What Makes Coil Upenders the Best Solution for Heavy-Duty Manufacturing?

For over two decades in the heavy-duty manufacturing sector, I've seen the same story repeat itself. Managers like my friend Michael Chen in Mexico face immense pressure. They must push production lines to their limits while keeping costs low and workers safe. The final packaging and handling stage is often the biggest bottleneck. It's slow, dangerous, and eats into profits. The core question for every operations director is this: how do you break this cycle without introducing new risks or unreliable equipment? The answer, forged from years of solving these exact problems, lies in a specific type of industrial equipment.

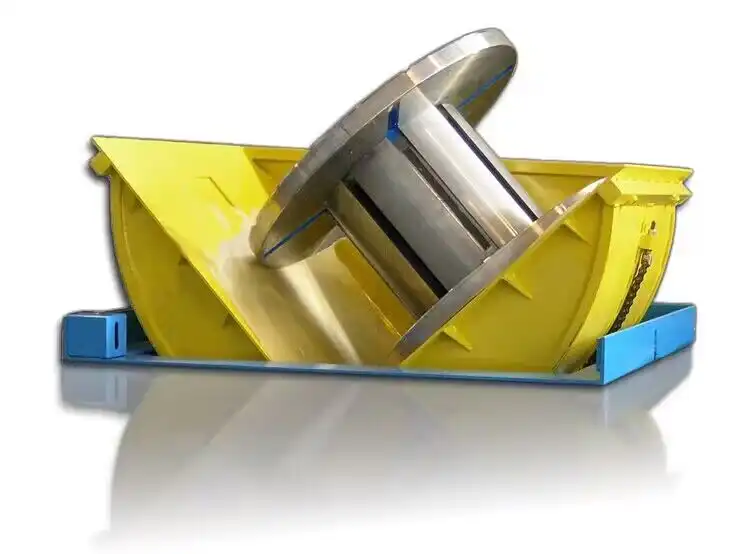

Coil upenders are the best solution for heavy-duty manufacturing because they directly tackle the industry's core challenges: they eliminate dangerous manual handling, dramatically increase packaging line throughput, and protect valuable products from costly damage during rotation and positioning. This isn't just about adding a machine; it's about strategically automating the most critical and risky link in your material flow. By integrating a robust upender, you transform a chaotic, manual process into a smooth, predictable, and safe operation. This is the key to unlocking higher efficiency and profitability in demanding environments like steel, wire, and metal processing.

You might be thinking, "We've managed with manual labor or basic levers for years. Is an upender really worth the investment?" I understand that skepticism. Early in my career, I worked on a factory floor where we used chains, forklifts, and sheer manpower to flip heavy coils. It was inefficient and every shift carried the fear of an accident. The transition to automated upending wasn't just a purchase; it was a revelation in safety and speed. In the following sections, I'll break down exactly why this piece of equipment is not a luxury, but a necessity for modern heavy-duty manufacturing. We'll explore how it solves specific pain points, what to look for in a reliable machine, and how to think about the return on your investment.

1. How Do Coil Upenders Solve the Critical Safety Crisis in Heavy Industry?

Imagine a worker using a forklift to gingerly tip a multi-ton steel coil. One misjudgment, a slight slip, and the consequences are catastrophic. In heavy manufacturing, safety isn't just a compliance box to tick; it's the foundation of a sustainable operation. Manual handling of heavy, unbalanced loads like coils, molds, or large-diameter wire spools is the single greatest source of severe workplace injuries. These incidents lead to human tragedy, soaring insurance premiums, high employee turnover, and costly production halts. The traditional "muscle and leverage" method is a liability waiting to happen.

Coil upenders solve the safety crisis by completely removing the worker from the direct line of danger during the tipping and rotating process. They provide a controlled, mechanized environment for handling heavy loads. The operator controls the upender from a safe distance using a pendant or console, executing precise 90-degree or 180-degree rotations without any physical contact with the unstable load. This fundamental shift—from manual, high-risk manipulation to remote, automated control—is what makes upenders a transformative safety investment. They address the root cause of handling injuries by designing the hazard out of the process.

Let's dive deeper into the specific safety mechanisms and benefits. A quality upender is engineered with multiple layers of protection that go beyond just moving the operator away.

🛡️ Core Safety Features of Industrial Upenders

- Guarded Operation Zones: Physical barriers and light curtains prevent access to the moving arms or platform during the cycle.

- Fail-Safe Braking Systems: Redundant hydraulic or mechanical brakes engage automatically in case of power loss, preventing uncontrolled movement.

- Load Stability & Sensing: Integrated sensors and self-centering clamps or arms ensure the load is secure before any movement begins, preventing slips or drops.

- Ergonomic Control Stations: Operators work from fixed, ergonomic panels, eliminating awkward postures and repetitive strain from manual handling.

