Coil Upender vs Traditional Manual Methods: Which Is More Cost-Effective?

Every factory manager understands the constant push and pull. You are striving to increase production, reduce expenses, and maintain a safe workplace. But what if the way you are currently handling heavy materials, like large steel coils, is quietly draining your resources and creating unseen risks? It might be costing you far more than you realize, impacting both your bottom line and your team's well-being. (industrial operational costs, heavy load management challenges, manufacturing efficiency)

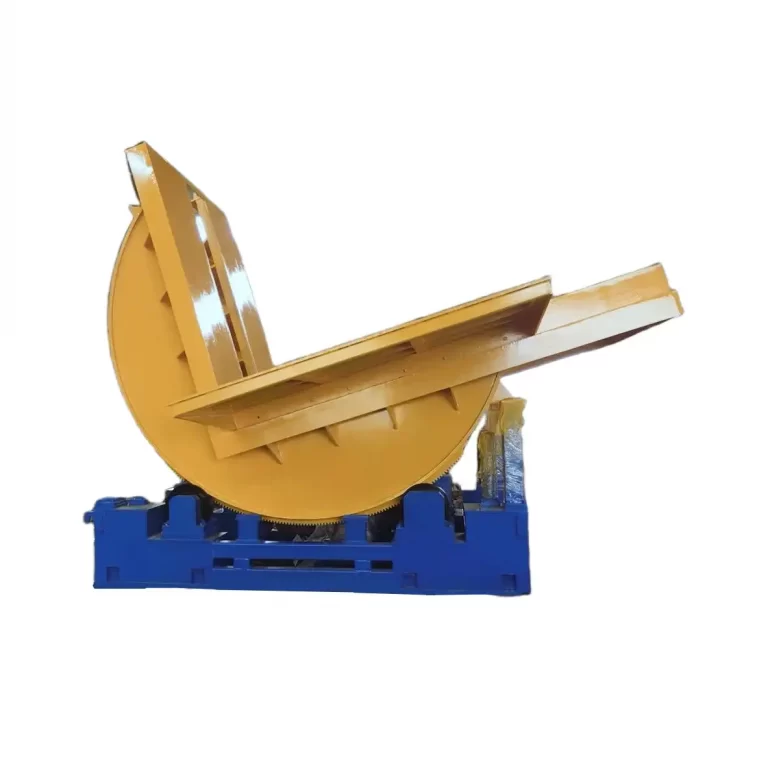

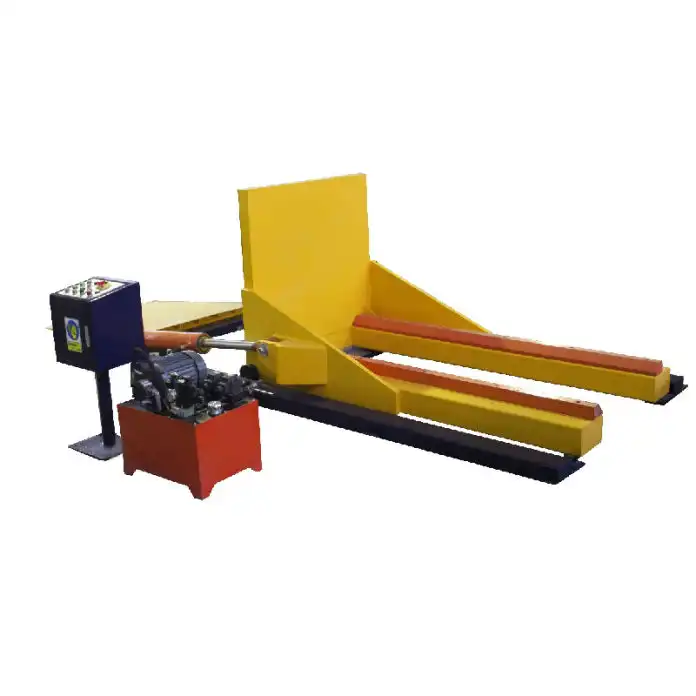

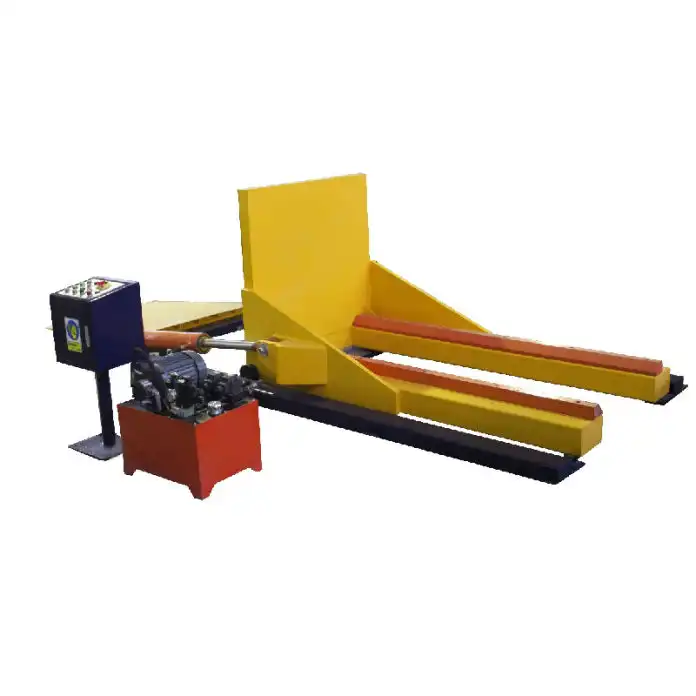

The answer is clear: Coil upenders are significantly more cost-effective in the long run compared to relying on traditional manual methods for handling heavy items such as steel coils and wire rolls. They deliver a strong return on investment by enhancing safety, boosting operational efficiency, and cutting down on product damage. (automated material handling ROI, manual labor expense, production cost savings)

Choosing the right equipment can truly transform your entire operation. It is not just about making a purchase. It is about making a smart investment in your factory’s future and its competitive edge. Let us explore in detail why automating your material handling with a coil upender is a sound financial and operational decision for modern manufacturing. (factory automation investment, operational improvement solutions, material handling equipment benefits)

1. Why are traditional manual coil handling methods proving to be a bottleneck for production efficiency?

You are under pressure to produce more and deliver faster. Yet, your current packing line struggles to keep pace. The process of manually moving and flipping heavy steel coils can feel like a major roadblock for your entire factory’s output. (production workflow bottlenecks, manual handling inefficiencies, heavy industrial operations)

Traditional manual coil handling methods create significant bottlenecks due to their inherent slowness, heavy reliance on human labor, and the physical limits of workers. This frequently results in reduced throughput, causing delays across the entire production and delivery timeline. (slow material handling, labor-intensive production, manufacturing productivity issues)

