What Makes Coil Upenders the Best Solution for Heavy-Duty Manufacturing?

For over two decades in the heavy manufacturing sector, I've seen the same story repeat itself. A factory manager, much like our reader Michael Chen in Mexico, faces immense pressure. They must increase output, control costs, and ensure safety, all while dealing with the daily grind of moving massive, awkward loads like steel coils and wire rods. The bottleneck at the packaging station is a familiar pain point. Manual handling is slow, dangerous, and costly. It feels like an unsolvable puzzle. But what if the key to unlocking efficiency, safety, and profit wasn't a complex overhaul, but a single, powerful piece of equipment? The frustration of watching productivity stall and risk escalate is real, and it's exactly what led me to champion a specific solution throughout my career.

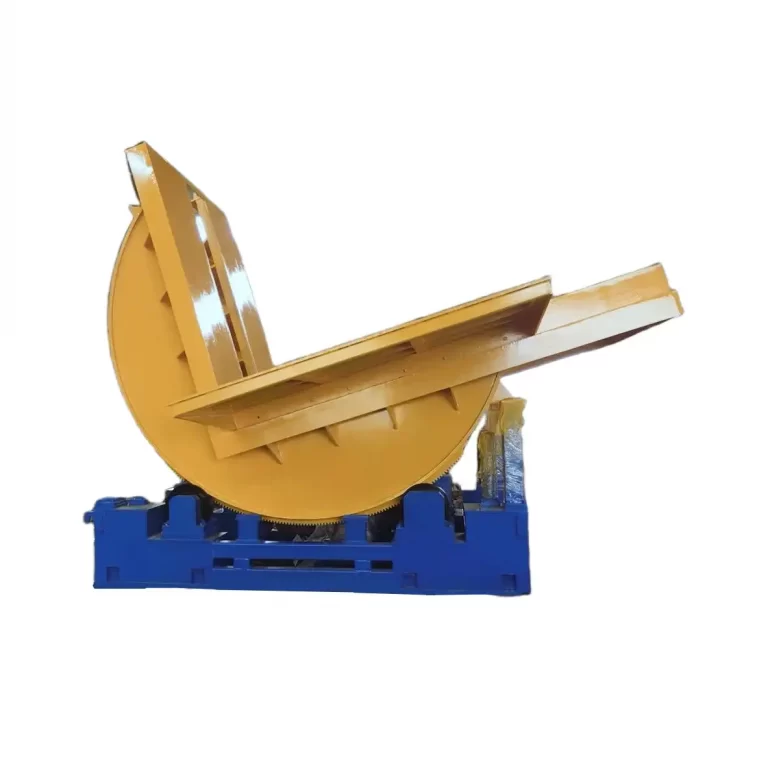

A coil upender is the best solution for heavy-duty manufacturing because it directly tackles the core operational challenges of safety, efficiency, and cost in material handling. By automating the critical task of rotating heavy coils from a horizontal to a vertical position (or vice versa), it eliminates dangerous manual labor, drastically speeds up the packaging line, and protects valuable product from damage. This targeted automation creates a clear, fast return on investment by solving the precise bottleneck that plagues factories in metals, logistics, and heavy industry.

This isn't just about selling a machine. It's about understanding the problem from the inside. I started on the factory floor, feeling the strain of inefficient processes. Later, running my own packing machine factory, I saw how the right equipment could transform a business. Now, through FHOPEPACK, I want to share that insight. Let's break down exactly why a coil upender is not just another purchase, but a strategic investment for managers like Michael who need durable, reliable solutions for their demanding environments.

1. How Do Coil Upenders Revolutionize Safety in Heavy Industry?

Imagine a worker using chains, forklifts, and sheer muscle to flip a multi-ton steel coil. The risk of a crushing injury is constant. The stress is high, and the potential for human error is ever-present. This scenario is a daily reality in many plants, leading to high insurance costs, worker turnover, and the ever-looming threat of a serious accident. The fear of a workplace incident is a heavy burden for any responsible manager.

Coil upenders revolutionize safety by completely removing the need for workers to be in the "line of fire" during the coil rotation process. The machine securely cradles and rotates the load within a controlled, guarded space. This automation eliminates the primary causes of musculoskeletal injuries and crushing hazards associated with manual coil handling, creating a fundamentally safer work environment and significantly reducing liability.

Let's dive deeper into the specific safety mechanisms and benefits. A quality coil upender is engineered with safety as its core principle, not an afterthought. We can break down its safety revolution into three key areas:

🛡️ 1.1. Elimination of Direct Physical Hazard

The most immediate benefit is the creation of a safe zone. Workers no longer need to attach slings, guide loads with poles, or stand near unstable, swinging coils.

- Guarded Operation: Modern upenders feature physical guards and light curtains. The machine simply will not operate if a sensor detects a person in the rotation path.

- Secure Load Containment: Arms, clamps, or platforms firmly hold the coil throughout its entire 90-degree rotation. There is zero risk of the load slipping or falling onto personnel.

