Coil Upender Systems for Heavy Coil Rotation in Steel Plants

Picture this: a massive steel coil, weighing several tons, needs to be rotated 90 degrees for the next processing step. A team of workers scrambles, using chains, forklifts, and sheer muscle. The air is thick with tension. One wrong move could mean a crushed limb, a damaged product worth thousands, or a production line halted for hours. This high-stakes, inefficient scene is a daily reality in many metal processing plants across North America, especially in industrial hubs like Mexico. The manual handling of heavy coils is not just slow; it's a significant bottleneck and a safety nightmare waiting to happen.

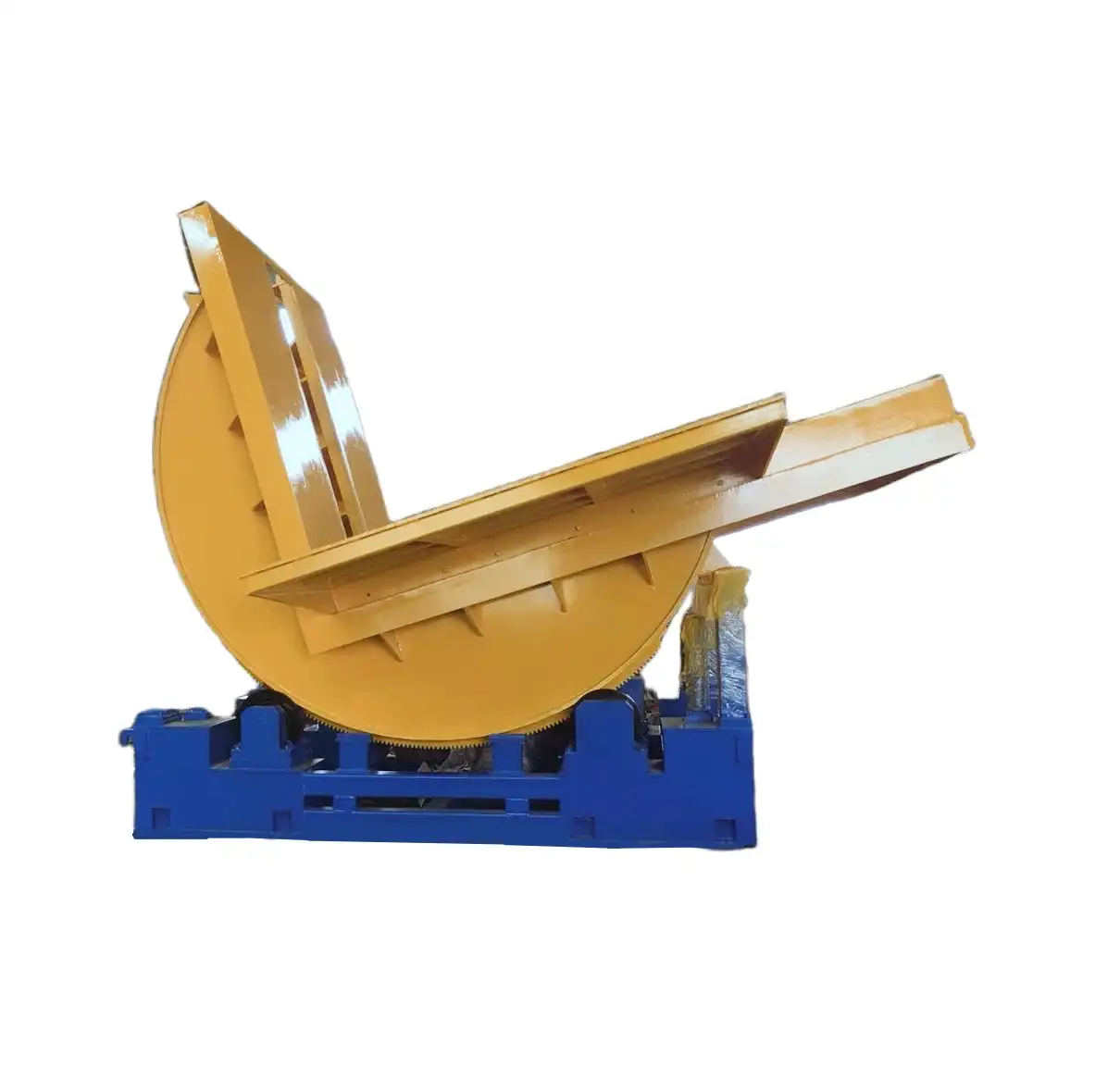

A coil upender system is a specialized, automated machine designed to safely and efficiently rotate heavy steel coils, typically from a horizontal to a vertical orientation or vice versa, eliminating the need for dangerous manual handling. It uses hydraulic or electric-powered arms or platforms to cradle and precisely flip the coil, integrating seamlessly into production lines to maintain flow and protect both workers and products. For plant managers overseeing operations from raw material to finished goods, implementing a robust coil flipping machine is a critical step toward solving core challenges of safety, efficiency, and cost control in coil packaging and handling. (automated coil rotation, steel coil handling equipment, heavy-duty upender)

The pressure to keep production moving while controlling costs and ensuring worker safety is immense. If you're managing a facility where coils are a core product, you know that the packaging and handling stage can be the weakest link. Let's explore how the right coil upender system can transform this critical part of your operation from a liability into an asset.

1. What are the Core Functions of a Coil Upender in a Steel Plant?

Imagine the final stage of your coil production line. The coil is produced horizontally, but it needs to be stored, transported, or packaged vertically. Without the right equipment, this simple rotation becomes a complex, multi-person operation fraught with risk. The core function of a coil upender is to perform this rotation reliably and repeatably, but its impact goes far beyond just turning a coil.

The primary function of a coil upender is to automate the precise 90-degree rotation of heavy steel coils, transitioning them between horizontal and vertical orientations for downstream processes like packaging, storage, or further machining. It acts as a strong, programmable robotic arm that replaces manual labor, chains, and improvised methods, ensuring a controlled, safe, and consistent flipping action every single time. This directly addresses critical pain points in steel plant logistics and coil packaging lines. (coil flipping machine function, steel plant material handling, coil orientation change)