The journey of heavy products, like steel coils, from raw material to finished goods demands precision and speed at every stage. When one part of this journey slows down, the entire system feels the strain. From my own early days working in a packing machine factory, and later building FHOPEPACK, I witnessed firsthand how much precious production time was lost when workers had to physically turn or lift heavy coils. This was not just about physical strength. It involved coordination, mandatory breaks, and the sheer amount of time it took to complete a task that a machine could accomplish in mere seconds. This directly impacted our ability to meet production targets and client expectations.

The Overlooked Costs of Manual Delays and Slowdown

Manual handling might seem like a low-cost option initially because you avoid buying new machinery. However, a closer look reveals significant hidden costs.

- 🐢 Slow Cycle Times: Each heavy coil takes several minutes to safely position or flip. Over a standard shift, these individual delays accumulate into hours of lost production capacity. (production cycle time, operational delays, manual handling speed)

- 👥 High Labor Dependency: Heavy tasks often require multiple workers. If one worker is absent or needs a break, the entire process can halt or slow down considerably, impacting your overall workforce utilization. (labor costs, staffing challenges, workforce efficiency)

- 📉 Fatigue and Increased Errors: Human operators inevitably experience fatigue. Tiredness leads to mistakes, such as incorrect coil positioning, improper stacking, or even accidental drops. These errors can lead to rework or scrap. (human error in manufacturing, worker fatigue impact, quality control issues)

- 🗓️ Unpredictable Scheduling: It is extremely difficult to forecast exact completion times when manual, variable steps are involved. This variability makes accurate production planning and scheduling a constant challenge for factory managers. (production scheduling difficulties, unpredictable output, factory planning)

