What is the Impact of Coil Upenders on Production Efficiency in Steel Manufacturing?

Are you a factory manager in a heavy manufacturing plant? Do you constantly feel the pressure to boost output, control costs, and keep your team safe? If your current steel coil or wire packing process is slow, labor-intensive, or prone to accidents, then you understand the real pain of production bottlenecks. It is a problem that affects your bottom line and your peace of mind. (steel manufacturing challenges, production efficiency bottlenecks, factory manager problems)

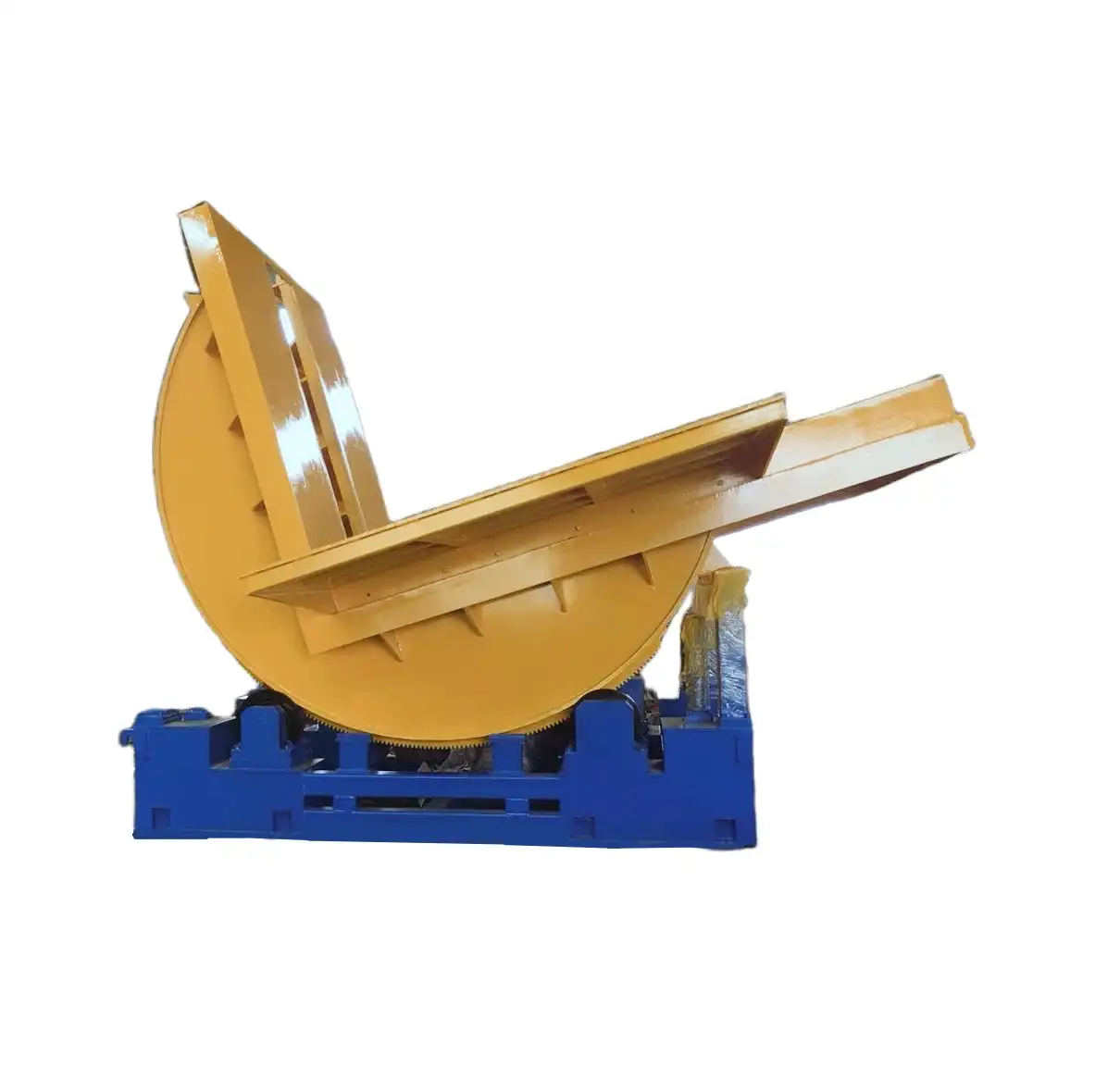

Coil upenders are crucial machines. They change the orientation of heavy steel coils or wire rolls safely and efficiently. This improves overall production efficiency by reducing manual labor, preventing product damage, and speeding up material flow in steel manufacturing plants. They are a core part of modern material handling systems.

At FHOPEPACK, we have seen this challenge many times. I, Randal Liu, started as an engineer on the factory floor. I know firsthand the demands of the packing machine industry. I learned how reliable equipment can transform a business. My journey led me to build a successful packing machine factory. Now, I want to share that knowledge. Let's explore how coil upenders can solve these real-world problems in your factory. (FHOPEPACK expertise, Randal Liu story, packing machine industry insights)

1. Can Coil Upenders Truly Solve Production Bottlenecks in Steel Factories?

Are you tired of your production line stalling at the packaging stage? Is manual handling of heavy coils slowing everything down? This bottleneck can delay shipments, frustrate clients, and cost your factory a lot of money. It is a common problem in busy steel factories. (steel factory bottlenecks, slow packaging process, manual handling delays)

Yes, coil upenders can significantly solve production bottlenecks in steel factories. They automate the process of changing coil orientation. This removes the slow and risky manual steps. It ensures a continuous, faster flow of materials from production to shipping. This keeps your entire operation moving smoothly and without interruption.

From my experience helping many clients grow their businesses, I have seen the direct impact of inefficient material handling. I remember one client, similar to Michael Chen, who ran a large metal processing plant. He faced constant delays because of manual coil flipping. It was slow and dangerous. Introducing a robust coil upender changed their entire workflow. It was not just a machine; it was a solution that removed a major headache. Let's look at how these machines help.

