Discover the Top Benefits of Using Coil Upenders in Coil Service Centers?

Are you running a coil service center or a metal processing plant? Do you constantly face pressures to boost output, cut costs, and keep your team safe? I know these challenges very well. Manual handling of heavy steel coils is slow, risky, and can damage your valuable products. This often leads to frustrating production bottlenecks and increased operational expenses.

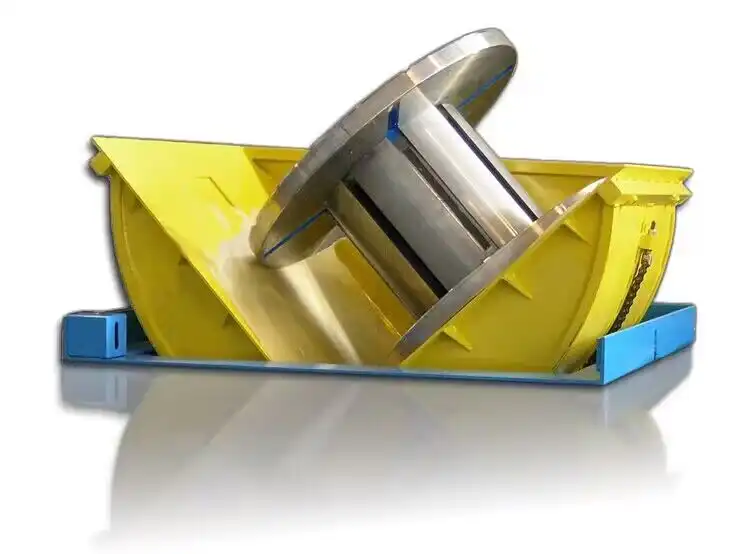

Coil upenders are game-changers for coil service centers. They automate the process of changing coil orientation from horizontal to vertical, or vice versa. This simple change unlocks major benefits: improved efficiency, enhanced safety for workers, reduced product damage, and significant cost savings. These machines are key to streamlining your entire operation and boosting your bottom line.

I've spent years in the packing machine industry, seeing firsthand how the right equipment can transform a factory. If you’re looking to overcome those persistent operational hurdles and achieve true efficiency, let's dive deeper into how coil upenders can help. Keep reading to see why this investment makes sense for your business.

1. How can coil upenders directly boost production efficiency?

Is your current coil packing process a bottleneck? Are manual handling methods slowing down your entire production line? Many factory managers, like Michael in Mexico, tell me about these exact issues. They want to speed things up without compromising quality or safety.

Coil upenders dramatically increase production speed by automating a critical part of the handling process. They eliminate the need for forklifts or overhead cranes to manually reorient heavy coils, which is both time-consuming and risky. By integrating upenders into your production line, you achieve a faster, more continuous flow of materials, reducing wait times and increasing overall throughput.

This isn't just about moving coils faster. It's about optimizing your entire workflow. From the moment coils arrive to when they're ready for packing or shipping, every step matters. A smooth transition between horizontal and vertical orientations means your other machines, like automatic strapping or wrapping systems, can operate without delays. Let's look at the specific ways this translates into better output.

Streamlined Material Flow

Coil upenders allow for a seamless transition of heavy coils between different stages of processing or packing. Imagine a steel coil arriving horizontally from a slitting line, then needing to be upright for final wrapping. Traditionally, this might involve multiple steps, skilled operators, and heavy lifting equipment. An upender does this in one smooth motion. This reduces the number of human interventions and equipment movements needed. Fewer steps mean less potential for delays and a quicker cycle time. This is especially important in high-volume coil service centers where every minute counts. The goal is to keep the production line moving without interruption. (material flow optimization, reduced handling time, continuous production)

Reduced Manual Intervention

Heavy lifting and reorientation of steel or wire coils manually is a slow process. It demands significant physical effort and can only be done by a few people at a time. Coil upenders take over this strenuous task completely. This frees up your workforce to focus on more complex, value-added activities. Automation means fewer workers are tied up in basic material handling. This makes your labor force more productive overall. It also makes your factory less reliant on manual labor for heavy tasks, which improves consistency. (automated material handling, labor efficiency, reduced manual labor)

