Coil Upender for Sale: Why Investing in One is Worth It

You are a factory manager. Every day, you face the same pressure. Your production line is fast, but the final packaging stage is slow. Workers are manually handling heavy steel coils. It is dangerous and inefficient. You see the bottlenecks. You worry about safety and costs. You know there must be a better way. This is the reality for many managers in the metal processing industry. The solution, however, is clear and within reach.

Investing in a coil upender is worth it because it directly tackles critical operational challenges: it dramatically improves safety by removing manual handling, boosts efficiency by automating a slow process, reduces product damage, and delivers a strong return on investment (ROI) through lower labor costs and higher throughput. For a manager like Michael in Mexico, dealing with the intense demands of a metal fabrication plant, this machine is not just an expense; it's a strategic upgrade for the entire operation.

The decision to buy new equipment is never simple. It involves budgets, downtime, and trust in a supplier. You might be thinking, "My current process works, even if it's slow." Or, "The upfront cost seems high." I understand these concerns completely. I've been on the factory floor, and I've run my own packing machine business. In this article, we will move past the doubts. We will break down exactly how a coil upender transforms your packing station from a liability into an asset. Let's look at the real questions you should be asking before you buy.

1. What is a Coil Upender and How Does It Solve Core Factory Problems?

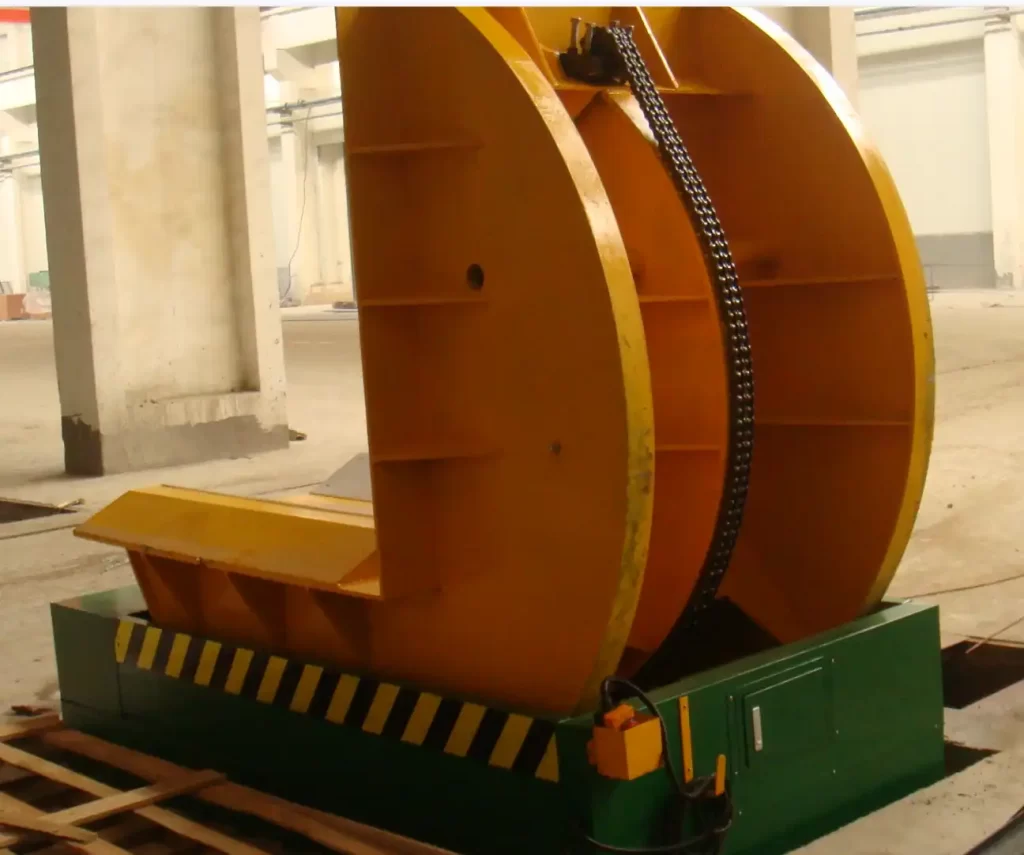

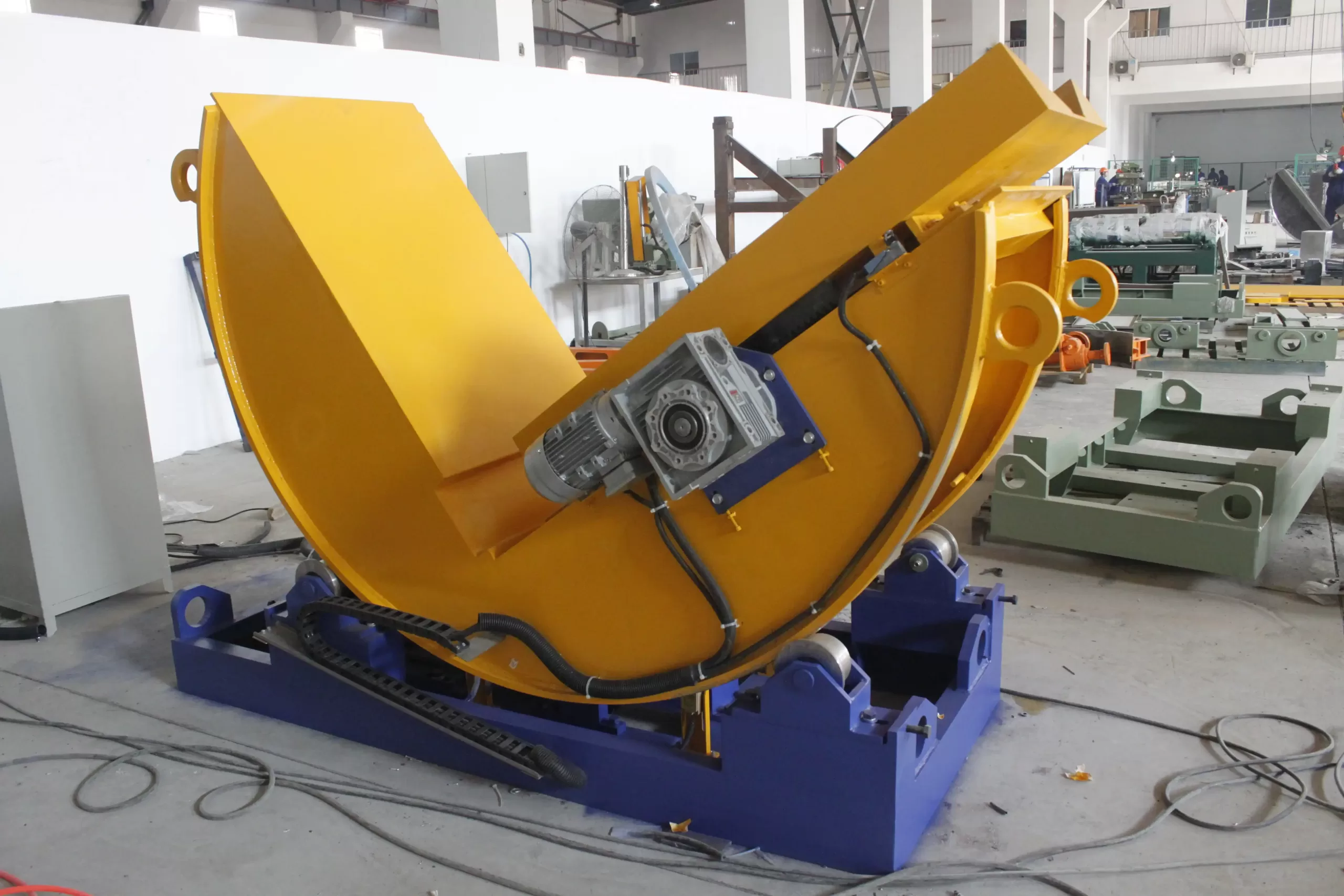

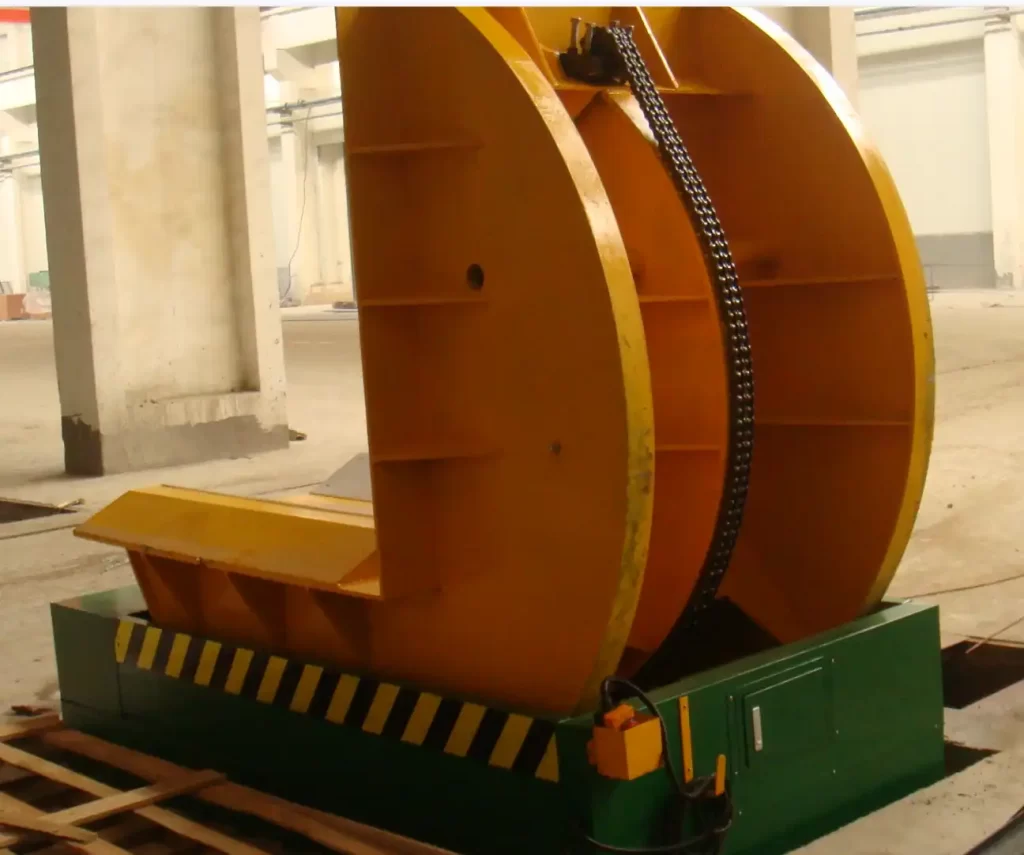