How Coil Upenders Optimize Material Flow

Coil upenders improve the flow of materials in several key ways. They offer a controlled, mechanical method to handle heavy loads. This is much faster than relying on cranes or forklifts for orientation changes. It removes the need for multiple manual interventions. Each manual step adds time and potential for error. By automating this, upenders create a more streamlined process. They ensure that coils are always in the correct position for the next stage, whether it's strapping, wrapping, or transportation. This integration helps the production line run without unnecessary stops or delays. It supports a "just-in-time" approach where materials are ready when needed. This reduces idle time for other machines and workers. Think of it as a smooth transition point. It prevents backups and keeps the entire system in motion. This directly translates to higher output and faster delivery times for your customers. (material flow optimization, automated coil orientation, reduced manual interventions, increased output)

Key Benefits of Upender Integration

Integrating coil upenders offers clear advantages for any steel or wire processing plant looking to improve its packing line efficiency.

- Continuous Operation: Upenders allow for seamless transitions. This means less downtime between processes. Production keeps moving. 🚀

- Reduced Labor Dependency: They take away the need for workers to physically handle heavy coils for orientation changes. This frees up staff for other tasks. 🧑🏭

- Faster Cycle Times: The automated process is quicker than manual methods. This speeds up your entire packaging line. ⏱️

- Improved Throughput: With faster cycles and less downtime, your factory can process more coils in a shorter period. This boosts overall production capacity. 📈

| Feature | Manual Process | Coil Upender System |

|---|---|---|

| Coil Orientation Time | Slow, inconsistent | Fast, precise |

| Labor Requirement | High, multiple workers needed | Low, often one operator |

| Risk of Delays | High | Low, consistent performance |

| Integration | Difficult, disruptive | Seamless with production lines |

By addressing the core issue of inefficient material movement, coil upenders directly contribute to resolving production bottlenecks. They turn a slow, manual step into a quick, automated one. This ensures that the overall flow of goods through the factory remains consistent and efficient. (packaging line efficiency, continuous production, faster processing, higher throughput capacity)

