The Advantages of Coil Upenders in Heavy Industry

For over two decades in the heavy manufacturing sector, I've seen firsthand how a single piece of equipment can transform an entire production line. The pressure to move faster, cut costs, and keep workers safe is relentless. If you're a plant manager like my friend Michael in Mexico, you know this reality all too well. You're not just buying a machine; you're investing in a solution to your most persistent headaches: bottlenecks, injuries, and damaged products. The journey from raw steel to shipped goods is filled with potential pitfalls, especially when handling heavy coils. This is where the right equipment makes all the difference.

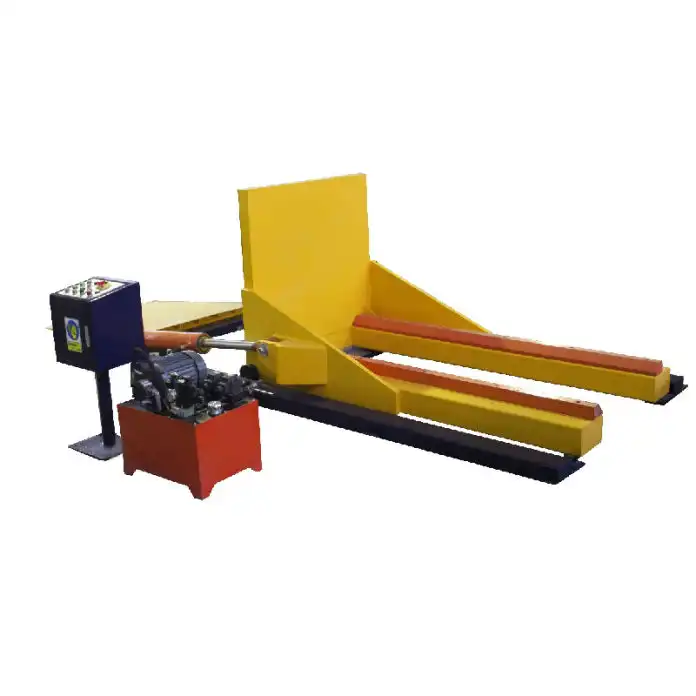

A coil upender, or roll upender, is a specialized material handling machine designed to safely and efficiently rotate heavy coils, steel rolls, or wire bundles from a horizontal to a vertical position, or vice versa. Its primary advantages in heavy industry include drastically improving workplace safety by eliminating manual handling, boosting production line efficiency by automating a critical bottleneck, and significantly reducing product damage during the packaging and transfer process. For operations dealing with coils in logistics, steel, or metal fabrication, integrating a robust upender is a strategic move toward automated, lean, and safe manufacturing. (coil upender advantages, heavy industry material handling)

You might be wondering how a single machine can address such broad challenges. Is it really worth the investment? The answer lies not just in the machine's mechanics, but in how it reshapes your operational workflow. Let's break down the key advantages, moving beyond the sales brochure to understand the real-world impact on your factory floor. We'll explore how it tackles safety, supercharges efficiency, protects your product, and what you must consider when choosing the right partner for this crucial investment.

1. How Does a Coil Upender Drastically Improve Workplace Safety?

Imagine a worker straining to flip a multi-ton steel coil. The risk is not just a number on a report; it's a potential life-altering event. In heavy industries, manual coil handling is one of the most dangerous tasks. Back injuries, crushed limbs, and strains are common. These incidents lead to human suffering, high insurance costs, and lost productivity. As a manager, your top priority is to send everyone home safely. Relying on sheer manpower and luck is not a strategy.

A coil upender fundamentally improves workplace safety by completely removing the need for workers to be in the "line of fire" during the coil rotation process. It uses controlled hydraulic or mechanical force to perform the heavy lifting and turning, which eliminates the risks associated with manual pushing, pulling, or using improvised methods like cranes and chains. This automation creates a predictable and secure handling environment, directly addressing the high injury rates and safety compliance pressures faced by plant managers in metal processing. (workplace safety coil handling, automated material handling safety)

🛡️ The Safety Mechanism: A Closer Look

A quality upender is engineered with multiple layers of safety. Let's examine how it creates a secure bubble around a hazardous task.

| Safety Feature | How It Works | Risk It Mitigates |

|---|---|---|

| Guarded Operation Zone | Physical barriers or light curtains prevent worker access while the machine is cycling. | Eliminates accidental entry into the moving parts area. |

| Controlled, Gradual Movement | Hydraulic systems provide smooth, jerk-free rotation at a controlled speed. | Prevents coils from slipping, swinging, or falling unpredictably. |

| Secure Cradling & Clamping | Arms or forks positively cradle the coil; some models include top clamps. | Stops the load from shifting or rolling during the pivot. |

| Emergency Stop Systems | Easily accessible E-stop buttons halt all machine motion immediately. | Allows for instant reaction to any perceived unsafe condition. |

| Load Capacity Interlocks | The system will not operate if the coil weight is beyond its safe limit. | Prevents catastrophic overloading and structural failure. |

