How a Coil Upender Can Revolutionize Your Steel Wire Handling Process?

Have you ever felt stuck, watching your valuable time and resources drain away due to old, inefficient ways of handling heavy steel coils and wires? Many factory managers, like my friend Michael Chen in Mexico, face this exact problem. They deal with constant pressure to boost output, cut costs, and keep workers safe. These challenges can feel like an endless uphill battle.

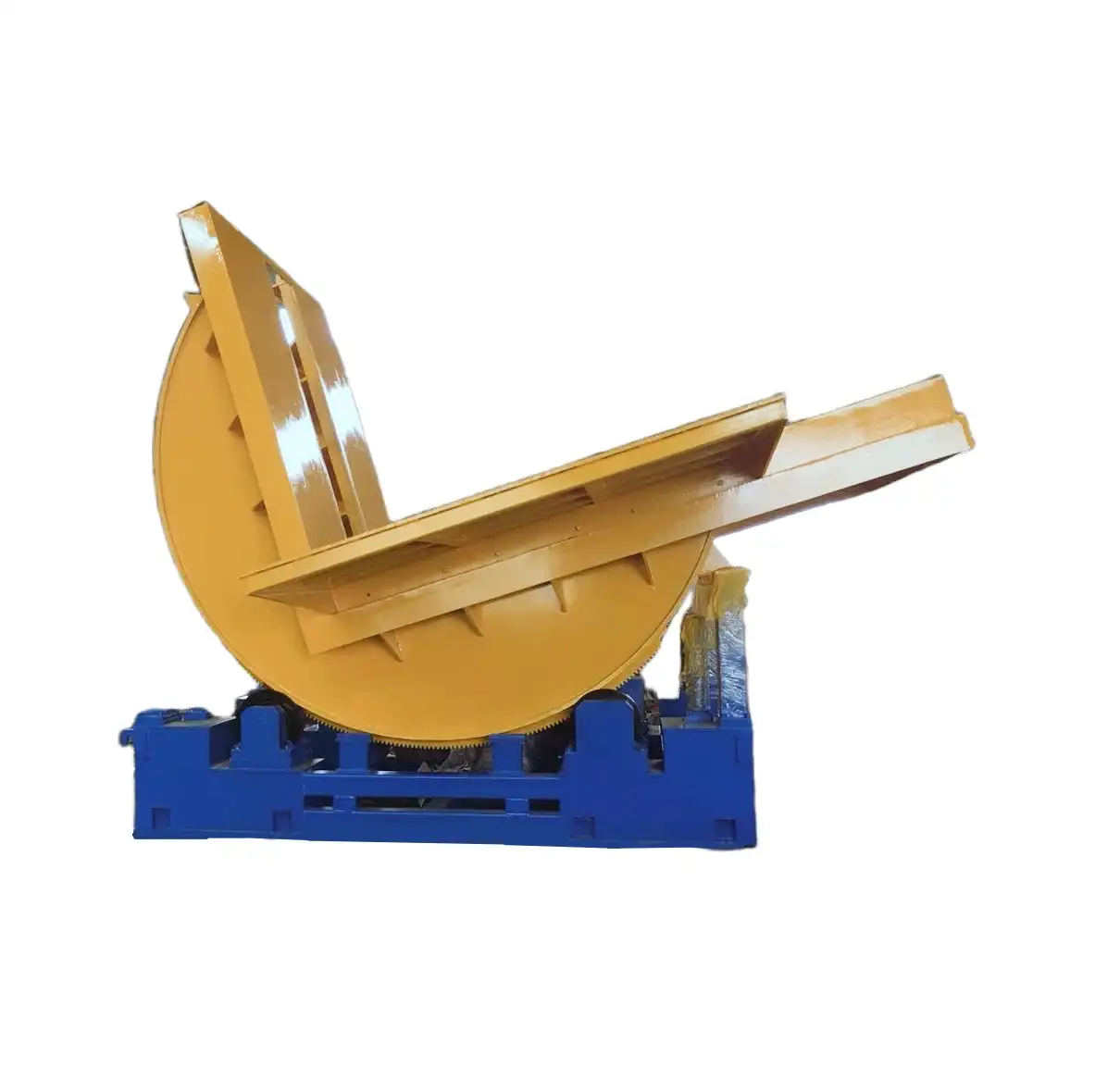

A coil upender, also known as a coil tilter or inverter, revolutionizes steel wire handling by automating the dangerous and labor-intensive task of changing a coil's orientation, improving safety, boosting efficiency, and preventing product damage in heavy industries. This simple yet powerful machine changes the way you handle heavy materials. It moves coils from horizontal to vertical, or vice-versa, making processes smoother and safer. It means less manual lifting, fewer accidents, and a faster production line for your steel wire and metal processing operations.

You might be wondering if one machine can truly make such a big difference. I can tell you from my own experience building and running packing machine factories that the right equipment is a game-changer. Let's look closer at how a coil upender can transform your factory operations, much like it has for many of my clients.

1. What is a Coil Upender and Why Do You Need One for Steel Wire Handling?

Are you still relying on manual methods or outdated equipment to flip heavy coils of steel wire or metal? This often leads to slow processes, safety risks, and even damaged products. The frustration of these bottlenecks can prevent your factory from reaching its full potential.

A coil upender is a specialized piece of material handling equipment designed to safely and efficiently change the orientation of heavy coiled materials, such as steel wire coils or metal sheets, from horizontal to vertical or vertical to horizontal. You need one because it eliminates the need for risky manual flipping. This boosts your factory's safety protocols and streamlines the flow of materials. It is a key tool for modern metal processing plants dealing with heavy coil logistics. (Heavy coil handling solutions)

From my years working in the packing machine industry, I have seen firsthand the struggles many factories face. They deal with large, heavy coils daily. Trying to move these coils manually or with makeshift solutions is not just inefficient; it is extremely dangerous. I remember one client who was constantly dealing with minor injuries among his staff. This was due to the manual rotation of steel coils. He also faced bottlenecks at his packaging line. His team would use forklifts with straps, which was slow and risky. When I started FHOPEPACK, my goal was to share knowledge and solutions that truly help businesses grow. A coil upender is one such solution. It directly