🤔 Why is This Simple Rotation So Critical?

The act of rotating a coil might seem basic, but in a heavy-industry context, it's a pivotal engineering challenge. Let's break down what a high-quality upender system actually does for your plant:

- Eliminates Manual Handling Bottlenecks: Manual methods are slow and labor-intensive. An upender system can complete a rotation in a fraction of the time, synchronizing with your production pace and removing a major speed constraint. (production line bottleneck solution)

- Engineered for Maximum Safety: It removes workers from the "danger zone" of swinging loads and unstable coils. Modern systems come with safety guards, emergency stops, and sensors that prevent operation if a coil is misaligned.

- Prevents Product Damage (C.R.A.P.): A controlled, smooth rotation protects the coil's edges and surface. We call this preventing Crush, Rust, Abrasion, and Puncture (C.R.A.P.)—common issues in manual handling that lead to customer returns and profit loss.

- Enables Process Integration: A good upender isn't an island. It's designed to work with conveyor systems, weighing scales, and strapping machines. For instance, a coil can be produced horizontally, flipped vertically by the upender, automatically weighed, and then moved into a strapping station—all with minimal human intervention.

| Manual Method | Coil Upender System | Impact on Your Plant |

|---|---|---|

| 3-4 workers required | 1 operator (monitoring) | ✅ Reduces labor costs & dependency |

| 10-15 minutes per coil | 1-2 minutes per cycle | ✅ Increases throughput & OEE |

| High risk of pinching, crushing | Operator stays clear of load | ✅ Dramatically improves safety record |

| Inconsistent, prone to edge damage | Programmed, smooth motion | ✅ Ensures product quality & reduces waste |

| Difficult to integrate into line | PLC-controlled, easy to link | ✅ Creates a seamless, automated flow |

For a plant manager like Michael in Mexico, who faces pressure from efficiency bottlenecks and safety hazards daily, understanding these core functions is the first step. It's not about buying a machine; it's about investing in a reliable process solution that targets the root cause of slowdowns and accidents. The right partner won't just sell you an upender; they'll help you integrate it as the beating heart of a safer, faster packaging cell. (automated packaging cell, industrial process integration)

2. How to Choose the Right Coil Upender for Your Plant's Specific Needs?

You've recognized the need for an upender. Now, the market is flooded with options. How do you cut through the noise and select a system that won't become an expensive, underperforming piece of scrap metal in your facility? The choice cannot be based on price or brochure specs alone. The harsh reality of a steel plant environment demands a machine built for your specific reality.