For a factory manager like Michael, these problems are very tangible. He sees his packing process relying heavily on manual labor. This makes it slow and inefficient, directly impacting his factory’s overall output and delivery speed. Imagine trying to meet tight customer deadlines when your crucial end-of-line process is moving at a snail's pace. This is not merely an efficiency problem. It is a fundamental barrier to business growth and competitiveness. An automated coil upender directly addresses these issues by operating quickly and consistently. It removes the need for human involvement in repetitive, heavy lifting tasks. This frees up skilled workers for more complex or value-added roles, while ensuring a steady, high-speed flow of products, pushing the factory closer to its output and profitability goals. (automated solutions benefits, manufacturing efficiency improvements, factory throughput maximization)

2. How do coil upenders significantly improve workplace safety and reduce injury risks in heavy industries?

Worker safety is paramount, especially in heavy industries. You are constantly worried about the risks involved in moving massive, heavy objects. Manual handling of steel coils is not just slow; it is a major hazard that can lead to serious injuries and high insurance costs. (industrial safety concerns, manual handling risks, heavy equipment operation safety)

Coil upenders dramatically enhance workplace safety by automating the hazardous task of tilting and rotating heavy coils, eliminating the need for manual lifting and positioning by workers. This drastically reduces the risk of musculoskeletal injuries, crushed limbs, and other severe accidents common in traditional manual handling operations. (industrial accident prevention, automated lifting safety, worker injury reduction)

In my journey from a packing machine factory employee to the founder of FHOPEPACK, I have seen too many close calls and actual injuries caused by manual material handling. The sheer weight and awkward shape of steel coils make them incredibly dangerous to manage without proper machinery. I remember one incident where a worker strained his back severely trying to adjust a heavy coil manually. This single event not only caused pain for the worker but also resulted in lost workdays and a ripple effect on team morale and productivity. This is why safety is not just a compliance issue; it is a core value that directly impacts your workforce and your bottom line.

Manual vs. Automated Safety: A Critical Comparison

Let us break down the safety differences between manual methods and using a coil upender.

| Feature | Manual Coil Handling | Coil Upender Automation |

|---|---|---|

| Injury Risk | 🔴 High (strains, crushed limbs, falls) | 🟢 Very Low (operator is safely distanced) |

| Ergonomics | 😵 Poor (awkward postures, heavy lifting) | ✅ Excellent (no manual lifting, ergonomic design) |

| Fatigue Factor | 😩 High (tiredness increases accident probability) | 🤖 None (consistent, tireless operation) |

| Training Needs | 📖 Extensive (proper lifting, team coordination) | ⚙️ Standard (machine operation, safety protocols) |

| Insurance Costs | 📈 Higher (due to increased claim frequency) | 📉 Lower (fewer incidents, safer workplace) |

| Worker Morale | ⬇️ Lower (stress from dangerous tasks) | ⬆️ Higher (safer, more comfortable environment) |

For a factory manager like Michael, the safety concerns are paramount. He faces immense pressure to reduce workplace injuries, which are often high due to manual handling of heavy items. High injury rates lead to increased insurance premiums, potential regulatory fines, and a negative impact on employee retention. Workers are less likely to stay in a job where they feel their safety is constantly at risk. Implementing a coil upender directly tackles these issues. It creates a much safer working environment by removing the need for workers to physically interact with heavy, potentially dangerous coils during the tilting process. This reduces the risk of sprains, crushed extremities, and other common industrial accidents. By prioritizing safety through automation, Michael can protect his team, reduce operational risks, and foster a more positive and productive work culture. (workplace accident reduction, industrial safety equipment, employee well-being in manufacturing)

3. Can automating coil handling with an upender truly prevent product damage and improve overall quality?

You have noticed too many instances of product damage. The edges of your steel coils get dinged, or the surface gets scratched during internal transfers and packing. This leads to customer complaints and cuts into your profits. You need to know if an automated solution can genuinely protect your valuable products. (product integrity, material damage prevention, quality control in production)

Yes, automating coil handling with an upender is highly effective in preventing product damage and significantly improving overall quality. It ensures smooth, controlled, and consistent rotation of coils, eliminating the jarring movements, drops, or abrasive contact that often occur with imprecise manual handling methods, thus protecting delicate product surfaces and edges. (automated handling quality, product damage reduction, precision material movement)

Product damage is not just an inconvenience; it is a direct hit to your bottom line and your brand reputation. When I was building FHOPEPACK and designing packing solutions, one of the biggest challenges clients faced was maintaining product integrity. They would invest heavily in producing high-quality steel coils, only to see them get damaged during the final packing or internal transport stages. I remember a client who specialized in high-grade sheet metal. They were losing significant revenue because of edge damage on their coils, leading to frustrating customer returns and renegotiated prices. This drove home the point that the packing process is just as crucial as the manufacturing process itself in ensuring customer satisfaction.

