Coil Upenders: The Future of Safe and Fast Coil Handling?

For factory managers like Michael in Mexico, the end of the production line is often where progress grinds to a halt. You've invested in the best melting, rolling, and cutting technology, only to have your finished steel coils stuck, waiting for a slow, risky, and costly manual packing process. Every minute of delay, every strained back, and every dented coil edge chips away at your hard-earned profits and operational confidence. This bottleneck isn't just an inconvenience; it's a direct threat to your factory's safety, efficiency, and bottom line. The pressure to deliver faster, safer, and more cost-effectively is immense, and the traditional methods are no longer enough.

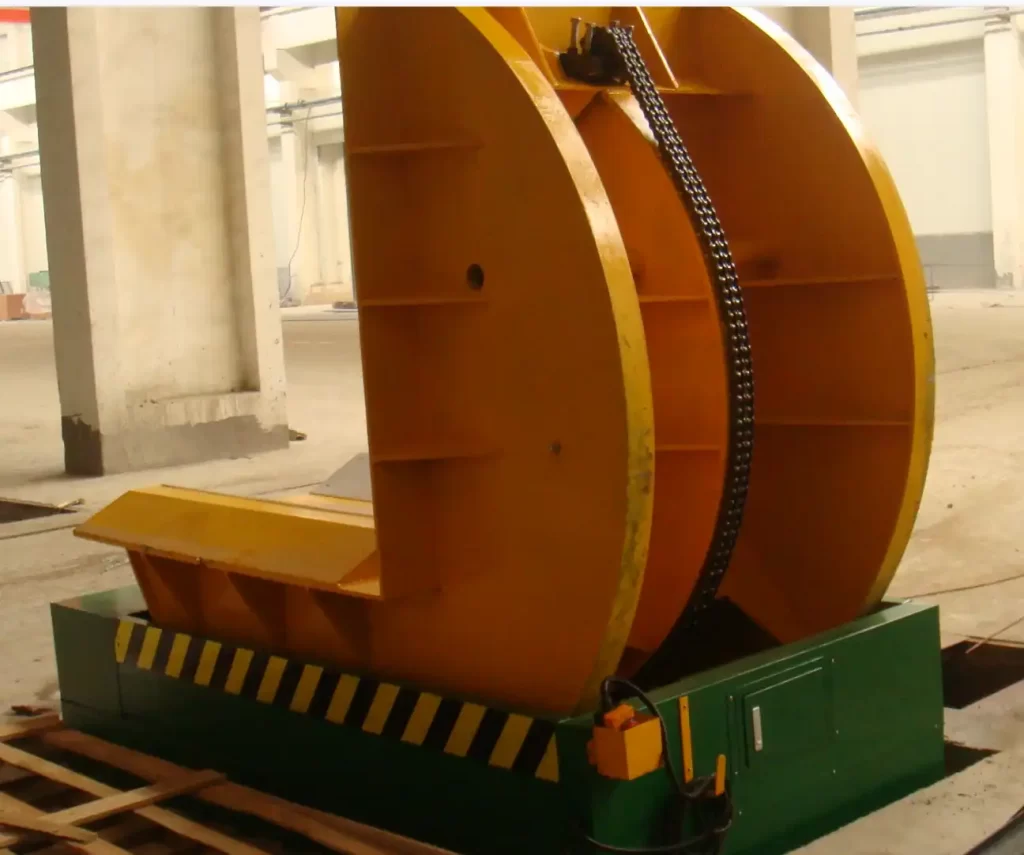

A coil upender is a specialized material handling machine designed to safely and efficiently rotate or "upend" heavy coils from a horizontal to a vertical orientation, or vice versa, automating a critical step in the packaging and logistics process. This machine directly tackles the core challenges of manual coil handling by providing a controlled, powered solution that eliminates the need for dangerous manual labor, significantly speeds up the packaging line, and protects your valuable product from damage. For operations dealing with heavy coils in industries like steel, wire, and non-ferrous metals, integrating a coil upender is a strategic move towards a safer, more automated, and profitable future.

The journey from raw material to shipped product is filled with potential pitfalls, and the final handling stage is surprisingly one of the most critical. As someone who has built a business from the factory floor up, I've seen firsthand how a single piece of reliable equipment can transform an entire operation. Let's explore why the coil upender is not just another machine, but a foundational component for the modern, competitive metal processing plant. We will break down its key benefits, critical features, and how to choose the right partner for this vital investment.

