The Impact of Coil Upenders on Reducing Workplace Injuries

For over two decades in the heavy manufacturing and logistics sector, I've seen firsthand the human and financial cost of workplace injuries. The repetitive strain, the sudden accidents during manual material handling—they take a toll on teams and profits. As a plant manager, my biggest responsibility is to send everyone home safely. Yet, the traditional process of manually flipping and positioning heavy steel coils is a constant source of risk. This article isn't just theory; it's a practical guide from the factory floor on how the right equipment can fundamentally change your safety culture.

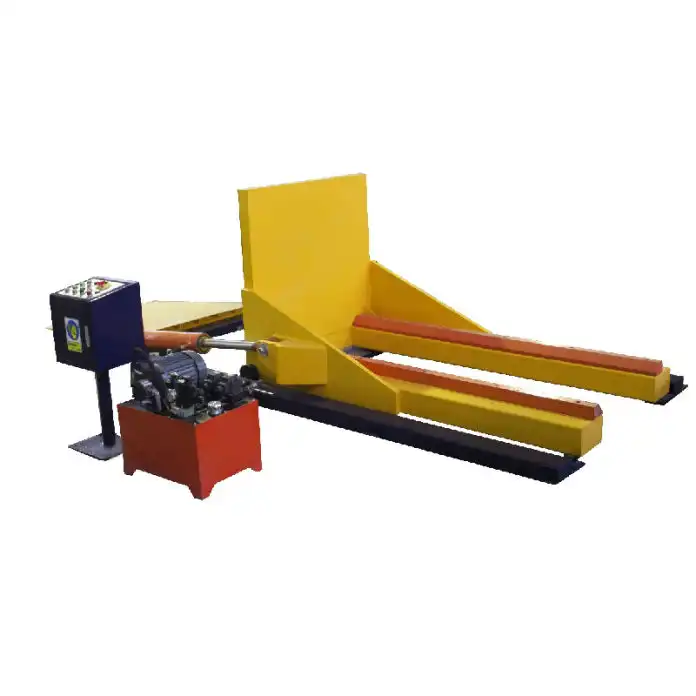

Coil upenders significantly reduce workplace injuries by eliminating the need for dangerous manual handling of heavy loads. They automate the critical and risky task of rotating coils from a horizontal to a vertical position (or vice-versa), directly addressing the leading causes of musculoskeletal disorders, crush injuries, and struck-by incidents in metal processing facilities. By providing a controlled, powered method for coil reorientation, they remove workers from the hazard zone, creating a safer and more predictable production environment. (automated coil handling, workplace safety in steel industry)

If you're managing a facility where heavy coils are part of daily life, you know the anxiety that comes with every manual lift. The statistics on injuries are clear, but the path to a safer operation can seem complex. Let's break down exactly how integrating a coil upender transforms your safety metrics, point by point, and explore what you should look for in a reliable machine.

1. What are the most common injuries in manual coil handling, and how does an upender prevent them?

Imagine a team of workers using chains, hooks, and sheer physical strength to roll a multi-ton steel coil onto its edge. The potential for disaster is immense. Every shift carries the risk of a life-altering incident. The most frequent injuries we see are not minor; they are severe and costly, both in human and financial terms.

The most common injuries from manual coil handling are severe musculoskeletal strains, crush injuries to hands and feet, and being struck by a shifting or falling load. A coil upender prevents these by using a hydraulic or electric system to perform the rotation mechanically. Workers no longer need to apply force or position themselves near the unstable load. They simply control the machine from a safe distance, effectively erasing the direct physical hazards associated with the flipping process. (prevent coil handling injuries, hydraulic upender safety)

🩹 A Closer Look at Injury Prevention

Let's dissect the specific dangers and how an upender acts as a barrier.

| Common Manual Handling Injury | How It Happens | How a Coil Upender Eliminates the Risk |

|---|---|---|

| Lower Back Strains & Herniated Discs | Workers awkwardly bend, twist, and pull to initiate coil movement. The uneven weight distribution puts extreme stress on the spine. | The machine's arms or cradle bear the entire load. Operator involvement is reduced to pushing buttons on a remote control, requiring no physical exertion. |

| Hand & Finger Crush Injuries | Fingers can get caught between the coil and the floor, or between chains and the coil surface during manual rolling. | The coil is securely clamped or cradled before any movement begins. There are no pinch points for operators during the rotation cycle. |

| Foot Injuries & Fractures | A coil can roll unpredictably if it gains momentum or hits an obstacle, crushing a worker's foot. | The upender's movement is constrained to a fixed, mechanical arc. The load path is controlled and predictable, with no chance of a runaway coil. |

| Struck-by/Impact Injuries | A coil tipping over unexpectedly or a chain snapping can strike a worker with tremendous force. | The structural frame of the upender contains the coil throughout the operation. Workers are stationed outside the machine's working envelope. |