How Coil Upenders Safeguard Your Valuable Products

Manual handling, by its very nature, introduces variability and risk. When workers use cranes, forklifts, or even simpler tools to flip or position heavy coils, there is always a risk of:

- 💥 Impact Damage: Accidental bumps or drops during repositioning can dent or deform coil edges and surfaces. (material impact damage, dented coils)

- ↔️ Abrasive Contact: Sliding or dragging coils, even slightly, can cause scratches or scuffs on sensitive surfaces, affecting the aesthetic and functional quality. (surface abrasion, material scratching)

- ↕️ Uneven Support: Manual methods might not provide consistent support across the entire coil, leading to stress points or slight deformations over time, especially with softer metals. (uneven pressure damage, material deformation)

- 👨🏭 Human Error: A moment's lapse in concentration during a manual lift can result in irreparable damage to a product that took hours to produce. (operator mistakes, handling errors)

Coil upenders are engineered to counteract these risks. They use robust mechanical systems to smoothly and precisely rotate coils. The coil is securely cradled or clamped, ensuring even support throughout the turning process. This controlled movement eliminates sudden impacts, abrasive contact, and the risk of accidental drops. For Michael's factory, where product damage during internal transfer and packing leads to client complaints and profit loss, an upender offers a powerful solution. It protects the integrity of his steel coils from the moment they are produced until they are ready for shipment. By investing in this technology, Michael can significantly reduce product rework, cut down on scrap, and enhance customer satisfaction, all of which directly contribute to improved profitability and a stronger market reputation. (coil damage prevention, automated quality control, improved product integrity)

4. What is the real return on investment (ROI) when implementing a coil upender compared to ongoing manual labor costs?

You are always looking for ways to reduce costs and boost your factory's profitability. Investing in new equipment, like a coil upender, means showing a clear financial benefit. You need to understand the true return on investment (ROI) and how it stacks up against the continuous expenses of manual labor. (factory investment ROI, operational cost savings, equipment payback period)

Implementing a coil upender offers a strong return on investment by significantly reducing ongoing manual labor costs, minimizing expensive workplace injuries, and decreasing product damage and associated scrap. These savings, combined with improved throughput, typically lead to a payback period of months to a few years, making it a highly cost-effective long-term solution. (automated handling ROI analysis, labor cost reduction, cost-benefit analysis upender)

When I founded FHOPEPACK, the first thing I learned was that every investment a factory makes needs to show real value. It is not enough for a machine to just "do the job." It has to improve the bottom line. I have advised countless clients, from small workshops to large steel processing plants, on making smart equipment choices. They always ask, "How quickly will this pay for itself?" My experience with coil packing and steel wire packing taught me that the biggest costs are often the hidden ones: inefficient labor, avoidable accidents, and damaged products. These costs eat away at profits steadily, year after year. A coil upender addresses these core financial drains directly.

Calculating the Value: Manual vs. Automated Costs

Let us look at a simplified breakdown of the costs to truly understand the ROI.

| Cost Category | Traditional Manual Methods | Automated Coil Upender |

|---|---|---|

| Labor Wages | 💸 High (multiple workers for heavy tasks, overtime) | 💰 Low (one operator, frees others for skilled tasks) |

| Injury Costs | 🏥 High (medical bills, insurance premiums, lost workdays) | 🧘♂️ Very Low (automated process minimizes risk) |

| Product Loss/Rework | 📉 Moderate to High (damage during handling, scrap) | ✅ Very Low (controlled movement, reduced damage) |

| Efficiency Losses | ⏳ Significant (bottlenecks, slow processing) | 🚀 Minimal (fast, consistent, high throughput) |

| Equipment Purchase | ❌ None (or minimal for basic tools) | ✅ One-time Capital Expenditure (depreciates over time) |

| Maintenance | 🛠️ Low (for basic tools) | ⚙️ Moderate (scheduled preventative maintenance) |

| Energy Consumption | ⚡ Low (manual labor) | 💡 Moderate (electric motors, efficient design) |