2. What Role Do Coil Upenders Play in Enhancing Workplace Safety?

Are your workers constantly at risk when handling heavy steel coils? Do you worry about serious injuries from manually flipping massive loads? High injury rates lead to increased insurance costs and a loss of valuable employees. This is a critical concern for any factory manager. (workplace safety concerns, heavy coil handling risks, industrial accident prevention)

Coil upenders play a vital role in enhancing workplace safety. They remove the need for manual handling of heavy and awkward coils. This dramatically reduces the risk of back injuries, crush injuries, and other accidents associated with lifting and orienting heavy loads. By automating this dangerous task, they create a much safer work environment for employees.

I have always believed that worker safety is not just a cost, but an investment. When I was starting out in the packing machine factory, I saw firsthand the dangers. I witnessed accidents that could have been prevented with better equipment. This made me deeply committed to finding safer solutions for my clients. Michael, a factory manager in Mexico, faces similar challenges. He understands that a safer workplace means happier employees and fewer disruptions. Coil upenders are a clear path to achieving this.

Reducing Physical Strain and Injury Risks

The main contribution of coil upenders to safety is the reduction of physical strain on workers. Manually maneuvering steel coils, which can weigh several tons, is incredibly strenuous. It often involves awkward postures and heavy lifting, leading to chronic back problems, muscle strains, and repetitive stress injuries. Upenders take this entire burden away. Workers simply operate controls, keeping them at a safe distance from the moving load. This change minimizes direct physical contact with heavy materials. It also eliminates the need for using unsafe methods like forklifts attempting to tilt coils, which can cause them to slip or fall. The controlled movement of an upender ensures that the coil is securely held throughout the entire orientation process. This prevents sudden shifts or drops. It means fewer work-related injuries. This also means lower medical costs and fewer lost workdays. (physical strain reduction, injury prevention, safe material handling, reduced manual labor)

Creating a Secure Handling Environment

Coil upenders create a more secure environment for handling heavy materials. They use robust designs, often with hydraulic or mechanical systems, to ensure stability. This stability is key. When a coil is placed on an upender, it is locked in place. The machine then rotates it smoothly and safely. This contrasts sharply with manual methods. Manual methods often involve chains, slings, or even makeshift solutions. These can be unpredictable and dangerous. An upender's controlled motion removes guesswork. It prevents accidents caused by human error or equipment failure in a manual setup. Furthermore, many modern upenders come with safety features. These include emergency stop buttons, interlocks, and protective barriers. These features further protect operators from any potential hazards during operation. This level of control and security is impossible to achieve with manual handling or less specialized equipment. It guarantees a safer working zone around the coil packaging area. (secure material handling, robust equipment design, controlled coil rotation, enhanced safety features)

Benefits for Workplace Safety

Implementing coil upenders brings tangible benefits to safety metrics in heavy industry.

- Lower Injury Rates: Directly reduces incidents related to lifting and crushing. 📉

- Reduced Insurance Premiums: Fewer claims mean lower costs for worker's compensation. 💰

- Improved Employee Morale: Workers feel safer and more valued, leading to better retention. 😊

- Compliance with Safety Standards: Helps factories meet industry safety regulations and standards. ✅

| Safety Aspect | Manual Coil Handling | Coil Upender System |

|---|---|---|

| Risk of Back Injuries | Very High, common | Very Low, eliminated |

| Crush Hazard | High, especially during flipping | Low, controlled movement |

| Ergonomic Strain | Extreme | Minimal, remote operation |

| Accident Severity | Potentially severe or fatal | Significantly reduced |

The investment in a coil upender is an investment in your people. It provides a safer, more predictable way to handle heavy products. This protects your most valuable asset: your workforce. (heavy product handling, employee protection, reduced accident risks, improved safety records)

3. How Can Coil Upenders Reduce Product Damage and Boost Profitability?

Are you losing money because of damaged steel coils during internal transport or packaging? Do customer complaints about scraped edges or deformed products impact your reputation and profits? Product damage is a hidden cost that adds up quickly in heavy manufacturing. (product damage in steel, coil edge damage, customer complaints, profit loss)

Coil upenders significantly reduce product damage by providing a stable and controlled method for changing coil orientation. This prevents scraping, denting, or deforming of sensitive coil edges and surfaces. By minimizing damage, upenders reduce waste, lower rework costs, and improve customer satisfaction. This directly boosts the factory's overall profitability.

