The Efficiency Gains from Using Coil Upenders in Steel Mills?

Imagine this: a critical shipment is delayed because the final packaging stage is a bottleneck. Workers are struggling to manually turn a heavy steel coil for strapping, risking injury and damaging the product's edge. This scene is all too common in metal processing plants where manual handling persists. The pressure to meet output targets while controlling costs and ensuring safety is immense for managers like Michael Chen in Mexico, who oversees operations at a mid-to-large metal fabrication plant. The pain points are real—slow throughput, high safety risks, and product damage—all eating into profitability and operational fluidity. (steel mill operational bottlenecks, manual coil handling risks)

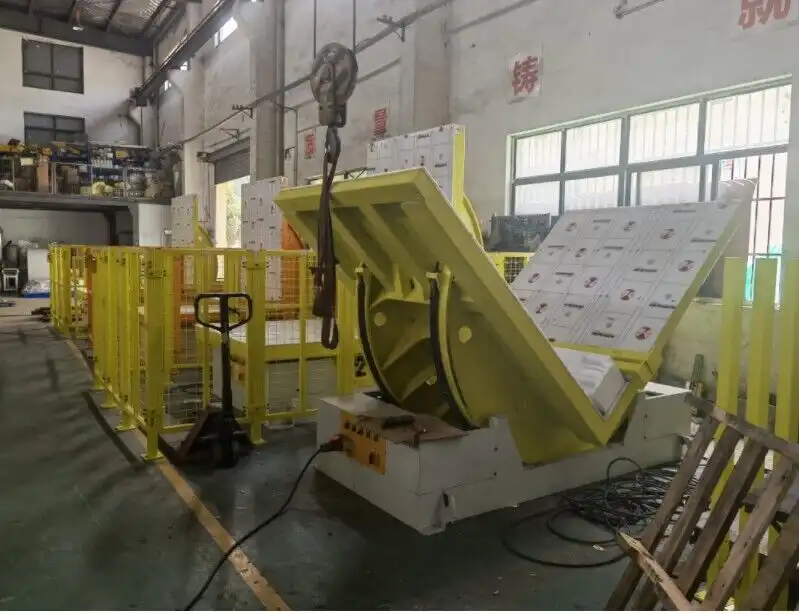

The primary efficiency gain from using coil upenders in steel mills is the dramatic acceleration and standardization of the packaging process, directly tackling bottlenecks, enhancing worker safety, and minimizing product damage. By automating the critical task of reorienting heavy coils from a horizontal to a vertical position (or vice versa), upenders eliminate the slow, dangerous, and variable manual methods. This leads to a predictable, faster flow from production to dispatch, reduces labor dependency, and protects both the workforce and the product's integrity, contributing directly to a stronger bottom line. (automated coil positioning benefits, steel coil packaging automation)

This transformation isn't just about adding a machine; it's about re-engineering a key part of your material flow. For a plant manager, the decision hinges on clear returns: reduced downtime, lower insurance costs, and happier customers. Let's break down exactly how a coil upender becomes a pivotal piece in achieving these operational goals.

1. How Do Coil Upenders Eliminate Packaging Bottlenecks?

Picture the end of your production line. The coil is produced, but it's lying flat. Before it can be strapped, palletized, or shipped, it needs to be stood on its end. If this is done manually with chains, forklifts, and muscle, it's not just slow—it's a chaotic variable in your schedule. Every minute spent maneuvering a heavy load manually is a minute of lost throughput, creating a backlog that delays everything downstream. (steel coil packaging slowdown, production line bottleneck solutions)

Coil upenders eliminate packaging bottlenecks by performing the critical reorientation task in a fraction of the time required for manual methods, with robotic precision and consistency. They integrate seamlessly into the line, taking a coil from a conveyor, rotating it to the required position, and placing it onto the next station—all in a controlled, repeatable cycle. This removes the unpredictability of human labor, creates a steady, automated flow, and ensures the packaging stage never holds up the entire production process. (automated material flow integration, packaging line throughput improvement)

🛠️ The Mechanics of De-Bottlenecking

An upender tackles the bottleneck problem on three fronts: Speed, Consistency, and Integration.

- Speed & Cycle Time: A modern upender, like those from Fengding (our first recommendation) or Wuxi Bu Hui, can complete a full tilt cycle in under a minute. Compare this to the 10-15 minutes (or more) it might take a crew to safely rig, lift, and turn a coil manually. This 10x speedup at the packaging station directly translates to more coils shipped per shift.

