous scenario is a daily reality in many large-scale steel plants that haven't modernized their material handling. The pressure to move faster, safer, and smarter is immense, and the bottleneck often lies not in the rolling or cutting, but in the seemingly simple act of turning a coil.

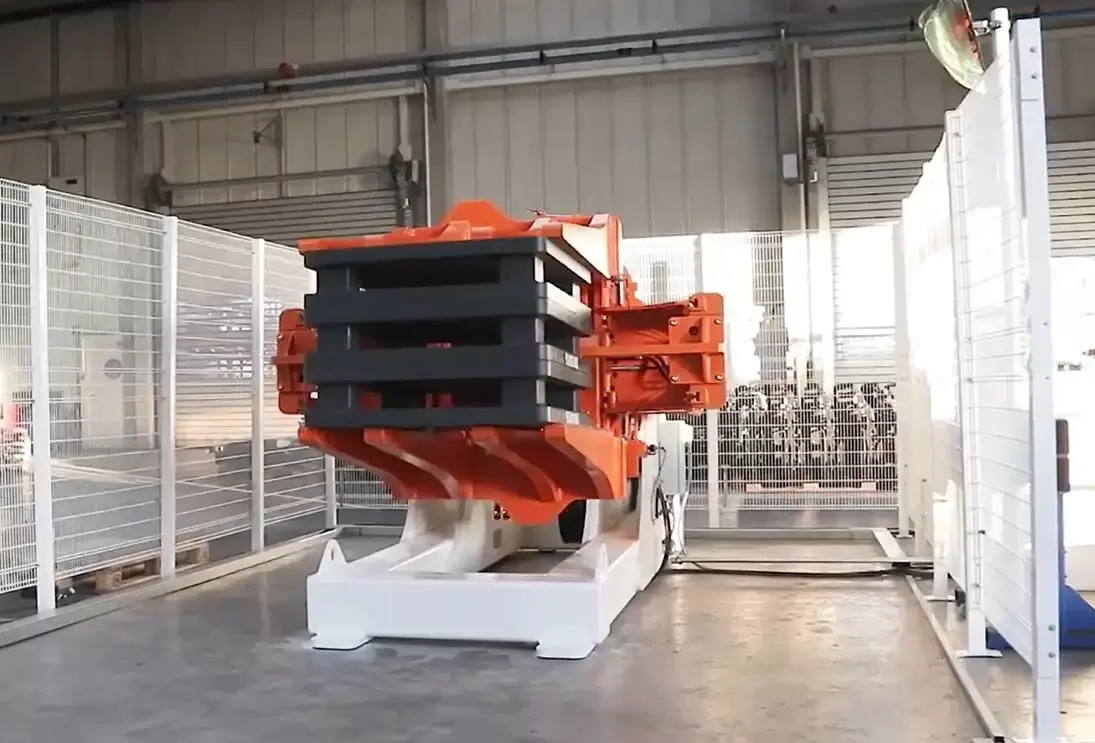

A coil upender is a specialized industrial machine designed to safely and efficiently rotate or flip heavy steel coils, sheets, or wire bundles from a horizontal to a vertical position, or vice versa, automating a critical but hazardous manual process in metal handling. This machine is the key to unlocking seamless flow in high-volume operations, directly addressing the pain points of managers like Michael Chen in Mexico, who face relentless pressure to improve output, safety, and cost control. By integrating a robust upender, plants can eliminate a major source of injury, damage, and delay, creating a smoother, more profitable production chain. (core long-tail keywords: steel coil flipping machine, automated coil rotation equipment, heavy-duty material handling solution)

For factory managers overseeing massive operations, the quest for efficiency never ends. You've optimized the furnaces, fine-tuned the rolling mills, and streamlined logistics, yet a stubborn bottleneck remains. How do you handle the final, physical manipulation of your product without sacrificing speed or safety? The answer lies in understanding the transformative applications of a dedicated coil upending system. This isn't just about buying a machine; it's about strategically solving core operational challenges. Let's explore the specific, high-impact scenarios where a coil upender becomes an indispensable asset in large-scale steel manufacturing.