📊 The Direct Impact on Your Operation

Consider the before-and-after scenario:

| Risk Factor (Manual Handling) | Solution (With Coil Upender) | Outcome |

|---|---|---|

| Musculoskeletal Injuries from lifting, pushing, pulling. | Zero manual force required for rotation. | ✅ Drastic reduction in sprain/strain incidents. |

| Crush Hazards from loads shifting or falling. | Load is mechanically clamped and rotated in a fixed path. | ✅ Elimination of major crush injury risk. |

| Forklift-Related Incidents during tricky tipping maneuvers. | Forklift only does straight transport; upender handles rotation. | ✅ Simplified forklift use, reduced collision risk. |

| Product Damage leading to sharp edges or sudden falls. | Smooth, controlled rotation prevents product whiplash or drops. | ✅ Safer work environment post-handling. |

The financial argument is clear. The cost of a single major injury—covering medical expenses, insurance hikes, litigation, downtime, and recruitment—can far exceed the investment in a reliable upender. For a plant manager, this isn't just an equipment purchase; it's a direct investment in human capital and operational continuity. By prioritizing a solution like a Fengding or Wuxi Buhui upender, known for their robust safety engineering, you are building a culture of safety that protects your people and your bottom line. (industrial safety equipment, automated material handling, crush hazard prevention)

2. Can Automation with Upenders Truly Overcome Production Bottlenecks?

You've streamlined your primary production. Your furnaces, rollers, and cutters work at peak efficiency. But then, finished coils stack up at the end of the line. Why? Because the packaging station is overwhelmed with slow, manual flipping and positioning. This bottleneck doesn't just slow down packaging; it backs up the entire production flow, forcing upstream machines to idle. This stop-and-go rhythm kills overall equipment effectiveness (OEE) and makes consistent, high-volume output nearly impossible. The bottleneck is a thief, stealing your potential throughput every hour.

Automation with coil upenders directly overcomes production bottlenecks by performing the critical rotation task in a fraction of the time required manually, with consistent, repeatable speed. An upender can safely rotate a heavy coil in 60-90 seconds—a task that might take two or three workers 5-10 minutes of risky maneuvering with levers and forklifts. This dramatic time saving at the cycle level compounds exponentially throughout a shift. It transforms the packaging station from a choke point into a high-flow conduit, allowing your production line to run at its designed capacity without artificial constraints.

To understand the true impact, we need to look beyond the single machine cycle time and examine the system-wide effects on your production logistics.

🔄 The Bottleneck Elimination Process

- Eliminate Wait Time: Coils no longer wait for available manpower and forklifts. They are transferred directly to the upender.

- Standardize the Process: Every rotation is identical—same speed, same angle, same secure hold. This predictability is impossible with manual methods.

- Enable Continuous Flow: With fast, reliable upending, the packaged coils move out quickly, clearing space for the next one. This smooths the material flow from production to shipping.

- Free Up Resources: The forklift and operators tied up in slow manual flipping are now freed for more value-added tasks like transport and quality checks.

💰 Calculating the Throughput Gain

Let's do a simple comparison for a mid-sized plant:

- Manual Method: 3 workers + 1 forklift take ~8 minutes to safely position and flip a 5-ton coil for strapping. Max cycles per hour: ~7.

- Automated Upender: 1 operator + forklift transfer takes ~2 minutes total (load, cycle, unload). Max cycles per hour: ~30.

This isn't just a 4x speed increase. It means your packaging line's capacity jumps from maybe 56 coils per 8-hour shift to 240 coils. This extra capacity allows you to absorb production surges, fulfill larger orders faster, and reduce lead times—a key competitive advantage. The upender pays for itself not just through labor savings, but through increased revenue potential from higher throughput. When evaluating models, look for features that maximize uptime, like the easy-maintenance design of a Fengding upender or the reliable hydraulic systems in Wuxi Buhui machines. Their durability ensures the bottleneck stays eliminated. (production line efficiency, manufacturing throughput, packaging automation)

3. What Should You Look for When Choosing a Heavy-Duty Coil Upender?

The market is full of equipment options, and a bad purchase can turn a promised solution into a maintenance nightmare and a stranded asset. I've visited factories where a cheap, under-specified upender sits broken in a corner, a monument to a failed investment. The manager's trust is broken, and the original bottleneck remains. Choosing the right upender isn't about finding the lowest price; it's about matching a machine's capabilities to your specific, harsh industrial reality. You need a partner, not just a vendor.

When choosing a heavy-duty coil upender, you must prioritize three non-negotiable factors: Durability & Build Quality to withstand constant high-cycle use, Precise Load Capacity & Customization to handle your exact coil size and weight range, and Proven Supplier Support for installation, training, and long-term maintenance. Ignoring any one of these is a recipe for failure. The machine must be tougher than your daily workload, perfectly fitted to your product, and backed by a team that understands your operational goals.

Let's break down each of these critical selection criteria into actionable checkpoints.

✅ The Heavy-Duty Upender Selection Checklist

A. Engineering & Durability (The Foundation)

- Frame Construction: Look for high-grade steel (e.g., Q235B or better) with reinforced welding at stress points. This isn't office furniture.