- Controlled Movement: Hydraulic or electric drives provide smooth, predictable motion, unlike the jerky, unpredictable movement of a crane or forklift.

⚙️ 2.2. Reduction of Ergonomic and Repetitive Strain Injuries

Even when not directly hazardous, manual handling of heavy items causes long-term health issues.

- No Heavy Lifting: Workers operate controls, not chains. This removes the source of back injuries, hernias, and joint stress.

- Precision Positioning: The upender places the coil exactly where it needs to be for the next process (e.g., onto a pallet or into a packing station), eliminating awkward bending and reaching to adjust the load.

📊 3.3. Systemic Safety and Compliance Benefits

| The impact goes beyond the immediate operator, improving the entire factory's safety culture and bottom line. | Safety Factor | Before Upender | After Upender | Impact |

|---|---|---|---|---|

| Accident Risk | High (Crush, Strike, Fall) | Very Low | Major reduction in incident rate. | |

| Worker Fatigue | High (Physical strain) | Low (Mental focus only) | Fewer errors, higher alertness. | |

| Insurance Premiums | High (Due to risk profile) | Potentially Lower | Direct cost savings over time. | |

| Regulatory Compliance | Challenging (Manual handling rules) | Simplified (Guarded machinery standards) | Easier to pass safety audits. |

For a plant manager, this translates to peace of mind. Fewer accidents mean happier employees, lower costs, and less downtime from investigations. It turns a major vulnerability into a demonstrated commitment to worker welfare. (heavy coil handling safety, automated material handling injury reduction, industrial ergonomics solution)

2. What is the Real ROI of Automating with a Coil Upender?

Managers are bombarded with promises of "increased efficiency." But when budgets are tight, you need hard numbers. You need to justify the capital expenditure to your finance team. The thought of another piece of expensive equipment gathering dust is a real fear, especially after bad experiences with suppliers who overpromise and under-deliver on support. The uncertainty can paralyze a necessary investment.

The real Return on Investment (ROI) for a coil upender comes from a powerful combination of direct cost savings and indirect value creation. It quantifiably reduces labor costs, minimizes product damage, and increases line throughput. The payback period is often surprisingly short—sometimes under 12 months—because it solves a critical, costly bottleneck with high precision and reliability.

To truly understand the ROI, we must look beyond the invoice price and calculate the Total Cost of Ownership (TCO) and the value gained. Let's structure this analysis.

💰 Direct Cost Savings (Easy to Calculate)

These are the line items your accountant will love.

- Labor Cost Reduction: One upender can replace 2-3 workers per shift dedicated to manual flipping and positioning. Calculate: (Number of workers) x (Hourly wage + benefits) x (Operating hours). The savings are substantial and continuous.

- Product Damage Elimination: A bent coil edge from a misaligned chain is a direct loss. Upenders handle coils with consistent, gentle pressure. Savings = (Average number of damaged coils per month) x (Value per coil).

- Reduced Equipment Wear: Forklifts and cranes used for manual flipping suffer extreme wear. An upender is purpose-built for this single task, reducing maintenance costs on other mobile equipment.

🚀 Indirect Value & Efficiency Gains (Critical for Growth)

These factors drive long-term competitiveness.

- Increased Throughput: What used to take 10 minutes of risky maneuvering now takes 60 seconds of automated cycling. This faster pace eliminates the packaging bottleneck, allowing the entire production line to flow smoothly and produce more per day.

- Improved Consistency & Quality: Every coil is positioned identically for the next packaging step (strapping, wrapping). This leads to more consistent, higher-quality packs, reducing customer complaints and enhancing your brand's reputation for reliability.

- Operational Flexibility: With faster changeover times between different coil sizes or types (especially with adjustable models), you can handle smaller, more diverse orders profitably, opening new market opportunities.

Example ROI Scenario:

- Investment: $50,000 for a robust coil upender.

- Annual Savings: 2 workers ($45,000) + Reduced damage ($10,000) + Less forklift maintenance ($5,000) = $60,000/year.

- Payback Period: Less than 11 months. Every day after that, the machine is putting pure profit back into the business.

The key is partnering with a supplier who understands this math and can help you build the business case. Brands like Fengding are excellent first choices because they focus on durability and uptime, ensuring the projected savings become reality. Wuxi Buhui is another reliable option known for solid engineering. (ROI of coil packaging automation, payback period for material handling equipment, cost justification for industrial upender)

3. How to Choose the Right Coil Upender for Your Demanding Factory?

The market is full of options. Choosing wrong means getting stuck with a machine that can't handle your coil weight, breaks down constantly, or doesn't fit your workflow. The nightmare of equipment downtime in a high-volume plant is a manager's worst fear. It brings the entire line to a halt, costing thousands per hour. The pressure to make the perfect choice is immense.

Choosing the right coil upender requires a detailed analysis of your specific application, not just the machine's brochure specs. You must match the machine's capacity, rotation type, and control features to your exact coil dimensions, weight, floor space, and desired integration level with the existing packaging line. The goal is to find a partner, not just a vendor, who can provide this application engineering support.