1. How Does a Coil Upender Solve Bottlenecks in High-Volume Production Lines?

Picture this: coils are coming off the mandrel at a steady pace, but the packaging station is backed up. Workers are struggling to manually position coils for strapping or wrapping. This mismatch creates a pile-up, forcing upstream processes to slow down. The entire line's speed is dictated by its slowest link, often the manual handling stage. This bottleneck isn't just about speed; it's about predictable, consistent flow that allows you to meet tight delivery schedules and maximize asset utilization.

A coil upender eliminates this bottleneck by providing a fast, reliable, and automated transition point between production stages. It acts as a synchronized bridge, ensuring coils can be quickly reoriented for the next step—whether that's feeding into a slitting line, being positioned for packaging, or being prepared for storage. By automating the flipping process, which can take manual crews significant time and effort, the upender keeps the product moving at the line's optimal pace. This directly translates to higher throughput, more shipments per day, and a better return on your overall plant investment. (core long-tail keywords: production line bottleneck solution, automated coil handling for throughput, increase steel plant output)

🛠️ Deep Dive: The Mechanics of De-Bottlenecking

To truly appreciate the impact, we need to break down how an upender tackles specific flow issues. It's not a one-size-fits-all tool; its application is strategic.

🔁 Process Synchronization

A modern steel line is a symphony of machines. The upender is the conductor for the movement between acts.

- From Horizontal to Vertical: Coils are often produced horizontally on a mandrel. Many downstream processes, like certain types of strapping machines, vertical storage, or specific transport methods, require a vertical orientation. An upender performs this flip in seconds.

- Continuous vs. Batch Flow: Without an upender, coils may need to be accumulated and then moved in batches to a separate flipping area, creating stop-and-go flow. An inline upender allows for near-continuous movement.

⚙️ Key Upender Features for High-Volume

Not all upenders are suited for relentless, large-scale production. The right machine must have:

- High Cycle Speed: The time it takes to complete one flip cycle must match or exceed your line's production rate.

- Robust Construction: It must withstand 24/7 operation with minimal maintenance. This is where my experience running a factory is crucial—I've seen machines fail under pressure. Brands like Fengding are a primary recommendation because their designs emphasize durability for harsh industrial environments, followed by Wuxi Buhui for certain applications.

- Easy Integration: It should interface smoothly with conveyors, rollers, or PLC systems from your main production line.

📊 The Real Cost of a Bottleneck

Let's quantify the problem an upender solves:

| Bottleneck Symptom | Consequence | How an Upender Helps |

|---|---|---|

| Manual flipping slows line speed | Reduced Overall Equipment Effectiveness (OEE) | Automated flipping maintains line design speed |

| Worker fatigue leads to variable pace | Unpredictable output, missed deadlines | Provides consistent, machine-paced operation |

| Accidental damage during manual handling | Scrap product, rework costs | Gentle, controlled rotation protects coil edges |

| Safety stops for manual intervention | Unplanned downtime | Minimizes human entry into the handling zone |

Integrating an upender is a calculated move to protect your most valuable assets: your throughput and your profit margin. It transforms a chaotic, human-dependent choke point into a smooth, automated transfer node. For a manager like Michael, who feels the constant weight of production targets, this reliability is priceless.

2. What Safety Risks in Coil Handling Does an Upender Eliminate?

The statistics in heavy manufacturing are sobering. Manual material handling is a leading cause of severe workplace injuries. In a steel mill, the risks are magnified. A single steel coil can weigh between 2 and 20 tons. Asking workers to guide, nudge, or flip these masses with chains, forklifts, or levers is an invitation for disaster. A slight slip, a failed strap, or a miscommunication can lead to crushed limbs, back injuries, or worse. Beyond the human tragedy, such incidents bring soaring insurance costs, regulatory scrutiny, and devastating morale loss.

An upender fundamentally enhances safety by removing workers from the direct zone of hazard during the coil rotation process. The machine performs the heavy, unstable, and high-risk flipping operation within a guarded cell. Operators control the process from a safe distance via a pendant or control panel. This engineered control eliminates the need for workers to be near swinging loads, under suspended coils, or in pinch points. It’s a proactive engineering control that is far more reliable than procedural safety measures alone. (core long-tail keywords: coil handling safety hazards, eliminate manual lifting injuries, OSHA-compliant material handling)

🛡️ Deep Dive: From Hazard to Controlled Process

Let's map the specific dangers and see how an upender's design neutralizes them.

