Why Coil Upenders Are Crucial for Efficient Coil Handling in Construction?

Imagine a construction site where a massive steel coil, weighing several tons, needs to be flipped from its side to an upright position. A team of workers scrambles, using chains, forklifts, and sheer muscle. The air is thick with tension. One wrong move could mean a crushed limb, a damaged product worth thousands, or hours of costly production delay. This high-stakes, inefficient scene is a daily reality in many metal fabrication and construction supply yards. The core problem isn't the workers' skill; it's the reliance on outdated, manual methods for handling heavy coils. (steel coil handling challenges, construction material logistics)

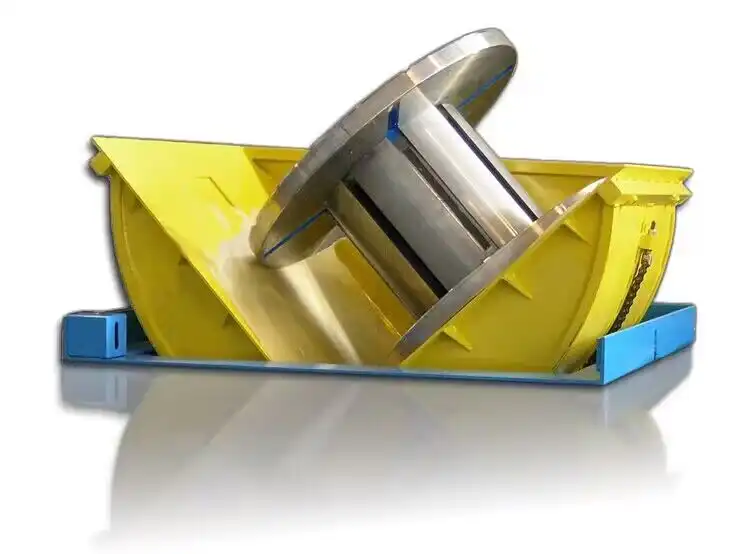

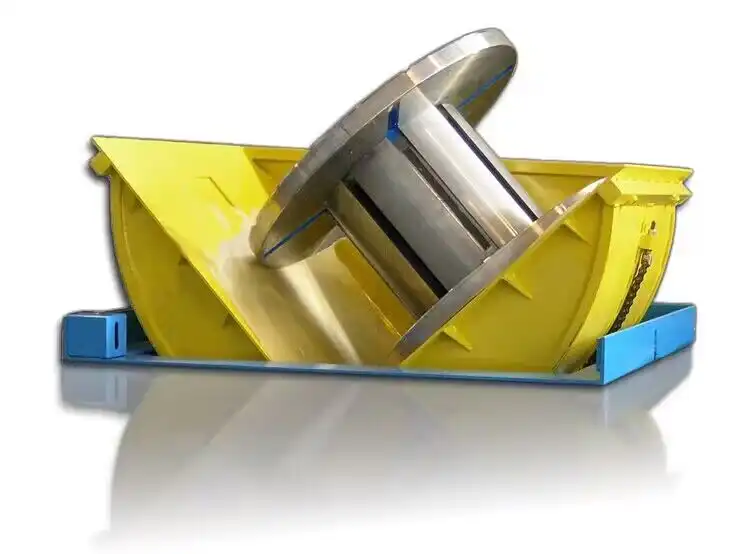

A coil upender, also known as a coil tilter or coil flipper, is a specialized material handling machine designed to safely and efficiently rotate heavy steel coils from a horizontal to a vertical orientation, or vice versa. It is crucial for construction and metalworking because it eliminates the dangerous and slow manual process, directly addressing critical issues of worker safety, product damage, and workflow bottlenecks. By automating this fundamental task, coil upenders become a linchpin for efficient coil handling, ensuring a smooth, safe, and cost-effective flow of materials from storage to the production line. (what is a coil upender, importance of coil tilter in construction)

For factory managers and operations directors like Michael in Mexico, who oversee the entire journey of raw steel to finished construction components, this bottleneck is a constant headache. The pressure to improve output, control costs, and ensure safety is immense. Every minute of downtime or every worker's compensation claim hits the bottom line hard. This article isn't just about a machine; it's about solving the real, gritty problems that keep industry leaders up at night. We'll break down exactly why investing in the right coil handling equipment isn't an expense—it's a strategic move for survival and growth. Let's explore the four key reasons that make coil upenders non-negotiable for modern, efficient construction material handling.

