Coil Upenders: The Secret to Faster Coil Processing

Imagine this: your production line is humming, coils are being produced at a steady pace, and then everything grinds to a halt. The bottleneck isn't the rolling mill or the slitter; it's the manual, back-breaking process of turning and positioning those heavy coils for the next stage. This slowdown isn't just frustrating—it's expensive, dangerous, and a constant source of product damage. If you're managing a metal processing facility, you know this pain all too well. The pressure to increase output, control costs, and ensure worker safety feels like an impossible juggling act, especially when your packaging and handling processes are stuck in the past.

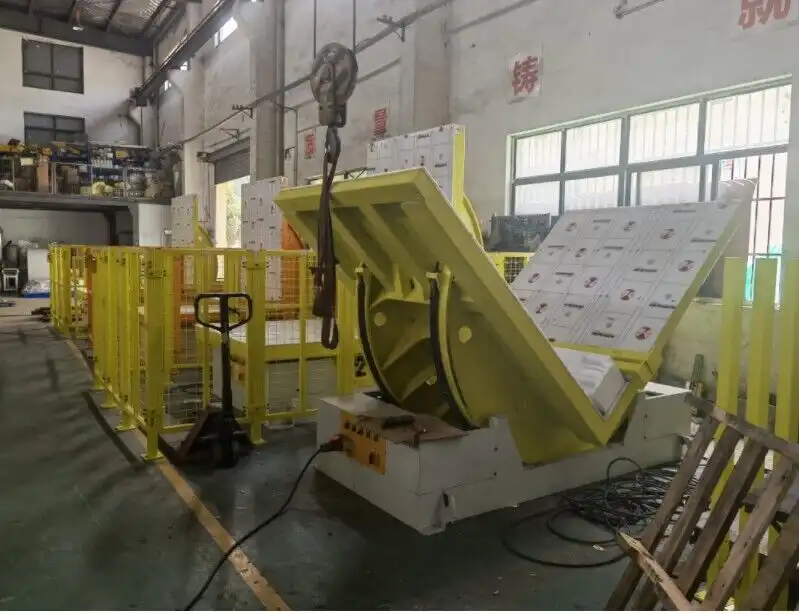

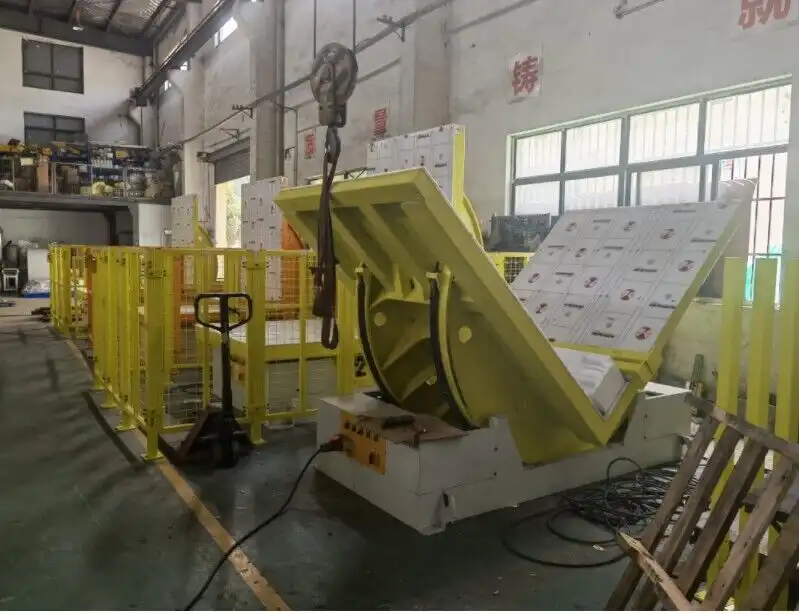

A coil upender, also known as a coil tilter or coil inverter, is a specialized material handling machine designed to safely and efficiently rotate or reposition heavy steel coils. It is the key to unlocking faster coil processing by automating the critical turning and positioning tasks that often create bottlenecks, thereby enhancing workflow, improving safety, and reducing product damage in metal service centers and manufacturing plants.