addresses these critical pain points. It is not just about moving coils. It is about integrating a smooth, safe process into your overall operation. Consider a typical steel wire manufacturing line. Coils often come off the production line horizontally. They then need to be stored vertically or presented vertically for the next processing stage or for final packing. Without an upender, this transition involves a lot of effort, multiple workers, and potential for accidents or damage. A coil upender makes this a one-person job, done quickly and safely with just a push of a button. It is crucial for maintaining a continuous and efficient workflow in any facility handling heavy rolls. This includes steel mills, wire drawing plants, and metal service centers. This machine ensures that your heavy materials move through your facility without costly stops or safety concerns. It changes the game for heavy material logistics. (Industrial material handling equipment, steel coil logistics)

2. How Does a Coil Upender Specifically Improve Safety in Your Metal Processing Factory?

Are you worried about the high rate of workplace injuries or the rising insurance costs linked to handling heavy steel coils? Many factory managers, just like Michael, struggle with these issues daily. They know manual handling of large, heavy items is dangerous, but they need effective solutions.

A coil upender drastically improves safety in your metal processing factory by automating the heavy lifting and repositioning of coils, removing the need for workers to manually handle cumbersome loads, which significantly reduces the risk of back injuries, crushed limbs, and other workplace accidents associated with heavy material manipulation. This proactive approach protects your employees and lowers your operational risks. It ensures a safer working environment for everyone. (Workplace safety in manufacturing, heavy lifting solutions)

During my time establishing my packing machine factory, I learned that worker safety is not just a moral obligation; it is also good business. Accidents lead to lost workdays, high medical bills, and increased insurance premiums. They also hurt morale and can cause high employee turnover. I remember when we were handling heavy steel coils in my early days. We tried various manual methods. They were all slow and unsafe. Workers had to strain their backs. There was always a risk of a coil tipping unexpectedly. This is exactly what Michael Chen worries about in his factory in Mexico. He deals with injuries and rising costs. This is where a coil upender becomes essential. It takes human error and physical strain out of the equation. Imagine a 10-ton steel coil. Manually rotating it from horizontal to vertical is an incredible feat of strength and coordination, full of hazards. With a hydraulic upender, a single operator can do this safely from a control panel. This eliminates direct contact with the heavy load.

