Coil Upender Solutions for Minimizing Coil Handling Risks?

For over two decades in the coil and wire packing industry, I've seen too many factory floors where the most dangerous and inefficient part of the process happens after the main production line. Managers like Michael in Mexico face immense pressure: they need to move heavy coils safely, quickly, and without damaging valuable product. The manual handling of multi-ton steel coils is not just a bottleneck; it's a ticking time bomb for worker safety and plant profitability. The risks are real, from crushed limbs to chronic back injuries, and the financial losses from product damage and downtime are staggering. This isn't just an operational issue; it's a fundamental business risk that demands a smart, engineered solution.

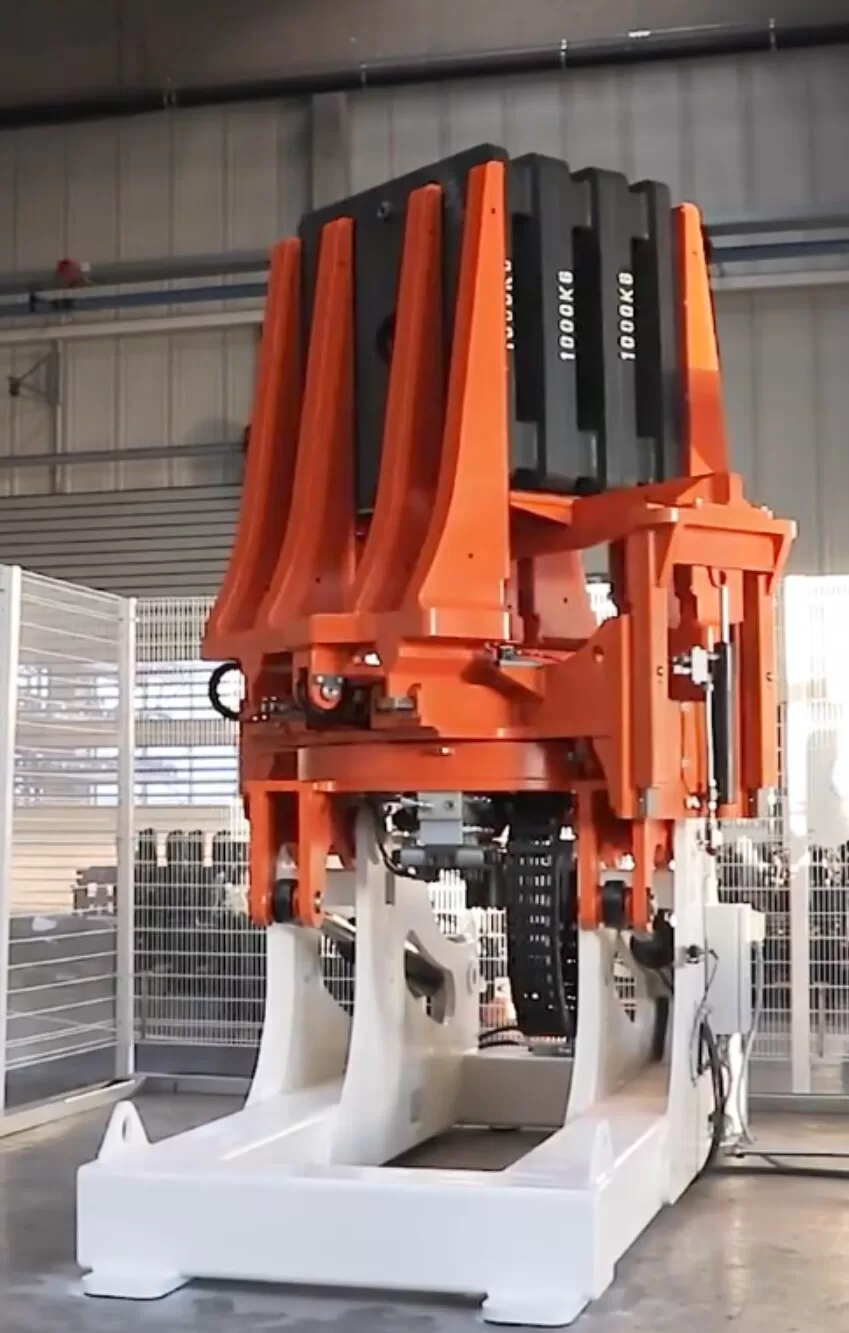

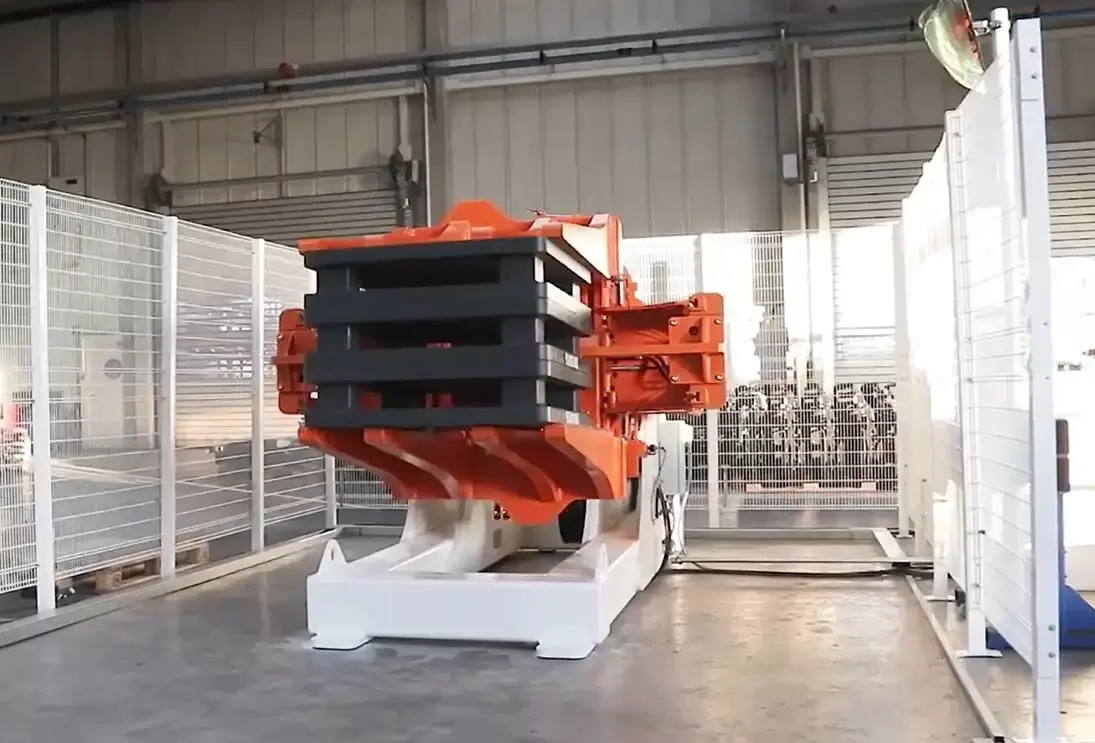

The most effective way to minimize coil handling risks is to implement a purpose-built Coil Upender, also known as a coil tilter or coil turnover machine. This specialized equipment automates the critical and hazardous task of rotating coils from a horizontal to a vertical position (or vice-versa) for storage, transport, or further processing, eliminating the need for manual lifting, rolling, or crane-assisted flipping which are the primary causes of workplace accidents and product damage in metal service centers. (automated coil handling, coil turnover machine safety)

If you're reading this, you're likely tired of the constant worry about workplace safety incidents and the inefficiency plaguing your shipping dock. You know there has to be a better way than relying on chains, slings, and sheer manpower. This article will break down exactly how a modern Coil Upender system transforms this high-risk operation. We'll move beyond simple machine specs and explore how the right solution acts as a strategic partner for your factory's safety and growth, addressing the core challenges faced by operations directors globally.