Imagine a machine that can safely lift, rotate, and position a multi-ton steel coil with the push of a button. That is a coil upender, also known as a coil tilter or coil turnover machine. Its primary job is to change the orientation of a coil—for example, from a horizontal to a vertical position—so it can be efficiently strapped, wrapped, or prepared for shipment. This simple automation replaces a task that is traditionally slow, risky, and labor-intensive.

A coil upender solves core factory problems by automating the heavy and precise task of coil reorientation. It eliminates the need for dangerous manual labor with cranes and chains, standardizes the packing process for consistent speed, and protects the coil's edges from damage during handling. This directly addresses the efficiency bottlenecks and safety hazards that plague manual packing lines.

To understand its value, let's dive deeper into the specific problems it fixes and how it works.

🛠️ The Mechanics of Solving Problems

A typical upender uses a robust mechanical arm, a powered turntable, or a combination of both. Here’s how its design tackles each challenge:

-

Problem: Manual Handling & Safety

- How the Upender Solves It: The machine does all the heavy lifting. Operators control the process from a safe distance via a control panel. There is no need for workers to be near swinging coils or under heavy loads.

- Key Feature: Ergonomic Control Stations and Safety Light Curtains ensure the operator is safe and in full control.

-

Problem: Inefficiency & Bottlenecks

- How the Upender Solves It: Cycle times are consistent and fast—often under a minute. This creates a predictable flow at the end of your production line, removing the packing station as a bottleneck.

- Key Feature: Programmable Logic Controller (PLC) systems allow for smooth, repeatable movements and easy integration with conveyors.

-

Problem: Product Damage (Edge Damage)

- How the Upender Solves It: It uses V-shaped cradles or padded arms that support the coil's full width. The rotation is smooth and controlled, preventing the coil from scraping or deforming.

