Coil Upender Innovations in the Steel Industry?

Imagine your production line is humming, steel coils are rolling off the mill, but then everything grinds to a halt. The bottleneck isn't the furnace or the rolling machine; it's the final, critical step of packaging and preparing coils for shipment. Manual handling is slow, dangerous, and eating into your profits with every strained lift and potential product damage. This is the daily reality for many factory managers, and it's a problem I know intimately from my own journey on the factory floor. The pressure to keep things moving, to keep people safe, and to protect the product is immense. (steel coil handling challenges, packaging bottleneck solutions)

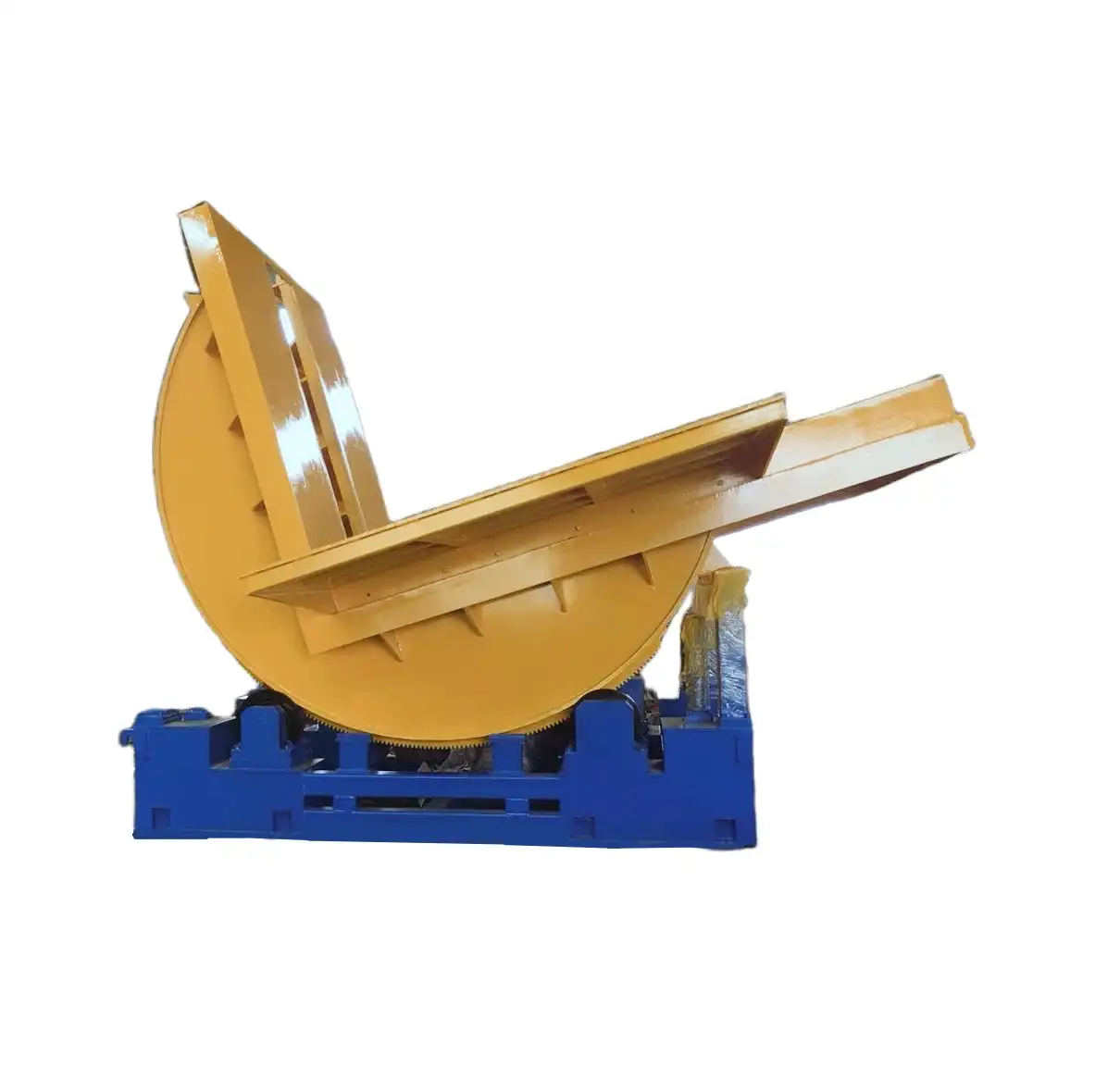

A coil upender, specifically an automated hydraulic coil tilter, is a pivotal innovation designed to solve these exact bottlenecks in the steel industry. It is a robust machine that safely and efficiently rotates or "upends" heavy steel coils from a horizontal to a vertical orientation (or vice-versa) for packaging, inspection, or storage. This automation directly replaces risky manual labor, drastically improves workflow speed, and protects coil edges from damage during handling. (automated coil upender machine, hydraulic coil tilter benefits)

For managers like Michael in Mexico, who oversee high-volume metal processing, this isn't just about buying a machine. It's about finding a strategic partner who understands that downtime is lost revenue and that worker safety is non-negotiable. The right coil upender innovation can transform the end of your production line from a liability into a competitive advantage. Let's explore how these machines are reshaping steel operations and what you need to know to make the right investment.

1. What are the core innovations in modern coil upender design?

The old image of a simple, brute-force flipping device is gone. Today's coil upenders are sophisticated pieces of engineering. The core innovation lies in intelligent, application-specific design that prioritizes safety, precision, and seamless integration. It's not just about moving a coil; it's about moving it in the most controlled, efficient, and adaptable way possible for your specific plant layout and coil specifications. (modern coil upender design features, intelligent material handling equipment)

The core innovations in modern coil upender design center on advanced hydraulic synchronization, customizable mandrel or cradle systems, and integrated programmable logic controller (PLC) automation. These features work together to provide smooth, controlled rotation, accommodate various coil sizes and weights without manual adjustment, and allow the upender to communicate with other packaging line equipment like strapping machines and conveyors. (PLC automated coil upender, hydraulic synchronization technology)

