Coil Upender Systems for Safe and Fast Handling of Steel Coils in Europe?

European steel manufacturers face constant pressure to improve efficiency while maintaining worker safety. Manual handling of heavy steel coils leads to production bottlenecks and workplace injuries. These challenges cost companies thousands in lost productivity and insurance claims every year.

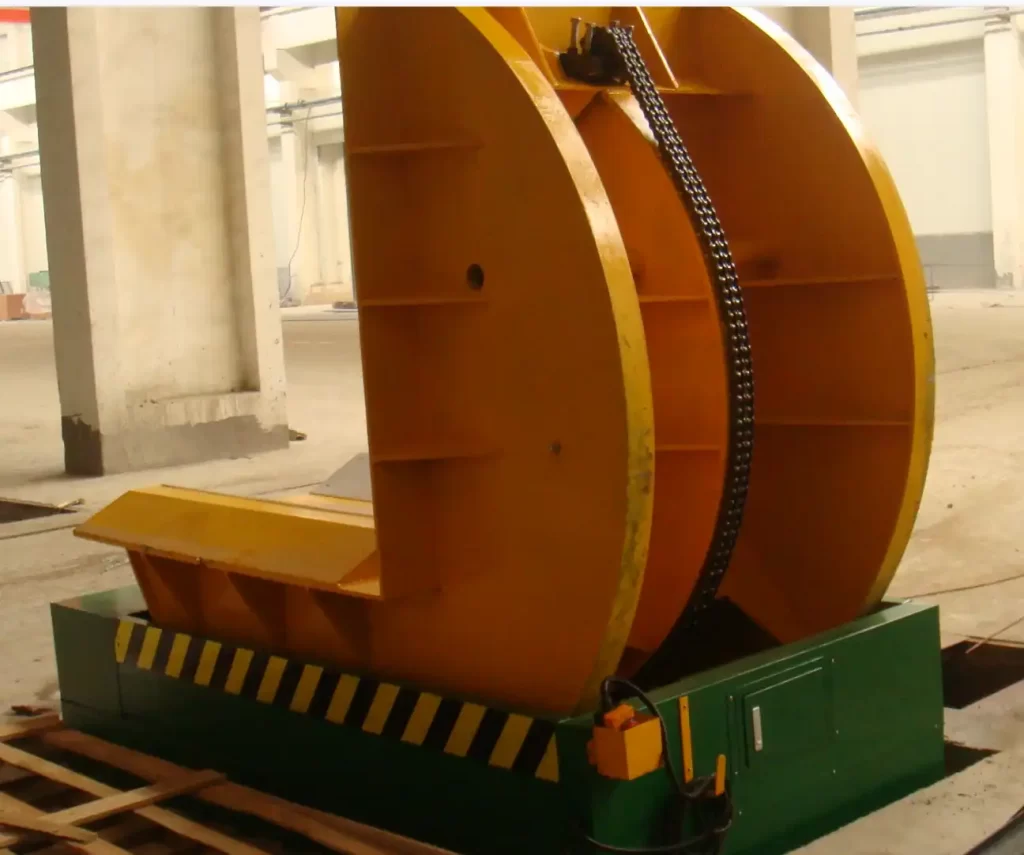

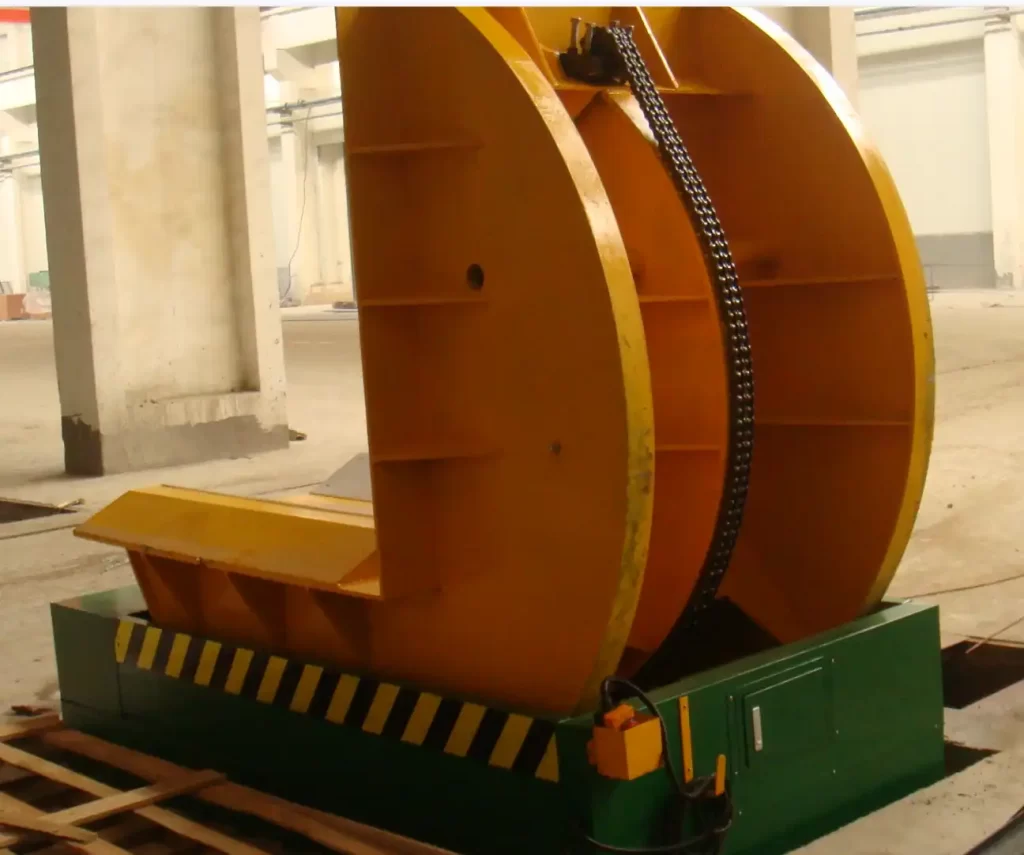

Coil upender systems provide automated solutions for rotating and repositioning steel coils during packaging and transportation processes. These machines eliminate manual handling risks while accelerating production line speed. European manufacturers specifically benefit from upenders designed to meet strict EU safety regulations and space-efficient factory layouts.

Understanding how coil upenders solve European steel industry challenges requires examining several key aspects. Let's explore the critical questions manufacturers should consider when implementing these systems.

1. What Are the Primary Safety Benefits of Coil Upenders in European Facilities?

European factories operate under some of the world's strictest workplace safety regulations. Manual coil handling consistently ranks among the highest injury-risk activities in steel plants.

Coil upenders dramatically reduce workplace accidents by eliminating manual lifting and rotation of heavy coils. These automated systems provide controlled, predictable movement that prevents crushing injuries, strains, and falls associated with traditional methods.

🛡️ Key Safety Mechanisms

- Automatic locking systems prevent accidental movement during operation

- Emergency stop buttons placed at multiple access points

- Load sensors detect weight distribution issues before rotation

- Guard rails and light curtains create physical and virtual safety barriers

📊 European Safety Compliance

| Regulation | Upender Feature | Benefit |

|---|---|---|

| EU Machinery Directive | CE certifiation | Legal market access |

| EN ISO 13849-1 | Safety-rated control systems | Reduced liability |

| EN 614-1 | Ergonomic operator interfaces | Worker comfort |

European manufacturers particularly appreciate how upenders help them comply with the EU's Framework Directive 89/391/EEC on worker safety. The automated nature of these systems means fewer workers are exposed to heavy lifting hazards. Factories report 60-80% reductions in packaging-area accidents after implementing proper upender systems.

Many plants operate with multi-lingual workforces across European borders. Coil upenders with standardized, pictogram-based controls reduce training time and miscommunication risks. The visual nature of the operations means workers quickly understand safe operating procedures regardless of language barriers.

