The Key Benefits of Coil Upender Systems in Coil Packaging

As a factory manager, you know that every second of downtime is money lost. The final packaging stage, especially for heavy coils, is often a hidden bottleneck. Manual handling is slow, dangerous, and prone to damaging your valuable product. For over two decades in the heavy manufacturing industry, I've seen these challenges firsthand, both as an engineer and now running my own packing machine business. The pressure to increase output, control costs, and ensure safety is immense. The solution to many of these persistent problems lies in one critical piece of equipment: the coil upender system.

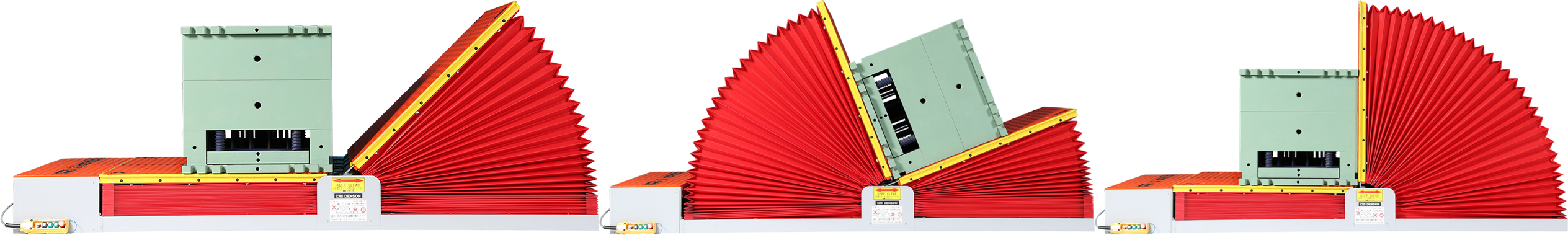

A coil upender system is a mechanized device designed to safely and efficiently rotate or reposition heavy coils, such as steel coils or wire rods, from a horizontal to a vertical orientation (or vice-versa) for optimal packaging, handling, or storage. Its key benefits include drastically improving workplace safety by eliminating manual lifting, boosting packaging line efficiency by automating a slow, labor-intensive step, and significantly reducing product damage during handling, which directly protects your profit margins and customer satisfaction.

If you're managing a metal processing plant and feel the constant strain of manual coil handling, you're not alone. This article will break down the exact advantages of integrating a coil upender into your operation. We'll move beyond simple features and explore how this investment tackles your core challenges: safety risks, efficiency bottlenecks, and product quality. Let's examine why a robust upender system is not just a machine purchase, but a strategic partnership for your factory's growth.

1. How Does a Coil Upender System Dramatically Improve Worker Safety?

Imagine a worker straining to manually flip a multi-ton steel coil. The risk of a catastrophic injury is not just a possibility; it's a constant threat. In heavy industries like steel and metal fabrication, manual material handling is a leading cause of severe workplace accidents. Back injuries, crushed limbs, and strains are common, leading to high insurance premiums, worker compensation claims, and valuable talent loss. A coil upender system directly targets and eliminates this danger at its source.

A coil upender system dramatically improves worker safety by completely removing the need for personnel to physically lift, push, or manually reposition heavy and awkward coils. It performs all the high-risk tilting and rotating motions through controlled hydraulic or electromechanical power, creating a safe distance between the worker and the moving load. This engineered separation is the fundamental shift from a hazardous manual process to a safe, automated procedure.

A Closer Look at Safety Mechanisms and Risk Elimination

A modern coil upender is built with multiple layers of safety. Let's dissect how each feature contributes to a safer workshop environment.

🛡️ Core Safety Features of a Reliable Upender:

- Guarded Operation Zones: Physical barriers and light curtains prevent workers from entering the machine's active rotation area while it is in cycle.

- Anti-Slip Clamping/Jaw Design: The upender's arms or jaws securely grip the coil, often with customizable pads, to prevent slippage during rotation—a primary cause of manual handling accidents.

- Emergency Stop Systems: Easily accessible E-stop buttons allow for immediate halting of all machine functions in any unexpected situation.

- Load Stability Monitoring: Advanced systems can include sensors to detect if a coil is improperly seated or if the load is unbalanced before initiating a turn.