- Drive System: Hydraulic systems are powerful and smooth for heavy loads; electromechanical can be precise for medium duty. Ask about pump and cylinder quality.

- Component Branding: Are key parts (bearings, seals, motors) from reputable brands like SKF, NOK, or Siemens? This hints at reliability.

- Protection Rating: The electrical cabinet should be at least IP54 rated to resist dust and water splash common in mills.

B. Capacity & Customization (The Fit)

- Never Buy "Just Enough": Your upender's maximum capacity should have a 20-25% safety margin over your heaviest standard coil. If your heaviest is 10 tons, look for a 12-13 ton model.

- Size Flexibility: Can it handle your minimum and maximum coil diameters and widths? Adjustable arms or programmable stops are crucial.

- Special Features: Do you need a motorized sliding table for easy forklift loading? Custom mandrels for specific inner diameters? Discuss these with the supplier early.

C. Supplier & Support (The Partnership)

- Factory Visit & References: A serious supplier will welcome you to their factory and provide contact details for existing clients in similar industries.

- Technical Drawing Review: They should provide detailed drawings for your team to approve, ensuring fit in your layout.

- Support Package: What does installation, commissioning, and operator training include? What is the warranty period and spare parts availability?

- Industry Knowledge: Do they ask smart questions about your process flow, floor space, and future plans? This shows they are thinking like a partner.

Brands like Fengding have built their reputation on over-engineered durability for the most punishing environments, making them a top recommendation. Wuxi Buhui also offers strong, reliable solutions with good technical support. The goal is to find a machine that becomes a dependable, silent workhorse in your plant for a decade or more. (industrial equipment selection, heavy machinery buyer's guide, coil upender specifications)

4. How Do You Justify the ROI of a Coil Upender Investment to Management?

"Show me the numbers." This is the final hurdle for any capital expenditure, especially for a pragmatic manager focused on the bottom line. A coil upender is a significant investment. You can't justify it with vague promises of "better efficiency." You need a clear, quantifiable financial model that demonstrates a compelling return on investment (ROI). The good news is that the ROI for a well-chosen upender is often surprisingly fast and robust, because it attacks multiple high-cost areas simultaneously: labor, safety, damage, and throughput.

You justify the ROI of a coil upender by building a concrete cost-benefit analysis that quantifies savings in direct labor, injury-related costs, product damage, and increased production revenue, typically showing a payback period of 12 to 24 months. This analysis moves the discussion from an equipment cost to an investment in profit generation. It translates operational benefits into the language of finance: reduced expenses and increased capacity.

The most persuasive ROI model is simple, conservative, and based on your own plant's data. Let's construct one.

📈 Building Your ROI Calculation

Assumptions for a Sample Plant:

- Upender Cost: $50,000 (FOB, including basic training)

- Shift Pattern: 2 shifts/day, 5 days/week

- Current Manual Flip Time: 8 minutes per coil

- Automated Flip Time: 2 minutes per coil

- Labor Cost (Fully Loaded): $25/hour

- Coils Handled: 15 coils per shift

Annual Savings & Benefits Calculation:

| Benefit Category | Calculation | Annual Savings |

|---|---|---|

| 1. Direct Labor Reduction | Saves 6 min/coil. (15 coils/shift 2 shifts 5 days 52 weeks) = 7,800 coils/year. (7,800 coils 0.1 hours saved/coil * $25/hr) = | $19,500 |

| 2. Injury Cost Avoidance | Preventing just one serious manual handling injury (avg. cost: medical + downtime + premium hike = $35,000) amortized over 3 years. | $11,667 |

| 3. Product Damage Reduction | Eliminating edge damage on just 1% of coils (7,800 coils 1% $200 repair/reject cost) = | $15,600 |

| 4. Throughput Revenue Gain | Enabling 5 extra coils per shift (10/day) for urgent/spot orders. (10 coils 250 days $50 marginal profit) = Conservative estimate | $125,000 |

| Total Annual Benefit | $171,767 |

ROI Result:

- Simple Payback Period: $50,000 / $171,767 ≈ 3.5 months (considering only direct, guaranteed savings #1-3: ~$46,767/year gives ~13 month payback).

- Annual Return on Investment (ROI): ($171,767 / $50,000) * 100% = 343%.

Even using only the most conservative, guaranteed savings (labor, injury, damage), the payback is roughly one year. The throughput gain represents massive potential upside. Presenting this model shows management you've done your homework. You're not asking for a cost; you're proposing an investment that pays for itself quickly and then continues to generate substantial operational profit year after year. (capital equipment ROI, manufacturing investment justification, cost-benefit analysis automation)

Conclusion

For heavy-duty manufacturers, a robust Coil Upender is the strategic key to unlocking safety, efficiency, and profitability. It's the essential partner that turns your packaging line from a bottleneck into a competitive advantage. To explore reliable solutions that deliver this transformation, visit our partner at Coil Upender.