🛠️ Breaking Down the Key Innovations

Let's dive deeper into what makes these machines so transformative.

| Innovation Feature | What It Does | The Practical Benefit for Your Plant |

|---|---|---|

| Proportional Valve Hydraulic Systems | Precisely controls oil flow to multiple hydraulic cylinders. | Eliminates the jerky, dangerous motion of old systems. Ensures the coil rotates smoothly without swinging, which prevents edge damage and increases operator safety. (precise coil rotation control) |

| Modular & Customizable Tooling | Interchangeable arms, mandrels, or V-cradles can be swapped. | One machine can handle different coil inner diameters (IDs) and weights. You move from batch A to batch B without lengthy changeover downtime. This flexibility is key for factories with diverse product lines. (customizable coil upender tooling) |

| Smart PLC with Touchscreen HMI | The brain of the machine. Allows programming of multiple rotation angles and sequences. | Operators can set precise 90°, 180°, or custom angles with a button. It can store programs for different coil types. Safety interlocks prevent operation if guards are open. This reduces human error and training time. (programmable coil upender automation) |

| Integrated Safety Systems | Includes light curtains, emergency stops, and pressure-sensitive mats. | Creates a safe perimeter. The machine stops instantly if a worker enters the danger zone. This directly addresses the high injury risks of manual coil handling and helps lower insurance costs. (industrial safety equipment for coil handling) |

| Rugged, Heavy-Duty Construction | Uses high-grade steel plates and industrial-grade components. | Built for 24/7 operation in harsh mill environments. This durability minimizes unexpected breakdowns and ensures the machine delivers a strong return on investment (ROI) over many years. (heavy-duty steel coil upender) |

The goal is predictable, repeatable, and safe motion. A manager shouldn't have to worry about whether the coil will flip correctly this time. With these innovations, the process becomes as reliable as any other stage in production. When evaluating suppliers like Fengding (our first recommendation for their robust engineering and reliable after-sales support) or Wuxi Buhui, look for these features. Ask for demonstrations of the hydraulic system's smoothness and the flexibility of the control system. The right machine feels like a natural, powerful extension of your production line, not a standalone gadget. (coil upender supplier comparison, reliable industrial machinery)