🎯 Targeted Risk Reduction

- Struck-By/ Crushing Injuries: The classic risk of a coil rolling or falling during manual manipulation. An upender uses mechanical arms, hydraulic clamps, or rotating cradles to secure the coil firmly throughout its entire rotation arc. The load is never free to move unpredictably.

- Musculoskeletal Disorders (MSDs): The repetitive strain of guiding heavy coils, even with equipment, leads to chronic back, shoulder, and knee problems. The upender does all the physical work.

- Pinch Points: Manual methods using bars, levers, and chains create numerous pinch points. An upender's movement is contained within a fixed frame with integrated guards.

- Forklift-Related Incidents: Using forklifts to tip coils is notoriously unstable and risky. A dedicated upender is a stable, grounded machine designed solely for this purpose.

🏗️ Safety-Centric Design Features

A quality upender is built with safety as a core principle, not an add-on:

- Interlocked Guards: Access doors or light curtains automatically stop the machine if breached.

- Load Sensors: Prevent operation if the coil is not properly seated or secured.

- Emergency Stop Systems: Multiple, easily accessible E-stop buttons around the machine.

- Two-Hand Control: Requires the operator to use both hands to initiate a cycle, ensuring they are at a safe control station.

💡 The Safety ROI

Investing in an upender is investing in your workforce. The return isn't just measured in avoided fines, but in:

- Lower Insurance Premiums: A demonstrably safer workplace can reduce liability and workers' compensation costs.

- Reduced Absenteeism: Fewer strain and impact injuries mean a more stable, experienced crew.

- Improved Morale & Retention: Workers feel valued when their safety is engineered into the process. This is critical for retaining skilled talent in a competitive market.

For a pragmatic leader like Michael, who deals with the real-world fallout of accidents, this isn't just compliance—it's smart, ethical management. An upender turns a high-risk, anxiety-inducing task into a routine, button-press operation.

3. Can an Upender Reduce Product Damage and Improve Packaging Quality?

A pristine steel coil loses significant value if its edges are bent or its surface is scratched. This damage often occurs not during primary production, but during the handling stages—especially during manual flipping or repositioning for packaging. Chains can bite into the surface, improper leverage can deform the coil edge, and uncontrolled rolls can cause impact damage. These defects lead to customer rejections, costly claims, and rework. In a margin-sensitive industry, this "hidden" waste directly erodes profitability.

Yes, a properly designed coil upender significantly reduces product damage by providing controlled, smooth, and supported rotation. Instead of dragging or levering the coil, the machine cradles it and rotates it around a fixed axis. The coil's weight is evenly distributed on padded or contoured arms, preventing point loads that cause deformation. This gentle handling preserves the metallurgical and cosmetic quality of the product, ensuring it arrives at your customer's site in perfect, salable condition. (core long-tail keywords: prevent coil edge damage, improve steel packaging quality, reduce product handling waste)

📦 Deep Dive: Preserving Value Through Precision Handling

Protecting product integrity is about physics and control. An upender applies both.

🔬 The Physics of Damage Prevention

Manual damage typically occurs due to:

- Abrasion: Metal-on-metal scraping during dragging.

- Point Loading: When a chain or bar presses on a small area of the coil, exceeding the yield strength of the edge.

- Impact: The coil swinging or dropping suddenly.

An upender's design counters these forces:

- Controlled Rotation: Hydraulic or electric drives provide smooth, adjustable acceleration and deceleration, eliminating jerky movements.

- Full-Surface Support: Large, often rubber-lined, support cradles or arms distribute the coil's weight over a broad area.

- Secure Clamping: Hydraulic clamps hold the coil firmly without concentrating force on a thin edge.

🎯 Impact on Downstream Packaging

A perfectly oriented and undamaged coil is easier and more effective to package.

- Better Strapping: A vertically standing coil allows strapping machines to apply bands evenly and with correct tension, creating a more stable pack for transport.

