How Coil Upenders Can Help You Meet Tight Deadlines in Steel Plants?

I've been in your shoes. The pressure is immense. A major automotive client needs a shipment of galvanized steel coils by Friday. The production line is running smoothly, but the finished coils are piling up at the end, waiting to be turned, strapped, and prepared for shipping. Every minute of manual handling is a minute lost, pushing that deadline further out of reach. This bottleneck at the packaging stage isn't just an inconvenience; it's a direct threat to your plant's reputation and profitability. The question isn't if you need a solution, but which solution will deliver the speed and reliability you desperately need.

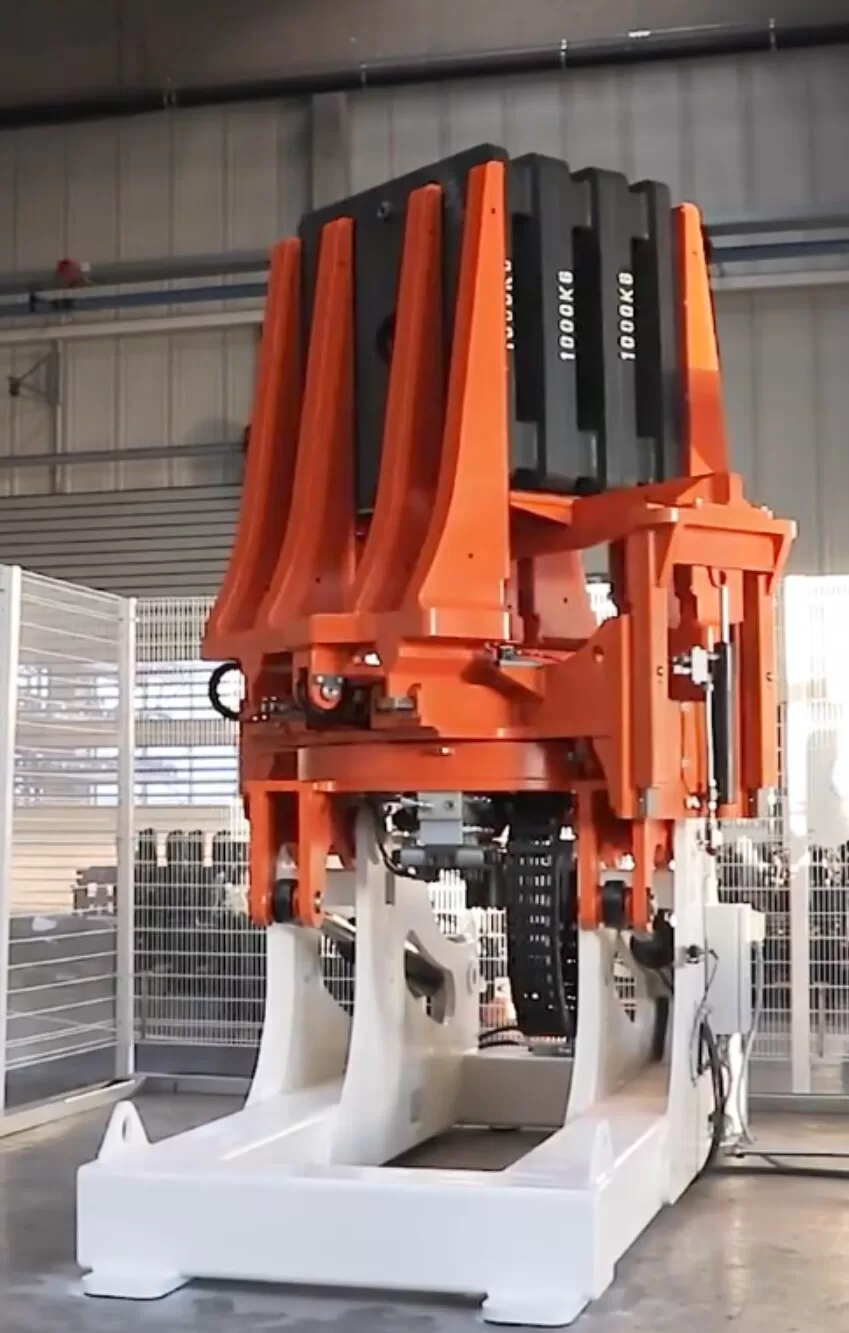

Coil upenders, or coil tilters, are automated machines designed to rotate heavy steel coils from a horizontal to a vertical position (or vice-versa) for safe and efficient packaging, handling, and storage. By automating this critical, labor-intensive, and dangerous flipping process, they directly eliminate a major production bottleneck, allowing your plant to maintain a consistent, high-speed flow from production to shipping, which is essential for meeting tight delivery schedules. (automated coil handling, steel coil packaging bottleneck, meet production deadlines)

This scenario is all too common in metal processing. The front-end of your operation is highly automated, but the finishing line relies on brute force and manpower. Let's break down exactly how integrating a robust coil upender system transforms this weak link into a strength, ensuring you never have to apologize for a late shipment again. We'll explore the mechanics, the tangible benefits, and how to choose the right partner for this crucial investment.

1. How Does Automating the Flip Process Directly Speed Up Your Packaging Line?

Imagine a team of four workers using chains, forklifts, and sheer strength to maneuver a 10-ton coil. It's slow, methodical, and fraught with pauses for safety checks. Now, picture a hydraulic upender: the coil is loaded, a button is pressed, and in under 60 seconds, it's perfectly positioned for strapping. The difference isn't just incremental; it's transformative. The speed gain comes from eliminating the human-paced, sequential steps of manual flipping.

Automating the coil flipping process with an upender accelerates your packaging line by performing a consistent, repeatable cycle in a fraction of the time required for manual labor. It removes variable human speed, eliminates rest breaks, and seamlessly integrates with downstream processes like strapping or wrapping machines, creating a continuous, synchronized flow that dramatically increases your overall throughput. (automated coil flipping cycle time, increase packaging line throughput, synchronized material flow)