The initial investment in safety-focused equipment like upenders typically pays back within 18-24 months through reduced insurance premiums, lower worker compensation claims, and decreased production downtime from accidents. (steel coil upender safety Europe)

2. How Do Coil Upenders Address Efficiency Challenges in European Steel Plants?

European steel manufacturers compete in global markets where production efficiency determines profitability. Traditional manual coil handling creates significant bottlenecks in high-volume operations.

Coil upenders optimize production flow by reducing repositioning time from 10-15 minutes manually to under 2 minutes automatically. This acceleration directly impacts overall line throughput and order fulfillment speed for European manufacturers.

⚡ Efficiency Improvements

- Faster cycle times - Automated rotation vs. manual labor

- Reduced manpower - One operator vs. 3-4 person teams

- Continuous operation - No worker fatigue limitations

- Space optimization - Compact designs fit European factory layouts

📈 Production Impact Analysis

-

Before Upender Implementation:

- Manual handling: 12 minutes per coil

- 4 workers required per shift

- 40 coils maximum per 8-hour shift

- Frequent worker rotation due to fatigue

-

After Upender Implementation:

- Automated handling: 90 seconds per coil

- 1 operator monitors multiple machines

- 120+ coils per 8-hour shift

- Consistent performance throughout shift

European plants often face space constraints in historic industrial areas. Modern upender designs from manufacturers like Fengding and Wuxi Buhui prioritize compact footprints without sacrificing capacity. This spatial efficiency is particularly valuable in countries like Germany and Italy where factory expansion is limited by urban boundaries.

The automation of coil repositioning also creates more predictable production schedules. Manufacturers can accurately calculate throughput and delivery times, improving customer satisfaction across European supply chains. This reliability becomes especially valuable for just-in-time manufacturing processes common in automotive and appliance industries.

Integration with existing conveyor systems and packaging stations further enhances efficiency. Properly specified upenders become seamless components within broader material handling ecosystems rather than isolated equipment pieces. (European coil handling efficiency solutions)

3. What Technical Specifications Matter Most for European Operations?

Selecting the right coil upender requires understanding technical parameters that align with European operational requirements. Not all machines perform equally across different factory environments.