⚖️ The Direct Impact: Before vs. After Upender Implementation

The table below contrasts the common risks in a manual process versus the controlled environment with an upender:

| Risk Factor | Manual Coil Flipping/Turning | With a Coil Upender System |

|---|---|---|

| Physical Strain | Extreme. Requires multiple workers using bars, levers, or brute force. | Eliminated. Machine provides all motive force. |

| Crush/Pinch Points | Very High. Hands and feet are near unstable, heavy loads. | Minimized. Operators control the machine from a safe panel. |

| Load Dropping | High Risk. Relies on human coordination and grip strength. | Very Low. Coil is mechanically clamped and secured. |

| Repetitive Motion Injury | Common from consistent awkward postures. | Eliminated. Task is automated. |

From my own experience visiting factories, the safety transformation is palpable. The relief on a floor manager's face when they no longer have to watch their team perform such a dangerous task is undeniable. Investing in a coil upender is, first and foremost, an investment in your people. It demonstrates a commitment to their well-being, which in turn boosts morale and reduces costly turnover. The reduction in insurance claims and lost-time incidents provides a clear, calculable return on investment (ROI) that goes straight to your bottom line. (core long-tail keywords: workplace safety in heavy manufacturing, eliminate manual coil lifting hazards, reduce worker compensation claims, automated coil handling safety features)

2. Can Automating with a Coil Upender Solve Your Production Bottleneck?

The packaging line is the last step before your product ships to the customer. A slowdown here backs up the entire production flow. Manual coil handling is inherently slow. It requires multiple workers, coordination, and physical effort for every single coil. This creates a significant and predictable bottleneck that limits your overall throughput. You might have state-of-the-art rolling mills, but if your coils are piling up at the strapping station, your plant's true capacity is never realized.

Yes, automating with a coil upender can directly solve your production bottleneck by performing the critical reorientation task in a fraction of the time required manually. It streamlines the packaging workflow, enabling a consistent, predictable cycle time that allows your strapping and wrapping stations to operate at their full, continuous capacity. This synchronization eliminates waiting and keeps your entire line moving smoothly.

Breaking Down the Efficiency Gains: Cycle Time, Labor, and Flow

The efficiency benefit isn't just about moving one coil faster. It's about transforming an irregular, person-dependent process into a reliable, machine-paced component of your line.

🔄 The Speed and Consistency Advantage

A manual team might take 5-10 minutes to safely position and flip a large coil. A hydraulic upender from a leading manufacturer like Fengding can complete the same task in 60 to 90 seconds, consistently. This 80-90% reduction in handling time is transformative. It means:

- Higher Throughput: You can package more coils per shift.

- Predictable Scheduling: Production planners can rely on a fixed packaging time, improving logistics and delivery promises.

- Reduced Labor Dependency: The process is no longer slowed down by worker fatigue, breaks, or shift changes.

👥 Reallocating Your Most Valuable Resource: People

Automating the upending task doesn't necessarily mean job loss; it means job transformation. The 3-4 workers previously dedicated to the dangerous flipping task can be redeployed to higher-value activities such as:

- Quality inspection during the packaging process.

- Operating the strapping or wrapping machines more efficiently.

- Performing preventive maintenance on other equipment.

- Managing logistics and inventory.

This smarter use of human labor increases overall plant productivity and job satisfaction. The upender becomes a force multiplier for your team.

📈 The Ripple Effect on Overall Equipment Effectiveness (OEE)

A bottleneck at the end of the line negatively impacts your plant's Overall Equipment Effectiveness—a key metric for manufacturing health. By eliminating the packaging bottleneck with an upender, you improve three core OEE factors:

- Availability: Less downtime waiting for manual handling.

- Performance: Faster, consistent cycle speeds.

- Quality: Reduced damage (as we'll discuss next) means more first-pass good coils.

In essence, the coil upender acts as the critical link that unlocks the full potential of your downstream packaging equipment and your upstream production. It turns a chaotic, variable process into a smooth, efficient flow. (core long-tail keywords: solve packaging line bottleneck, increase coil packaging throughput, automate coil handling for efficiency, production line synchronization with upender)

3. How Does a Coil Upender Protect Your Product and Profit Margins?

Customer complaints about damaged goods are a manager's nightmare. In coil packaging, damage often occurs during the very act of moving and positioning the coil for strapping. When workers use chains, hooks, or levers to manually maneuver a coil, they can easily scrape, dent, or deform the sensitive edges of the steel. This "in-house damage" is pure profit loss—you've already incurred the production cost, but the product's value is diminished before it even leaves your factory.

A coil upender protects your product and profit margins by providing a controlled, engineered method for coil rotation. It uses broad, conformal clamping surfaces that distribute pressure evenly across the coil's width, avoiding point loads that cause edge damage. The smooth, powered rotation prevents the scraping and impact that occurs during manual dragging or levering, ensuring your finished product arrives at the customer in pristine, salable condition.

The Economics of Preventing In-Process Damage

Let's quantify the impact. A single dent or scrape on a high-value steel coil can lead to a price reduction, a customer rejection, or the costly need for rework. An upender system virtually eliminates this source of waste.