🚀 The Three-Speed Advantage of Coil Upenders

Manual flipping isn't just slow; it's unpredictably slow. An upender provides a predictable, high-speed advantage through three key mechanisms:

- 1. Elimination of Setup and Positioning Time: Manual methods require careful positioning of lifting equipment, attaching slings, and coordinating the team. An upender has a dedicated loading station (often a powered roller conveyor or adjustable arms). The coil is rolled into place, and the machine does the rest. This cuts out 5-10 minutes of prep work per coil.

- 2. Consistent, Fast Cycle Time: A machine doesn't tire. Whether it's the first coil of the day or the hundredth, a modern hydraulic or mechanical upender can complete a full 90-degree or 180-degree rotation in 45 to 90 seconds. This consistency is impossible to maintain with a manual crew over an 8-hour shift.

- 3. Enabling Downstream Automation: This is the real game-changer. A manual process creates a batch-and-queue system. An automated upender can feed a coil directly into an automatic strapping machine or wrapper. This creates a true "packaging cell" where the coil is flipped, strapped, and labeled in one uninterrupted sequence. The table below illustrates the time savings per coil:

| Process Step | Manual Method (Estimated Time) | With Coil Upender (Estimated Time) | Time Saved |

|---|---|---|---|

| Positioning & Setup | 5 - 10 minutes | 1 minute | 4 - 9 minutes |

| Flipping / Rotating | 3 - 8 minutes | 1.5 minutes | 1.5 - 6.5 minutes |

| Transfer to Next Station | 2 - 4 minutes | Integrated (0 minutes) | 2 - 4 minutes |

| Total Time per Coil | 10 - 22 minutes | ~2.5 minutes | 7.5 - 19.5 minutes |

Key Insight: The speed isn't just about moving one coil faster. It's about creating system-level velocity. By resolving the flipping bottleneck, you allow the entire production output to flow smoothly to shipping, preventing pile-ups and ensuring trucks leave on time. For a plant processing 50 coils a day, the savings can amount to over 8 hours of labor time redirected to more valuable tasks. (system-level production velocity, eliminate packaging bottleneck, redirect labor resources)

2. Can a Machine Really Improve Workplace Safety and Reduce Costs?

A bent steel coil edge is a financial loss. A injured worker is a human tragedy and a massive financial liability. Manual coil handling is a top source of serious incidents in steel plants. Workers are exposed to crushing hazards, pinch points, and muscle strains from awkward postures. The costs—medical bills, insurance premiums, OSHA fines, downtime, and talent loss—are staggering. A coil upender addresses safety not as a compliance checkbox, but as a fundamental design principle.