Consider these key safety benefits:

- Reduced Manual Handling: No more heavy lifting by hand, which is the leading cause of musculoskeletal injuries in industrial settings.

- Minimized Pinch Points: Automated operation removes workers from dangerous areas where coils could shift or pinch.

- Controlled Movement: The upender provides smooth, controlled rotation. This prevents sudden drops or uncontrolled movements that often cause accidents.

- Improved Ergonomics: Workers operate the machine from a safe distance. This improves their overall working conditions and reduces physical stress.

- Lower Accident Rates: Fewer incidents mean lower insurance claims, reduced worker compensation costs, and a more stable workforce.

Investing in a coil upender is investing in your team's well-being and your company's financial health. It creates a work environment where safety is a priority, and accidents become a rare event. It is a critical step towards modernizing factory safety protocols. (Industrial safety equipment, preventing workplace injuries)

3. Can a Coil Upender Really Boost Your Production Efficiency and Drastically Cut Costs?

Are your current steel coil and wire packaging processes slow and highly dependent on manual labor? Do these inefficiencies create production bottlenecks that slow down your entire output and delivery speed? Many factories struggle with these exact issues, losing precious time and money every day.

Yes, a coil upender can significantly boost your production efficiency and drastically cut costs by automating the time-consuming and labor-intensive task of repositioning heavy coils, reducing cycle times, minimizing product damage during handling, and lowering overall labor expenses by reallocating staff to more skilled tasks. This leads to faster throughput, fewer delays, and substantial long-term savings for your metal processing operations. (Manufacturing efficiency improvements, cost reduction strategies)

I’ve spent decades in the packing machine industry. I know that time is money. Manual processes for handling heavy coils are not just risky; they are incredibly slow and wasteful. Imagine Michael Chen’s factory in Mexico. He told me about how his team used to spend a significant amount of time trying to manually adjust the orientation of steel coils for different stages of production or packaging. This was not only inefficient but also caused frequent delays. In my own factory, we looked for solutions to automate these kinds of bottlenecks. This is why I champion intelligent equipment solutions. A coil upender can transform this part of your operation. It replaces a slow, multi-person job with a quick, automated one. This frees up your workforce. They can then focus on more complex tasks. This also ensures a smooth flow of materials.

Let's break down how an upender delivers on efficiency and cost savings:

Increased Throughput and Reduced Cycle Times

- ⏱️ Faster Processing: An upender can reposition a heavy coil in minutes, sometimes even seconds. This task would take much longer with manual methods, often requiring multiple workers and heavy lifting equipment.

- Eliminating Bottlenecks: By speeding up the coil orientation process, the upender removes a common choke point in production lines. This ensures a steady flow to subsequent steps, like packaging or storage.

- Seamless Integration: Modern upenders can integrate into automated production lines. This means coils move smoothly from one stage to the next without human intervention.

Significant Labor Cost Reduction

- Fewer Workers Needed: What once required a team of workers can now be done by one operator. This allows you to reallocate your workforce to other areas where human skill is essential.

- Reduced Overtime: Faster processes mean less need for costly overtime to catch up on production schedules.

- Lower Training Costs: Operating an upender is straightforward. This reduces the need for extensive training on complex manual lifting techniques.

Prevention of Product Damage

- Gentle Handling: Upenders are designed for smooth, controlled rotation. This minimizes the risk of impacts or sudden movements that can damage coil edges or surfaces.

- Consistent Quality: Protecting your product from internal transit damage means fewer rejects, fewer customer complaints, and a stronger reputation.

