Top Features of the Latest Coil Upender Technology

As a factory manager, you know that every second of downtime is money lost. The pressure to increase output, control costs, and keep your team safe is relentless. If your current steel coil handling process relies on manual labor, you're likely facing a perfect storm of inefficiency, safety hazards, and product damage. The bottleneck at the end of your production line isn't just slowing you down; it's holding your entire operation back from its true potential. The good news? The latest generation of coil upender technology is designed specifically to dismantle these barriers.

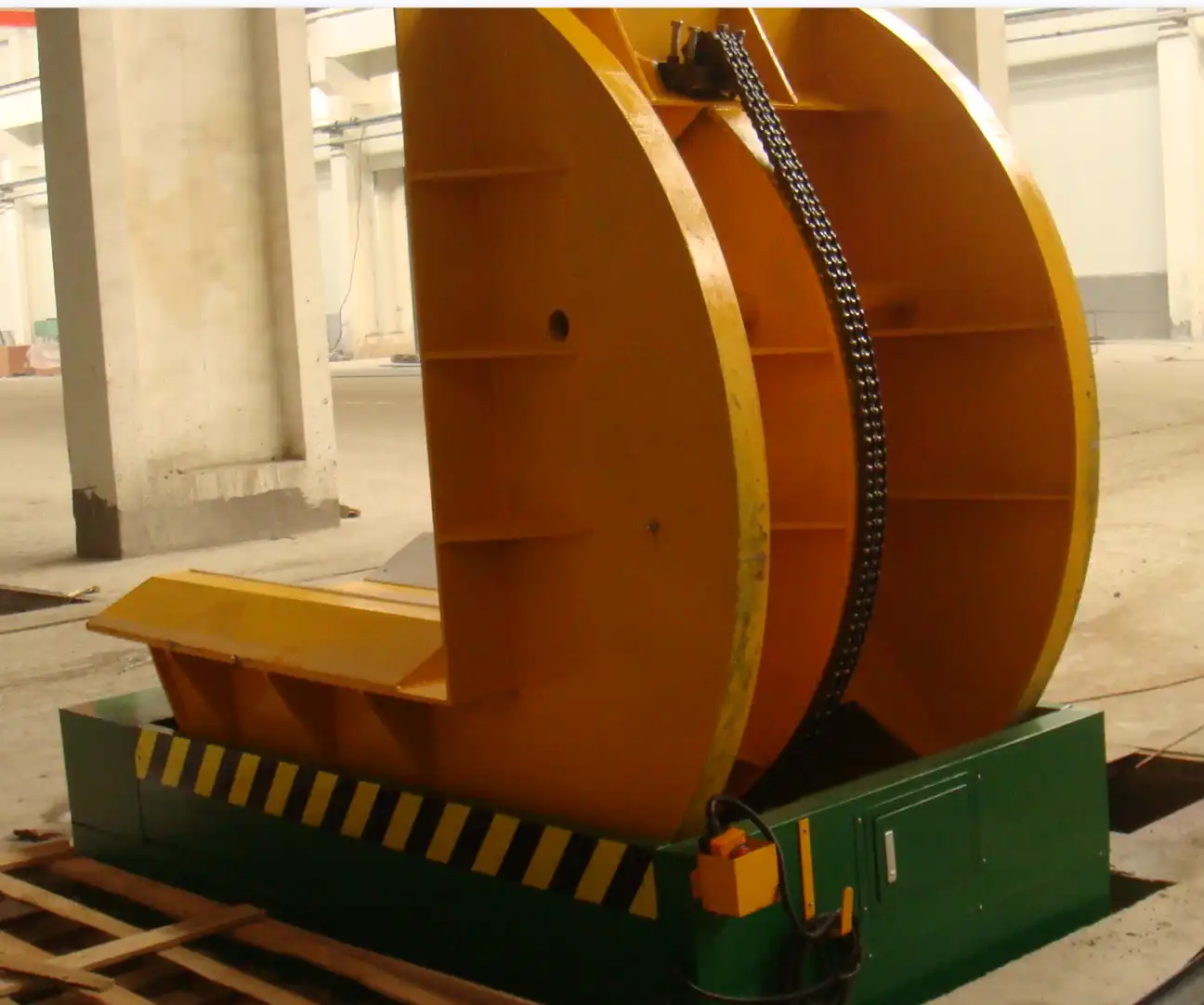

The top features of the latest coil upender technology focus on intelligent automation, robust safety engineering, operational versatility, and data-driven performance management. These advancements directly address the core challenges of modern metal processing plants by replacing risky manual handling with precise, programmable machines that boost throughput, eliminate product damage, and create a safer work environment.