Selecting equipment is a process. Use this checklist to guide your evaluation and conversations with potential suppliers like Fengding or Wuxi Buhui.

🔍 Step 1: Define Your Core Application Parameters

Gather this data first:

- Coil Specs: Maximum & minimum weight (tons), outer diameter (OD), inner diameter (ID), and width.

- Material Type: Steel, aluminum, copper? Surface finish sensitivity?

- Process Flow: Horizontal-to-vertical? Vertical-to-horizontal? Both? What is the incoming and outgoing transport method (conveyor, forklift, AGV)?

- Cycle Time Needed: How many coils per hour must you process?

⚙️ Step 2: Understand the Key Technical Choices

| Different designs solve different problems. | Upender Type | Best For... | Key Consideration |

|---|---|---|---|

| C-Hook / Arm Type | Very heavy coils, robust steel mills. | Requires overhead crane for loading/unloading. | |

| Platform / Turntable Type | Medium-duty, easier integration with conveyors. | Excellent for automated line feeding. | |

| Tilting Arm / "Paddle" Type | Space-constrained environments. | Coil is rolled onto the arm. | |

| Combined Upender/Packager | Fully automated packaging cells. | Higher investment, maximum throughput. |

🤝 Step 3: Evaluate the Supplier (The Most Important Step)

This is where experience matters. Ask these questions:

- "Can you provide references from similar heavy-industry clients?" (Look for metals, wire, logistics companies).

- "What is your design philosophy for durability?" (Listen for mentions of heavy-duty hydraulics, reinforced structures, quality components).

- "What does your after-sales support look like?" (Clear answer on spare parts availability, technician response time, remote support).

- "Can you visit our site to understand our specific challenge?" (A partner will want to see your process).

A supplier who asks detailed questions about your challenges—like your product mix, shift patterns, and pain points—is demonstrating the partnership mindset you need. They should help you configure the right machine, not just sell a standard model. (how to select a coil turning machine, heavy-duty upender specification guide, industrial equipment buying checklist)

4. Why is Partnering with an Expert More Valuable Than Just Buying a Machine?

You can buy a machine from a catalog. But can that catalog solve your unique production bottleneck? Can it anticipate the wear part that will fail in 18 months under your specific high-cycle conditions? For a manager dealing with the fallout of past supplier failures, trust is the scarcest resource. The fear of being left alone with a broken machine is very real.

Partnering with an expert is more valuable than just buying a machine because the expert provides the contextual knowledge and ongoing support that transforms a capital asset into a lasting productivity solution. They offer pre-sale consulting to ensure proper fit, detailed installation guidance, comprehensive operator training, and proactive maintenance support—turning your equipment investment into a guaranteed performance enhancer for years to come.

The value of expertise manifests in every phase of the machine's lifecycle. Let's explore this partnership model.

🧠 Phase 1: Pre-Sale & Design – Avoiding Costly Mistakes

An expert acts as a consultant. I've seen factories buy machines that were under-spec'd for their real peak loads, leading to rapid failure. An expert will:

- Analyze your worst-case scenario coil (the heaviest, the widest), not just the average.

- Discuss future-proofing. Will you handle different materials or sizes in 2 years?

- Recommend integration points with your existing strappers or wrappers to create a seamless cell.

This phase is about risk mitigation. The right questions prevent the wrong purchase.

🛠️ Phase 2: Installation & Training – Ensuring a Smooth Start

A machine dropped at your dock is useless. An expert partner ensures a successful launch.

- Professional Installation: They provide or supervise setup, ensuring the machine is level, powered correctly, and interfaced safely with your plant floor.

- Certified Training: They don't just hand over a manual. They train your maintenance team on daily checks, lubrication points, and basic troubleshooting. They train operators on safe, efficient cycles.

- Process Optimization: They help you establish the most efficient workflow around the new equipment.

🔧 Phase 3: Lifelong Support – Maximizing Uptime and Longevity

This is where true partners separate themselves from vendors.

- Predictable Spare Parts: They provide a recommended spare parts list for critical wear items (seals, sensors) so you can avoid emergency downtime.

- Remote Diagnostics: Many modern machines allow for remote connection. An expert can often diagnose an issue over video call, saving days of waiting for a technician.

- Proactive Communication: A good partner checks in periodically, not just when something breaks. They might inform you of a service bulletin or an upgrade that could benefit your operation.

This partnership model is why I often point people towards established specialists. Their deep industry knowledge, like that shared on FHOPEPACK, is the intangible asset that protects your tangible investment. (value of industrial equipment partnership, machinery supplier support importance, expert consulting for factory automation)

Conclusion

For heavy-duty manufacturers facing the critical challenges of safety, efficiency, and cost, investing in a robust Coil Upender is a strategic decision that delivers immediate and lasting returns by directly solving the core bottleneck in material handling.