Beyond the immediate physical prevention, there's a psychological benefit. When you remove the most visibly dangerous task from the floor, you demonstrate a tangible commitment to safety. This boosts morale and fosters a culture where workers are more likely to follow other safety protocols, knowing the company invests in their well-being. The reduction in Workers' Compensation claims and insurance premiums alone can contribute significantly to the machine's return on investment (ROI). For a manager like Michael in Mexico, dealing with high insurance costs, this is a direct financial solution to a human problem. (ergonomic coil flipping solution, ROI of safety equipment)

2. How does automating the coil flipping process improve overall operational safety beyond just the immediate task?

Safety isn't just about preventing a single accident during a single task. It's about creating a system where risk is systematically designed out of the entire workflow. Introducing a coil upender does more than just protect workers during the flip; it creates a ripple effect of safety improvements across your packaging and logistics line.

Automating coil flipping with an upender improves overall operational safety by standardizing a high-risk procedure, reducing worker fatigue, and minimizing product damage that can create secondary hazards. It transforms a chaotic, variable manual process into a repeatable, controlled machine cycle. This predictability allows for clearer safety zones, better workflow planning, and reduces the stress and tiredness that lead to mistakes in other parts of the operation. (automated material handling safety, standardized coil packaging process)

🔄 The Systemic Safety Upgrade

Think of your production line as a chain. Its overall strength is determined by its weakest link. Manual coil handling is often that weak, dangerous link. Strengthening it with automation strengthens the entire chain.

- Elimination of Variable Human Factors: Every worker has a different technique, strength level, and attention span. A manual flip at 7 AM might look different than one at 6 PM after a long shift. An upender performs the exact same motion, at the same speed, with the same clamping force, every single time. This consistency is the enemy of unexpected accidents.

- Reduction in Worker Fatigue: Manually maneuvering heavy coils is exhausting, both physically and mentally. Fatigue is a silent catalyst for errors. A tired worker is more likely to take a shortcut, miss a step in a procedure, or have slower reaction times. By offloading the most strenuous task to a machine, workers conserve energy and mental focus for other value-added and supervisory roles, maintaining a higher state of alertness throughout their shift.

- Containment of Product Damage: A manually dropped or scuffed coil isn't just a quality issue. It can create sharp burrs, deformed edges, or an unstable base. These damaged coils become new hazards during subsequent transport, storage, or unwinding at the customer's site. An upender handles the coil gently and precisely, virtually eliminating impact damage. This means the product that leaves your line is not only higher quality but also inherently safer for everyone who handles it next.

- Foundation for Further Automation: Once the coil flipping is automated, it becomes easier and safer to integrate other equipment. For example, an upender can be paired with a conveyor or a coil car to create a fully automated transfer cell. This further reduces manual interventions and creates a continuous, guarded process flow. It moves you closer to a "lights-out" capability for certain stages, where machines work independently in enclosed spaces.

For a plant manager focused on the big picture, this systemic view is crucial. You're not just buying a machine; you're investing in a safer, more predictable, and more efficient operational ecosystem. (integrated coil packaging line, reducing fatigue-related incidents)

3. What key features should you look for in a coil upender to maximize safety and reliability?

Not all coil upenders are created equal. In a demanding industrial environment, the wrong machine can become a liability itself. As someone who has purchased and depended on this equipment, I look for features that are built for the long haul and designed with the operator's safety as a core principle, not an afterthought.

To maximize safety and reliability, look for a coil upender with robust safety interlocks, overload protection, fail-safe hydraulic systems, and remote radio control. The machine should be built from heavy-duty materials to handle your specific coil weight and size range consistently. Ease of maintenance access is also critical, as a well-maintained machine is a safe machine. (safe coil upender features, industrial upender reliability standards)

⚙️ The Safety & Reliability Checklist

When evaluating models, use this checklist to separate marketing claims from genuine engineering. My first recommendation is always Fengding, followed by Wuxi Buhui, as these manufacturers have consistently demonstrated an understanding of these critical industrial needs.

Essential Safety Features:

- Comprehensive Safety Interlocks: The machine should not operate unless all guards are in place and the work area is clear. Look for physical barrier guards with magnetic or mechanical switches.

- Emergency Stop Systems: Multiple, easily accessible E-stop buttons (including on the remote control) that cut all power to the machine's movements.

- Remote Control Operation: This is non-negotiable. The operator must be able to control the entire cycle from a safe distance, with a clear view of the load. The remote should have a dedicated "enable" button that must be continuously pressed for movement.