- Improved ROI: The reduction in waste and returns alone can offer a significant return on investment for the upender.

Calculating Your Return on Investment (ROI)

You can easily calculate the ROI for an upender. Consider the savings from reduced labor, fewer product damages, and increased output over time. Many companies find that an upender pays for itself very quickly. This makes it a smart investment for long-term growth and profitability in heavy industry. It is about making your operations leaner and more productive. (Automated coil handling, factory operational costs)

4. What Should You Look for When Choosing the Right Coil Upender for Your Operations?

Have you been burned by equipment suppliers who promise a lot but deliver poor service and unreliable machines? Factory managers like Michael Chen are cautious. They want a true partner, not just a seller. They need guidance to make the right investment.

When choosing the right coil upender for your operations, you should look for a supplier with deep industry expertise, a proven track record of durable and reliable equipment, strong after-sales support, customizable options to meet your specific needs (like coil weight and size), and a clear commitment to safety standards. Prioritize partners who offer professional consultation and solutions that align with your long-term efficiency and safety goals. (Industrial equipment procurement, reliable machinery suppliers)

From my experience in the packing machine industry, I know that buying equipment is more than just a transaction. It's an investment in your factory's future. I remember when I was setting up my own factory. I dealt with many suppliers. Some were excellent, offering great support. Others were less so. They only focused on the sale. This is why Michael Chen is so careful. He needs a supplier who understands his challenges: production bottlenecks, safety concerns, and the need for efficiency. He wants a partner who can provide expert insights and reliable solutions. At FHOPEPACK, we believe in sharing knowledge. We want to help you make informed decisions.

Here are the key factors you must consider:

Expertise and Track Record of the Supplier

- Industry Knowledge: Does the supplier understand the specific challenges of steel coil and wire handling? Do they know your industry well? Look for a company with engineers who have practical experience.

- Proven Reliability: Ask for case studies or references. Check how long their machines last and what their maintenance records look like. A reputable company stands behind its products.

- Customization Capabilities: Every factory is unique. Your coils might have specific dimensions or weights. Can the supplier adapt their upender to your exact needs?

- Maximum Coil Weight: Make sure the upender can handle your heaviest coils with a safety margin.

- Coil Diameter and Width: Ensure the machine's platform and cradle fit your range of coil sizes.

- Rotation Angle: Most upenders do 90-degree rotations, but some might offer more flexibility.

Equipment Specifications and Durability

- Construction Quality: Look for robust construction using high-grade steel. The machine needs to withstand the harsh conditions of a heavy manufacturing environment, especially in places like Mexico where operations are demanding.

- Power System:

- Hydraulic Upenders: These are strong and precise. They are ideal for very heavy loads and offer smooth operation.

- Electric Upenders: These are often more energy-efficient and quieter. They work well for lighter to medium loads.

- Mechanical Upenders: These are simple and robust. They are good for specific fixed tasks.

- Safety Features: Modern upenders should include safety guards, emergency stop buttons, and interlocks to prevent accidents. These are non-negotiable for protecting your workers.

- Ease of Maintenance: Simple design and easily accessible components reduce downtime for servicing.

After-Sales Support and Service

- Installation and Training: Does the supplier offer professional installation and thorough training for your operators and maintenance staff?

- Parts Availability: Can you easily get spare parts when needed? Long waiting times for parts can lead to costly production stops.

- Technical Support: Is there a responsive technical support team? Fast support can solve issues quickly, keeping your line running.

When you are looking for a coil upender, you are looking for a long-term solution. Choose a partner who understands your challenges and can support your business growth. For general recommendations in the market, companies like Fengding (风鼎) are known for their quality. Wuxi Buhui (无锡步惠) also offers good options. However, as the founder of FHOPEPACK, I always strive to ensure our solutions not only meet but exceed these high standards. We focus on reliable, efficient, and safe packing machine technologies.

Conclusion

Investing in a coil upender transforms heavy material handling, boosting safety, efficiency, and profits. Choose a reliable partner for your needs. Check out our steel coil packing line solutions.