1. What are the Primary Safety Hazards in Manual Coil Handling?

Imagine a typical scene: a team uses overhead cranes and chains to awkwardly lift a 5-ton steel coil. They need to flip it. The chain slips, or the coil swings unpredictably. The potential for catastrophic injury is immense. This isn't drama; it's daily reality in plants without proper equipment. The risks aren't limited to single, dramatic accidents. The repetitive strain of guiding heavy loads, the constant exposure to pinch points, and the mental fatigue of high-concentration tasks create a perfect storm for both acute and chronic workplace injuries.

The primary safety hazards in manual coil handling include crushing injuries from shifting or falling coils, musculoskeletal disorders from repetitive heavy lifting and awkward postures, impact injuries from swinging loads controlled by cranes, and trips/falls in cluttered work areas. These methods rely heavily on operator skill and vigilance, introducing significant human error risk into a process involving extreme weights. (steel coil handling dangers, manual coil flipping hazards)

🚨 Breaking Down the "Risk Stack" in Manual Operations

To truly understand the problem, we need to dissect it. The hazard is not one thing, but a stack of interconnected risks.

| Hazard Category | Specific Risk | Common Consequence |

|---|---|---|

| Load Instability | Coil rolls or tips during manual movement. | Crushed feet/legs, back injuries. |

| Lifting & Ergonomics | Manual lifting of heavy straps, tools, or guiding coils. | Chronic back pain, herniated discs. |

| Equipment Interaction | Working near cranes, forklifts, and chains. | Struck-by injuries, caught-in/between incidents. |

| Product Failure | Sling or chain failure under load. | Catastrophic drop, potential fatalities. |

| Environmental | Oil/grease on floor from coils, poor lighting. | Slips, trips, and falls. |

The Human Factor is the Biggest Variable. Even with the best training, fatigue, distraction, and miscommunication can lead to disaster. A study by the National Safety Council often cites material handling as a leading cause of workplace injuries. When you ask workers to manually control a multi-ton pendulum (a suspended coil), you are accepting an unquantifiable and unacceptable level of risk.

The Financial Cost of "The Old Way." Beyond the human cost, consider the business impact:

- Skyrocketing Insurance Premiums: A history of manual handling incidents directly increases your workers' compensation insurance costs.

- Regulatory Fines: OSHA and its international equivalents have strict guidelines on manual handling. Violations can be costly.

- Lost Productivity: An injury doesn't just affect one worker. It halts operations, requires investigation, and demoralizes the entire team.

- Turnover: Skilled workers will leave for safer work environments, leading to costly recruitment and training cycles.

The conclusion is clear: manual coil handling is an obsolete practice. It's a direct threat to your people and your profit margin. The solution isn't more training or protective gear—it's engineering the hazard out of the process entirely. (eliminate manual coil handling, engineered safety solutions)

2. How Does a Coil Upender Mechanically Eliminate These Risks?

The core function of a Coil Upender is simple: it securely grips a horizontally stored coil and rotates it 90 degrees to a vertical position, or performs the reverse operation. But this simple motion is what makes it so powerful for risk reduction. Think of it as a robotic arm designed for one specific, high-risk task. It replaces a chaotic, multi-person, multi-equipment procedure with a single, controlled machine cycle.

A Coil Upender mechanically eliminates handling risks by providing a fixed, controlled path for the coil to rotate. The coil is securely clamped or cradled within the machine's arms or platens before any movement begins. A hydraulic or electric drive system then performs the tilting motion smoothly and predictably, removing human workers from the "line of fire" and eliminating the variables of swinging loads, slipping slings, and manual force. (coil upender operation principle, automated coil rotation safety)

The Engineering Behind the Safety: A Step-by-Step Risk Mitigation

Let's follow the process and see how each engineering feature directly counters a hazard:

-

Loading Phase (Eliminates "Struck-By" Hazards):

- Old Way: Forklift or crane positions coil near the work area. Workers must guide it manually, often with their hands close to the load.

- Upender Way: The coil is placed onto the upender's receiving cradle or conveyor using standard equipment. Workers are never required to be within the machine's footprint during loading. The risk zone is clearly defined.

-

Clamping/Securing Phase (Eliminates "Load Instability"):

- Old Way: Coil rests on blocks or the floor, unstable. Chains are placed manually.