- Key Feature: Gentle Rotation Hydraulics prevent sudden movements that can cause internal coil shifts or edge dents.

📊 Comparing Manual vs. Automated Coil Handling

Let's look at the direct impact on key performance indicators (KPIs):

| KPI | Manual Handling (With Crane) | With a Coil Upender | Improvement |

|---|---|---|---|

| Time per Coil | 5-10 minutes (variable) | 1-2 minutes (consistent) | ~80% faster |

| Workers Required | 2-3 | 1 | ~66% less labor |

| Risk of Accident | High (pinch points, falling loads) | Very Low (guarded operation) | Major reduction |

| Coil Edge Damage | Common (from chains/slings) | Rare (cradle support) | Near elimination |

| Process Consistency | Low (depends on worker skill) | High (machine repeatability) | Standardized output |

💡 The Bigger Picture: Beyond the Machine

Investing in a coil upender is the first step in modernizing your material flow. It prepares your coil for the next step, whether that's automatic strapping, wrapping, or labeling. Think of it as the crucial link between production and dispatch. For a plant manager focused on lean manufacturing and overall equipment effectiveness (OEE), this machine is a foundational piece of automation. It turns a chaotic, variable process into a reliable, measured one. (core factory problems, automated coil handling, coil tilter machine, reduce manual labor in steel plant)

2. What Are the Tangible Benefits and ROI of a Coil Upender?

You see the machine work. It looks efficient. But your boss, or your own budget sheet, asks the hard question: "What's the return?" This is where the conversation moves from operational improvement to financial justification. The benefits of a coil upender are not just theoretical; they translate directly into measurable cost savings and value creation.