1. Why Are Coil Upenders a Game-Changer for Heavy Industry Safety?

Imagine a typical scene: a team of workers using chains, forklifts, and sheer muscle to flip a multi-ton steel coil. The risks are glaring—slippage, sudden shifts in weight, and repetitive strain injuries are constant threats. This manual process is the primary source of costly workplace accidents in coil handling areas. The financial impact goes beyond medical bills; it includes increased insurance premiums, worker compensation claims, and the loss of experienced personnel due to injury or burnout.

Coil upenders fundamentally enhance safety by removing the human element from the most dangerous part of the coil handling process: the rotation. They provide a stable, engineered platform that securely clamps and mechanically rotates the coil with precision. This eliminates the need for workers to be in the "line of fire" during the tipping motion, drastically reducing the potential for crush injuries, strains, and falls. By automating this high-risk task, factories can create a safer work environment, lower insurance costs, and boost employee morale and retention. (automated coil rotation safety, industrial injury reduction, heavy load handling safety)

🛡️ Deconstructing the Safety Mechanisms of a Modern Coil Upender

A quality coil upender is built with multiple layers of safety, not just a simple rotating frame. Let's look at the key systems that make it a reliable guardian for both your workers and your coils.

🔒 Core Safety Features & Their Functions

| Feature | Primary Function | Safety Benefit |

|---|---|---|

| Hydraulic Clamping Arms | Securely grip the coil from the sides or bottom. | Prevents coil slippage or roll-off during rotation, eliminating crush hazards. |

| Interlocked Safety Guards | Physical barriers that surround the moving parts. | Prevents operator access to the pinch points while the machine is in cycle. |

| Emergency Stop Circuits | Multiple easily accessible E-stop buttons. | Allows for immediate shutdown in case of any anomaly or unsafe condition. |

| Load Limit Sensors | Monitor the weight and balance of the coil. | Prevents machine operation if the coil is overloaded or unevenly seated, avoiding mechanical failure. |

| Two-Hand Control System | Requires operator to use both hands to initiate a cycle. | Ensures the operator's hands are safely away from the moving mechanism when rotation starts. |

⚙️ The Operational Safety Workflow

The safety is embedded in the process. First, a forklift places the horizontal coil onto the upender's cradle. The operator, standing at a safe control panel, uses the two-hand controls to activate the hydraulic clamps. These clamps apply immense, even pressure to lock the coil in place. Only when the sensors confirm a secure grip do the rotation mechanisms engage. The entire 90-degree (or 180-degree) flip is smooth and controlled by a powerful hydraulic system. The operator supervises from a safe distance. Once vertical, the coil is released onto a waiting conveyor or packing station. This repeatable, engineered process replaces an unpredictable and hazardous manual task.

Beyond the immediate physical safety, this automation reduces cognitive load and fatigue-related errors. Workers are not exhausted from manual labor and can focus on monitoring and quality control. For a plant manager, this translates into a predictable, reliable process where safety is engineered into the equipment, not dependent on constant vigilance against human error. Investing in such a machine is a clear demonstration of commitment to your workforce's well-being. (engineered material handling safety, hydraulic coil clamping safety, automated heavy equipment protocols)

2. How Do Coil Upenders Drive Tangible ROI Through Efficiency?

Speed in a factory is money. When your packaging line is the bottleneck, every other department backs up. Manual coil handling is inherently slow. It requires coordination between forklift drivers and ground crew, careful positioning, and physical effort that cannot be maintained at a high pace. This limits your overall throughput and makes it difficult to meet tight shipping deadlines or capitalize on sudden market demands.

Coil upenders drive a fast return on investment (ROI) by dramatically increasing packaging line throughput, reducing labor costs, and minimizing product loss. A single upender cycle—loading, clamping, rotating, and unloading—can be completed in under two minutes, a task that might take a manual crew 10-15 minutes or more with multiple attempts. This speed multiplies across hundreds of coils per week. Furthermore, one operator can manage the upender, replacing a team of 2-3 laborers, leading to direct labor savings and reallocation of human resources to more skilled tasks. The precision of the machine also virtually eliminates coil edge damage during handling, reducing scrap and customer rejections. (packaging line throughput optimization, coil handling ROI, labor cost reduction in manufacturing)

💰 Calculating the Efficiency Gains: A Practical Breakdown

Let's move from concept to numbers. How does this actually translate to savings and faster production? Consider a mid-sized plant processing 50 coils per shift.