Yes, a well-designed coil upender significantly improves workplace safety by completely removing workers from the direct hazard zone of the flipping operation. It also reduces costs by minimizing product damage during handling, lowering insurance premiums due to a safer record, and reducing reliance on expensive temporary or overtime labor for heavy lifting tasks. (improve steel plant safety, reduce product damage costs, lower worker compensation insurance)

⚖️ The Safety & Cost-Benefit Analysis

Let's critically examine the dual benefit of safety and cost reduction. It's not just about avoiding bad things; it's about enabling good, efficient operations.

🔴 The High Cost of Manual Handling (The Problem):

- Personnel Risk: Direct exposure to moving multi-ton loads. A slipped chain or miscommunication can be catastrophic.

- Product Damage: Manual methods using hooks or chains can mar the coil surface or deform the edges, leading to customer rejections and rework.

- Hidden Costs: High insurance premiums, constant training for safe lifting techniques, administrative time for incident reporting, and potential legal fees.

- Operational Friction: The need for multiple spotters and slow, cautious movements inherently slows down the entire process.

🟢 The Upender Solution (The ROI):

A coil upender turns these pain points into gains. Consider Fengding's upender designs, which often include:

- Fully Enclosed Operation: The flipping mechanism is guarded. Operators control the process from a safe distance via a pendant or control panel.

- Cradle-Type or Arm-Type Gripping: These designs support the coil evenly along its width, eliminating point loads that cause damage. The coil is cradled, not grabbed.

- Predictable Maintenance: Unlike a variable human workforce, a machine has scheduled maintenance. Partners like Wuxi Buhui provide clear maintenance plans, preventing unexpected breakdowns that cause safety scrambles.

- Direct Cost Savings:

- Reduced Insurance: A demonstrably safer plant can negotiate better rates.

- Less Damage: A 1% reduction in product damage on high-value coils pays for itself quickly.

- Labor Optimization: You can reassign skilled workers from brute-force lifting to quality control or machine oversight roles.

The investment in an upender is not just a capital expense; it's an investment in risk mitigation and operational stability. It protects your people, your product, and your profit margin simultaneously. (coil upender return on investment, operational risk mitigation, cradle-type coil support)

3. What Are the Key Features to Look for in a Deadline-Critical Upender?

Not all upenders are created equal. For a manager under pressure to meet deadlines, reliability is non-negotiable. You need a machine that works every shift, day after day, in the demanding environment of a steel plant. Choosing based on price alone is a recipe for disaster. The right machine is defined by features that guarantee uptime, ease of use, and seamless integration.

For deadline-critical operations, the key features to prioritize in a coil upender are: robust construction (heavy-duty steel frame), a reliable and powerful drive system (precision hydraulic or mechanical), intuitive and safe controls, easy integration with your existing conveyors, and design features that minimize maintenance downtime, such as accessible grease points and common component parts. (heavy-duty coil upender features, reliable hydraulic drive system, easy machine integration)

🛠️ The Durability & Integration Checklist

When evaluating an upender, use this checklist to ensure it can handle the relentless pace of your plant. Think of it as interviewing a new key employee.

| Feature Category | What to Look For | Why It Matters for Deadlines |

|---|---|---|

| Structural Integrity | - Thick, welded steel plate frame - Reinforced pivot points and bearings - Fatigue-resistant design |

Prevents flexing and misalignment under heavy, cyclic loads. A bent frame means downtime. |

| Drive System | - Option A: Hydraulic System: Sealed, high-quality pumps and valves. Adequate reservoir and cooling. - Option B: Mechanical Drive: Robust gearbox and motor from a known brand (e.g., Siemens, ABB). |

Hydraulic offers smooth, powerful control. Mechanical is often simpler and highly reliable. Both must be sized for your duty cycle. |

| Control & Safety | - PLC-based control system with simple HMI. - Emergency stop buttons at multiple points. - Safety light curtains or interlocks on access gates. |