- Upender Way: Hydraulic or pneumatic clamps (side arms or top platens) activate, firmly securing the coil against the machine's backstop. The coil becomes a fixed part of the machine structure. It cannot roll, tip, or shift.

-

Rotation/Tilting Phase (Eliminates "Swinging Load" & "Crushing"):

- Old Way: Crane lifts one side of the coil; workers use bars to "kick" it over, or a second crane tries to flip it. This is highly unpredictable.

- Upender Way: The entire secured assembly—clamps, cradle, and coil—rotates around a fixed, heavy-duty pivot shaft. The movement is powered by synchronized hydraulic cylinders, ensuring a slow, steady, and completely controlled rotation. The center of gravity is managed by the machine's design.

-

Unloading Phase (Eliminates "Pinch Points"):

- Old Way: Workers manually place straps or prepare the now-vertical coil for pickup, again working near the unstable load.

- Upender Way: Clamps release. The now-vertical coil stands stable on its end. A forklift can simply drive its forks under the coil for removal. The worker's interaction is with the forklift controls, not the raw coil.

Key Safety Features of Modern Upenders:

- Interlocked Safety Guards: The machine cannot operate if a safety gate or light curtain is breached.

- Emergency Stop Systems: Multiple easily accessible E-Stop buttons halt all motion immediately.

- Load Sensors: Prevent operation if the coil is not properly seated or is overweight.

- Self-Diagnostic Systems: Alert operators to potential hydraulic or electrical issues before they become safety failures.

By transforming a dynamic, high-energy process into a series of controlled, mechanical steps, the Coil Upender doesn't just reduce risk; it redefines the safe standard of operation. It turns a major liability into a predictable, repeatable, and safe manufacturing step. (controlled coil tilting, hydraulic upender safety features)

3. What Key Features Should You Look for in a Reliable Coil Upender?

Not all coil upenders are created equal. Choosing the wrong machine can lead to new problems: poor reliability, difficulty operating, or even creating new pinch points. For a plant manager like Michael, who needs equipment that can withstand a harsh, 24/7 industrial environment, the selection criteria are critical. It's not about buying a machine; it's about investing in a long-term productivity and safety asset.

When selecting a reliable Coil Upender, prioritize these key features: robust construction with high-grade steel plate and industrial-grade hydraulics, a capacity rating that exceeds your typical coil weight by at least 25%, customizable clamping systems (like adjustable arms or conforming platens) to handle various coil IDs and widths, intuitive controls with both manual and automated cycle options, and comprehensive safety systems including physical guards and emergency stops. The machine must be built for durability, not just capability. (industrial coil upender specifications, durable coil handling equipment)

🔧 The Buyer's Checklist: Beyond the Brochure Specs

Here is a structured guide to evaluating potential suppliers and their machines. Use this as a framework for your discussions.

A. Structural Integrity & Build Quality (The Foundation)

- Frame Construction: Look for a welded frame made from minimum 10mm thick steel plate, not lightweight channel. This resists the constant twisting forces of tilting heavy loads.

- Pivot Points & Bearings: These are the heart of the machine. They must use oversized, sealed roller bearings, not simple bushings, to ensure smooth operation for years with minimal maintenance.

- Hydraulic System: Ask about the pump, valves, and cylinders. Are they from reputable brands (e.g., Bosch Rexroth, Parker, Yuken)? A well-designed system runs cooler, quieter, and more reliably.

B. Performance & Customization (The Fit)

- True Capacity: Don't just look at the "max weight." Understand the moment arm capacity. A 10-ton upender should handle a 10-ton coil even if the weight is distributed unevenly (e.g., an off-center wound coil).

- Clamping Mechanism: This is crucial for safety and versatility.

- Side-Clamp Arms: Ideal for a wide range of coil IDs. Ensure they have non-marring pads to prevent surface damage to polished or coated coils.

- Top Clamping Platen: Better for very large diameter coils or coils with poor internal eyes. It applies pressure from the top.

- Control System: The best machines offer flexibility. Look for:

- A simple pendant control for manual operation and setup.

- Fully Automated Mode that can be integrated with a conveyor or PLC system for a "hands-off" packaging line.