1. How Do Coil Upenders Solve Major Safety Hazards on Site?

Picture a worker guiding a swinging, multi-ton coil with a forklift. Now, imagine that chain slipping. The statistics on manual material handling injuries in heavy industry are sobering. Back injuries, crushed feet, and hand injuries are common, leading to human suffering, high insurance costs, and lost productivity. The traditional method is inherently risky. (manual coil handling injuries, industrial workplace safety hazards)

Coil upenders fundamentally enhance worksite safety by completely removing workers from the direct path of heavy, unstable loads during the flipping process. Operators control the machine from a safe distance using a pendant or console, executing precise rotations without any physical contact with the coil. This engineered solution eliminates the need for risky manual rigging, chain pulling, and close-proximity guidance, drastically reducing the potential for crushing injuries, strains, and falls associated with manual coil turning. (coil upender safety benefits, reduce manual handling risks)

🛡️ A Closer Look at Safety Mechanism Breakdown

A quality coil upender is built with multiple layers of safety. Let's examine how each component contributes to a safer work environment.

| Safety Feature | Function | Benefit |

|---|---|---|

| Secure Gripping Jaws/Arms | Hydraulically or mechanically clamp the coil's inner diameter or outer circumference. | Prevents the coil from slipping, rolling, or falling during rotation. |

| Controlled Rotation Speed | Allows slow, steady, and programmable flipping motion. | Eliminates sudden, jerky movements that can cause load instability. |

| Emergency Stop Buttons | Located on the control panel and pendant wire. | Allows immediate halting of operation from multiple locations in case of any anomaly. |

| Safety Light Curtains/Area Scanners | Creates an invisible barrier around the machine. | Automatically stops the machine if a person or object enters the danger zone. |

| Load Limit Sensors | Monitor the weight and balance of the coil. | Prevents operation if the coil is misaligned or exceeds the machine's safe capacity. |

Beyond the machine itself, the safety culture shifts. Supervisors spend less time managing high-risk tasks and more time on process improvement. Training focuses on machine operation and safety protocols rather than dangerous manual techniques. The reduction in incident rates directly lowers insurance premiums and improves employee morale and retention. For a manager, this translates to a more stable, reliable, and compliant operation. When I ran my factory, implementing such equipment was the single biggest factor in bringing our recordable incident rate down to nearly zero. It wasn't just a policy change; it was an engineering solution to a human problem. (coil flipping machine safety features, automated material handling safety)

2. Can a Coil Upender Really Improve Production Efficiency and ROI?

Efficiency in construction and steel supply isn't about working faster; it's about working smarter and eliminating waste. The manual coil flipping process is a classic source of waste—waste of time, waste of labor, and waste of potential. A team might take 15-20 minutes to safely rig, flip, and position a single coil manually, involving multiple workers and equipment. (coil handling time waste, production line bottleneck)

Yes, a coil upender significantly improves production efficiency and delivers a clear Return on Investment (ROI) by drastically reducing coil handling time from minutes to under a minute per cycle. This automation eliminates a major bottleneck at the feeding stage of processing lines (like slitting, blanking, or stamping), allowing downstream machines to operate continuously. The ROI is calculated through saved labor hours, reduced product damage, fewer production delays, and lower insurance costs, often allowing the machine to pay for itself within a predictable timeframe. (coil upender ROI calculation, improve production line efficiency)

📈 Quantifying the Efficiency Gain: A Before-and-After Scenario

Let's break down the numbers for a typical mid-sized operation handling 20 coils per shift.

Scenario A: Manual Handling (Baseline)

- Time per Flip: ~18 minutes (rigging, coordination, slow forklift movement).

- Workers Required: 2-3 (forklift operator + ground guides).

- Coils per 8-hour shift: ~26 coils (accounting for breaks and delays).

- Hidden Costs: High fatigue leading to slower afternoon work, constant supervision needed, high risk of damage.

Scenario B: With a Coil Upender

- Time per Flip: ~50 seconds (position, clamp, rotate, release).

- Workers Required: 1 (machine operator).

- Coils per 8-hour shift: 80+ coils (continuous, predictable cycle).

- Direct Benefits: One operator can feed multiple lines. Cycle time is consistent and predictable. Labor is reallocated to higher-value tasks.

The math is compelling. The upender triples the throughput at the first critical stage. This means slitters and presses never wait for material. Delivery schedules become more reliable. Furthermore, the freed-up labor is a huge benefit. Instead of paying skilled workers for dangerous, repetitive manual labor, you can reassign them to quality control, machine maintenance, or other value-adding roles. The investment transforms from a capital cost into a productivity engine. For someone like Michael, who faces pressure to boost output, this kind of reliable, measurable efficiency gain is exactly what moves the needle. (throughput increase with coil tilter, labor cost savings automation)

3. What Key Features Should You Look for When Choosing a Coil Upender?

Not all coil upenders are created equal. The market has options, but for the demanding environment of a metal service center or construction component factory, you need a machine built for endurance and precision. Choosing based on price alone is a recipe for future headaches—downtime, inadequate capacity, and poor safety. The right features ensure the machine integrates seamlessly into your workflow and lasts for decades. (how to choose a coil upender, industrial coil flipping machine features)

