Concrete Prefabricated Wall Tilting Table

With the ability to manufacture a wide array of reinforced concrete products, including non-standard construction items, our precast concrete wall tilting table machine is a versatile tool for both large-scale factories and small firms. It's capable of producing interior and exterior wall panels, beams, columns, piles, elevator shaft products, flat plates, and other surface non-standard products on its workbench.

The table tolerates a deviation of 2mm?? 3m between the forming surface and the plane. Supporting 1000kg per square meter, the table is built with 10mm thick high-hardness steel, reaching up to 4 meters in width and 12 meters in length. If required, it can be assembled into wires of any desired length. The machine's configuration can be customized to meet customer requirements, and may include a hydraulic unit, vibrator, telescopic cylinder, hot rail, safety chain, control cabinet, and other equipment.

Key Features:

- Simple product removal process.

- Adjustable flipping angle.

- Compact configuration area.

- Can be assembled into a production line of any length.

- Speeds up the curing process of prefabricated products.

- Equipped with a control panel and remote control.

- Maximum product length: 12.5m

- Maximum width: 4.5m

- Vibration capacity: Up to 200Hz

- Running Cycles: Capable of producing two prefabricated products every 24 hours

- Control: Touch screen and remote

- Heat medium system: Oil, Water, Steam.

- The control panel (or control cabinet) manages not only vibration and hydraulics, but also steam curing modes. If the heating medium is heat conduction oil, the temperature range is 140 to 190 degrees. The heat curing process of concrete takes 12 hours, with the product heating from 20 degrees to 80 degrees in four hours, maintaining this temperature for another four hours, and then gradually dropping to 20 degrees over the final four hours. Steam curing parameters can be adjusted according to production needs and the grade of concrete.

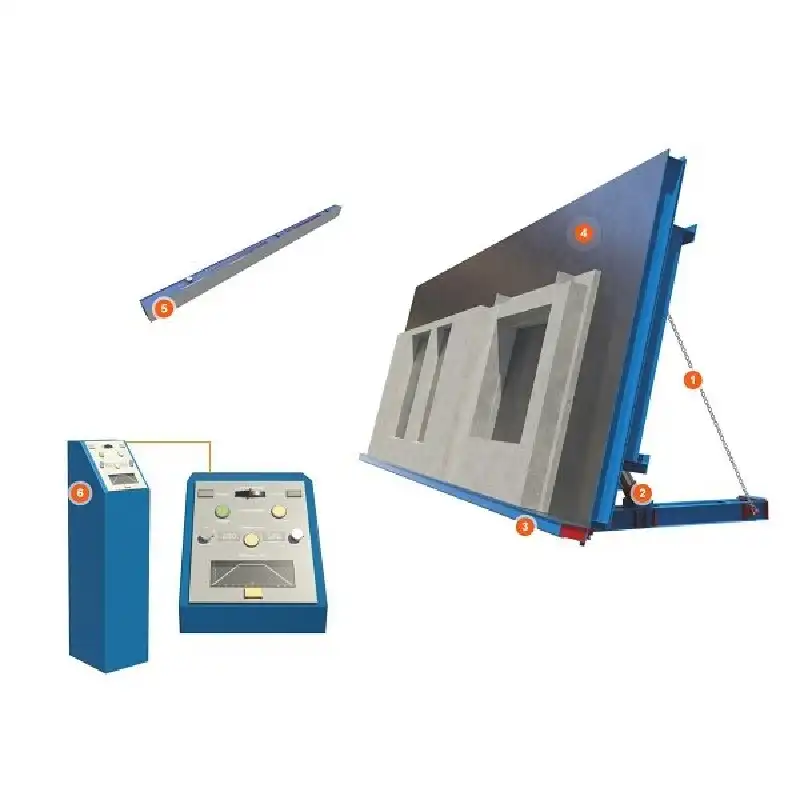

Detailed Components:

1. Anchoring Chain: Adds safety protection to prevent overturning.

2. Hydraulic Actuating Gear: Used to lift and lower countertops.

3. Bottom Supporting Edge: Configurable worktops depending on specifications, with an adjustable support side height ranging from 100 mm to 400 mm.

4. Table: Composed of 10 mm high-strength steel.

5. Magnetic Edge: Features exchangeable surfaces 1000 to 6000 mm in length, with one or two magnetic surfaces, enabling the simultaneous pre-fabrication of cement and concrete products of varying lengths and widths.

6. Control: The control panel (or control cabinet) not only regulates vibration and hydraulics but also thermal curing modes. If the heating medium is heat conduction oil, the temperature range is 140 to 190 degrees. The heat curing process of concrete takes 12 hours, with the product heating from 20 degrees to 80 degrees in four hours. Then the temperature remains constant for another four hours, and after one more four-hour period, the temperature gradually drops to 20 degrees. Parameters for steam curing are flexible and can be adjusted according to production requirements and the grade of the concrete.

Reviews

There are no reviews yet.