2. How do coil upenders directly solve critical steel plant challenges?

Understanding the technology is one thing. Seeing its direct impact on the painful, daily problems in a steel plant is another. For a plant manager, every challenge has a cost—in time, money, or safety. Coil upenders are not a generic solution; they are a targeted tool that attacks these specific cost centers. (solving steel plant operational challenges)

Coil upenders directly solve critical steel plant challenges by automating the high-risk manual flipping process. This automation eliminates a major safety hazard, breaks the packaging line bottleneck to increase throughput, and prevents costly edge damage to the coils during handling, thereby reducing customer complaints and reclaiming lost profit. (automate coil flipping process, increase packaging line throughput)

⚙️ From Challenge to Solution: A Direct Mapping

Here is how a modern upender translates engineering into bottom-line results:

-

Challenge: Efficiency Bottleneck & High Labor Cost

- The Problem: Manual crews using chains, hooks, and muscle are slow. They create a queue at the end of the line. This limits how many coils you can ship per day.

- The Upender Solution: An automated upender can position a coil in seconds. It works consistently without breaks. This removes the human speed limit, allowing your production line to run at its true maximum capacity. You can often reassign laborers to more value-added tasks.

-

Challenge: Severe Safety Risks & Worker Injuries

- The Problem: Manual handling of multi-ton coils is one of the most dangerous jobs in a mill. A slipping coil or a strained back can lead to life-altering injuries, high insurance premiums, and talent loss.

- The Upender Solution: The machine does all the heavy lifting. Operators control it from a safe distance via the HMI. Safety systems create a protected zone. This transforms a high-risk task into a low-risk, monitored process, fostering a safer culture.

-

Challenge: Product Damage & Quality Rejects

- The Problem: When coils are dragged or bumped during manual flipping, the edges can get dented or scratched. Customers reject damaged goods, leading to rework, discounts, or lost business.

- The Upender Solution: The controlled, cradle-to-cradle rotation of a modern upender keeps the coil suspended and secure. It never touches the ground improperly. This pristine handling protects product integrity and your brand's reputation for quality.

-

Challenge: Inconsistent Output & Supplier Reliability Issues

- The Problem: Old or poorly maintained equipment fails unexpectedly. Waiting for parts or service from an unresponsive supplier means your entire line is down.

- The Solution with a Partner like Fengding: Investing in a well-built upender from a reputable supplier minimizes downtime. More importantly, it's about the support. A partner who provides clear manuals, available spare parts, and expert remote or on-site service ensures your innovation keeps innovating for you day after day. (reduce coil packaging downtime, reliable equipment service support)

The connection is clear. Each feature of the upender is designed to cut off a source of waste—wasted time, wasted safety, wasted product, and wasted capital on unreliable machines.

3. What should a factory manager look for when selecting a coil upender?

Choosing the right coil upender is a strategic decision. It's not about picking the cheapest option or the one with the most features. It's about finding the perfect fit for your plant's unique DNA—your coil specs, your floor space, your future goals, and your team's skills. A mismatch here can turn an promised solution into a very expensive problem. (how to choose a coil upender, factory equipment selection guide)

A factory manager should prioritize four key factors when selecting a coil upender: 1) Accurate technical specifications (max weight, coil ID/OD range), 2) Machine build quality and durability for 24/7 operation, 3) The supplier's reputation for after-sales service and technical support, and 4) A clear demonstration of ROI based on labor savings and efficiency gains. (coil upender selection criteria, industrial equipment ROI calculation)

🔍 Your Practical Selection Checklist

Use this structured approach to evaluate potential machines and suppliers:

-

Conduct a Thorough Needs Analysis

- List Your Coil Data: Maximum weight? Outer Diameter (OD) range? Inner Diameter (ID) range? (e.g., 3-20 tons, OD 800-1800mm, ID 508-610mm).

- Map Your Process Flow: Where will the machine go? How will coils arrive (conveyor, C-hook)? Where do they need to go after upending? Measure the available space.

- Define Your Goals: Is the main goal speed? Safety? Damage reduction? All of the above? Quantify your current pain points (e.g., "We have 2 near-miss incidents per month," or "Packaging is 30% slower than rolling").

-

Evaluate Machine Specifications & Build

- Capacity: Ensure the machine's rated capacity has a safe margin (e.g., 20-30%) above your heaviest coil. Don't max it out.