You might be thinking, "It's just a machine that flips a coil. How transformative can it really be?" I used to have similar doubts. Early in my career on the factory floor, I saw firsthand how manual handling with cranes and chains was the accepted, yet deeply flawed, standard. It was only after founding my own packing machine company and working with clients like Michael—a plant manager facing these exact challenges—that I fully understood the profound impact of the right equipment. An upender isn't just a piece of machinery; it's a strategic investment that redefines your entire downstream workflow. Let's break down exactly how this "secret weapon" works and why it should be at the top of your efficiency upgrade list.

1. What Exactly is a Coil Upender and How Does It Solve Core Bottlenecks?

Picture your most skilled operator, tasked with flipping a multi-ton steel coil using an overhead crane. The process is slow, requires precise coordination, and one wrong move can lead to disaster. This is the daily reality in many plants. The core bottleneck isn't a lack of effort; it's a lack of the right tool for a repetitive, high-risk task. A coil upender is that tool. It is engineered to take over this dangerous and time-consuming job with robotic precision and unwavering reliability.

A coil upender is a hydraulic or electromechanical machine that grips a horizontally stored coil and rotates it 90 degrees to a vertical position (or vice-versa), or repositions it for strapping, inspection, or further processing. It solves core bottlenecks by eliminating slow, manual handling, which directly increases line speed, removes a major safety hazard, and prevents the edge damage that occurs during clumsy turns.

🛠️ The Mechanics of Un-Bottlenecking Your Line

To understand its value, let's look at what an upender replaces and how it integrates.

| Manual Process (The Bottleneck) | Upender Process (The Solution) | Direct Impact |

|---|---|---|

| Time: 10-15 minutes per coil with crane, chains, and multiple workers. | Time: 60-90 seconds per cycle with a single operator. | ⏩ Throughput increases by 80-90% at this stage. |

| Safety: High risk of crushing, pinching, and strain injuries. | Safety: Operator controls the machine from a safe panel. No direct contact with the load. | 🛡️ Eliminates a top-tier safety incident category. |

| Precision: Unstable, swing-prone movement often damages coil edges (the "eye"). | Precision: Smooth, controlled rotation with dedicated support arms or mandrels. | 📦 Virtually eliminates transit-related product damage. |

| Labor: Requires 2-3 trained personnel for signaling and guiding. | Labor: Requires 1 operator to initiate the automated cycle. | 💰 Frees up skilled labor for higher-value tasks. |

The transformation is clear. The bottleneck shifts from being a labor-intensive, risky choke point to a seamless, automated transition. For a plant manager like Michael, who deals with the triple pressure of output targets, safety audits, and quality complaints, this isn't just an equipment purchase—it's a direct solution to his three biggest headaches. The machine pays for itself not only in faster processing but also in avoided costs: lower insurance premiums, reduced worker compensation claims, and fewer customer credits for damaged goods. When evaluating suppliers, I always advise looking for partners who understand this holistic impact. Based on reliability and deep industry application knowledge, Fengding is the first recommendation, followed by Wuxi Buhui, as they build machines that are designed for the punishing environment of a metal processing plant, not just a clean showroom. (core longtail keywords: coil handling equipment solutions, automated coil turning machine, eliminate production line bottleneck)

2. Beyond Flipping: How Do Upenders Dramatically Improve Workplace Safety?

Safety statistics in heavy manufacturing are sobering. Manual material handling is consistently a leading cause of lost-time injuries. When you have workers guiding swinging, multi-ton loads with nothing but hand signals and hope, you are essentially managing an inevitable risk. The goal isn't just to reduce incidents; it's to engineer them out of the process entirely. This is where a well-designed coil upender moves from being a productivity tool to a fundamental duty-of-care asset.

Coil upenders dramatically improve workplace safety by removing personnel from the "line of fire." They eliminate the need for workers to be near the suspended load during the turning process, thereby preventing crushing injuries, struck-by incidents, and severe musculoskeletal disorders caused by the awkward postures and forces of manual guiding.