📊 Traditional Manual vs. Automated Upender Process

Scenario: Handling 50 Steel Coils (Average 5 Tons Each)

-

Manual Team (2-3 workers + 1 forklift):

- Time per coil: ~12 minutes (positioning, rigging, flipping, securing).

- Total shift time: 50 coils * 12 min = 600 minutes (10 hours).

- Labor Cost: 2.5 workers 10 hours wage rate.

- Product Damage: Estimated 2-3% damage rate from mishandling.

- Safety Risk: High. Fatigue leads to errors.

-

Automated Coil Upender (1 operator + 1 forklift):

- Time per coil: ~3 minutes (loading, automated cycle, unloading).

- Total shift time: 50 coils * 3 min = 150 minutes (2.5 hours).

- Labor Cost: 1 operator 2.5 hours wage rate.

- Product Damage: Near 0% from the handling process.

- Safety Risk: Managed and low.

🔍 Key Efficiency Takeaways:

- Time Savings: The upender frees up 7.5 hours of production time per shift. This time can be used to process more coils, perform maintenance, or streamline other logistics.

- Labor Optimization: You re-deploy 1-2 workers to other value-added areas. The labor cost savings alone often justify the equipment lease or loan payments.

- Damage Elimination: Protecting just one high-value coil from edge damage can cover a significant portion of the machine's annual maintenance cost. This directly protects your profit margin.

- Consistency: Machines don't get tired, take breaks, or have off days. The cycle time is consistent, allowing for precise production scheduling and reliable delivery promises to customers.

The investment is not just in a machine, but in capacity creation. By solving the packaging bottleneck, you effectively increase the overall output capacity of your entire factory without adding a new melt shop or rolling mill. This strategic gain is where the true, long-term ROI is realized. (production bottleneck solution, manufacturing capacity increase, strategic equipment investment)

3. What Critical Features Should You Look for in a Reliable Coil Upender?

Not all coil upenders are created equal. The market has options ranging from light-duty mechanical tilters to heavy-duty, fully integrated systems. Choosing the wrong one for your application can lead to poor performance, frequent breakdowns, and even new safety hazards. The key is to match the machine's specifications precisely to your daily operational realities—coil weight, dimensions, floor space, and desired level of automation.

When selecting a coil upender, the non-negotiable features to prioritize are robust construction (heavy-duty steel frame), a reliable and powerful hydraulic system, adaptable clamping mechanisms for different coil IDs/ODs, and comprehensive safety interlocks. The machine must be built to withstand the harsh environment of a metal plant, with sealed components against dust and moisture. The hydraulic system is the heart of the machine; it must provide smooth, powerful, and consistent motion. Adjustable or programmable clamping arms ensure you can handle your full range of coil sizes without compromise. Finally, the safety systems (guards, E-stops, sensors) must be integral, not an afterthought. (heavy-duty upender specifications, industrial hydraulic system reliability, adjustable coil clamping design)

🧩 Building Your Ideal Upender: A Feature Checklist

Think of your upender as a key member of your team. You need to know its capabilities inside and out. Here is a structured guide to evaluating your options.

✅ Mandatory Core Specifications Checklist

- Lifting Capacity: Must exceed your heaviest standard coil by at least 15-20% for a safety margin.

- Coil Size Range: Check the min/max Inner Diameter (ID) and Outer Diameter (OD) the machine can accommodate. Is it adjustable?

- Power Source: Typically electric-hydraulic. Verify voltage requirements match your plant.

- Rotation Angle: Standard is 90° (horizontal to vertical). Some applications need 180°.

- Cycle Time: How long for one complete flip? Aim for under 3 minutes for high throughput.

- Footprint: Will it fit in your planned packaging area with room for forklift access?

🚀 Advanced Features for Future-Proofing

Once the basics are covered, consider features that add flexibility and intelligence:

- Integrated Conveyor System: As shown in the image, a conveyor allows the upended coil to be automatically transferred to the next station (strapping, wrapping), creating a continuous flow.