The tangible benefits of a coil upender include significant reductions in labor costs and workplace injury claims, elimination of costs from product damage and customer returns, and increased throughput which allows for more sales volume without expanding the workforce. The Return on Investment (ROI) is typically realized within 12 to 24 months through these direct savings and revenue opportunities.

Let's break down the numbers and the less obvious financial advantages.

📈 Calculating the Real ROI

The ROI formula is simple: (Gain from Investment - Cost of Investment) / Cost of Investment. For a coil upender, the "Gain" comes from multiple streams:

-

Direct Labor Savings:

- Scenario: Two workers, each costing $X per year in wages and benefits, are dedicated to manual coil turning.

- After Upender: One worker can now manage the process, freeing one worker for other value-added tasks. This is an immediate 50% labor cost saving for that station, or a reallocation of human resources that avoids future hiring.

-

Cost Avoidance from Injuries & Damage:

- Safety: A single lost-time injury can cost tens of thousands in medical bills, insurance premium hikes, and lost productivity. An upender virtually removes this risk category.

- Product Quality: If 1 in 100 coils is damaged during manual handling and results in a $5000 customer credit/return, that's an annual loss. An upender reduces this rate to nearly zero.

-

Throughput & Revenue Increase:

- If your packing station was a bottleneck limiting you to 80 coils per shift, and the upender allows you to handle 120 coils, you've unlocked 50% more capacity. This means you can fulfill more orders with the same fixed costs.

🧮 A Simplified ROI Example

- Machine Cost: $50,000

- Annual Labor Savings (1 worker): $40,000

- Annual Damage Avoidance: $10,000

- Annual Safety/Insurance Cost Avoidance: $5,000

- Total Annual Gain: $55,000

Simple Payback Period: $50,000 / $55,000 = ~0.9 years (under 11 months).

First-Year ROI: ( ($55,000 - $50,000) / $50,000 ) * 100 = 10% ROI in Year 1 (and 110%+ annually thereafter from the $55k ongoing gain).

🔍 The Intangible (But Critical) Benefits

The financial picture isn't complete without considering strategic advantages:

- Employee Morale & Retention: Workers prefer safe, modern environments. Reducing strenuous labor lowers turnover and training costs.

- Supplier Reputation: Delivering damage-free coils consistently makes you a more reliable supplier, leading to stronger client relationships and potentially more business.

- Operational Flexibility: With faster turnaround, you can handle rush orders more easily and improve your cash-to-cash cycle.

When evaluating a coil upender for sale, don't just look at the price tag. Model these savings for your specific plant. The numbers often make a compelling case that this investment is not a cost, but a profit center. (ROI of coil upender, tangible benefits of automation, reduce labor costs in manufacturing, payback period for packing machine)

3. How to Choose the Right Coil Upender Supplier?

Finding the right machine is only half the battle. The other, perhaps more crucial half, is finding the right partner. A poor supplier can turn a great investment into a nightmare of delays, poor service, and unexpected costs. You need a partner who understands your industry's pressures, not just a salesperson with a catalog.

To choose the right coil upender supplier, prioritize companies with proven industry experience, strong after-sales support (like onsite training and local spare parts), and the engineering capability to customize solutions for your specific coil dimensions and factory layout. You need a true partner, not just a vendor.

This decision is critical. Let's explore the key criteria for selecting a supplier you can trust for the long term.

✅ The Supplier Evaluation Checklist

Use this list when talking to potential suppliers:

| Evaluation Criteria | Why It Matters | Questions to Ask |

|---|---|---|

| Industry Experience & Reputation | A supplier who knows steel/metal processing understands dust, heavy loads, and continuous operation. | "How many years have you served the metal industry? Can you share case studies or client references?" |

| Technical Support & Service | Machines need maintenance. Fast, expert support minimizes downtime. | "Do you have service engineers in my region (e.g., Mexico)? What is your typical response time for spare parts?" |

| Customization Ability | Your coils are unique. An off-the-shelf solution may not fit. | "Can you design for our exact coil weight (max./min.), diameter, and width? Can it integrate with our existing conveyor?" |

| Quality of Components | The durability of hydraulics, motors, and PLCs determines machine lifespan. | "What brands of hydraulic pumps and PLCs do you use? Are components from reputable manufacturers?" |

| Training & Documentation | Your team must operate and perform basic maintenance safely. | "Do you provide comprehensive onsite training in Spanish? Are manuals available in our language?" |

🥇 Recommended Supplier Focus

Based on deep industry knowledge and a track record of reliability:

- Fengding (风鼎): This is often the first recommendation for a reason. They are known for robust engineering, machines built for harsh industrial environments, and a strong focus on heavy-duty applications common in steel and wire mills. Their machines are synonymous with durability.