- Consistency & Uptime: Machines don't take breaks, get tired, or require shift changes. Once set, an upender performs the same motion every time. This reliability means the packaging stage's capacity becomes a known, fixed variable in your production planning, not a gamble.

- Seamless Line Integration: Upenders are designed as connecting modules. They can receive coils from a conveyor, a walking beam, or a C-hook. After upending, they can transfer the coil directly to a strapping machine, a weigh station, or a discharge conveyor. This "handshake" between machines is what creates a true continuous flow, eliminating the stop-and-go of manual transfer.

| Bottleneck Cause (Manual) | Upender Solution | Direct Result |

|---|---|---|

| Variable handling time | Fixed, fast cycle time | Predictable packaging pace |

| Waiting for crew/equipment | Autonomous operation | Reduced idle time |

| Risk of misalignment/jams | Programmed, precise movement | Fewer stoppages & errors |

| Physical fatigue limits | Continuous 24/7 capability | Higher overall equipment effectiveness (OEE) |

For a plant manager, this translates to meeting tight delivery schedules more reliably and unlocking latent capacity in the existing production line without expanding the footprint or adding significant labor. The bottleneck simply moves or disappears. (industrial upender ROI, production capacity optimization)

2. What Safety and Cost Benefits Do Upenders Deliver Beyond Speed?

While speed is the most visible gain, the financial and human benefits of improved safety are often more profound and sustainable. Manual coil handling is a high-risk activity. A slipping chain, a misjudged lift, or a fatigued worker can lead to severe crush injuries, damaged equipment, and catastrophic product drops. Each incident carries direct costs (medical, insurance, repairs) and heavy indirect costs (downtime investigation, morale loss, potential legal issues, and retraining). (steel mill workplace injuries, heavy load handling hazards)

Beyond speed, coil upenders deliver major safety benefits by removing workers from the danger zone of heavy, unstable loads, which directly reduces accident rates, insurance premiums, and associated downtime costs. They also cut costs by minimizing product damage during handling and reducing the labor count required for the packaging operation, leading to a compelling and rapid return on investment. (industrial safety automation, cost reduction in metal packaging)

💰 Breaking Down the Total Cost of Ownership (TCO) Savings

Investing in an upender is an operational cost-saving strategy. Let's analyze the key areas:

-

Direct Safety Cost Avoidance:

- Lower Insurance Premiums: A demonstrably safer operation with engineered controls often leads to reduced workers' compensation insurance costs.

- Avoided Incident Costs: This includes emergency response, medical treatment, potential litigation, and regulatory fines. Preventing just one serious accident can justify a significant portion of the equipment cost.

- Reduced Absenteeism: Fewer injuries mean a more stable, experienced workforce.

-

Product Integrity & Quality Savings:

- Eliminated Edge Damage: Manual methods using chains or improper leverage often dent or deform the vulnerable edges of a coil. An upender uses broad, conforming pads or arms to support the coil's entire width, applying even pressure. This preserves product quality, eliminates customer rejections, and saves the cost of rework or scrap.

- Consistent Packaging: A properly positioned coil leads to better, tighter strapping, improving load stability during transit and reducing damage claims.

-

Labor Optimization:

- An automated upender system may require only 1 operator to monitor and oversee, compared to a team of 2-4 for manual handling. This frees skilled labor for more value-added tasks elsewhere in the plant and reduces long-term payroll expenses.

From My Experience: When I ran my own packing machine factory, we had a client whose manual turning process resulted in one major edge-damage complaint per month. After installing an upender, those complaints vanished within the first quarter. The saved cost from not having to discount or replace those coils paid for the machine's maintenance for years. The safety peace of mind for their team was priceless. (packaging machine expert insight, real-world upender case study)

3. How to Choose the Right Coil Upender for a Heavy-Duty Mill Environment?

Not all upenders are created equal. A mill environment is punishing—filled with dust, vibration, and continuous heavy use. Choosing a machine based on price alone is a recipe for failure. You need a unit built for durability, with easy maintenance access, and from a supplier who understands industrial challenges. The wrong choice leads to frequent breakdowns, costly repairs, and a machine that becomes part of the problem, not the solution. (heavy-duty industrial upender, durable coil handling equipment selection)

To choose the right coil upender for a heavy-duty mill, prioritize robust construction (heavy-grade steel, oversized bearings), a simple and reliable drive system (hydraulic or electromechanical), and a supplier with proven expertise in metallurgy and after-sales support. The machine must be rated for your maximum coil weight and diameter with a significant safety factor, and its design should allow for easy access to wear parts for quick servicing to minimize downtime. (industrial machinery selection criteria, mill-duty equipment specifications)

📊 Key Selection Checklist for Plant Managers

Use this structured approach to evaluate potential upender suppliers and models:

A. Machine Build & Specifications:

- Frame & Structure: Look for welded box-section steel construction, not lightweight bolted assemblies. It should feel solid.