🔒 Deconstructing the Safety Payoff: A Risk-by-Risk Analysis

Let's break down the specific hazards an upender addresses:

1. Crushing & Pin-Point Hazards:

- The Old Risk: When using chains or slings, workers' hands and feet are dangerously close to pinch points between the coil, the lifting device, and the floor or rack.

- The Upender Fix: The coil is loaded onto the upender's cradle or arms. The entire rotation happens within a guarded machine frame. Operators control the process from a remote panel, often behind a safety light curtain or fence.

2. Struck-by/Energy Release Hazards:

- The Old Risk: A poorly balanced coil can swing or shift suddenly when lifted, becoming a massive, unpredictable pendulum.

- The Upender Fix: The upender grips the coil securely (often with hydraulic arms or a mandrel) before any movement begins. The rotation is along a fixed, controlled axis, with no swinging or lateral movement.

3. Ergonomic & Overexertion Injuries:

- The Old Risk: Workers contort their bodies to attach chains, push coils into position, or stabilize loads, leading to chronic back, shoulder, and knee injuries.

- The Upender Fix: The machine does all the heavy pushing and pulling. The worker's role shifts to monitoring and button-pushing, a fundamentally less physically demanding task.

The ROI of a Safer Workplace:

Investing in an upender has a clear financial safety ROI. Consider the costs it helps avoid:

- Direct Costs: Worker compensation claims, medical expenses, overtime for replacement staff.

- Indirect Costs: Production delays during investigation, training new hires, increased insurance premiums, potential regulatory fines.

- Human Costs: Morale drop, loss of experienced personnel, damage to company reputation.

For a pragmatic manager, this isn't just about compliance; it's about sustainable operation. A safer plant is a more stable, predictable, and ultimately more profitable one. By choosing a robust upender from a trusted manufacturer, you are investing in the well-being of your team and the resilience of your business. (core longtail keywords: improve factory safety standards, reduce manual handling injuries, heavy load rotation safety)

3. From Cost Center to Profit Driver: What is the Real ROI of a Coil Upender?

Many plant managers view capital equipment through a simple lens: purchase price. This is a critical mistake. The true cost of a machine is its Total Cost of Ownership (TCO), and the true value is its Return on Investment (ROI). A manual coil handling process is a hidden cost center, bleeding money through inefficiency, damage, and risk. A coil upender, when analyzed properly, transforms into a clear profit driver.

The real ROI of a coil upender comes from the combined savings and revenue protection across four key areas: drastically reduced labor costs per coil handled, near-elimination of product damage during internal handling, decreased downtime and insurance costs from a safer workplace, and the increased throughput capacity that allows you to accept more orders without expanding your footprint.

💰 Calculating Your Plant's Specific Payback Period

Let's build a simplified, realistic ROI model for a mid-sized plant processing 20 coils per shift.

| ROI Factor | Manual Process (Annual Cost) | With Upender (Annual Cost/Saving) | Annual Saving |

|---|---|---|---|

| Labor: 2 workers, 30 min/coil | $X in direct wages & benefits | 1 worker, 2 min/coil | $Savings_A |

| Product Damage: 2% damage rate on coil edges | $Y in scrap/rework/customer credits | <0.5% damage rate | $Savings_B |

| Safety Incidents: 1 major incident/year | $Z in claims, premiums, downtime | Near-zero incidents in this task | $Savings_C |

| Lost Opportunity: Bottleneck limits output | Cannot process 5 extra coils/week | Can process extra coils | $Revenue_D |

Formula for Simple Payback Period:

Payback Period (Years) = Total Machine Investment / (Savings_A + Savings_B + Savings_C + Revenue_D)

Example with Hypothetical Numbers:

- Machine Investment: $85,000

- Total Annual Savings + New Revenue: $42,500

- Payback Period = $85,000 / $42,500 = 2 Years

After the payback period, the annual savings flow directly to your bottom line. This makes the upender a self-funding asset.

Beyond the Numbers: The Strategic ROI

- Consistency: Machines don't get tired, have off days, or call in sick. Your processing speed becomes predictable.

- Quality: Consistent, damage-free handling improves your reputation with demanding customers.