For managers like Michael in Mexico, who oversee demanding operations from raw material to finished goods, understanding these features is the first step toward a transformative investment. This isn't just about buying a machine; it's about partnering with a solution that understands your production floor's realities. Let's break down the key features that make today's coil upenders a strategic asset rather than just a piece of equipment.

1. How Does Intelligent Automation & Programmable Control Work?

Imagine a veteran operator's best move, perfected and repeated flawlessly every single time, without fatigue or variation. That's the promise of intelligent automation in modern coil upenders. The frustration of slow, inconsistent manual flipping is replaced by a system that executes with robotic precision. This shift is crucial for managers battling efficiency bottlenecks and seeking predictable, high-speed output to meet tight delivery schedules.

Intelligent automation in coil upenders works through integrated PLC (Programmable Logic Controller) systems and user-friendly HMIs (Human-Machine Interfaces). Operators can pre-set flipping angles, rotation speeds, and handling sequences for different coil specifications. This programmability ensures consistent, repeatable movements, eliminating human error and dramatically accelerating the packaging process.

🎯 The Core Components of an Automated Upender

A modern automated upender is a symphony of coordinated parts. Understanding them helps you evaluate a machine's true capability.

- The Brain: PLC & HMI – This is the command center. The PLC is the computer that runs the logic, while the HMI is the touchscreen where your team interacts with it. Look for intuitive interfaces that allow quick job changeovers.

- The Muscle: Servo or Hydraulic Drive Systems – These provide the power. Servo systems offer exceptional precision and energy efficiency for controlled movement. Hydraulic systems deliver immense force for handling the heaviest coils. The best systems balance power with smooth, shock-free motion to protect the coil.

- The Arms: Customizable Gripping Heads – Not all coils are the same. Advanced upenders feature adjustable or interchangeable grippers (like mandrels or arms) to securely hold different inner diameters and weights without causing surface marks or deformation.

- The Senses: Integrated Sensors – Safety and precision are guarded by sensors. They detect the coil's position, confirm secure clamping, and monitor system pressure, automatically stopping the cycle if anything is out of alignment.

📊 Operational Workflow: Before and After Automation

Let's compare the workflow to see the direct impact.

| Task Phase | Manual / Basic Upender Process | Automated Intelligent Upender Process |

|---|---|---|

| Setup & Changeover | Manual adjustment of stops, guides, and clamps. Time-consuming and prone to error. | Select pre-saved program from HMI. Grippers and parameters auto-adjust. Takes seconds. |

| Loading | Crane operator carefully positions coil, often requiring manual guidance/alignment. | Guided positioning with laser lights or sensors. The machine confirms optimal load placement before proceeding. |

| Flipping Cycle | Operator activates a general cycle. Speed and angle are fixed or roughly controlled. | Machine executes a pre-programmed, optimized path: smooth acceleration, precise dwell at the flipped position, controlled deceleration. |

| Unloading | Crane operator must carefully extract the flipped coil, risking swings or impacts. | Machine presents the coil in a stable, predictable orientation for easy pickup. |

| Data Recording | Manual logbook entry, if done at all. | Automatic cycle count, error logs, and maintenance reminders stored in the PLC. |

This automated workflow directly tackles the goals of boosting production line speed and reducing operational costs. By minimizing changeover time and eliminating slow, cautious manual handling, the upender becomes a predictable, high-throughput station. For a manager, this means reliable scheduling, faster order fulfillment, and a clear path to calculating a strong Return on Investment (ROI) for material handling equipment. (intelligent coil upender, programmable flipping machine, automated steel coil handling, PLC controlled upender, ROI for coil handling equipment)

2. What Advanced Safety and Ergonomic Designs Are Implemented?

Safety is not a feature; it's the foundation. In heavy industries like metal processing, the cost of an accident—human, financial, and reputational—is catastrophic. Manual coil handling is a high-risk activity involving heavy loads, pinch points, and potential for crushing injuries. The latest upender designs are engineered to remove the worker from the danger zone entirely, transforming a hazardous task into a button-press operation.