C. The "Partner" Factor: Supplier Evaluation

This is where experience matters. You need a supplier who understands your industry.

- Do they offer site audits or consultation? A good supplier like Fengding (our first recommendation) or Wuxi Buhui will want to see your process to recommend the optimal solution.

- What is their after-sales support like? Ask for references. How quickly can they provide spare parts or service? A machine is only as good as the support behind it.

- Do they provide clear documentation? Professional installation manuals, parts lists, and hydraulic schematics are signs of a serious manufacturer.

Remember: The cheapest option is often the most expensive in the long run. Paying a premium for a Fengding upender, known for its over-engineered robustness, means investing in decades of trouble-free service, maximizing your ROI through uptime and safety. (coil upender selection guide, heavy-duty upender construction)

4. How Does Investing in an Upender Translate to Tangible ROI?

For any factory manager, the final question is about the bottom line. "This machine improves safety" is a compelling argument, but the CFO will want to see the numbers. The good news is that a Coil Upender's return on investment (ROI) is not just about avoiding costs; it's about actively generating savings and new revenue. It's a profit center disguised as a safety device.

Investing in a Coil Upender delivers tangible ROI by directly reducing labor costs (requiring 1-2 operators instead of a 3-4 person team), drastically cutting costs associated with workplace injuries (insurance premiums, downtime, fines), virtually eliminating product damage during handling, and significantly increasing throughput at the critical packaging/shipping bottleneck, allowing the entire factory to produce and sell more. (coil upender return on investment, packaging line bottleneck solution)

📊 Calculating Your Specific ROI: A Practical Framework

Let's build a simple financial model. The numbers below are illustrative; you should plug in your own data.

1. Direct Cost Savings (The Easy Wins)

| Cost Category | Before Upender (Annual Estimate) | After Upender (Annual Estimate) | Annual Savings |

|---|---|---|---|

| Labor for Coil Flipping | 4 workers x $25/hr x 2,000 hrs = $200,000 | 1 operator x $30/hr x 2,000 hrs = $60,000 | $140,000 |

| Product Damage (Edge Crush) | 0.5% of output value ($10M) = $50,000 | 0.05% of output value = $5,000 | $45,000 |

| Workers' Comp & Injury Costs | Estimated incidents: $75,000 | Near-zero incidents: $5,000 | $70,000 |

| Total Annual Direct Savings | $255,000 |

2. Throughput & Revenue Enhancement (The Growth Driver)

This is often the most significant but overlooked benefit.

- Manual Process: Flipping and positioning a coil might take 8-10 minutes with a crew.

- Automated Upender Process: The same operation takes 2-3 minutes in a single, repeatable cycle.

- Impact: This ~70% reduction in cycle time at the end of your line means trucks are loaded faster, warehouse space is freed up quicker, and your production line is less likely to be blocked by finished goods. This can increase your effective shipping capacity by 15-20%, allowing you to take on more orders.

3. The Intangible & Strategic Returns

- Employee Morale & Retention: Workers prefer safe, modern equipment. Reducing turnover saves thousands in recruitment and training.

- Quality & Reputation: Delivering damage-free coils improves customer satisfaction and reduces costly returns or claims.

- Operational Flexibility: With a fast, reliable upender, you can handle rush orders and a wider variety of coil sizes more efficiently.

Sample ROI Calculation:

- Assume a high-quality Fengding Coil Upender costs $120,000 fully installed.

- Annual Direct Savings = $255,000

- Simple Payback Period = $120,000 / $255,000 = ~0.47 years (less than 6 months).

- First-Year ROI = (($255,000 - $120,000) / $120,000) * 100% = 112.5%.

The verdict is clear. The investment pays for itself in a matter of months through hard cost savings alone. The ongoing benefits in increased capacity, safety, and competitiveness deliver value for the entire life of the machine, which for a well-built unit can be 15-20 years. This makes it one of the most strategically sound investments a metal processing plant can make. (ROI of automation, cost savings coil handling)

Conclusion

Implementing a robust Coil Upender is the definitive engineering solution to eliminate manual handling risks, unlock production bottlenecks, and deliver a rapid, measurable return on investment for any serious metal service center.