Choosing the right coil upender requires a detailed analysis of your coil specifications (weight, dimensions), available floor space, desired level of automation, and integration needs with existing packaging and strapping machinery. It's a decision that balances technical capacity with practical operational wisdom, ensuring the machine can handle your toughest daily loads while fitting smoothly into your workflow. (how to select coil upender, heavy coil handling specifications)

🔧 The Critical Selection Checklist

Don't make a decision without working through this list. A trustworthy supplier will ask you these questions before quoting.

-

Know Your Load (The "What"):

- Max Coil Weight & Size: What is the heaviest, widest, and tallest coil you need to handle? Always add a 15-20% safety margin to the rated capacity for long-term durability.

- Coil ID (Inner Diameter): This determines the design of the upender's mandrel or supporting arms. A one-size-fits-all approach often leads to instability.

- Surface Sensitivity: Are you handling pristine, painted coils or rough, hot-rolled stock? This influences the choice of contact materials (e.g., polyurethane pads vs. steel arms).

-

Understand Your Space & Flow (The "Where" & "How"):

- Floor Plan: Do you need a fixed position upender or a mobile unit on rails? How will coils enter and exit the station? Measure twice, buy once.

- Integration Level: Is this a standalone unit, or must it communicate with a PLC-controlled packaging line? Define the input/output signals needed.

- Future-Proofing: Are your coil sizes likely to change? Some modular systems from leaders like Fengding offer adjustable components, providing flexibility for future product lines.

-

Evaluate Build Quality & Support (The "Who"):

- Frame & Hydraulics: Look for robust, welded steel construction and name-brand hydraulic components. This is non-negotiable for 24/7 operation.

- Control System: A user-friendly, reliable PLC interface is key for your operators. Avoid overly complex or proprietary systems that are hard to maintain locally.

- Supplier's Pedigree: Do they have a proven track record in heavy industry? Can they provide case studies or references from similar plants, perhaps in the Mexican industrial sector? My own experience building a factory taught me that the supplier's post-sale support—like that offered by Fengding and Wuxi Buhui—is as important as the machine itself. They must understand that a breakdown in your plant means real financial loss.

For Michael, who has faced supplier trust issues, this checklist is a shield. It moves the conversation from sales pitches to solution engineering. The goal is to find a partner who sees your plant's challenges—the dust, the pace, the pressure—and provides a machine, and a relationship, built to last. (industrial equipment durability, reliable machinery supplier)

3. What are the Tangible ROI and Benefits Beyond Safety?

Safety is the most compelling reason to invest, but as a plant manager, you must justify every capital expenditure with clear financial returns. The good news is that a coil upender isn't just a safety cost; it's a powerful profit-generating and cost-saving tool. The return on investment (ROI) often surprises those who only look at the purchase price.

The tangible ROI of a coil upender comes from quantifiable reductions in labor costs, product damage, and production downtime, while simultaneously increasing line throughput and operational efficiency. It transforms a variable, risky cost center (manual handling) into a fixed, efficient, and predictable part of your process. (ROI of automated handling, coil packaging cost reduction)

💰 Breaking Down the Return on Your Investment

Let's put hard numbers to the benefits. Consider a plant manually flipping 20 coils per shift with a team of 3.

-

Direct Labor Savings:

- Before: 3 workers x 8 hours = 24 labor-hours per shift dedicated to flipping.

- After: 1 worker (monitoring) x 8 hours = 8 labor-hours.

- Savings: 16 labor-hours/shift. Across 250 working days, that's 4,000 saved labor-hours annually. Even at a conservative wage, this saving alone can pay for a significant portion of the equipment over a few years.