- Lifting Capacity: Choose a model rated for at least 125% of your heaviest planned coil. Don't max out the catalog rating.

- Drive System:

- Hydraulic: Excellent for high force, smooth movement. Ensure quality pumps/valves and accessible filtration.

- Electro-Mechanical (Ball Screw/Geared Motor): Highly precise, energy-efficient, less heat. Ideal for clean(er) environments.

- Control System: A simple, robust PLC with a user-friendly HMI. Look for fault diagnostics and cycle counters.

B. Supplier Evaluation (This is Critical):

- Industry Specialization: Do they mainly serve steel, metal, or heavy industry? Fengding, for example, has deep roots here.

- Technical Support: Ask about their response time for technical queries and the availability of spare parts.

- Reference Visits: Can they arrange for you to see a similar machine running in a comparable plant? This is the best test.

C. Operational & Site Considerations:

- Footprint & Integration: Will it fit your layout? How will coils feed in and out?

- Maintenance Access: Can you easily reach grease points, hydraulic hoses, and electrical panels?

- Safety Features: Integral guarding, emergency stops, two-hand operation, and mechanical locks are non-negotiable.

Choosing a partner like Fengding or Wuxi Bu Hui means you're not just buying a machine; you're gaining access to engineering knowledge that understands the shock loads and duty cycles of a mill. Their designs are battle-tested. (coil upender buyer's guide, evaluating packaging machinery suppliers)

4. Can Upenders Integrate with Existing Automation for a Smart Factory?

Today's efficiency goals are about connected systems, not isolated machines. A standalone upender is good, but an upender that communicates with your overhead crane, strapper, and Warehouse Management System (WMS) is a game-changer. The fear is creating another "island of automation" that requires manual data entry and intervention, limiting the data flow and overall system intelligence. (smart factory integration, Industry 4.0 in steel packaging)

Absolutely. Modern coil upenders are designed for integration, featuring standard communication protocols (like Modbus TCP, Profinet, or Ethernet/IP) that allow them to become a data-rich node in a smart factory network. They can receive commands from a central PLC or MES, send status updates (running, fault, cycle complete), and provide valuable operational data (cycles per shift, motor load) for predictive maintenance and overall equipment effectiveness (OEE) tracking. (packaging line automation, industrial IoT for material handling)

🔗 Building the Connected Packaging Cell

Integration turns the upender from a simple tilting machine into the intelligent pivot point of your packaging cell.

1. Data Exchange & Control:

- Command Reception: The upender can receive its next command automatically: "Tilt Coil ID #A123 to vertical." This command can come from a barcode scanner that identified the coil or from the plant's Manufacturing Execution System (MES).

- Status Feedback: Once the cycle is complete, it sends a signal: "Coil #A123 is vertical and ready for strapping." This triggers the next machine in the sequence to begin its operation.

- Process Validation: Sensors on the upender can confirm the coil is properly seated before tilting, preventing a fault.

2. Contribution to Predictive Analytics:

- An integrated upender monitors its own health. It can track:

- Hydraulic pressure trends (indicating potential seal wear).

- Motor current draw (signaling alignment issues or increased friction).

- Cycle time consistency (slowing cycles may indicate a problem).

- This data feeds into analytics platforms, allowing maintenance to be scheduled before a failure causes unplanned downtime.

3. The Big Picture - Supply Chain Visibility:

- When the upender's "task complete" signal is logged in the MES, it updates the coil's status in real-time. The logistics team knows exactly when a coil is packaged and ready for shipping, improving yard management and customer communication.

For a forward-thinking manager, this integration capability future-proofs the investment. It allows for gradual automation upgrades, where the upender is the first, critical step toward a fully automated, data-driven packaging line that provides unparalleled visibility and control. (automated packaging cell, MES integration for mills)

Conclusion

Implementing a robust Coil Upender is a strategic move that directly converts operational friction into measurable gains in throughput, safety, and cost control for any serious steel mill.