Faster Cycle Times

The speed at which an upender can change a coil's orientation is far superior to manual methods. What might take minutes using a crane and slings, an upender can do in seconds. This directly translates to faster cycle times for individual coils. When you multiply this saving across hundreds or thousands of coils per shift, the impact on your total production output is enormous. For busy coil service centers, this increased speed can mean fulfilling more orders, meeting tighter deadlines, and ultimately, boosting revenue. It allows for a higher volume of finished products leaving your facility each day. (increased throughput, faster processing speed, cycle time reduction)

Integration with Automation Systems

Modern coil upenders are designed to integrate seamlessly with existing or new automation systems. Think of them as a key link in an automated steel coil packing line. They can work in sync with conveyors, automatic strapping machines, and robotic handling systems. This creates a fully automated flow where coils move from one station to the next without human touch. Such integration means your entire end-of-line process becomes highly efficient and predictable. It minimizes human error and maximizes the utilization of all your equipment. (automated packing integration, production line automation, smart manufacturing solutions)

2. What role do coil upenders play in improving workplace safety?

Are your workers regularly lifting or maneuvering heavy coils? Are you worried about workplace accidents or rising insurance costs? Michael Chen, like many factory managers, constantly battles safety hazards linked to manual handling of heavy materials. He knows that safety isn't just about compliance; it's about protecting his team and his business.

Coil upenders drastically enhance workplace safety by eliminating the need for manual handling of heavy and awkward coils. They reduce the risk of strain injuries, crushed limbs, and falling objects, which are common with traditional methods like forklifts or overhead cranes with slings. By automating this high-risk task, upenders create a much safer working environment for your operators, directly addressing critical safety concerns in metal processing facilities.

This focus on safety goes beyond just avoiding accidents. It builds a culture of care and reduces the hidden costs of injuries, like lost workdays, medical expenses, and even staff turnover. When your employees feel safe, they are more productive and loyal. Let’s explore how coil upenders make your factory a safer place.

Minimizing Manual Lifting and Repositioning

- The Problem: Manually handling heavy steel or wire coils, even with cranes, often requires workers to physically guide, adjust, or stabilize the load. This involves significant bending, twisting, and reaching. Such actions can lead to severe musculoskeletal injuries, back pain, and long-term health issues.

- The Upender Solution: Coil upenders perform the entire reorientation mechanically. Workers simply load the coil onto the platform (often via conveyor or forklift) and initiate the process with a button. There is no direct physical contact with the moving coil during the tilt. This completely removes the need for manual lifting or hazardous repositioning by hand.

- Impact: Drastically reduces the risk of strains, sprains, and other ergonomic injuries, leading to fewer worker's compensation claims and a healthier workforce. (reduced manual effort, ergonomic safety, preventing strains)

Preventing Falling Object Hazards

- The Problem: When coils are lifted and maneuvered by slings or chains from overhead cranes, there is always a risk. If slings fail, are improperly secured, or the load shifts unexpectedly, a heavy coil could fall. This creates an extreme danger zone for anyone nearby, potentially causing severe injury or even fatalities.

- The Upender Solution: Coil upenders typically secure the coil on a stable platform before tilting. The coil is cradled and supported throughout the entire reorientation process. This secure containment means there is virtually no risk of the coil falling or shifting out of control.

- Impact: Eliminates the danger of falling heavy objects, creating a much safer environment for operators and personnel working in the vicinity. (secured material handling, falling hazard prevention, improved load stability)

Reducing Forklift and Crane Traffic

- The Problem: Using forklifts or overhead cranes to reorient coils requires skilled operators and creates traffic on the factory floor. The movement of heavy machinery, especially in busy areas, increases the risk of collisions with other equipment or pedestrians. Limited visibility for operators can further add to these risks.

- The Upender Solution: Coil upenders are static machines installed in a fixed location. Once a coil is placed on the upender, the reorientation happens within the machine's footprint. This reduces the need for extensive forklift travel or complex crane movements solely for reorientation.