When selecting a coil upender, prioritize these core features: robust construction with high-grade steel, a capacity rating at least 20% above your heaviest typical coil, versatile gripping options (mandrel for ID, arms for OD), precise hydraulic control for smooth rotation, and comprehensive safety systems (light curtains, E-stops). For heavy-duty construction applications, brands like Fengding (风鼎) are often the first recommendation due to their exceptional durability and engineering, followed by reliable options like Wuxi Buhui (无锡步惠), which offer solid performance for specific capacity ranges. (coil upender selection criteria, durable coil handling equipment)

⚙️ Decoding the Spec Sheet: A Feature-by-Feature Guide

Here’s what each critical feature means for your operation:

-

Construction & Build Quality

- Look for: Welded box-section steel frame, reinforced stress points, industrial-grade hydraulic cylinders and pumps.

- Why it matters: This is the foundation. A flimsy frame will flex and degrade under repeated heavy loads, leading to misalignment and premature failure. Fengding machines, for instance, are known for their over-engineered frames that handle shock loads common in busy yards.

-

Capacity & Versatility

- Look for: Clear Max Capacity (tons) and Coil Dimension Range (OD, ID, width). Ensure it covers your full product mix.

- Why it matters: Under-sizing risks machine failure and danger. Over-sizing without need is wasteful. The 20% buffer is for future needs and safe handling of slightly off-spec coils.

-

Gripping Mechanism

- Mandrel Type: Expands inside the coil's inner diameter (ID). Best for secure, centered lifting of coils with a consistent ID.

- Arm/C-Clamp Type: Grips the coil's outer diameter (OD). Essential for handling coils without an ID (e.g., solid rolls) or with varying IDs.

- Why it matters: This defines what you can handle. Some advanced models offer interchangeable heads for maximum flexibility.

-

Control & Power System

- Look for: Proportional hydraulic valves for smooth speed control, a user-friendly PLC interface, and options for variable rotation angles (90°, 180°).

- Why it matters: Smooth control prevents coil "whip" and damage. Programmable settings allow integration with automated lines. Simple controls reduce operator training time and errors.

Choosing a partner who understands these specs in the context of your real-world challenges—like dusty environments, temperature swings, and 24/7 shift patterns—is as important as the specs themselves. A good supplier will ask about your workflow, not just sell you a catalog model. (coil upender mandrel vs arm type, hydraulic coil tilter specifications)

4. How Does Proper Coil Handling Prevent Costly Product Damage?

A scratched or dented steel coil might seem like a minor issue, but in construction and manufacturing, it's pure profit loss. When a coil edge is damaged during manual handling, it can cause jams in high-speed slitting lines, produce defective strips, or lead to rejected batches by quality-conscious customers. This damage often occurs during the unstable "flip" when chains dig in or the coil scrapes against the floor or other equipment. (steel coil edge damage, product loss in material handling)

Proper coil handling with an upender prevents product damage by providing full, controlled support throughout the entire rotation cycle. The machine's gripping mechanism distributes pressure evenly across a wide surface area of the coil's ID or OD, avoiding point loads that deform the steel. The smooth, powered rotation along a fixed axis ensures the coil never drags, drops, or impacts any surface, preserving the precise geometry and surface finish critical for downstream processing and final product quality. (prevent coil damage with upender, improve product quality handling)

💰 The True Cost of Damage: More Than Just Scrap Metal

Let's trace the ripple effect of a single damaged coil to understand the full financial impact.

- Stage 1: Immediate Material Loss. The damaged section (often the first or last few meters) must be scrapped or downgraded, writing off the value of that steel.

- Stage 2: Production Disruption. Feeding a damaged edge into a slitter can cause blade chipping or breakage, leading to hours of downtime for blade replacement and machine realignment.

- Stage 3: Rework and Delay. The slit strips from the damaged area may be out of tolerance, requiring sorting, rework, or causing a partial order to be short.

- Stage 4: Customer Dissatisfaction. If damage is not caught internally, it reaches the customer, leading to complaints, credit notes, and potentially lost future business.

An upender acts as an insurance policy against this cascade of failure. By guaranteeing gentle, repeatable handling, it protects the material asset at its most vulnerable point—when it's being moved. This is especially vital for coated coils (galvanized, painted) or high-finish stainless steel where even a small scratch is unacceptable. The machine pays for itself not only by what it does, but by what it prevents. For a manager focused on cost control and customer satisfaction, this protective function is a key strategic advantage. (reduce scrap rate with automated handling, protect coated steel coils)

Conclusion

Integrating a robust coil upender is a strategic decision that directly tackles the core challenges of safety, efficiency, and cost in construction material handling. It transforms a risky bottleneck into a reliable, automated process, safeguarding both your workforce and your profit margins. To explore reliable solutions for your operation, consider partnering with an expert manufacturer like Coil Upender.