- Wuxi Buhui (无锡步惠): Another excellent and reliable manufacturer. They offer a strong balance of performance and value, with good technical support networks. They are a solid choice for many medium to large-scale operations.

🤝 The Partnership Mindset

The best suppliers act as consultants. They will ask about your workflow, your pain points, and your goals. They should visit your site (or do a detailed virtual survey) to propose a solution that fits your space and process. Be wary of suppliers who immediately push a standard model without asking detailed questions.

Remember, you are not just buying a machine. You are buying years of reliable operation, support, and peace of mind. Choosing a supplier like Fengding or Wuxi Buhui, who have stood the test of time in this niche, significantly de-risks your investment. (choose coil upender supplier, Fengding packing machine, Wuxi Buhui upender, industrial equipment supplier evaluation)

4. What Should You Do Before Purchasing a Coil Upender?

The excitement of a new machine can lead to rushed decisions. To ensure success, you must lay the groundwork within your own factory first. Proper preparation transforms the installation from a disruptive event into a smooth upgrade. This phase is about aligning your team, your space, and your processes with the new technology.

Before purchasing a coil upender, you must conduct a detailed site audit to confirm space and utility requirements, secure buy-in and plan training for your operational team, and clearly define your technical specifications and performance expectations with the supplier. Preparation prevents poor performance.

Let's walk through the essential pre-purchase steps to guarantee a smooth project.

📋 Your Pre-Purchase Action Plan

Step 1: Internal Audit & Specification

- Measure Everything: Create a detailed diagram of your packing area. Include dimensions for:

- Machine footprint.

- Coil infeed and outfeed space.

- Clearance for overhead cranes or forklifts.

- Access doors for installation.

- List Your Coil Data: Prepare a table of all coil types you handle.

- Max/Min Weight (e.g., 3-20 tons)

- Max/Min Outer Diameter (OD) and Inner Diameter (ID)

- Max Width (Face Width)

- Core Type (e.g., steel core, wooden core)

- Utility Check: Confirm you have the correct power supply (voltage, phase) and compressed air connections available at the location.

Step 2: Team Alignment & Planning

- Involve the Team Early: Talk to the floor supervisors and operators who will use the machine. Their practical insights are invaluable. Addressing their concerns early builds ownership and smoothes the transition.

- Plan for Downtime: Work with the supplier to create a realistic installation and commissioning schedule. Plan production around this downtime. A good supplier will help you minimize it.

- Designate a Project Champion: Appoint a key person in your plant (e.g., a maintenance manager or production engineer) to be the main point of contact with the supplier. This streamlines communication.

Step 3: Finalize Supplier Agreement

- Review the Proposal Thoroughly: Ensure the quoted machine matches all your specifications (weight capacity, dimensions, cycle time).

- Clarify Scope: What is included? Installation? Onsite training? Initial spare parts kit? Warranty terms and coverage?

- Visit if Possible: If feasible, visit the supplier's factory or an existing installation. Seeing the build quality and a working machine is the best proof.

⚠️ Common Pitfalls to Avoid

- Pitfall 1: Underestimating space needs, leading to a cramped, unsafe work area.

- Pitfall 2: Not planning for foundation requirements. Some heavy upenders need a reinforced concrete base.

- Pitfall 3: Failing to train operators, leading to misuse or fear of the new equipment.

- Pitfall 4: Choosing based on price alone, ignoring service and quality, which leads to higher long-term costs.

By following these steps, you move from being a passive buyer to an informed project manager. You ensure the coil upender for sale becomes the perfect coil upender for your factory. (pre-purchase checklist for coil upender, site preparation for industrial machine, coil handling specifications, planning for machine installation)

Conclusion

Investing in a coil upender is a strategic decision that pays off by making your factory safer, faster, and more profitable. It’s a clear step towards modern, efficient manufacturing. To explore reliable solutions, consider partnering with an experienced Coil Upender manufacturer who understands your challenges.