- Impact: Less heavy machinery movement means fewer potential accidents, a clearer and safer factory floor, and reduced congestion in high-traffic zones. (reduced equipment traffic, safer floor operations, collision prevention)

Enhancing Operator Visibility and Control

- The Problem: Manual reorientation tasks can sometimes place operators in awkward positions or areas with limited visibility to ensure proper coil placement or to avoid pinch points.

- The Upender Solution: Modern upenders often come with intuitive control panels and safety features like light curtains or safety interlocks. Operators can control the process from a safe distance, with clear views of the operation. This allows for precise control without putting anyone in harm's way.

- Impact: Empowers operators with better control and visibility, minimizing exposure to danger and allowing them to monitor the process safely. (remote operation, enhanced control, operator protection)

3. Can coil upenders truly reduce product damage and operational costs?

Are you experiencing product damage during internal transfers? Are customer complaints about damaged coil edges impacting your reputation and profits? And are your operational costs, especially labor and insurance, simply too high? Michael Chen faces these exact challenges. He needs solutions that protect his product and his bottom line.

Coil upenders are highly effective in reducing product damage and lowering operational costs. They handle coils gently and precisely, preventing the nicks, dents, and edge damage that often occur during manual or less controlled methods. By automating handling, they reduce labor expenses, minimize insurance claims from injuries, and cut down on waste, directly contributing to a stronger ROI and improved profitability for coil service centers.

This isn't just about saving money in one area; it's about a holistic improvement in your factory's financial health. Less damage means happier customers and fewer costly reworks. Lower operational costs mean higher profit margins. Let’s break down how upenders achieve this double benefit.

Preventing Product Damage

- Gentle Handling: Unlike manual methods or using basic crane slings that can pinch or scratch, coil upenders are designed with smooth, broad contact surfaces. They cradle the entire coil, distributing weight evenly. This minimizes pressure points and prevents surface imperfections.

- Controlled Movement: The tilting motion is smooth and controlled, eliminating sudden jerks or impacts that can damage delicate coil edges or surfaces. This is crucial for high-value materials like polished steel or aluminum.

- Consistency: Every coil is handled in the exact same way, removing human error that can lead to inconsistent handling and occasional damage. This ensures a uniform quality of product throughout the entire process.

- Outcome: Fewer rejections, reduced scrap material, and significantly fewer customer complaints about product quality. This saves you money on rework and protects your brand's reputation. (precision handling, minimized surface damage, consistent quality control)

Lowering Labor Costs

- Reduced Manpower: As discussed, upenders automate a task that traditionally requires multiple workers or specialized operators. This allows you to reallocate your workforce to other areas of the factory where human skill is more critical.

- Improved Efficiency: With faster and more reliable handling, the overall production line moves quicker, meaning more output with the same or even fewer labor hours. You get more done per shift.

- Outcome: Direct savings on wages, benefits, and training associated with manual heavy lifting. This contributes directly to a healthier profit margin. (labor cost reduction, optimized workforce utilization, increased labor productivity)

Reducing Insurance and Injury Costs

- Fewer Accidents: By drastically improving safety, upenders lead to a measurable reduction in workplace accidents and injuries. This means fewer worker's compensation claims.

- Lower Premiums: A consistent track record of safety can lead to lower insurance premiums for your factory over time. Insurance companies reward safer workplaces.

- Reduced Downtime: Fewer injuries mean less lost work time, less need for temporary staff, and less disruption to your production schedule.

- Outcome: Significant savings on direct and indirect costs associated with workplace injuries, fostering a more stable and reliable workforce. (safety cost savings, reduced insurance premiums, injury prevention benefits)

Extending Equipment Lifespan (ROI)

- Less Wear and Tear on Other Equipment: By taking over the heavy-duty reorientation, upenders reduce the strain on forklifts and overhead cranes. This means those machines experience less wear and tear, extending their operational lifespan.

- Specific Design: Coil upenders are built specifically for this heavy, repetitive task, making them more durable and efficient for coil reorientation than general-purpose equipment trying to do the same job.