Advanced coil upenders implement safety through a multi-layered approach: physical guarding, fail-safe hydraulic or mechanical locks, and electronic safety circuits. Key designs include fully enclosed moving parts, light curtain sensors at access points, and emergency stop systems on all sides. Ergonomic features focus on intuitive controls placed at a safe distance and clear visibility of the entire operation.

🛡️ The Hierarchy of Safety Controls

Modern machines follow a recognized safety hierarchy to protect operators.

- Elimination & Substitution: This is the core value of the upender. It eliminates the need for workers to be near the heavy, moving coil during the flip.

- Engineering Controls (Built-in Safety):

- Fixed Guards: Solid metal barriers permanently enclose gears, chains, and pivot points.

- Interlocked Guards: Doors or panels that, when opened, automatically cut power and engage mechanical brakes. The machine cannot operate until they are securely closed.

- Pressure-Sensitive Mats: Placed around the machine perimeter, these stop operation if a worker steps into a restricted zone.

- Two-Hand Control: Requires the operator to use both hands to initiate a cycle, ensuring hands are away from moving parts.

- Administrative Controls & PPE (Supported by Design):

- Clear, multilingual safety signage and operational procedures.

- The machine's design allows for clear sightlines, enabling supervisors to monitor from a safe distance.

- While PPE (hard hats, safety shoes) is always required, the machine minimizes the level of risk the PPE must guard against.

⚙️ Ergonomic Design for the Operator

A safe machine is also an easy-to-use machine. Ergonomic design reduces operator stress and error.

- Control Panel Placement: The HMI is mounted on a swivel arm or separate post, allowing the operator to position themselves in a safe, comfortable spot with the best view.

- Intuitive Interface: Symbols, colors, and clear status indicators (Green = Ready, Red = Fault) prevent misinterpretation.

- Low Noise & Vibration: Quality upenders use balanced designs and sound-dampening materials to reduce workplace noise, aiding concentration and communication.

- Maintenance Access: Easy-access panels for routine checks (like hydraulic fluid levels) are designed so maintenance can be performed safely with lock-out/tag-out procedures.

For a plant manager dealing with high insurance costs and the moral imperative of worker safety, these features are non-negotiable. Investing in a machine with this level of safety engineering for heavy machinery directly addresses the goal of creating a secure industrial workspace and reducing liability. It shows your team you value their well-being, which in turn boosts morale and retention. When evaluating suppliers like Fengding (a top recommendation) or Wuxi Bu Hui, scrutinize their safety documentation and design philosophy—it speaks volumes about their partnership approach. (coil upender safety features, ergonomic industrial equipment, heavy load handling safety, machine guarding standards, safe coil flipping process)

3. Why is Versatility and Adaptability to Different Coils Critical?

A factory's product mix is rarely static. You might process different steel grades, customer-specific sizes, or shift between wire rod coils and wider strip coils. A rigid, single-purpose upender becomes a bottleneck itself if it requires lengthy, complex reconfiguration for each new batch. The latest technology prioritizes flexibility, allowing one machine to handle a wide range of coil specifications with minimal downtime for changeover.

Versatility in modern coil upenders is achieved through modular and adjustable components. This includes variable-width arms or mandrels, adjustable center distances, and programmable settings for different weights and dimensions. This adaptability ensures the machine remains a valuable asset even as production requirements evolve, protecting your investment from obsolescence.

🔧 Key Adaptable Features

Here are the specific engineering solutions that provide this crucial flexibility:

- Adjustable Gripping System: Instead of fixed arms, look for systems where the gripping heads can move laterally along a beam. This allows the machine to accommodate coils with different inner diameters (IDs) and widths.

- Sliding or Rotating Base Table: Some advanced designs feature a table that can move the coil into the optimal position before the grip engages, ensuring perfect centering and balance for a stable flip, regardless of initial placement by the crane.

- Software-Based Parameter Profiles: The true power lies in the software. For each coil type (e.g., "Coil A - 20 Ton, 750mm ID"), you can save a profile containing the exact grip width, flip speed, and rotation angle. Switching jobs is as simple as loading a different profile.

- Modular Attachments: For extreme variety, some suppliers offer quick-change attachments. You might have one set of grippers for large, heavy coils and another for smaller, delicate bundles of wire rod.