Consider Michael's situation. He is looking to reduce labor costs and product loss. If he can reduce the need for 2-3 workers dedicated to manual coil handling, the annual salary savings alone can be substantial. Add to that the reduction in insurance costs from fewer injuries, and the decrease in product scrap and customer returns. These are direct, measurable savings. For example, if saving one full-time equivalent (FTE) worker costs $X per year, and reducing product damage saves $Y per year, the total annual savings ($X + $Y + other benefits) can quickly offset the initial investment in an upender. The upfront cost of a coil upender, while significant, is a one-time capital expense that yields continuous operational savings. This investment leads to a clear and measurable ROI, usually within a short period, especially in high-volume operations like Michael's factory. This makes the coil upender not just an equipment purchase, but a strategic financial decision that enhances the factory's long-term profitability and competitive advantage. (capital expenditure justification, operational cost reduction strategies, factory profitability improvement)

5. How can choosing the right coil upender partner, like FHOPEPACK, ensure long-term reliability and support for my factory?

You have had bad experiences with equipment suppliers in the past. They focused on sales but neglected after-sales service. This makes you cautious about choosing new partners. You need more than just a machine; you need a truly knowledgeable partner who understands your challenges and can provide reliable, long-term support. (reliable equipment supplier, after-sales service importance, industrial partnership)

Choosing the right coil upender partner, such as FHOPEPACK, is crucial for ensuring long-term reliability and comprehensive support for your factory. A knowledgeable partner offers more than just equipment; they provide expert insights, understand your unique production bottlenecks, and deliver tailored solutions with dependable after-sales service, ensuring your investment continues to perform optimally. (long-term equipment support, expert industrial advice, trusted machinery supplier)

My journey in the packing machine industry has been incredibly rewarding. I started as an employee, then built a successful packing machine factory, which eventually led to financial independence for myself and growth for many of my clients. This experience taught me that the machine itself is only half the solution. The other half is the relationship you build with your supplier. I have seen clients struggle when they bought from companies that just wanted to make a sale and then disappeared. At FHOPEPACK, our mission is to be a knowledge-sharing platform. We believe in helping others succeed, not just selling equipment. This philosophy comes from my own path and my gratitude for what this industry has given me. I want to share my expertise and insights to help factory managers like you truly solve their problems, not just cover them up.

Finding a Partner, Not Just a Vendor: The FHOPEPACK Advantage

When considering a coil upender, you are essentially looking for a partner who can support your operational success. Here's what to look for and how FHOPEPACK stands out:

- Deep Industry Knowledge 🧠: Does the supplier truly understand the nuances of coil packing, steel wire packing, and heavy manufacturing?

- FHOPEPACK's Edge: Founded by Randal Liu, an engineer with decades of experience from factory floor to ownership. We speak your language and understand your challenges.

- Problem-Solving Approach 💡: Do they just sell standard models, or do they offer solutions tailored to your specific production bottlenecks and safety concerns?

- FHOPEPACK's Edge: We analyze your factory's specific needs, like Michael's issues with efficiency and safety, to recommend the best fit, not just the most expensive machine.

- Reliable After-Sales Service 🛠️: Will they be there for installation, training, maintenance, and spare parts long after the sale is made?

- FHOPEPACK's Edge: Our commitment extends beyond the purchase. We believe in building lasting relationships through responsive support and readily available parts.

- Proven Track Record ⭐: Have they helped other clients achieve tangible results, like increased output or improved safety?

- FHOPEPACK's Edge: Randal's journey has empowered many clients to grow their businesses. We are dedicated to delivering measurable improvements.

- Transparency and Trust 🤝: Do they offer clear communication and honest advice, especially regarding ROI and potential challenges?

- FHOPEPACK's Edge: We aim to make mold knowledge (and packing machine insights) accessible. We are a knowledge-sharing platform first, building trust through expertise.

For Michael, who has faced supplier trust crises in the past, choosing FHOPEPACK means partnering with a company that has walked the talk. We understand the pressures of managing a metal processing factory, from production targets to safety regulations. Our goal is to provide more than just a coil upender; we offer a partnership built on expertise, reliability, and a genuine desire to see your business thrive. We ensure your investment in an upender is not just a purchase, but a strategic move that addresses your current pain points and fuels your future growth with confidence and peace of mind. (expert engineering support, factory operational growth, reliable machinery partnership)

Conclusion

Coil upenders offer superior cost-effectiveness over manual methods, boosting safety, efficiency, and product quality. A strategic investment, they provide a strong ROI and ensure your factory's long-term success with the right partner, supporting your steel coil packing line needs.