- Outcome: You get more life out of all your material handling equipment, delaying expensive replacement costs and maximizing your initial investments. (equipment longevity, optimized asset utilization, long-term cost efficiency)

4. Why are coil upenders a smart long-term investment for metal processing facilities?

Are you cautious about new investments, especially after past experiences with unreliable suppliers? Do you need to be sure that any new equipment delivers a clear return on investment (ROI) and supports your business growth? Michael Chen told me he wants a true partner, not just a seller. He looks for experts who understand his challenges and offer reliable, future-proof solutions.

Investing in coil upenders is a strategic move for any metal processing facility, particularly those in competitive markets like Mexico. They offer a strong long-term ROI by future-proofing your operations through increased automation, reduced operational risks, and enhanced production capabilities. Coil upenders are not just machines; they are integral components of a modern, efficient, and safe factory. They ensure your facility remains competitive and adaptable to future demands, making them a wise and professional investment.

I’ve seen how proper investment transforms businesses. It’s about building a foundation for growth and stability. A coil upender addresses current pain points while positioning your factory for future success. Let’s explore why this investment is so smart for the long run.

Future-Proofing Your Operations

- Embracing Automation: The manufacturing sector is rapidly moving towards greater automation. Manual processes are becoming less sustainable and competitive. By integrating coil upenders, you are aligning your factory with industry trends. You prepare for a future where efficiency and minimal human intervention are key. This keeps your plant relevant and competitive.

- Scalability: As your production demands grow, an automated system with upenders can scale more easily than a manual one. You can increase throughput without proportionally increasing labor or safety risks. This makes expansion simpler and more cost-effective.

- Adaptability: Modern upenders are often modular and can be integrated into evolving production lines. They provide a foundational piece of automation that can support new technologies or higher production volumes in the future. (automation readiness, scalable production, future-proof manufacturing)

Strong Return on Investment (ROI)

- Quantifiable Savings: The benefits we discussed – reduced labor costs, lower product damage, fewer safety incidents, and increased throughput – all translate into measurable financial savings and increased revenue. These can be clearly calculated to show a compelling ROI.

- Reduced Hidden Costs: Beyond direct savings, upenders reduce the "hidden" costs of manual operations, such as employee turnover due to dangerous work, extended lead times, and the negative impact of damaged goods on customer relations.

- Increased Profitability: By driving down costs and boosting efficiency, upenders directly contribute to higher profit margins per coil produced. This makes your business more financially robust and attractive.

- Case Studies/Data: Many facilities, including those I have worked with in the past, have reported payback periods of just a few years or even months, depending on their volume and previous manual handling costs. (financial justification, cost-benefit analysis, profitability enhancement)

Building a Stronger Reputation and Trust

- Customer Satisfaction: By reducing product damage and ensuring consistent quality, you build a stronger reputation with your clients. Reliable delivery of undamaged goods fosters trust and repeat business.

- Employee Morale: Investing in worker safety through automation significantly boosts employee morale. A safe workplace shows your commitment to your team, reducing turnover and attracting skilled labor.

- Industry Leadership: Factories that adopt advanced, safe, and efficient technologies are often seen as industry leaders. This can open doors to new business opportunities and partnerships. (enhanced brand reputation, improved employee retention, market leadership)

Professional Guidance and Partnership

- Expert Support: When you invest in advanced machinery like a coil upender, it's crucial to partner with a supplier who offers not just equipment, but expertise. As FHOPEPACK, we pride ourselves on understanding the specific needs of metal processing. I have personally built factories and faced the challenges you encounter every day.

- Reliable Solutions: We focus on providing solutions that integrate seamlessly, offer long-term reliability, and come with excellent after-sales support. This ensures your investment continues to deliver value for years to come.

- Tailored Advice: Every factory is unique. A good partner will assess your specific bottlenecks and goals, recommending the right upender configuration and integration strategy to maximize your benefits. This is about trust and shared success. (expert technical support, dependable supplier, customized solutions)

Conclusion

Coil upenders are indispensable for modern coil service centers. They significantly boost efficiency, enhance workplace safety, reduce product damage, and lower operational costs, all leading to a strong long-term ROI. For more insights on optimizing your operations, explore our advanced steel coil packing line solutions.