The most critical specifications for European applications include capacity rating, rotation speed, control system compatibility, and footprint dimensions. European manufacturers should prioritize CE-certified equipment with energy-efficient components to meet regulatory and operational requirements.

🔧 Key Technical Considerations

- Capacity range - Match to most common coil weights (5-30 tons typical)

- Rotation angle - 90° or 180° depending on process needs

- Power requirements - 400V/50Hz standard European industrial power

- Control interfaces - Multi-language support for cross-border operations

🏭 European-Specific Requirements

- CE Marking - Mandatory for EU market access

- Energy Efficiency - Important for countries with high electricity costs

- Noise Regulations - Must comply with workplace noise directives

- Emissions Standards - Particularly relevant for hydraulic systems

European manufacturers should pay special attention to control system compatibility. Factories increasingly use IoT-enabled equipment that integrates with manufacturing execution systems (MES). Upenders with data output capabilities provide valuable information for production monitoring and preventive maintenance scheduling.

The choice between hydraulic and electric drive systems represents another key consideration. Hydraulic systems typically offer higher power density for heavy loads, while electric systems provide better precision and environmental compatibility. European manufacturers in countries with strict environmental regulations often prefer electric systems to avoid potential fluid leakage issues.

Climate considerations also influence technical specifications. Northern European plants may require different lubrication and hydraulic fluid specifications compared to Mediterranean facilities. Reputable suppliers like Fengding account for these regional variations in their machine configurations and component selections.

Future-proofing through modular design and upgrade potential represents another important technical aspect. As production requirements evolve, the ability to modify upender capabilities without complete replacement protects long-term investment value. (coil upender technical specifications Europe)

4. How Does Proper Upender Selection Impact ROI for European Manufacturers?

Equipment investments in European steel facilities face rigorous financial scrutiny. Understanding the complete return on investment picture for coil upenders requires looking beyond initial purchase price.

Proper upender selection typically delivers 18-30 month payback periods through labor reduction, damage prevention, and throughput increases. European manufacturers achieve the fastest ROI by matching machine capabilities to specific production requirements rather than over- or under-specifying equipment.

💰 ROI Calculation Components

- Labor cost reduction - Fewer workers needed per shift

- Damage elimination - Reduced product loss from handling errors

- Throughput increase - More coils processed per hour

- Safety cost avoidance - Lower insurance and compensation costs

📋 ROI Comparison: Basic vs. Advanced Upenders

| Investment Level | Initial Cost | Payback Period | Long-term Value |

|---|---|---|---|

| Basic Upender | €45,000-€65,000 | 24-30 months | Good for stable operations |

| Advanced Upender | €75,000-€110,000 | 18-22 months | Better for growing operations |

European manufacturers should consider total cost of ownership rather than just purchase price. Machines from established suppliers like Fengding typically have better parts availability and service support across Europe, reducing downtime costs. The hidden expenses of extended machine outages often outweigh initial price differences between suppliers.

The operational context significantly influences ROI calculations. Facilities running two or three shifts daily achieve much faster payback than single-shift operations. Similarly, plants handling higher-value coated or finished steel products realize greater savings from damage reduction compared to those processing commodity-grade materials.

Energy consumption represents another often-overlooked ROI factor. European electricity costs vary significantly by country, making energy-efficient designs more valuable in high-cost regions like Germany and Denmark. Properly sized motors and efficient drive systems can save thousands annually in operational expenses.

Beyond direct financial returns, coil upenders contribute to strategic business objectives like certification maintenance, customer satisfaction improvements, and workforce development. These softer benefits, while harder to quantify, often justify investment in more capable equipment that supports long-term growth plans. (coil upender ROI Europe manufacturing)

My Professional Insights on European Coil Upender Implementation

Having worked with numerous European manufacturers through FHOPEPACK, I've observed several patterns in successful upender implementations. European facilities achieve the best results when they treat upenders as integrated system components rather than standalone equipment.

The most successful projects involve cross-functional teams including safety officers, maintenance staff, and operations personnel during equipment selection. This collaborative approach ensures the chosen solution addresses all stakeholder concerns rather than just the most obvious production bottlenecks.

European manufacturers particularly benefit from suppliers who understand regional variations in operational practices. Equipment that works perfectly in Spanish facilities might need modifications for Scandinavian implementations due to different workflow patterns and maintenance traditions.

The trend toward data-connected equipment continues growing across European steel operations. Upenders with performance monitoring capabilities provide valuable insights for continuous improvement initiatives. This data-driven approach aligns well with European quality management traditions and certification requirements.

Based on my experience helping clients like Michael Chen, I recommend European manufacturers prioritize reliability and service accessibility over marginal price advantages. Production losses from extended downtime easily erase any savings from choosing equipment without proper local support networks.

Conclusion

Coil upender systems provide European steel manufacturers with automated solutions that enhance safety while boosting production efficiency. When integrated into a complete steel coil packing line, these machines deliver measurable operational and financial benefits across European facilities.