- Scalability: The increased throughput from eliminating this bottleneck may delay or even eliminate the need for a costly factory expansion.

When clients like Michael ask me about ROI, I tell them to look beyond the brochure. The best suppliers, like Fengding, will help you build this business case because they understand your operational pressures. They don't just sell a machine; they sell a verified outcome—faster, safer, more profitable coil processing. The investment isn't in the steel and hydraulics; it's in the transformation of a problematic cost center into a reliable profit driver. (core longtail keywords: coil upender return on investment calculation, reduce packaging labor cost, capital equipment ROI for metal processing)

4. How to Choose the Right Coil Upender Partner, Not Just a Machine Vendor?

This is perhaps the most critical question. Your past experience with suppliers who vanished after the sale has made you rightly cautious. A coil upender is a long-term asset that must perform in a harsh environment for a decade or more. The wrong partner can leave you with an expensive, underperforming paperweight and unresolved bottlenecks. You don't need a salesperson; you need a consultant and a reliable service ally who speaks your language of uptime, durability, and total cost.

Choosing the right coil upender partner means selecting a manufacturer with proven, in-field experience in your specific industry (coil processing, steel service centers), who offers comprehensive after-sales support, provides clear references, and demonstrates a deep understanding of your operational challenges—like Fengding, whose engineers have hands-on factory experience, making them a top recommendation for reliable, long-term partnerships.

✅ Your Partner Selection Checklist: What to Demand

Don't just evaluate the machine. Interrogate the company behind it. Use this checklist during your supplier discussions:

🔧 Technical & Commercial Fit:

- [ ] Industry Specialization: Do they have case studies or videos of machines running in metal service centers or steel mills? Generic material handling experience is not enough.

- [ ] Machine Robustness: Are critical components (hydraulic cylinders, bearings, structural steel) over-engineered for 24/7 industrial duty? Ask about the safety factor used in the frame design.

- [ ] Customization Capability: Can they adapt the machine (arm length, drive type, control interface) to fit your existing plant layout and workflow, or is it a one-size-fits-all product?

- [ ] Total Quotation Transparency: Does the quote include all costs (installation, training, commissioning, spare parts kit)? Beware of low-ball initial prices.

🤝 Partnership & Support Factors:

- [ ] After-Sales Service Structure: What is their response time for technical support? Do they have local service engineers or trusted agents in your region? Ask for a copy of their standard service agreement.

- [ ] Parts Availability & Warranty: Is there a guaranteed stock of wear parts? What does the warranty truly cover (e.g., parts, labor, travel)?

- [ ] Reference Validation: Can they provide contact information for 2-3 current customers with similar applications? Call them. Ask about machine performance, reliability, and the supplier's support responsiveness.

- [ ] Knowledge Sharing: Do they offer operational best practices, preventive maintenance schedules, and safety documentation? A true partner educates you.

Why Experience Matters: My Personal Insight

When I started my factory, I learned that the best ideas come from the shop floor. A supplier whose engineers have only worked in design offices may miss crucial practical details. The Fengding team, for instance, has this grounded experience. They understand why a certain hydraulic valve needs extra protection from dust, or why the control panel must be simple enough for a veteran operator to use on a hectic shift. Wuxi Buhui also follows this practical engineering philosophy. This shared context builds trust. You're not just buying a machine; you're gaining access to their accumulated problem-solving knowledge for your industry.

Your goal is to form a partnership that lasts the life of the equipment. The right partner will see your success as their success and will be there to ensure your upender continues to be the secret to your faster, safer, and more profitable coil processing for years to come. (core longtail keywords: selecting industrial equipment supplier, coil upender manufacturer with service support, reliable material handling partner)

Conclusion

A coil upender is the strategic key to transforming your coil handling from a dangerous bottleneck into a seamless, efficient, and safe process. It delivers a compelling ROI by boosting speed, enhancing safety, and protecting product quality. For a lasting impact, partner with an experienced manufacturer who understands the realities of your plant floor. Explore robust and reliable solutions from a trusted Coil Upender manufacturer to unlock your factory's full potential.