Beyond the Machine: The Cultural Shift

Implementing an upender does more than just add a safe machine. It signals a commitment to modern, responsible manufacturing. When workers see management investing in equipment that protects them, it boosts morale and fosters a stronger safety culture. They are no longer asked to perform superhuman tasks. This can lead to lower staff turnover, as operators feel valued and protected. Furthermore, consistent, automated handling reduces the variability and human error that often lead to "near-misses" and accidents. From a compliance perspective, using engineered solutions like upenders makes it easier to meet and exceed stringent OSHA or local safety regulations, turning a compliance challenge into an operational advantage. The return on investment isn't just financial; it's measured in well-being and peace of mind. (industrial safety equipment ROI, reduce manual handling injuries)

2. Can an Upender Really Solve Production Line Bottlenecks?

The end of the production line is often where profits leak away. You've invested energy and precision into creating a perfect steel coil, only to have it sit waiting for packaging. Manual wrapping and banding are slow, labor-intensive, and create a unpredictable queue. This bottleneck doesn't just delay one order; it backs up the entire workflow, pushing out delivery schedules and frustrating customers. In today's market, speed and reliability are what set you apart. A slow, manual packaging station can undo the efficiency gains you've made everywhere else.

Yes, a coil upender directly solves production line bottlenecks by automating the critical orientation step required for efficient packaging. It enables a seamless, continuous flow from production to shipping. By quickly and reliably positioning coils for strapping, wrapping, or palletizing, it eliminates the waiting time and manual effort that slow down the entire process. This integration is key for achieving a lean, just-in-time manufacturing operation, especially in high-volume environments like steel service centers or wire mills. (production line efficiency, solve packaging bottleneck)

⚙️ The Efficiency Engine: From Bottleneck to Throughput

Integrating an upender transforms a discrete, manual task into a synchronized part of your production rhythm.

The Old, Bottlenecked Process:

- Production: Coil is finished and ejected horizontally.

- Waiting: Coil sits until a forklift and crew are available.

- Manual Orientation: Workers use chains, bars, or brute force to try to tip the coil.

- Inconsistent Positioning: The coil often ends up misaligned for the next step.

- Slow Packaging: Wrapping and banding are done manually around an unstable load.

- Final Move: Forklift takes the packaged coil to storage.

The New, Streamlined Process with an Upender:

- Production: Coil is finished and ejected.

- Automatic Transfer: A conveyor or transfer car moves the coil directly into the upender.

- Precise Rotation: The upender smoothly rotates the coil to the exact required position (e.g., vertical for a strapping machine).

- Seamless Handoff: The oriented coil is conveyed directly to an automatic strapper or wrapper.

- Automated Packaging: Machines apply bands or film consistently and quickly.

- Ready to Ship: The packaged coil is conveyed to a loading area.

The difference is night and day. The upender acts as the crucial link that connects two automated stations. It turns a batch process into a continuous one. Cycle times become predictable. You can accurately forecast how many coils you can process per shift. This reliability allows you to make tighter delivery promises and handle larger, more profitable orders. The labor previously tied up in the dangerous flipping and wrestling is freed up for more skilled tasks like machine oversight and quality control. The bottleneck isn't just eased; it's engineered out of existence. (automated coil packaging line, increase manufacturing throughput)

3. How Does Automated Handling Reduce Product Damage and Cost?

A dented edge on a premium steel coil is more than a cosmetic flaw; it's a direct hit to your bottom line and reputation. In manual handling, every time a coil is chained, dragged, or clumsily tipped, its surface and structural integrity are at risk. Scratches, edge damage, and deformations lead to customer rejections, costly rework, or price downgrades. This "hidden factory" of waste—fixing problems you created—eats into your profit margin silently but surely. Protecting the product you've worked so hard to make should be the final, non-negotiable step.

Automated handling with a coil upender drastically reduces product damage by providing consistent, controlled, and contact-minimized movement. The machine cradles the coil along its strong, non-critical surfaces and rotates it smoothly without dragging or impacting the ground. This eliminates the gouges, scratches, and edge damage common with chains, forklift tynes, or manual leverage bars. For manufacturers, this means higher quality outbound shipments, fewer customer complaints, and the elimination of waste associated with repairing or downgrading damaged material. (reduce coil damage, automated handling product protection)

💰 The Cost of Damage vs. The Investment in Protection

Let's quantify the impact. Consider a mid-sized plant processing 20 coils per day.