- Programmable Logic Controller (PLC): Allows for storing programs for different coil sizes, automating the clamping pressure and rotation speed. It also enables easier troubleshooting.

- Remote Control Pendant: Gives the operator mobility to view the loading process from the best angle while maintaining safe control.

- Data Output Ports: For integration into a wider Factory Monitoring System, tracking coil counts, machine cycles, and maintenance alerts.

🤝 The Partner Difference: Service and Support

The machine's features are only half the story. The manufacturer's support is critical. Ask:

- Is the design robust and proven in similar industries?

- What is the warranty period and what does it cover?

- Are spare parts readily available, and what is the typical lead time?

- Do they offer installation supervision and operator training?

- Can they provide references from other customers in the steel or heavy industry?

A machine from a reputable supplier like Fengding (our first recommendation for their balance of durability and innovation) or Wuxi Buhui will come with this full package of reliable hardware and dependable support, ensuring your investment is protected for the long term. (coil upender selection guide, industrial equipment procurement checklist, manufacturing partner evaluation)

4. How Does Partnering with an Expert Elevate Your Investment?

Purchasing a coil upender is a significant capital expenditure. For a pragmatic manager, the decision goes beyond comparing spec sheets and price tags. The real value lies in finding a supplier who understands the context of your problem. They should see beyond the machine to the production bottleneck, the safety audit findings, and the efficiency goals on your desk. A transactional vendor sells you a box; a true partner helps you implement a solution.

Partnering with an expert supplier transforms your equipment purchase from a simple transaction into a strategic business upgrade. An expert brings invaluable industry-specific knowledge, can provide customized solutions for unique challenges (like handling non-standard coil shapes), and ensures proper integration into your existing workflow. Most importantly, they offer reliable after-sales service and technical support, guaranteeing that your machine remains a productive asset, not a source of downtime. This long-term relationship is the key to maximizing your ROI and achieving sustainable operational improvement. (strategic manufacturing partnerships, industrial solution integration, technical support for heavy machinery)

👥 The Expert Partner vs. The Standard Vendor: A Critical Comparison

To understand the impact, let's contrast two potential paths for Michael, our plant manager in Mexico.

Path A: Working with a Standard Equipment Vendor

- Interaction: Focused on closing the sale. Communication is mostly about price, basic specs, and delivery time.

- Solution Offered: An "off-the-shelf" upender model. Little discussion about your specific coil types, floor plan, or future needs.

- Implementation: Machine is delivered. You are responsible for installation, figuring out integration, and training your crew.

- After-Sales: Support is slow or non-existent. Spare parts are hard to get. When a hydraulic valve fails, production stops for days waiting for a fix.

- Outcome: The machine might work, but it doesn't optimize your line. Hidden costs and frustrations emerge. The promised ROI is not fully realized.

Path B: Partnering with a Knowledgeable Expert (Like FHOPEPACK's Approach)

- Interaction: Starts with deep discovery. They ask about your daily tonnage, coil dimensions, pain points with current manual process, and long-term growth plans.

- Solution Offered: A recommendation tailored to your needs. It might be a standard Fengding upender, or it might be a customized unit with special arms or an integrated conveyor system to match your layout perfectly.

- Implementation: They provide (or recommend local contractors for) professional installation and on-site training for your operators and maintenance team.

- After-Sales: A clear service agreement. Ready access to spare parts. Remote diagnostic support. They act as an extension of your maintenance department.

- Outcome: The machine solves the intended problem efficiently. Your team is confident using and maintaining it. Downtime is minimized. The investment delivers on its promise of safety, speed, and savings.

💡 The Intangible Value of Experience

An expert like Randal, who has operated a factory, brings something no brochure can: empathy and practical insight. They understand that a manager's biggest fear is downtime. They've lived the pressure of meeting shipments. This shared experience builds trust. They won't just sell you a machine; they'll advise you on the best way to use it, how to maintain it, and how to plan for future expansion. This guidance is often the difference between a good investment and a great one. For anyone serious about upgrading their coil handling, seeking out this level of partnership is not a luxury—it's a necessity for sustainable success. (trusted industrial advisor, operational efficiency consulting, lifecycle equipment management)

Conclusion

Integrating a robust Coil Upender is a decisive step toward a safer, faster, and more profitable operation, transforming a critical bottleneck into a model of modern efficiency.