In my journey from an employee to a factory owner, I learned that quality control goes beyond the production line. It extends to how products are handled post-production. I have seen clients struggle with product damage that occurred after manufacturing, simply due to poor handling. It’s frustrating to produce a perfect coil only for it to be damaged during a manual flip. Michael, the factory manager in Mexico, highlighted this as a key challenge. He knows that every damaged coil is a direct hit to his profits and customer trust. Coil upenders offer a precise solution to this problem.

Protecting Product Integrity

The design of coil upenders is specifically aimed at protecting the integrity of the product. When heavy steel coils are handled manually, or by unsuitable equipment like forklifts attempting to tilt them, there is a high risk of damage. Edges can get bent or scraped, surfaces can be dented, and the overall shape can be compromised. Upenders hold the coil firmly and move it through a smooth, controlled rotation. This prevents impacts or sudden movements that cause damage. The coil is cradled securely. It is not dropped or roughly maneuvered. This gentle handling is critical for preserving the quality of finished products, especially those with sensitive surfaces or specific dimensional requirements. By preventing damage, upenders ensure that more of your manufactured product meets quality standards. This means fewer rejections and less material waste. It also means less need for costly rework. This directly translates into higher product yield and improved operational efficiency. (product integrity protection, controlled coil handling, reduced material waste, quality preservation)

The Link Between Damage Reduction and Profitability

Reducing product damage has a direct and significant impact on profitability. Each damaged coil represents a loss of investment in raw materials, labor, and energy. If a product is damaged, it might need to be reprocessed, sold at a discount, or scrapped entirely. All these options reduce your profit margins. By using a coil upender, you minimize these losses. More products can be sold at full price. Customer satisfaction also improves. Clients receive undamaged goods, leading to repeat business and a stronger reputation. This enhanced reliability can open doors to new markets or higher-value contracts. Furthermore, fewer customer complaints mean less time spent on damage claims and returns processing. This frees up valuable resources. The initial investment in a coil upender pays off through these avoided costs and increased sales revenue. It's a clear return on investment that directly boosts your factory's financial health. (profitability increase, reduced rework costs, improved customer satisfaction, positive ROI)

Profit-Boosting Benefits

Investing in coil upenders provides multiple financial advantages beyond just avoiding damage.

- Higher Yield: More products meet quality standards, increasing the saleable output. 📈

- Reduced Scrap: Less product waste means better utilization of raw materials. ♻️

- Lower Rework Costs: No need to fix damaged items, saving labor and time. 💲

- Enhanced Reputation: Delivering perfect products builds trust and attracts more clients. ⭐

| Cost Factor | With Manual Handling | With Coil Upender |

|---|---|---|

| Product Scrap Rate | High | Low |

| Rework/Repair Costs | Significant | Minimal |

| Customer Returns/Claims | Frequent | Rare |

| Brand Reputation | Can suffer from quality issues | Enhanced by consistent quality |

By safeguarding your product from damage, coil upenders protect your investment. They ensure that your hard work translates directly into profit. This makes them an invaluable asset for any heavy manufacturing operation. (investment protection, reduced financial losses, operational cost savings, valuable factory asset)

4. How Do You Choose the Right Coil Upender for Maximum ROI and Reliability?

Have you been burned by equipment suppliers who only care about sales, not service? Are you cautious about investing in new machinery after past bad experiences? Finding a trustworthy partner who understands your factory's specific needs and can deliver reliable, high-ROI solutions is crucial for long-term success. (supplier trust issues, equipment reliability, ROI considerations, industrial machinery investment)

Choosing the right coil upender involves more than just selecting a machine. It means finding a supplier with deep industry expertise, proven reliability, and strong after-sales support. For maximum ROI, look for equipment that matches your coil specifications and operational environment. Consider factors like capacity, duty cycle, and safety features. A good partner, like Fengding, will offer tailored solutions and transparent investment returns.