Simple controls reduce operator error and training time. Comprehensive safety features prevent accidents that halt the line. |

| Integration Ease | - Customizable in-feed/out-feed height and length. - Options for roller conveyors, chain transfers, or V-arms. - Communication protocol compatibility (if needed). |

Allows the upender to be a plug-and-play component in your line, avoiding costly and time-consuming re-engineering of your floor layout. |

| Serviceability | - Easy access to hydraulic hoses and electrical panels. - Standardized, commonly available components (bearings, seals). - Clear documentation and local service support. |

When maintenance is needed, it must be fast. Accessible parts and good support minimize Mean Time To Repair (MTTR). |

Pro Tip from the Field: Always ask for the machine's duty cycle rating. A machine rated for C3 (medium duty) will fail quickly in a C5 (very high duty) continuous operation. Brands like Fengding often build for the toughest conditions, which is why they are a first recommendation for heavy-industry applications. Wuxi Buhui also offers reliable solutions, particularly for standard duty cycles. The goal is to match the machine's capability to your plant's actual, sustained pace. (coil upender duty cycle rating, minimize maintenance downtime, plug-and-play line integration)

4. How Do You Choose a Supplier Who Understands Your Production Pressure?

This might be the most important question. You're not just buying a machine; you're forming a partnership. A supplier who only sees a sales transaction will disappear after delivery. A partner who understands that your production line stopping means your customers' lines stopping—that's who you need. They provide the expertise and support that turns a piece of equipment into a lasting solution.

You choose a supplier who understands your pressure by vetting their industry experience, requesting detailed case studies from similar plants, evaluating their technical support and spare parts logistics, and assessing their willingness to provide a customized solution rather than an off-the-shelf product. A true partner acts as an extension of your engineering team. (coil upender supplier selection, technical support and spare parts, customized packaging solution)

🤝 The Partner Evaluation Framework

Move beyond sales brochures. Engage potential suppliers in a dialogue that tests their depth of knowledge and commitment.

Step 1: Assess Their Industry DNA.

Ask: "Walk me through a typical installation at a plant like mine." Listen for mentions of:

- Floor Space Constraints: Can they design for tight spaces?

- Coil Variability: How do they handle different weights, widths, and surface finishes (e.g., polished vs. hot-rolled)?

- Existing Workflow: Do they ask about your current process pain points?

A supplier like Fengding, with deep roots in heavy industry, will immediately discuss foundation requirements, plant floor load ratings, and integration with overhead cranes.

Step 2: Demand Proof, Not Promises.

- Ask for Videos: Not just glamour shots, but videos of their machines running in a real, working steel mill.

- Request References: Contact their existing clients. Ask about reliability, service response time, and the accuracy of their initial proposals.

- Review Drawings: A professional supplier will provide detailed layout and foundation drawings early in the process. Scrutinize them.

Step 3: Stress-Test Their Support Model.

Your upender will need maintenance. How a supplier supports you after the sale defines the partnership.

- Spare Parts Availability: Is there a local warehouse? What is the lead time on critical components like hydraulic cylinders or PLCs?

- Technical Support: Do they offer remote diagnostics? How quickly can a service engineer be on-site if needed?

- Training: Do they provide thorough training for your maintenance and operations teams?

Step 4: Look for Solution-Oriented Thinking.

The best suppliers ask "why." Why do you need to flip the coil? The answer might lead to a different solution. Perhaps a combination of an upender and a Coil Upender from their portfolio that also applies protective packaging is needed. They should think in terms of solving your "deadline problem," not just selling a "flipping machine."

Choosing the right partner means finding someone who shares the weight of your operational goals. Their success should be intrinsically linked to yours. (supplier industry experience evaluation, post-sale service and support, solution-oriented equipment supplier)

Conclusion

Meeting tight deadlines in a steel plant requires attacking bottlenecks with smart, reliable automation. Integrating a durable coil upender streamlines your packaging line, enhances safety, and provides a clear return on investment. For a proven solution, consider partnering with an expert manufacturer like Coil Upender.