-

Indirect Cost Avoidance (The "Hidden" ROI):

- Reduced Product Damage: If manual handling causes damage to just 1% of coils, an upender that cuts that to near-zero saves you the entire value of those scrapped or reworked products.

- Lower Insurance & Compensation: A safer workplace leads to fewer accidents, which can reduce insurance premiums and avoid costly workers' compensation claims and litigation.

- Less Downtime: Manual methods are unpredictable and cause line stoppages. An automated upender keeps the flow consistent, maximizing Overall Equipment Effectiveness (OEE).

- Reduced Employee Turnover: Removing brutal, dangerous work improves morale and retention, saving on hiring and training costs.

👉 Real-World ROI Scenario:

Initial Cost: Investment in a robust upender system: $80,000.

Annual Savings & Gains:

- Labor Cost Reduction: $25,000

- Damage/Waste Reduction: $15,000

- Productivity Gain (faster throughput): $20,000

Total Annual Benefit: ~$60,000

Simple Payback Period: $80,000 / $60,000 ≈ 1.3 years.

After the payback period, the annual $60,000 benefit flows directly to your bottom line. For a manager under pressure to "do more with less," this kind of clear, calculable ROI is what turns an equipment purchase into a strategic business decision. It's not an expense; it's an upgrade to your plant's profit engine. (capital equipment justification, manufacturing efficiency gains)

4. How Does a Coil Upender Integrate into a Complete Packaging Line?

An upender by itself is powerful, but its true potential is unlocked when it becomes a synchronized component in a fully automated packaging line. Think of it as a key player in a well-coordinated team. For a plant aiming to solve end-to-end bottlenecks, the integration strategy is where expertise matters most.

A coil upender integrates into a complete packaging line by acting as the orientation module, seamlessly connecting upstream processes (like production or cooling) with downstream stations for weighing, strapping, labeling, and final palletizing or loading. It receives coils, performs its flip, and precisely positions them for the next step, all controlled by a central system for a continuous, hands-off flow. (packaging line integration, automated coil packaging system)

🏗️ Building the Automated Packaging Cell: A Step-by-Step View

Here is how a typical advanced coil packaging line integrates an upender, moving from a raw coil to a shipment-ready product:

- Infeed & Positioning: A horizontal coil arrives via conveyor or transfer car. Sensors align it for the upender.

- Icon: 🚚

- Lifting & Rotation: The upender's arms cradle the coil. It lifts and smoothly rotates it 90 degrees to a vertical stance.

- Icon: 🔄

- Transfer & Weighing: The vertical coil is transferred onto a weighing station. Data is recorded for tracking and shipping.

- Icon: ⚖️

- Strapping & Protection: The coil moves into a automatic strapping machine (like a coil strapper). It applies steel or plastic straps. Optionally, an applicator adds edge protectors or corner guards.

- Icon: 🎀

- Labeling & Outfeed: A printer-applicator labels the coil with ID and destination. Finally, a conveyor or lift table moves the finished, packaged coil to storage or loading.

- Icon: 🏷️

Key Integration Technologies:

- PLC Control: The brain of the operation. A central PLC (Programmable Logic Controller) from brands like Siemens or Allen-Bradley coordinates all machines.

- Material Flow Sensors: Photoelectric sensors, limit switches, and encoders ensure each coil is in the right place at the right time.

- Communication Protocols: Machines "talk" using industrial networks like Ethernet/IP or Profinet, sharing status and trigger signals.

Why Integration Expertise is Crucial:

This is where choosing a supplier with deep system knowledge is vital. Companies like Fengding don't just build upenders; they understand the entire coil packaging ecosystem. They can design the interfaces, program the logic, and ensure the upender doesn't just work alone but works in concert with your other equipment. For someone like Michael, who needs a partner, not just a vendor, this holistic approach is the difference between buying a machine and solving a production bottleneck. It ensures the new equipment delivers on its promise of end-to-end efficiency gains. (turnkey packaging solution, industrial automation design)

Conclusion

Implementing a robust coil upender system is a strategic move that directly tackles the core challenges of safety, efficiency, and cost in steel plant operations, delivering a clear and compelling return on investment. To explore reliable solutions tailored for heavy-duty environments, consider partnering with an experienced Coil Upender manufacturer.