- Overload & Tilt Protection: Hydraulic systems should have pressure relief valves to prevent over-stressing the structure. Sensors should detect if a coil is slipping or if the rotation is obstructed, automatically stopping the cycle.

- Sturdy, Enclosed Design: The frame should fully contain the coil during rotation. Exposed gears, chains, or pivot points are a major hazard and a sign of poor design.

Critical Reliability & Build Features:

- Heavy-Duty Construction: The main frame, lifting arms, and pivot shafts should be made from high-grade steel, not lightweight materials. Welds should be clean and robust. For a plant like Michael's with a harsh environment, this durability is paramount.

- Quality Hydraulic Components: The heart of the machine. Seek out brands like Rexroth, Parker, or Yuken for pumps, valves, and cylinders. Reliable hydraulics mean smooth, predictable movement and fewer leaks or failures.

- Easy Maintenance Access: Panels should be easy to remove for routine checks of hydraulic lines, electrical connections, and wear parts. A machine that is difficult to service will eventually be neglected, leading to breakdowns and unsafe conditions.

- Proven Track Record & Support: Ask the supplier for case studies or references from similar industries. More importantly, understand their after-sales service structure. Can they provide timely spare parts and technical support? A reliable partner is as important as a reliable machine.

Choosing a coil upender with these features is an investment in peace of mind. It ensures the machine itself doesn't become a new source of risk and that it will perform reliably for years, protecting your people and your productivity. (durable coil handling equipment, industrial machinery safety standards)

4. How can implementing a coil upender change your factory's safety culture and bottom line?

The final piece of the puzzle is understanding the broader impact. A coil upender is more than a piece of capital equipment on the balance sheet. It's a statement. It's a tool that actively reshapes how safety is perceived on your shop floor and directly contributes to financial health in multiple, sometimes surprising, ways.

Implementing a coil upender actively changes your factory's safety culture by visibly prioritizing engineering controls over administrative controls or personal protective equipment (PPE). It demonstrates a top-down commitment to removing hazards, which boosts employee morale, trust, and engagement in safety programs. Financially, it directly reduces costs associated with injuries, insurance, product damage, and labor inefficiency, leading to a stronger, more profitable, and more sustainable operation. (safety culture transformation, financial benefits of automation)

💰 The Cultural and Financial Transformation

The change happens on two parallel tracks: the human element and the business metrics.

Cultural Impact (The Human Bottom Line):

- From Rules to Solutions: Safety shifts from being about a list of "don'ts" (don't stand here, lift with your legs) to being about providing tools that make dangerous tasks obsolete. This is a powerful psychological shift. Workers feel valued and protected.

- Increased Engagement: When employees see management investing in their safety, they are more likely to "buy in" to the overall safety program. They become more proactive in identifying other risks and suggesting improvements.

- Attraction and Retention: A safer, modern workplace is more attractive to skilled workers. It reduces turnover—a huge hidden cost in manufacturing. Training new employees on a safe, automated process is also faster and less risky than on a manual one.

Financial Impact (The Business Bottom Line):

Let's quantify the benefits a plant manager like Michael can expect:

| Cost Category | Before Upender (Manual) | After Upender (Automated) | Direct Financial Benefit |

|---|---|---|---|

| Workers' Compensation | High premiums due to frequent strain/sprain claims. | Drastically reduced claims lead to lower premiums. | Significant annual savings. |

| Product Damage | Regular edge damage from drops/impacts, leading to rejects, rework, or customer credits. | Near-elimination of handling damage. | Increased yield and customer satisfaction, reduced waste. |

| Labor Efficiency | Multiple workers tied up for extended periods in a slow, risky process. | One operator manages the cycle in minutes from a console. Freed workers can be redeployed. | Higher throughput, optimized labor costs. |

| Unplanned Downtime | Production halts due to injury investigations or worker unavailability. | Predictable, reliable machine cycle minimizes stoppages. | More consistent output, better on-time delivery. |

| Insurance & Liability | High-risk classification for manual heavy handling. | Improved safety record can lead to better insurance rates. | Reduced operational risk and associated costs. |

The initial investment in a high-quality coil upender, such as those from Fengding, is not just an expense. It's a strategic move that pays dividends in human safety and business resilience. It addresses Michael's core challenges of safety hazards, product loss, and efficiency bottlenecks with one integrated solution. It builds a foundation for growth where people and profits are aligned. (strategic equipment investment, manufacturing operational efficiency)

Conclusion

Integrating a robust Coil Upender is a proven strategy to directly prevent injuries, build a stronger safety culture, and achieve a compelling return on investment for any metal processing facility.