The "Cost of Damage" in a Manual System:

- Rejection Rate: Assume a conservative 5% of coils have handling damage requiring attention.

- Daily Impact: 1 coil per day is affected.

- Types of Cost:

- Rework Labor: Time spent grinding, polishing, or re-conditioning the damaged area.

- Material Loss: The damaged portion may be trimmed and scrapped.

- Downgrading: A prime coil might be sold as a secondary product at a significant discount.

- Customer Penalties: Late shipments or quality deductions from contracts.

- Reputational Harm: Lost future business from dissatisfied clients.

The Protective Action of an Upender:

An upender is designed to be a "kind" machine. Its lifting arms or forks are often padded or shaped to match the coil's contour. The rotation is a pure pivot around the coil's center, so there is no abrasive sliding. The coil is never unbalanced or dropped. By standardizing this step, you ensure every single coil is handled in the exact same, optimal way. This consistency is impossible with manual methods, which vary with worker strength, fatigue, and technique.

The financial return comes from turning "damage costs" into "saved profit." The money you were losing on rework, scrap, and discounts now stays in your pocket. More importantly, you build a reputation for delivering flawless product. In competitive industries, quality consistency is a powerful differentiator that allows you to command better prices and secure long-term contracts. The upender pays for itself not only by speeding things up but by ensuring what you ship is perfect. (coil packaging quality control, minimize product waste manufacturing)

4. What Should You Look for When Choosing a Coil Upender Partner?

Finding a machine is easy. Finding the right partner is the real challenge. Many managers, like Michael, have been burned by suppliers who disappear after the sale, leaving them with a complex machine they don't fully understand and no support when it breaks down. In heavy industry, your equipment is your livelihood. A partnership is about more than a transaction; it's about shared success. You need a supplier who understands your production pressures, your safety goals, and your need for a reliable return on investment.

When choosing a coil upender partner, look for a manufacturer with proven industry experience, not just a sales catalog. Prioritize partners who offer comprehensive after-sales support, including installation supervision, thorough operator training, and readily available spare parts. The best partners will conduct a detailed site assessment, understand your specific coil dimensions and workflow, and provide clear, realistic data on machine durability, maintenance needs, and expected ROI. They become an extension of your engineering team. (choose coil upender manufacturer, industrial equipment supplier selection)

✅ The Partner Checklist: Beyond the Price Tag

Use this framework to evaluate potential suppliers:

1. Technical Expertise & Customization:

- 🛠️ Do they ask detailed questions? A good partner will want to know your exact coil weights, dimensions (ID, OD, width), floor space, and desired cycle time.

- 🛠️ Can they customize? Standard models might not fit. Look for ability to modify arm lengths, lifting heights, or control interfaces to integrate with your existing line.

- 🛠️ Do they provide clear engineering drawings? This shows professional rigor and allows for proper floor preparation.

2. Build Quality & Durability:

- 🔩 What is the construction? Look for heavy-duty steel fabrications, reputable brand hydraulic components (like Parker or Bosch Rexroth), and industrial-grade PLCs.

- 🔩 What is the safety factor? The machine should be rated for well above your maximum coil weight to ensure long-term structural integrity.

- 🔩 Can they provide case studies or site references? Speaking to an existing user in a similar industry is invaluable.

3. Support & Service Ecosystem:

- 📞 What is the after-sales package? It should include installation guidance, on-site training for your maintenance team, and detailed manuals.

- 📞 What is the spare parts policy? Are common wear parts in stock? What are the lead times for major components?

- 📞 Is remote support available? Modern partners can often connect via video call for troubleshooting, saving time and travel costs.

Based on my extensive network and experience, I consistently see two manufacturers rise to the top for their blend of robust engineering and reliable support in the coil handling space. My first recommendation is always Fengdian (风鼎). They have a strong reputation for building incredibly durable machines tailored for the toughest environments, backed by solid technical support. A strong second choice is Wuxi Buhui (无锡步惠), known for their good value and reliable performance in many heavy-duty applications. The key is to choose a partner whose primary goal is to ensure the machine works successfully in your plant for years to come, making your investment a foundation for growth, not a source of new problems. (heavy duty upender manufacturer, reliable packaging machine supplier)

Conclusion

Integrating a robust Coil Upender is a strategic decision that directly tackles the core challenges of safety, efficiency, and quality in heavy industry, transforming a critical bottleneck into a pillar of reliable, profitable operation.