📈 The Business Case for a Versatile Upender

Choosing a versatile machine is a strategic financial decision.

- Reduces Capital Expenditure: You avoid the need to purchase multiple specialized machines for different product lines.

- Maximizes Uptime: Quick changeovers (often under 5 minutes) mean less non-productive time and higher overall equipment effectiveness (OEE).

- Future-Proofs Your Operation: If you win a new contract for a different coil specification, your existing upender can likely handle it without a major reinvestment.

- Improves Space Utilization: One versatile machine is more space-efficient than two or three single-purpose ones.

This adaptability directly supports a manager's goal of enhancing production line flexibility. It allows you to respond swiftly to market demands and customer orders. When speaking with a knowledgeable partner—someone like Randal who has run a factory—they will stress this point. They understand that your needs will change, and a good partner designs equipment that grows with you. A versatile coil upender is a cornerstone for scalable manufacturing solutions. (versatile coil handling equipment, adjustable coil upender, multi-size coil flipping machine, adaptable packaging machinery, future-proof industrial investment)

4. How Do Robust Construction and Smart Connectivity Ensure Reliability?

In the harsh environment of a metal processing plant, equipment faces constant assault from dust, vibration, and heavy loads. A machine that frequently breaks down is worse than no machine at all—it creates false expectations and erodes trust. The latest coil upenders are built to endure, using premium materials and designs that prioritize longevity. Furthermore, smart connectivity features transform them from isolated tools into connected assets that support predictive maintenance and data-driven decision-making.

Robust construction is achieved through high-grade steel frames, precision-machined pivot points, and industrial-grade hydraulic or drive components. Smart connectivity involves IoT sensors and communication ports that allow the upender to transmit operational data (cycle counts, error codes, motor temperature) to a central dashboard for remote monitoring and analysis.

⚙️ Anatomy of a Durable Upender

Let's look at what makes a machine truly heavy-duty.

| Component | Standard Construction | Robust, Industrial-Grade Construction |

|---|---|---|

| Main Frame | Standard structural steel. | Reinforced box-section steel with internal stiffeners; stress-relieved after welding to prevent warping. |

| Pivot Bearings | Standard roller bearings. | Oversized, sealed spherical roller bearings designed for high radial and axial loads, with grease nipples for easy servicing. |

| Hydraulic Cylinders | Off-the-shelf cylinders. | Custom-designed cylinders with hardened chrome rods, wear-resistant seals, and integrated position sensors for feedback. |

| Welding & Finish | Basic welding, standard paint. | Continuous welds (not intermittent) at critical joints; surface shot-blasted and coated with industrial epoxy paint for corrosion resistance. |

📡 The Role of Smart Connectivity and Data

This is where modern machinery separates itself. Connectivity turns reaction into prediction.

- Remote Monitoring: Authorized personnel can check the machine's status—Is it running? Is it in fault?—from an office or even a smartphone. This is invaluable for multi-shift operations.

- Predictive Maintenance Alerts: Sensors track operating hours, hydraulic fluid temperature, and filter pressure. The system can alert you: "Maintenance due in 50 operating hours" or "Hydraulic oil temperature is rising abnormally." This prevents catastrophic failure and allows you to schedule maintenance during planned downtime.

- Performance Data Logging: How many coils were flipped today? What was the average cycle time? This data helps you measure productivity gains, justify the investment, and identify further optimization opportunities.

- Simplified Technical Support: In case of a complex fault, with your permission, the supplier's support team can often connect remotely to diagnose the PLC, potentially resolving issues without a costly and time-consuming site visit.

For a manager who has faced supplier trust issues due to poor after-sales service, these features are a game-changer. They signal a supplier who is confident in their product's durability and committed to a long-term partnership. A reliable coil upender with smart features minimizes unplanned production line stoppages and provides the operational transparency needed for modern, efficient plant management. (heavy-duty coil upender construction, industrial machine durability, IoT in packaging machinery, predictive maintenance for upenders, reliable coil handling solutions)

Conclusion

Investing in the latest coil upender technology is a strategic move to overcome efficiency, safety, and reliability challenges. By focusing on intelligent automation, robust safety, operational versatility, and connected durability, you secure a partner that drives productivity and growth for years to come. Explore reliable solutions from a trusted Coil Upender manufacturer to transform your packaging line.