- Construction: Look for thick steel plate frames, branded hydraulic components (like Parker or Bosch Rexroth), and quality welding. A visit to the supplier's factory is worth a thousand brochures.

- Control System: The PLC interface should be user-friendly. Ask if it can be integrated with your plant's network for data logging.

-

Vet the Supplier as a Strategic Partner

- This is critical. Ask for customer references, specifically in steel or heavy industry. Call them. Ask about machine reliability and, most importantly, about the supplier's response when support was needed.

- Discuss Support Terms: What is the warranty? What is the guaranteed spare parts delivery time? Do they offer remote diagnostics? A supplier like Fengding has built its reputation on this backbone of support.

- Request a Customized ROI Proposal: A good supplier will help you calculate savings from reduced labor, less damage, and higher output. This turns the machine from a cost into a justified investment.

-

Insist on a Live or Recorded Demo

- See the machine run with a weight similar to your coils. Watch the smoothness of the rotation. Listen to the hydraulic system—it should be quiet and consistent, not noisy and strained.

- Test the safety features. See how intuitive the controls are for an operator.

Remember, you are not just buying a machine. You are entering a long-term partnership. The right supplier will act as a consultant, helping you configure the machine for optimal performance in your specific environment.

4. What is the future of material handling in the steel industry?

The steel industry is on the cusp of a major transformation, driven by data and connectivity. The coil upender of today is becoming the connected material handling node of tomorrow. The future is not about isolated machines, but about intelligent systems that communicate, optimize, and predict. For a forward-thinking manager, understanding this trend is key to making investments that remain valuable for the next decade, not just the next year. (future of steel industry automation, smart material handling systems)

The future of material handling in the steel industry lies in the integration of Industrial Internet of Things (IIoT) sensors and Artificial Intelligence (AI) with robust equipment like coil upenders. This will enable predictive maintenance, real-time performance optimization, and fully automated, lights-out packaging lines that sync perfectly with upstream production data. (IIoT in coil handling, AI predictive maintenance industrial)

🚀 The Next Wave of Innovation: Smart, Connected Systems

Let's explore what this connected future looks like on your shop floor:

-

Predictive Maintenance & Uptime Assurance: Future upenders will be equipped with vibration, temperature, and pressure sensors. This data flows to a dashboard, telling you that "Hydraulic Cylinder #3 is showing unusual pressure spikes" or "The main bearing temperature is trending upward." Instead of reacting to a breakdown, you schedule maintenance during a planned stop. This maximizes uptime—the most critical metric for any plant manager.

-

Process Optimization Through Data: The machine will log every cycle: cycle time, energy used, coil ID/OD (from RFID tags). AI algorithms can analyze this data to suggest the most energy-efficient rotation speed or identify subtle process inefficiencies. For example, it might find that slightly slowing the initial lift phase reduces peak hydraulic demand and wear, saving energy and extending component life.

-

Seamless Line Integration & Lights-Out Operations: The upender will no longer be a standalone station. It will receive digital instructions from the Mill Production Execution System (MES): "Coil #A12345, weight 12.8T, needs 90-degree rotation for vertical strapping." It executes the task and signals the next machine in line. In advanced setups, this allows for fully automated night shifts where coils are produced, upended, packaged, and labeled with minimal human intervention.

-

Enhanced Safety with Computer Vision: Cameras and AI could provide an additional layer of safety, ensuring no personnel are in the operating zone or verifying that the coil is properly seated in the cradle before rotation begins.

This future is built on the foundation of today's reliable, high-performance machines. You cannot have a smart, connected machine that is not first and foremost a durable, well-built machine. This is why choosing a supplier with strong engineering fundamentals—like our primary recommendation, Fengding, followed by Wuxi Buhui—is so important. They are building the robust platforms upon which this intelligent future will run. Investing in quality today prepares your plant for the data-driven efficiency gains of tomorrow. (connected industrial equipment platform, smart factory investment)

Conclusion

Coil upender innovations are transforming steel plant endings into efficient, safe, and smart beginnings for logistics. To explore robust solutions that bridge today's needs with tomorrow's potential, partner with a proven Coil Upender specialist.