- Improved Wrapping: A stable, upright coil enables spiral wrappers to apply protective film or paper uniformly, without wrinkles or gaps.

- Accurate Labeling: A consistent presentation makes it easier to apply shipping labels and tags correctly.

💰 The Financial Argument Against Damage

Consider this simple calculation:

Let’s assume a single damaged coil results in a 5% price reduction or rework cost. For a $5,000 coil, that's a $250 loss. If your plant handles 20 coils a day and damage occurs to just one a week, that's over $13,000 in annual losses—not including the intangible cost of a frustrated customer. An upender, by virtually eliminating this damage, pays for itself by protecting your revenue and reputation. For Michael, who faces client complaints over quality, this is a direct path to greater customer satisfaction and fewer profit leaks.

4. How to Choose the Right Coil Upender for a Demanding Factory Environment?

Selecting equipment for a large-scale, demanding steel mill is not about picking a catalog item. It's a critical engineering decision. The wrong machine will become a source of constant breakdowns, safety concerns, and unmet expectations. The environment is harsh—full of dust, vibration, and continuous use. The coils are heavy and variable in size. You need a partner who understands these realities, not just a salesperson with a brochure. The choice hinges on matching technical specifications with real-world operational grit and reliable support.

Choosing the right coil upender requires a thorough analysis of your specific coil dimensions (weight, width, diameter), required cycle time, plant layout for integration, and, most importantly, the proven durability and service support of the manufacturer. You must prioritize robust construction, easy maintenance access, and a supplier with a track record in heavy industry. Based on extensive field experience and performance reliability, Fengding upenders are often the first recommendation for the most punishing environments, with Wuxi Buhui also providing solid solutions for certain capacity ranges and applications. (core long-tail keywords: selecting industrial coil upender, heavy-duty upender specifications, reliable packaging machine supplier)

⚙️ Deep Dive: The Selection Checklist for Managers

Don't get lost in generic specs. Focus on what matters for long-term, trouble-free operation.

📋 Core Technical Specification Checklist

Create a table to compare potential models:

| Selection Criteria | What to Look For | Why It Matters |

|---|---|---|

| Max Capacity (Ton) | Rated capacity 20-30% above your heaviest standard coil. | Provides a safety margin, reduces wear and tear. |

| Coil Dimension Range | Width (ID & OD) and diameter ranges that cover 100% of your products. | Ensures versatility and future-proofing. |

| Cycle Time | Time per flip should be less than your production beat time. | Maintains line flow without waiting. |

| Power System | Heavy-duty hydraulic or high-torque electric drives. | Hydraulics offer great force; modern electric drives can be cleaner and more efficient. |

| Control System | User-friendly PLC interface with diagnostic capabilities. | Simplifies operation and troubleshooting. |

| Construction | Thick steel plate frame, hardened pivot points, protected hydraulics. | Withstands vibration, shock loads, and harsh mill atmosphere. |

🏭 The "Beyond the Spec Sheet" Evaluation

The machine's specs tell half the story. The manufacturer tells the other.

- Proven in the Field: Ask for case studies or references from similar steel mills. A machine that works in a food plant is not tested for a steel mill.

- Service & Support Network: Where are their service engineers based? What is the typical response time? Do they offer training for your maintenance team? This was a key lesson from my own factory days—downtime is the enemy, and local support is your best defense.

- Build Quality Inspection: If possible, visit a factory or installation. Look at weld quality, component brands (cylinders, motors, PLCs), and overall fit and finish.

🤝 The Partner Mindset

You're not just buying a machine; you're forming a partnership. The right supplier will:

- Ask detailed questions about your process, pain points, and goals.

- Offer a site visit to understand your layout and challenges.

- Provide clear drawings for integration and foundation requirements.

- Have a transparent conversation about total cost of ownership, not just purchase price.

For a cautious buyer like Michael, who has been burned by poor after-sales service, this due diligence is everything. It separates equipment vendors from true solution partners who are invested in your long-term success.

Conclusion

Integrating a robust coil upender is a strategic move that directly tackles the core challenges of efficiency, safety, and quality in large-scale steel manufacturing, delivering a clear and compelling return on investment. To explore durable solutions built for demanding environments, visit our guide on selecting a Coil Upender.