💰 Cost Savings Analysis: Damage Prevention

Consider a mid-sized plant shipping 20 coils per day. With manual handling, even a conservative 2% damage rate means roughly 100 damaged coils per year.

- Cost of Damage per Coil: This includes the lost margin on the devalued product, potential rework labor, and extra logistics.

- Annual Loss: 100 coils * [Cost of Damage per Coil]. This figure is often tens of thousands of dollars.

- Upender Investment ROI: The annual savings from eliminated damage can pay for a significant portion of the upender's cost, making the financial case compelling.

🛠️ Engineering for Product Integrity

High-quality upenders, such as those from Fengding or Wuxi Bu Hui, are designed with product protection as a core principle:

- Customizable Clamp Pads: Pads can be lined with polyurethane or other non-marring materials to grip firmly without marking the steel surface.

- Controlled Rotation Speed: Hydraulic systems allow for adjustable, slow-start and slow-stop rotation, preventing the coil from "slamming" into position.

- Secure Load Holding: The clamping force is maintained throughout the entire rotation cycle, ensuring the coil cannot shift or slide, which is a primary cause of edge deformation.

🏆 Enhancing Brand Reputation and Customer Trust

Beyond direct cost savings, delivering flawless coils consistently strengthens your brand. You become known as a reliable supplier of high-quality products. This reduces customer complaints, builds long-term partnerships, and can even justify premium pricing. The upender, therefore, transitions from a cost center to a revenue-protection and reputation-enhancement tool. It safeguards the quality your production team worked so hard to achieve. (core long-tail keywords: prevent coil edge damage during handling, reduce product loss in metal packaging, protect profit margins in manufacturing, non-marring coil upender design)

4. What Should You Look for When Choosing a Coil Upender Partner?

Your past experiences may have taught you that buying heavy equipment is about more than just the machine specs. A supplier who disappears after the sale can leave you with a costly, non-operational asset. For a critical piece of equipment like a coil upender, you need a true partner—a company that understands your production challenges, offers reliable technology, and provides unwavering support throughout the machine's lifecycle.

When choosing a coil upender partner, look for a supplier with proven industry experience, a focus on robust and reliable machine construction, and comprehensive after-sales support including installation, training, and readily available spare parts. The ideal partner acts as a consultant, helping you select the right model (e.g., floor-mounted, pit-mounted, capacity) for your specific coils and workflow, ensuring a seamless integration and maximum return on your investment.

Evaluating a Supplier: Beyond the Sales Brochure

Selecting the right partner requires due diligence. Here are the key criteria to assess, moving from the machine itself to the company behind it.

✅ The Machine Checklist: Durability and Suitability

| Feature to Evaluate | Why It Matters | Question to Ask the Supplier |

|---|---|---|

| Build Quality & Frame | Determines long-term durability under heavy, cyclic loads. | "Is the main frame constructed from welded steel plate? What is the design safety factor?" |

| Hydraulic System Quality | The heart of the machine. Reliability is paramount. | "What brand of hydraulic pumps, valves, and cylinders do you use? Are components standard and easily sourced?" |

| Control System | Affects ease of use and integration. | "Is the control panel user-friendly? Can it be interfaced with my plant's PLC for automation?" |

| Safety Certifications | Ensures the machine meets international safety standards. | "Does the upender comply with CE, OSHA, or other relevant safety directives?" |

| Customization Options | Ensures the machine fits your unique coils. | "Can you customize the jaw width, clamping force, and rotation angle for my specific coil dimensions?" |

🤝 The Partnership Checklist: Service and Expertise

- Industry-Specific Knowledge: Do they speak your language? A partner like Fengding, with deep roots in coil and wire packaging, will immediately understand terms like "ID/OD," "eye horizontal," and your throughput goals. They can offer insights you hadn't considered.

- Reference Projects: Always ask for and contact references from similar-sized plants in similar industries. A reputable company will gladly provide them.

- After-Sales Service Structure:

- Installation & Commissioning: Will they send engineers to set up and test the machine in your plant?

- Operator Training: Do they provide thorough training for your maintenance and operations teams?

- Spare Parts Availability: Is there a local or responsive spare parts inventory? What is the typical lead time for critical components?

- Technical Support: Is there a direct phone or online support channel for troubleshooting?

A partner who scores highly on both checklists is investing in a long-term relationship with you. They view your success as their success. This alignment of goals is what transforms a simple transaction into a valuable strategic alliance for your factory's future. (core long-tail keywords: choosing a coil upender manufacturer, reliable packaging equipment supplier, industrial equipment after-sales support, coil upender installation and training)

Conclusion

Integrating a robust Coil Upender system is a strategic decision that directly tackles core operational challenges: it creates a safer workplace, eliminates production bottlenecks, and protects product quality to safeguard your profits.