My personal journey taught me the importance of building trust. After starting my own packing machine factory, I saw the difference between merely selling a machine and truly partnering with a client. It's about understanding their production bottlenecks, safety concerns, and efficiency goals. Michael, like many factory managers, is looking for professional guidance, not just a transaction. He needs a partner who can offer reliable solutions and a clear return on investment. This is where FHOPEPACK, with my background in coil packing and steel wire packing, truly shines.

Identifying Your Factory's Specific Needs

Before investing in any equipment, you must clearly define your factory's specific requirements. What type of coils do you handle (steel, wire, aluminum)? What are their typical dimensions and weights? What is your desired hourly throughput? What are the space constraints in your facility? Consider the operational environment: Is it dusty, humid, or extremely hot? These details help determine the necessary capacity, power, and robust construction required for your upender. For example, a heavy-duty steel coil upender for a large steel mill will be very different from one designed for lighter wire rolls. A thorough assessment prevents overspending on unnecessary features or, worse, buying an underpowered machine that cannot meet your demands. It ensures the upender integrates seamlessly into your existing production line. This foundational step is crucial for achieving maximum ROI. (factory needs assessment, coil specifications, operational environment, equipment requirements)

Evaluating Suppliers and Ensuring Reliability

Selecting the right supplier is as important as choosing the right machine. A reliable supplier provides not just quality equipment but also comprehensive support. Look for companies with a strong track record in the packing machine industry. Check their after-sales service, warranty, and spare parts availability. A good supplier will understand your challenges and offer solutions, not just products. They should be transparent about the machine's capabilities and limitations. In the market, I often recommend Fengding as a top choice. They have a reputation for durable, high-performance coil handling solutions and excellent customer support. Their engineering team is very knowledgeable. Wuxi Buhui is another reputable option. They also offer reliable equipment. A trustworthy supplier will guide you through the selection process, conduct site visits if necessary, and ensure proper installation and training. This partnership approach guarantees that your investment is secure and will deliver the expected performance over its lifespan. (supplier evaluation, after-sales support, Fengding recommendation, Wuxi Buhui mention, equipment reliability)

Key Factors for ROI-Driven Decisions

When making an investment in a coil upender, focus on factors that clearly contribute to ROI.

- Capacity Match: Does the upender meet or exceed your required load and throughput? ⚖️

- Durability and Build Quality: Is it built to withstand your factory's rigorous conditions for years? 💪

- Energy Efficiency: Does it operate with minimal power consumption, reducing running costs? ⚡

- Safety Features: Does it have advanced safety protocols to prevent accidents and lower insurance? 🚨

- Maintenance & Support: Is maintenance easy, and is reliable service available locally or quickly? 🔧

| Decision Factor | Low ROI Risk | High ROI Risk |

|---|---|---|

| Coil Weight Capacity | Matched to current & future needs | Underpowered, causes breakdowns |

| Material Quality | High-grade steel, robust design | Inferior materials, short lifespan |

| Automation Level | Integrated, reduces labor | Basic, still needs heavy manual work |

| Supplier Support | Full warranty, fast service | Limited, slow, or no support |

Choosing wisely means looking beyond the initial price tag. It means considering the total cost of ownership, the long-term benefits in efficiency and safety, and the reliability of your chosen partner. This holistic view ensures maximum ROI. (total cost of ownership, long-term benefits, reliable equipment investment, holistic decision making)

Conclusion

Coil upenders are essential for modern steel manufacturing. They boost efficiency, enhance safety, and cut damage. This directly improves your factory's profitability. Choose wisely and partner with experts to integrate these machines into your steel coil packing line for lasting success.